Beruflich Dokumente

Kultur Dokumente

ATEX Classification Labelling of Electric Equipment PDF

Hochgeladen von

Akhil JoseOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ATEX Classification Labelling of Electric Equipment PDF

Hochgeladen von

Akhil JoseCopyright:

Verfügbare Formate

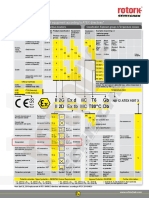

Labelling of explosion proof equipment

Labelling of explosion proof equipment according to ATEX 2014/34/EU

ClassificationClassification

and labelling andoflabelling

hazardous locations

of hazardous locations Classification

Classification Explosion

Explosion groups &groups & Temperature

Temperature classes

classes (gases, mists, vapours)

Flammable Hazardous locations Classification Product classification Equipment Explosion Examples depending on

medium Probability of a of hazardous protection group - explosion group

potentially explosive locations level - temperature class

atmosphere occuring Product Product (EPL)

group category

Ammonia Ethanol Petrol Acetal-de-

Continuously, for long Methane Cyclohe- Diesel fuel hyde

periods or frequently Zone 0 II IIA Ethane xene Fuel oil

Propane n-Butane n-Hexane

IIB

Gases, City gas

Acrylic

Ethylene

Ethylene

Ethyl glycol Ethyl ether

mists, Likely to occur Zone 1 II 1G Ga IIC nitrile oxide

Carbon

hydrogen

vapours

2G Gb

Hydrogen Acetylene Carbon

Infrequently and for short disulphide

periods only Zone 2 II 3G Gc

Attention: this list is only an extract of possible flammable

T1<450°C mediums and does not claim to be complet

complete !

Continuously, for long

periods or frequently Zone 20 II

TT2<300°C

T2 < 300°C

TT3<200°C

T3 <200°C

Dusts Likely to occur Zone 21 II 1D Da

T4<135°C

T <135°C

T4

2D Db

Infrequently and for short T5<100°C

<100°C

Zone 22 II 3D Dc

periods only

T6< 85°C

Notified bodies Product use depending on temperature class (T1 - T6). The temperature

class indicates the max. temperature of the exposed surface of the

Code Notified Body (NB) product. For dust explosion proof, the max. surface temperature is

number directly shown (e.g. T80°C).

0102 PTB (Germany) Temperature class

T

0158 EXAM (Germany)

Example:

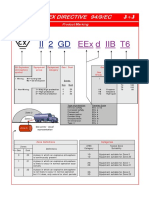

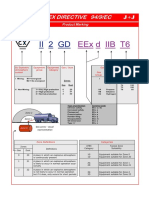

II 2 G Ex db IIC T6 Gb NB 12 ATEX 1007 X

0158

II 2 D Ex tb IIIC T80°C Db

Prevents transmission of flameproof da 0,1, 2 IIIA flammable fibres

the explosion outside enclosure EExdd db 1, 2 EN 60079-1

IIIB

dc 2

IIIC non conductive dust

For common use –

Prevents high increased Exe eb 1, 2

EN 60079-7

temperatures and sparks safety ec 2 conductive dust

ia 0,1,2,20,21,22 Code Dust classification

Low current / voltage supply intrinsic safety Exi ib 11,2,21,22 EN 60079-11

ic 2,22

pxb 1, 2, 21, 22

Positive pressure device pressurised Exp pyb 1, 2, 21, 22 EN 60079-2 long periods of For use under

apparatus pzc 2, 22

8 –

immersion special conditions X

ma 0,1,2,20,21,22

0,1,2,20 the effects of tem-

7 – porary immersion

Encapsulated moulding Exm mb 1,2,21,22

1,2,21 EN 60079-18

mc 2,22

2 22 6

totally protected strong jets of

against dust water

Parts immersed in oil to isolate

oil immersion Exo ob 1, 2

EN 60079-6 5

dust - limited low pressure jets

from explosive atmosphere oc 2 ingress from all directions This part is an Ex

solids objects sprays from all component and

4 > 1 mm directions certified as such and

Prevents transmission of Exq qb

explosion outside powder filling 1, 2 EN 60079-5 is therefore not

solids objects direct sprays up to suitable for use on

3 > 2,5 mm 60° from vertical its own U

solids objects direct sprays up to

As above, but for use in

protection “n” Exn nC 2

EN 60079-15 2

> 12,5 mm 15° from vertical CE conformity is

zone 2 nR 2

achieved by

solids objects vertical falling

1 incorporation into

ta 20, 21, 22 > 50 mm drops of water

equipment

protection by tb

Dust explosion proof

enclosure Ext 21, 22 EN 60079-31

no protection no protection

tc IP66

22 0

Protection principle Type of Code Sym- To

T use CENELEC IP Protection Protection Application Code

protection bol in zone against against

solids /dust water

Protection principle – Type of protection – EN 60079-0 General Requirements Ingress Protection EN 60529 Further information

www.schischek.com

Das könnte Ihnen auch gefallen

- Classification Labelling o EquipmentDokument1 SeiteClassification Labelling o EquipmentAbdul RahmanNoch keine Bewertungen

