Beruflich Dokumente

Kultur Dokumente

Elcon 215 DS

Hochgeladen von

Juan PedrerosCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Elcon 215 DS

Hochgeladen von

Juan PedrerosCopyright:

Verfügbare Formate

End stop Guidance’s

The Elcon DS is supplied with a hardened steel shaft for

the horizontal guidance. This provides an almost friction

free course of the saw beam.

As with the bottom beam, the heavy duty mid fence has an end stop.

This prevents the slipping of the panel when cutting horizontally.

Pneumatic Digital read-out

lifting rollers The cutting height and length can be read electronically.

This feature also enables the resetting of the display after

The bottom beam can be supplied with pneumatic lifting rollers. This

cutting the top side of a panel, the nett width of the strip

makes it easy to move heavy material and prevents any damage to the

can then be read easily and accurately.

machine and operator.

Frame

A fully self-supporting construction

with torsion-rigid carrying modu-

les is the basis for the steel length

guidance shaft. The tension free

guidance ruler guarantees an ac-

curacy within 0,1 mm/m. The har-

dened steel bar ensures a very

long life.

064_09006_folderlijn_DS_Def!.indd 1 19-03-2010 09:55:06

D

DS

D

E

DSX

Advance A

Advance2 Quadra B C

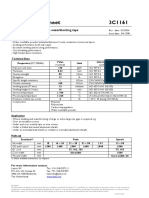

Technical data 155 185 215 Dimensions (mm) and weight 155 185 215

Maximum cutting length 3300 3300/4300 4300/5300 A 945 945 945

Maximum cutting height (hor) 1510 1810 2100 B 1450 1450 1450

Maximum cutting height (vert) 1550 1850 2150 C 4510 4510 5510

Maximum depth of cut 55 mm D 1980 2280 2580

Motor (S6) 3 kW E 2300 2600 2900

Speed 5100 rpm Weight in kgs 700 745 865

Diameter saw-blade 250 mm When cutting horizontally at the highest position: +160 mm.

Electric supply 400V/3ph/50Hz Extra space to the right: +300 mm.

Air requirements depending on options

Special sizes on request.

Extraction flow rate >1000 m3/h, 20 m/s

Family features across the Elcon range Features of the DS

n Unique long life guidance for saw beam n Integrated operating handles at two heights

n Super silent motor housing with insulation n Possibility for cutting out rectangles

n Safety: CE tested, Micro switch security, “Tilt” switch n Easy access to saw blade

n Precision: 0,1 mm/m (DIN 875/1) n Fault diagnostics

n Construction: robust modular welded frame,

heavy cast iron flip stop, on solid steel axis

Standard Accessories Optional Accessories

Repeat stop for strip cutting Automatically moving rear support frame

Double cut scoring with main blade Square stop extension

Programming rail for repetitive sizes Digital read-outs (horizontal and/ or vertical)

Mid fence in 3 parts with integrated end stop Double bearing bottom rollers, with pneumatic panel clamp

Panel entry rollers Extra pneumatic panel clamp

Panel tilting/placing guidance Pneumatic midfence

Extra support strips for smaller pieces Pneumatic lifting transport rollers

Double secured fine adjustable flip stop Patented Limpio double sided dust collection system,

Package with CD-ROM, user guide, emission less than 0,5 mg/m3

tooling and Internet support access TWIN scoring unit

Clipboard for cutting lists Filling-in piece for flip stop compartment

Fixed bottom blocks for stable panel support Electronic positioning module for vertical cutting

Integrated guidance rail cleaners 4 kW (S6) motor

Indestructible double chain guidance for saw unit Saw motor with 2 speeds

Electromagnetic brake on saw motor Infinitely variable speed control for saw motor

Lubrication system for solid aluminium

V-grooving router for Alu-bond materials

Elcon is continuously working on development and perfecting its product range, which may result in changes to product specifications without prior notice

PO Box 72 2450 AB Leimuiden The Netherlands T +31 (0) 172 50 88 91 F +31 (0) 172 50 78 92

Waaier 2 2451 VV Leimuiden The Netherlands E info@elcon.nl www.elcon.nl

064_09006_folderlijn_DS_Def!.indd 2 19-03-2010 09:55:07

DS ENG

The DS:

not only for wood...

