Beruflich Dokumente

Kultur Dokumente

Manufacturing Science II PDF

Hochgeladen von

Krishnan Velavan0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

12 Ansichten47 SeitenOriginaltitel

Manufacturing-Science-II.pdf

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

12 Ansichten47 SeitenManufacturing Science II PDF

Hochgeladen von

Krishnan VelavanCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 47

Lecture Notes on Manufacturing Seience-II by Animesh Pal, Depariment of Mechanical E

UNIT NO-I

‘Lecture Notes on Manufacturing Sclenc-I by Animesh Pal, Department of Mechanica! Engineering, KIOT: Kenpur

METAL CUTTING

MECHANICS OF METAL CUTTING

MACHINING

Machining is an essential process of finishing by which jobs are produced to the desired dimensions

and surface finish by gradually removing the excess material from the preformed blank in the form of

chips with the help of cutting tools moved past the work surface. Machining. is a removal process,

MACHINE TOOL,

A machine tool is a non-portable power operated and reasonably valued device or system of device in

which energy is expended to produce jobs of desired size, shape and surface finish by removing excess

‘material from the preformed blanks in the form of chips with the help of cutting tools moved past the

work surface,

Meterial removal is essentially done on machine tools, which may be Lathe, Milling, Drilling, Shaping,

Planing, Broaching and Grinding machines.

‘The functions of machine tools are:

+ Holding the workpiece

+ Holding the tool

* Moving the tool or the work piece or both relative to each other,

* Supply energy required to cause metal cutting,

Every machine tool has a primary cutting tool for metal removal

METAL CUTTING:

Machining is the process of removing unwanted material from W/P in the form of unwanted chip. If

‘the material is Metal then itis known as metal Cutting,

‘TYPES OF METAL CUTTING:

GS two basic methods of metal cutting using a single point tool are the orthogonal (2 D) and obtique

@D).

7 Orthogonal Cutting (2-D): Orthogonal cutting takes place when the cutting face of the tool is 90

degree to the line of action of the tool.

2. Oblique Cutting (3-D): Ifthe cutting face is inclined at an angle less than 90 degree to the line of

action of the tool, the cutting action is known as oblique.

‘Lecture Notes on Manufacturing Science-II by Animesh Pal, Department of Mechanical Engineering, KIOT, Kanpur

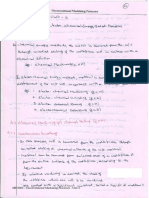

DIFFERENCE BETWEEN ORTHOGONAL AND OBLIQUE CUTTING

Orthogonal Cutting (2-D)_

Oblique Cutting (3-D)_

Mor chip

Cutting edge

Inclination

cutting

Gitect ion

‘The cutting edge of the tool remains normal

{to the direction of tool feed or work feed.

The direction of the chip flow velocity is

normal to the cutting edge of the tool.

The cutting edge of the tool remains inclined at

an acute angle to the direction of tool feed or

work feed

The direction of the chip flow velocity is at an

angle with the normal to the cutting edge of

the tool. The angle is known as chip flow angle

Here only two components of forces are

acting: Cutting Force and Thrust Force. So

the metal cutting may be considered as a two

dimensional cutting.

Here three components of forces are acting:

Cuting Force, Radial force and Thrust Force or

feed force. So the metal cutting may be

considered as a three dimensional cutting

Inclination angle is 0°

Inclination angle is non Zero

Chip get coiled in a tight way resulting heat

Less concentration of heat and pressure

and pressure | _|

Less tool life More tool life

Examples: Slotting, Parting, Planning. Examples: Milling, Turning, Drillin

GEOMETRY OF SINGLE POINT TURNING TOOL

Both material and geometry of the cutting tool play very important roles on their performances

in achieving effectiveness, efficiency and overall economy of machining,

CLASSIFICATION: (ACCORDING TO THE

(POINTS) INVOLVED.)

NUMBER OF MAJOR CUTTING EDGES

+ Single point: turning, shaping, planning, slotting tools etc.

+ Double point: drilling tools

+ Multipoint: Milling, broaching, hobbing tools etc.