- ATEX Classification Labelling of Electric EquipmentDokument1 SeiteATEX Classification Labelling of Electric EquipmentLudi D. LunarNoch keine Bewertungen

- Labelling of Explosion Proof Equipment: Ii2Gexdiict6 Ii 2D Ex TB Iiic T80°C GB DB GB DB GB T80°C T80°C DBDokument1 SeiteLabelling of Explosion Proof Equipment: Ii2Gexdiict6 Ii 2D Ex TB Iiic T80°C GB DB GB DB GB T80°C T80°C DBChirack Singh Tony AntonyNoch keine Bewertungen

- ATEX Electric Equipment Classification Labelling PDFDokument1 SeiteATEX Electric Equipment Classification Labelling PDFRamius HamdaniNoch keine Bewertungen

- Labelling of explosion proof equipment according to ATEX 2014/34/EUDokument1 SeiteLabelling of explosion proof equipment according to ATEX 2014/34/EUfrancisNoch keine Bewertungen

- Classification and Labelling of Electric Explosion Proof ATEX PDFDokument1 SeiteClassification and Labelling of Electric Explosion Proof ATEX PDFRamesh KumarNoch keine Bewertungen

- Potentially Explosive Atmospheres ATEX Ignition Source ClassificationDokument1 SeitePotentially Explosive Atmospheres ATEX Ignition Source ClassificationDANE80Noch keine Bewertungen

- ATEXGuidelines LowDokument1 SeiteATEXGuidelines LowalphieNoch keine Bewertungen

- Marking requirements for electrical equipment used in explosive gas atmospheresDokument1 SeiteMarking requirements for electrical equipment used in explosive gas atmospheresBinhvvNoch keine Bewertungen

- Marking Electrical Equipment Ex PDFDokument1 SeiteMarking Electrical Equipment Ex PDFrakacyuNoch keine Bewertungen

- Marking Non Electrical Equipment Ex PDFDokument1 SeiteMarking Non Electrical Equipment Ex PDFNicolae VisanNoch keine Bewertungen

- Marking Non Electrical Equipment Ex PDFDokument1 SeiteMarking Non Electrical Equipment Ex PDFMMNoch keine Bewertungen

- Marking Non Electrical Equipment Ex PDFDokument1 SeiteMarking Non Electrical Equipment Ex PDFAgus RianNoch keine Bewertungen

- Marking requirements for non-electrical explosion protected equipmentDokument1 SeiteMarking requirements for non-electrical explosion protected equipmentTurkish Medical CareNoch keine Bewertungen

- Standards, Zone DefinitionsDokument3 SeitenStandards, Zone DefinitionsKhalifa AljahawiNoch keine Bewertungen

- Marking IECEx Equipment ExDokument1 SeiteMarking IECEx Equipment Exadirocks89Noch keine Bewertungen

- ATEX For Non-ElectricalDokument1 SeiteATEX For Non-ElectricalRajesh KumarNoch keine Bewertungen

- Ex Poster Bartec 2019 eDokument1 SeiteEx Poster Bartec 2019 eSubin ThomasNoch keine Bewertungen

- A Guide To The Use Of... : Electrical Equipment in Potentially Explosive AtmospheresDokument4 SeitenA Guide To The Use Of... : Electrical Equipment in Potentially Explosive AtmospheresAsif Ullah KhanNoch keine Bewertungen

- Marking Electrical Equipment ExDokument1 SeiteMarking Electrical Equipment ExFendy ShirahNoch keine Bewertungen

- Hazardous Area Chart - BartecDokument1 SeiteHazardous Area Chart - BartecbandianwarNoch keine Bewertungen

- Polyester Resins For Filled Fire Retardant Applications: Firepel K320-A Series Polyester ResinDokument3 SeitenPolyester Resins For Filled Fire Retardant Applications: Firepel K320-A Series Polyester ResinA.Subin DasNoch keine Bewertungen

- Marking Iecex Equipment Ex..Dokument1 SeiteMarking Iecex Equipment Ex..jerrinjNoch keine Bewertungen