064_09006_folderlijn_DS_Def!.indd 3 19-03-2010 09:55:15

...also for plastic and aluminum

The DS models are equipped with all the functions needed for professional

use when also working with plastic and aluminium panels. In addition to these

functions there is a wide choice of accessories, including a scoring unit and a

V-grooving attachment.

Limpio-dust Limpio: clean, efficient

collection system

and unique

The patented Limpio-dust extraction system collects

the dust directly at the source, both from the front and

on the back side of the panel. The saw-blade runs in

an almost completely closed area with the dual ex-

traction points removing the dust directly at the point of

cut. With this unique system emission values, less than

0,5 mg/m3, are reached with a minimal extraction air

flow rate.

Extra advantages

of the Limpio-system are:

n Full support of the work piece over the total height

of the panel

n Ultimate machine frame protection, as the blade

can never cut into the panel supports.

064_09006_folderlijn_DS_Def!.indd 4 19-03-2010 09:55:19

Two versions

The Limpio system can be supplied in two versions.

The picture below is an example of a DS with a full

Limpio dust tray. A moving back support grid is su-

perfluous as the Limpio dust tray protects the full rear

side of the machine against any accidental damage

caused by cutting into it with the saw blade.

A combination of the two systems is the semi Limpio

version (see top picture), where the Limpio dust tray

is limited to above the mid-fence. This means that

the saw beam is always free for horizontal movement

and is not limited by the prominent position of the mid

fence. Therefore cutting strips horizontally on the mid

fence is easy and virtually dust free.

064_09006_folderlijn_DS_Def!.indd 5 19-03-2010 09:55:23

Measuring stop Double cut scoring

with optional extension

The robust flip stop (with fine Scoring is not only possi-

adjustment) on a 30 mm dia- ble with the TWIN III sco-

meter solid guidance shaft, ring unit, but also with the

can be equipped with a square main blade. With double-

stop-extension providing addi- cut scoring, the top layer of

tional panel support. the panel is scored with a

reduced saw blade plunge

while positioning the head I

for the main cut (I). Then,

the saw blade is plunged

fully into the panel and the

cut is completed (II).

II

V-Grooving

This option includes tracking rollers and a

V-grooving disc and enables the proces-

sing of aluminium sandwich panels and

plastic panels like Corian.

Repeat stop for strips

The grooving discs are available for Cutting a panel horizontally into strips of the same width

V-shaped grooving of 90° or 135° and is easy with the adjustable repeat stop with track bearing.

U-shaped grooving of 10 or 15 mm.

The tracking-unit uses four

enlarged bearing

rollers with fine

adjustment, provi-

ding very accurate

depth adjustment.

Double bearing

bottom rollers

As an option, it is possible equip the machine with

double bearing aluminium bottom rollers. These are al-

ways combined with a pneumatic panel clamp to hold

the panels while cutting.

064_09006_folderlijn_DS_Def!.indd 6 19-03-2010 09:55:25

Das könnte Ihnen auch gefallen

- AccurL ESAY BEND NC Press Brake MB7-220Tx4000 E21Dokument5 SeitenAccurL ESAY BEND NC Press Brake MB7-220Tx4000 E21EnriqueMiguelPriceNoch keine Bewertungen

- CDP Mini Split Quick ReferenceDokument7 SeitenCDP Mini Split Quick ReferenceMiguel GomezNoch keine Bewertungen

- Hdl5410Thb5254E: Boom Pump-52MDokument2 SeitenHdl5410Thb5254E: Boom Pump-52MAkhmad SebehNoch keine Bewertungen

- Aquarama Catalogo Stargate s4 en CompressedDokument2 SeitenAquarama Catalogo Stargate s4 en CompressedmusabNoch keine Bewertungen

- MB8 Automatic Sheet Metal Press Brake Bending Machine With DA56S SystemDokument8 SeitenMB8 Automatic Sheet Metal Press Brake Bending Machine With DA56S SystemryneleeNoch keine Bewertungen

- Offer For ACCURL Smart Swing Beam Shear MS7-12x3200-Crys PDFDokument7 SeitenOffer For ACCURL Smart Swing Beam Shear MS7-12x3200-Crys PDFJ Jack GutierrezNoch keine Bewertungen