Das könnte Ihnen auch gefallen

- 0139165martekting StrategyDokument40 Seiten0139165martekting StrategyajayuselessNoch keine Bewertungen

- MBA Notes - Marketing Definitions and ConceptsDokument22 SeitenMBA Notes - Marketing Definitions and ConceptsKrishnan VelavanNoch keine Bewertungen

- Marketing Management ZOSMLuTCjy PDFDokument524 SeitenMarketing Management ZOSMLuTCjy PDFpenusila6941100% (2)

- Cim Unit 1 Notes PDFDokument8 SeitenCim Unit 1 Notes PDFKrishnan VelavanNoch keine Bewertungen

- Manju PDFDokument24 SeitenManju PDFVishwanath PatilNoch keine Bewertungen

- Cim Unit 3 PDFDokument10 SeitenCim Unit 3 PDFKrishnan VelavanNoch keine Bewertungen

- Cim Unit 2 Notes PDFDokument23 SeitenCim Unit 2 Notes PDFKrishnan VelavanNoch keine Bewertungen

- Incentives and SubsidyDokument27 SeitenIncentives and SubsidyKrishnan VelavanNoch keine Bewertungen

- Cim Unit 2 Notes PDFDokument23 SeitenCim Unit 2 Notes PDFKrishnan VelavanNoch keine Bewertungen

- UNIT-1 Entrepreneur: Role of Entrepreneurship in Economic DvelopmentDokument10 SeitenUNIT-1 Entrepreneur: Role of Entrepreneurship in Economic DvelopmentKrishnan VelavanNoch keine Bewertungen

- Cim Unit 4 Notes PDFDokument4 SeitenCim Unit 4 Notes PDFKrishnan VelavanNoch keine Bewertungen

- ME 6004 - Unconventional Machining Processes - Unit 4Dokument24 SeitenME 6004 - Unconventional Machining Processes - Unit 4Krishnan VelavanNoch keine Bewertungen

- Cim Unit 1 Notes PDFDokument8 SeitenCim Unit 1 Notes PDFKrishnan VelavanNoch keine Bewertungen

- Entrepreneurship Development - by EasyEngineering - Net-7Dokument29 SeitenEntrepreneurship Development - by EasyEngineering - Net-7Krishnan VelavanNoch keine Bewertungen

- Analysis of CompositeDokument7 SeitenAnalysis of CompositeAshish VajirNoch keine Bewertungen

- Studies On Wear Behaviour of Aluminium 6061alloy R PDFDokument4 SeitenStudies On Wear Behaviour of Aluminium 6061alloy R PDFKrishnan VelavanNoch keine Bewertungen

- Failure Behavior of Composite Laminates PDFDokument19 SeitenFailure Behavior of Composite Laminates PDFKrishnan VelavanNoch keine Bewertungen

- ME 6004 - Unconventional Machining Processes - Unit 5Dokument26 SeitenME 6004 - Unconventional Machining Processes - Unit 5Krishnan VelavanNoch keine Bewertungen

- Tribological Behaviour of Aluminium Alumina Graphite Hybrid MetalDokument17 SeitenTribological Behaviour of Aluminium Alumina Graphite Hybrid MetalKanchana DmNoch keine Bewertungen

- Research Article: Dry Sliding Friction and Wear Studies of Fly Ash Reinforced AA-6351 Metal Matrix CompositesDokument7 SeitenResearch Article: Dry Sliding Friction and Wear Studies of Fly Ash Reinforced AA-6351 Metal Matrix CompositesKrishnan VelavanNoch keine Bewertungen

- Unit 2 - Machine Tools PDFDokument96 SeitenUnit 2 - Machine Tools PDFKrishnan VelavanNoch keine Bewertungen

- PDFDokument33 SeitenPDFKrishnan VelavanNoch keine Bewertungen

- MT 2 PDFDokument65 SeitenMT 2 PDFBalakumar MurugesanNoch keine Bewertungen

- MT2 University Question PaperDokument4 SeitenMT2 University Question PaperKrishnan VelavanNoch keine Bewertungen

- ME 6004 - Unconventional Machining Processes - Unit 3Dokument21 SeitenME 6004 - Unconventional Machining Processes - Unit 3Krishnan VelavanNoch keine Bewertungen

- Tribological Behaviour of Al-6061 / Sic Metal Matrix Composite by Taguchi'S TechniquesDokument8 SeitenTribological Behaviour of Al-6061 / Sic Metal Matrix Composite by Taguchi'S TechniquesKrishnan VelavanNoch keine Bewertungen

- Unit 3 - Grinding-2 PDFDokument30 SeitenUnit 3 - Grinding-2 PDFKrishnan VelavanNoch keine Bewertungen

- Unit 2 Shaper Planer SlotterDokument25 SeitenUnit 2 Shaper Planer SlotterKrishnan VelavanNoch keine Bewertungen

- Tribological Behaviour of Al-6061 / Sic Metal Matrix Composite by Taguchi'S TechniquesDokument8 SeitenTribological Behaviour of Al-6061 / Sic Metal Matrix Composite by Taguchi'S TechniquesKrishnan VelavanNoch keine Bewertungen

- Unit 5 - Unconventional Machining Processes PDFDokument32 SeitenUnit 5 - Unconventional Machining Processes PDFKrishnan VelavanNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)