- Explaining ATEX & IECEx Certifications NotesDokument3 SeitenExplaining ATEX & IECEx Certifications Notes何吉飞Noch keine Bewertungen

- Safety Instructions for Endress+Hauser Proline Promag 50 FlowmeterDokument24 SeitenSafety Instructions for Endress+Hauser Proline Promag 50 FlowmeterShishir JhaNoch keine Bewertungen

- Explosion Proof DefinitionsDokument2 SeitenExplosion Proof Definitionsgallegos70Noch keine Bewertungen

- Intrinsic Safety: A Technical Seminar OnDokument32 SeitenIntrinsic Safety: A Technical Seminar OnGobinath BalasubramanianNoch keine Bewertungen

- Ex KodlariDokument1 SeiteEx KodlaridhnsekaranNoch keine Bewertungen

- COAL GASIFICATION TECHNOLOGIES AND THEIR SCALE UP POTENTIALDokument32 SeitenCOAL GASIFICATION TECHNOLOGIES AND THEIR SCALE UP POTENTIALMiftahul HudaNoch keine Bewertungen

- Eye C GasDokument3 SeitenEye C GasLuis ReyesNoch keine Bewertungen

- Lecture 02 - FuelsDokument12 SeitenLecture 02 - FuelsEkoms GamingNoch keine Bewertungen

- ΑΝΤΙΕΚΡΗΚΤΙΚΟΤΗΤΑDokument1 SeiteΑΝΤΙΕΚΡΗΚΤΙΚΟΤΗΤΑKonstantinos KantzavelosNoch keine Bewertungen

- AOC FR Resin K320-A - Technical DataDokument3 SeitenAOC FR Resin K320-A - Technical Dataomarjaime01Noch keine Bewertungen

- 3 Gasoline Pool CDDokument46 Seiten3 Gasoline Pool CDnareshpallaNoch keine Bewertungen

- Safe Oxygen Production Large Safe Hydrogen FacilitiyDokument5 SeitenSafe Oxygen Production Large Safe Hydrogen FacilitiyTS WongNoch keine Bewertungen

- Alvega: Salt - New Breakthrough Solid Acid Alkylation TechnologyDokument11 SeitenAlvega: Salt - New Breakthrough Solid Acid Alkylation TechnologyhamedNoch keine Bewertungen

- II 1/2G Ex DB IIC T4 Ga/Gb: Internally/externally EPL Internally/externallyDokument2 SeitenII 1/2G Ex DB IIC T4 Ga/Gb: Internally/externally EPL Internally/externallyDhananjay BhaldandNoch keine Bewertungen

- Topic 2 WEEK 5 8 Fire Fighting Onboard ShipsDokument27 SeitenTopic 2 WEEK 5 8 Fire Fighting Onboard Shipslawrence christian dragidoNoch keine Bewertungen

- Voluntary GHG Reporting Summary Tables Emissions Factors 2015 PDFDokument2 SeitenVoluntary GHG Reporting Summary Tables Emissions Factors 2015 PDFJorge Tení CaalNoch keine Bewertungen

- Egemaster-Non Sparking Tools Safety PDFDokument5 SeitenEgemaster-Non Sparking Tools Safety PDFZulfiqar AliNoch keine Bewertungen

- Session 2 - Explosion Protection FundamentalsDokument24 SeitenSession 2 - Explosion Protection Fundamentalsdijoz85Noch keine Bewertungen

- NEC Poster e PDFDokument1 SeiteNEC Poster e PDFRahul PatilNoch keine Bewertungen

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsVon EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsBewertung: 5 von 5 Sternen5/5 (1)

- Oman - IEA - Report - 1686634467 2023-06-13 05 - 34 - 33Dokument54 SeitenOman - IEA - Report - 1686634467 2023-06-13 05 - 34 - 33ดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- Din Iec 61850-7-4 A2 e 2006-09Dokument21 SeitenDin Iec 61850-7-4 A2 e 2006-09ดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- Hot - Tapping - 1683962219 2023-05-13 07 - 17 - 06Dokument84 SeitenHot - Tapping - 1683962219 2023-05-13 07 - 17 - 06ดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- Solaronics Catalogue 2015 Guide Technique en v5Dokument8 SeitenSolaronics Catalogue 2015 Guide Technique en v5ดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- BS en 80000-6-2008Dokument40 SeitenBS en 80000-6-2008ดั๊มพ์ วาสนาทิพย์100% (1)

- Singapore BIM Guide V2Dokument70 SeitenSingapore BIM Guide V2woodyjrNoch keine Bewertungen