- Ysd e Cat PPT-PPT KDokument4 SeitenYsd e Cat PPT-PPT KAdrian Bayu BagaskaraNoch keine Bewertungen

- Light Industrial Conveyor ENDokument6 SeitenLight Industrial Conveyor ENMumu moemoeNoch keine Bewertungen

- PRO SeriesDokument2 SeitenPRO SeriesJani CoolNoch keine Bewertungen

- ESAB CaB 460S Column and Boom for Flexible Weld MechanizationDokument2 SeitenESAB CaB 460S Column and Boom for Flexible Weld MechanizationEnaam AtaallahNoch keine Bewertungen

- HD 1020BB - 3 Axis Waterjet Cutting Machine QuotationDokument17 SeitenHD 1020BB - 3 Axis Waterjet Cutting Machine Quotationremuspopescu85Noch keine Bewertungen

- PNC 10catalogueDokument2 SeitenPNC 10catalogueParlin PasbarNoch keine Bewertungen

- C350 Ipower: Standard Equipment ApplicationsDokument1 SeiteC350 Ipower: Standard Equipment ApplicationsDein MasterNoch keine Bewertungen

- Hdl5530Thb6365E: Boom Pump-63MDokument2 SeitenHdl5530Thb6365E: Boom Pump-63MAkhmad SebehNoch keine Bewertungen

- Reversible: RAM 300 24V RAM 300 230VDokument2 SeitenReversible: RAM 300 24V RAM 300 230Vderbalijalel50% (2)

- Coring and Drilling Equipment OverviewDokument8 SeitenCoring and Drilling Equipment OverviewRyan A.Y.Noch keine Bewertungen

- Asb1036 Ridge As Rev 1Dokument24 SeitenAsb1036 Ridge As Rev 1pambay.quarshieNoch keine Bewertungen

- Tech - Clean Room at Kochi (REF - 11669)Dokument10 SeitenTech - Clean Room at Kochi (REF - 11669)Anand VLNoch keine Bewertungen

- DB Mmu-Ap 4HPDokument20 SeitenDB Mmu-Ap 4HPgeobits9889Noch keine Bewertungen

- S-TSK TLKDokument6 SeitenS-TSK TLKEdgarNoch keine Bewertungen

- Hi-TECH 230-4 (9.0)Dokument100 SeitenHi-TECH 230-4 (9.0)Ойген ЁхNoch keine Bewertungen

- 2007 HIE 2P AX10u 7 No4-English-With-Correct-Rollbar-1Dokument2 Seiten2007 HIE 2P AX10u 7 No4-English-With-Correct-Rollbar-1nqqcm6fw5nNoch keine Bewertungen

- DS312 Specification Sheet EnglishDokument4 SeitenDS312 Specification Sheet EnglishAntonio BocanegraNoch keine Bewertungen

- Catalogue 0501Dokument8 SeitenCatalogue 0501Neeraj VohraNoch keine Bewertungen

- BrakesDokument34 SeitenBrakesMilan GrujićNoch keine Bewertungen

- OFFER UVI15 UMC-500SS 2022 02 01 MotorojusDokument7 SeitenOFFER UVI15 UMC-500SS 2022 02 01 MotorojusMotorojus MotorojusNoch keine Bewertungen

- En CTL Range Brochure B4500130 04-2018 LowResDokument8 SeitenEn CTL Range Brochure B4500130 04-2018 LowResVinod GuptaNoch keine Bewertungen

- LRNC Tandem Roller Operators ManualDokument86 SeitenLRNC Tandem Roller Operators ManualSanath pkNoch keine Bewertungen

- AL800G - ALN800G English FranceDokument2 SeitenAL800G - ALN800G English FrancePhu MrNoch keine Bewertungen

- Technical Detail - EHRW + SHRWDokument10 SeitenTechnical Detail - EHRW + SHRWBalaji JenarthananNoch keine Bewertungen

- HSM Powerline Fa500.3 Brochure - CompressedDokument1 SeiteHSM Powerline Fa500.3 Brochure - CompressedJonathanNoch keine Bewertungen

- Keysight i3070 Inline 4 Module In-Circuit Test SystemDokument11 SeitenKeysight i3070 Inline 4 Module In-Circuit Test SystemDanielNoch keine Bewertungen

- VA1400 DataSheetDokument2 SeitenVA1400 DataSheetVikram DewanganNoch keine Bewertungen