- DIN IEC 61850-7-3 A1 Sept2006 Basic Communication Structure For Substations & Feeder EquipmentDokument11 SeitenDIN IEC 61850-7-3 A1 Sept2006 Basic Communication Structure For Substations & Feeder EquipmentexpertelectricguyNoch keine Bewertungen

- Jet MixerDokument3 SeitenJet Mixerดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- Experimental Study of Micro-Particle Fouling Under PDFDokument12 SeitenExperimental Study of Micro-Particle Fouling Under PDFดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- En 50216-10Dokument16 SeitenEn 50216-10ดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- Mathematical Model of Ejector and Experimental Verification PDFDokument4 SeitenMathematical Model of Ejector and Experimental Verification PDFRavi RanjanNoch keine Bewertungen

- Impact of Flow Velocity On Surface Particulate Fouling - Theoretical ApproachDokument8 SeitenImpact of Flow Velocity On Surface Particulate Fouling - Theoretical ApproachBamrung SungnoenNoch keine Bewertungen

- Sizing Shell and Tube Heat ExchangerDokument17 SeitenSizing Shell and Tube Heat ExchangerCallum Biggs100% (3)

- Acs Iecr 7b01462Dokument12 SeitenAcs Iecr 7b01462ดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- Heat Transfer and Fluid Flow Characteristics Study For In-Line Tube Bank in Cross-FlowDokument13 SeitenHeat Transfer and Fluid Flow Characteristics Study For In-Line Tube Bank in Cross-Flowดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- Type T205B Balanced Tank Blanketing RegulatorDokument24 SeitenType T205B Balanced Tank Blanketing Regulatorดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- A Technical Report On Design of Hot Oil SystemDokument25 SeitenA Technical Report On Design of Hot Oil SystemEvert AlexNoch keine Bewertungen

- Energies 13 05632 v2Dokument12 SeitenEnergies 13 05632 v2ดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- Type 1190: Installation Guide D101644X014 English - November 2015Dokument4 SeitenType 1190: Installation Guide D101644X014 English - November 2015ดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- Product Information: CapacitiveDokument16 SeitenProduct Information: CapacitiveGlobal CHNoch keine Bewertungen

- Type Y692 Gas Blanketing Regulator SystemDokument12 SeitenType Y692 Gas Blanketing Regulator Systemดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- Tank Blanketing and Vapor Recovery Solutions: Application MapDokument1 SeiteTank Blanketing and Vapor Recovery Solutions: Application Mapดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- Type 1190: Installation Guide D101644X014 English - November 2015Dokument4 SeitenType 1190: Installation Guide D101644X014 English - November 2015ดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- Pressure Equipment Directive (PED) Classification Guide For Regulator ProductsDokument8 SeitenPressure Equipment Directive (PED) Classification Guide For Regulator Productsดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- Pressure Equipment Directive (PED) Classification Guide For Regulator ProductsDokument8 SeitenPressure Equipment Directive (PED) Classification Guide For Regulator Productsดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- Types ACE95 and ACE95Sr Tank Blanketing ValvesDokument12 SeitenTypes ACE95 and ACE95Sr Tank Blanketing Valvesดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- Manuals Position Monitor Bracket PMB Mounting Kit Installation Sheet Fisher en en 6104004Dokument4 SeitenManuals Position Monitor Bracket PMB Mounting Kit Installation Sheet Fisher en en 6104004ดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- Predict Storage-Tank Heat Transfer Precisely-LibreDokument6 SeitenPredict Storage-Tank Heat Transfer Precisely-Libreดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- Manuals 1190 Low Pressure Gas Blanketing Regulator Instruction Manual Fisher en en 5985974Dokument24 SeitenManuals 1190 Low Pressure Gas Blanketing Regulator Instruction Manual Fisher en en 5985974ดั๊มพ์ วาสนาทิพย์Noch keine Bewertungen

- T04: Mass Balance in Non Reacting System (Introduction Tu Multi Unit) A. Sugar Factory Activity (6 Min)Dokument2 SeitenT04: Mass Balance in Non Reacting System (Introduction Tu Multi Unit) A. Sugar Factory Activity (6 Min)Dewi Mawaddatus SholekhahNoch keine Bewertungen

- Manufacturing porcelain figures using binder jetting 3D printingDokument8 SeitenManufacturing porcelain figures using binder jetting 3D printingcesarNoch keine Bewertungen

- CWP Cert PDFDokument4 SeitenCWP Cert PDFmurtazagulzar3Noch keine Bewertungen

- T06002.006 Viva E System Onsite Training Workbook Eff Date 09-13-21Dokument66 SeitenT06002.006 Viva E System Onsite Training Workbook Eff Date 09-13-21Zitouni LamineNoch keine Bewertungen

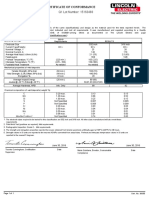

- Certificate of Conformance: Q1 Lot Number: 15163483Dokument1 SeiteCertificate of Conformance: Q1 Lot Number: 15163483interx00Noch keine Bewertungen

- N FactorDokument9 SeitenN FactorBiswajit Ghosh100% (1)

- Economics of Methanol Production From Natural GasDokument56 SeitenEconomics of Methanol Production From Natural Gaspabel lema0% (1)

- Satriana Et Al 2019 - European Journal of Lipid Science and TechnologyDokument1 SeiteSatriana Et Al 2019 - European Journal of Lipid Science and TechnologyMuhammad Dani SupardanNoch keine Bewertungen

- Chapter 2 Structure, Properties and Behavior of MatterDokument49 SeitenChapter 2 Structure, Properties and Behavior of Matteraxeman1nNoch keine Bewertungen

- Deformation and Fracture Mechanics of Engineering MaterialsDokument44 SeitenDeformation and Fracture Mechanics of Engineering MaterialsSyed Muhammad AliNoch keine Bewertungen

- Technical Data Sheet:: Polybutadiene Adducted With Maleic AnhydrideDokument1 SeiteTechnical Data Sheet:: Polybutadiene Adducted With Maleic AnhydrideRobert ThomasNoch keine Bewertungen

- Small STNTechnical ManualDokument8 SeitenSmall STNTechnical ManualMajid KhanNoch keine Bewertungen

- Oxford University Press - Online Resource Centre - Multiple Choice QuestionsDokument3 SeitenOxford University Press - Online Resource Centre - Multiple Choice Questionssadaf yousafzaiNoch keine Bewertungen

- 9h47.02 CD Emerald LyseDokument9 Seiten9h47.02 CD Emerald LyseanggitasaputriNoch keine Bewertungen

- OTC 25062-MS-Dr MuzDokument5 SeitenOTC 25062-MS-Dr Muzazmi68Noch keine Bewertungen

- A 421 - A 421M - 02 Qtqyms9bndixtqDokument4 SeitenA 421 - A 421M - 02 Qtqyms9bndixtqdelta lab sangliNoch keine Bewertungen

- Polymer CapacitorDokument19 SeitenPolymer CapacitorGilberto ManhattanNoch keine Bewertungen

- Acid Base SaltMay 24, 2023Dokument6 SeitenAcid Base SaltMay 24, 2023Archi SamantaraNoch keine Bewertungen

- Statistical Mechanics: Alice PaganoDokument253 SeitenStatistical Mechanics: Alice PaganoSharon Di SpenaNoch keine Bewertungen

- GilbertDokument24 SeitenGilbertVibhuti BhargavaNoch keine Bewertungen

- ACOT21 Round 2 - Gold TierDokument7 SeitenACOT21 Round 2 - Gold Tierjoe mamaNoch keine Bewertungen

- BS en 12255-14-2003-12 Wastewater Treatment Plants-Part 14 DisinfectionDokument16 SeitenBS en 12255-14-2003-12 Wastewater Treatment Plants-Part 14 DisinfectionAbey VettoorNoch keine Bewertungen

- Henkel Industrial Solutions Surface Treatment Selector GuideDokument2 SeitenHenkel Industrial Solutions Surface Treatment Selector GuideMax JunghannsNoch keine Bewertungen

- PWS&PQRDokument1 SeitePWS&PQRkuppiliramaNoch keine Bewertungen

- Asian Sciences Olympiad 2015 CONTEST: Rules and RegulationsDokument8 SeitenAsian Sciences Olympiad 2015 CONTEST: Rules and RegulationsNguyễn Thị HảiNoch keine Bewertungen

- PV Module IonDokument4 SeitenPV Module IonrmalewarNoch keine Bewertungen

- Iso 13438 2018Dokument9 SeitenIso 13438 2018Phạm Hùng CườngNoch keine Bewertungen

- Assignment Open and Closed Thermodynamic SystemDokument1 SeiteAssignment Open and Closed Thermodynamic SystemJenellie BahintingNoch keine Bewertungen

- Dual Nature of Matter and Radiation PDFDokument49 SeitenDual Nature of Matter and Radiation PDFabhishekNoch keine Bewertungen

- Eutronic - Arc - Spray 4HFDokument4 SeitenEutronic - Arc - Spray 4HFMuhammad irfanNoch keine Bewertungen