- SJ 410 460 530 - EnglDokument2 SeitenSJ 410 460 530 - EnglEmilian PopaNoch keine Bewertungen

- Soil Mixing Wall System: Product InformationDokument8 SeitenSoil Mixing Wall System: Product Informationnoto.sugiartoNoch keine Bewertungen

- MMV 1300 1500 - EnglDokument2 SeitenMMV 1300 1500 - EnglEmilian PopaNoch keine Bewertungen

- WEV 1500-125 RT 601243000 Angle Grinder EnglishDokument2 SeitenWEV 1500-125 RT 601243000 Angle Grinder EnglishTruong Dang VinhNoch keine Bewertungen

- MB8 3+1 Axis CNC Hydraulic Servo Press Brake Machine - DELEM DA52SDokument8 SeitenMB8 3+1 Axis CNC Hydraulic Servo Press Brake Machine - DELEM DA52SryneleeNoch keine Bewertungen

- WEG 132kW SpecificationDokument8 SeitenWEG 132kW Specificationbonginkosi mathunjwaNoch keine Bewertungen

- Rectilinear Displacement Transducer: Technical Data Mechanical DimensionsDokument2 SeitenRectilinear Displacement Transducer: Technical Data Mechanical DimensionsJan MaksNoch keine Bewertungen

- Water Swallable TapeDokument1 SeiteWater Swallable TapeSanthosh V RaajendiranNoch keine Bewertungen

- BG 33 H Fisa TehnicaDokument2 SeitenBG 33 H Fisa Tehnicalorenz sarimNoch keine Bewertungen

- Quot. 070g Mos-23 Al Areen Projects Spacifications.Dokument22 SeitenQuot. 070g Mos-23 Al Areen Projects Spacifications.Abuelgassim GarelnabiNoch keine Bewertungen

- AQUAPANEL Cement Board Outdoor Datasheet 0817Dokument3 SeitenAQUAPANEL Cement Board Outdoor Datasheet 0817xander1982Noch keine Bewertungen

- Wide Cutting On The Solid Body: MLT100 Table SawDokument2 SeitenWide Cutting On The Solid Body: MLT100 Table SawIka Novianty MANoch keine Bewertungen

- Remaclean-Hm-U8 5821481 Flyer I.10Dokument2 SeitenRemaclean-Hm-U8 5821481 Flyer I.10dexNoch keine Bewertungen

- Krone TrailersDokument1 SeiteKrone Trailersmatej1992Noch keine Bewertungen

- Column Boom Welding MachinesDokument8 SeitenColumn Boom Welding Machinesbahram bahramiNoch keine Bewertungen

- High-Speed CNC Vertical Machining Center: Page 1 of 8 May 1, 2017Dokument8 SeitenHigh-Speed CNC Vertical Machining Center: Page 1 of 8 May 1, 2017Saad MughalNoch keine Bewertungen

- HT-G2088 Flap BarrierDokument1 SeiteHT-G2088 Flap BarrierWin TeknologiNoch keine Bewertungen

- Instruction Manual: Double Pallets Electric Stacker Model: FD1229/FD1233/FD1529/FD1533Dokument37 SeitenInstruction Manual: Double Pallets Electric Stacker Model: FD1229/FD1233/FD1529/FD1533Shri ShriNoch keine Bewertungen

- Technical SheetDokument2 SeitenTechnical Sheetdesie yalewNoch keine Bewertungen

- DM901HDE: Diesel Driven & Electric DrillerDokument6 SeitenDM901HDE: Diesel Driven & Electric DrillerEnzo VanderlindenNoch keine Bewertungen

- BC Doosan DB130 Lot 1Dokument3 SeitenBC Doosan DB130 Lot 1Welly CholilNoch keine Bewertungen

- Brochure Omniplus 800 TC enDokument8 SeitenBrochure Omniplus 800 TC enMian GulfamNoch keine Bewertungen

- FRD HB Range 2019 NewDokument17 SeitenFRD HB Range 2019 Newrho myoung chullNoch keine Bewertungen

- Ds311de Specification Sheet EnglishDokument4 SeitenDs311de Specification Sheet EnglishFORMINNoch keine Bewertungen

- Data Sheet 3KA7131-3AA00: ModelDokument2 SeitenData Sheet 3KA7131-3AA00: ModelMARIAMNoch keine Bewertungen

- Deckel Fp4 Ma enDokument10 SeitenDeckel Fp4 Ma enRenan ValenteNoch keine Bewertungen

- Lenovo A328 - Lenovo A328 User GuideDokument42 SeitenLenovo A328 - Lenovo A328 User GuideDusan StefanovNoch keine Bewertungen

- LicenseDokument7 SeitenLicenseAdnan AvdukićNoch keine Bewertungen

- Driver's HandbookDokument285 SeitenDriver's HandbookXuan Hu100% (5)

- Metodo Simplex Metodo Simplex Programacion LinealDokument13 SeitenMetodo Simplex Metodo Simplex Programacion LinealJuan PedrerosNoch keine Bewertungen

- Property For Sale Stotfold 3 2902879304Dokument3 SeitenProperty For Sale Stotfold 3 2902879304Juan PedrerosNoch keine Bewertungen

- Property For Sale Stotfold 3 2902879304Dokument3 SeitenProperty For Sale Stotfold 3 2902879304Juan PedrerosNoch keine Bewertungen

- Player From Fee ( ) Million Fee ( ) MillionDokument2 SeitenPlayer From Fee ( ) Million Fee ( ) MillionJuan PedrerosNoch keine Bewertungen

- The Problem of Population and Growth A Review of The Literature From Malthus To Contemporary ModelsDokument37 SeitenThe Problem of Population and Growth A Review of The Literature From Malthus To Contemporary ModelsJuan PedrerosNoch keine Bewertungen

- COVID-19's Impact on Business PresentationsDokument2 SeitenCOVID-19's Impact on Business PresentationsRetmo NandoNoch keine Bewertungen

- 4.5.1 Forestry LawsDokument31 Seiten4.5.1 Forestry LawsMark OrtolaNoch keine Bewertungen

- Case Study - Soren ChemicalDokument3 SeitenCase Study - Soren ChemicalSallySakhvadzeNoch keine Bewertungen

- Social EnterpriseDokument9 SeitenSocial EnterpriseCarloNoch keine Bewertungen

- The SAGE Handbook of Digital JournalismDokument497 SeitenThe SAGE Handbook of Digital JournalismK JNoch keine Bewertungen

- API MidtermDokument4 SeitenAPI MidtermsimranNoch keine Bewertungen

- Supplier Quality Requirement Form (SSQRF) : Inspection NotificationDokument1 SeiteSupplier Quality Requirement Form (SSQRF) : Inspection Notificationsonnu151Noch keine Bewertungen

- ZOOLOGY INTRODUCTIONDokument37 SeitenZOOLOGY INTRODUCTIONIneshNoch keine Bewertungen

- BA 9000 - NIJ CTP Body Armor Quality Management System RequirementsDokument6 SeitenBA 9000 - NIJ CTP Body Armor Quality Management System RequirementsAlberto GarciaNoch keine Bewertungen

- Geneva IntrotoBankDebt172Dokument66 SeitenGeneva IntrotoBankDebt172satishlad1288Noch keine Bewertungen

- Civil Aeronautics BoardDokument2 SeitenCivil Aeronautics BoardJayson AlvaNoch keine Bewertungen

- 3 Intro To Ozone LaundryDokument5 Seiten3 Intro To Ozone LaundrynavnaNoch keine Bewertungen

- 2022 Product Catalog WebDokument100 Seiten2022 Product Catalog WebEdinson Reyes ValderramaNoch keine Bewertungen

- Global Cleantech Innovation Programme IndiaDokument122 SeitenGlobal Cleantech Innovation Programme Indiaficisid ficisidNoch keine Bewertungen

- PS300-TM-330 Owners Manual PDFDokument55 SeitenPS300-TM-330 Owners Manual PDFLester LouisNoch keine Bewertungen

- Craft's Folder StructureDokument2 SeitenCraft's Folder StructureWowNoch keine Bewertungen

- 04 Dasmarinas Vs Reyes GR No 108229Dokument2 Seiten04 Dasmarinas Vs Reyes GR No 108229Victoria Melissa Cortejos PulidoNoch keine Bewertungen

- MsgSpec v344 PDFDokument119 SeitenMsgSpec v344 PDFqweceNoch keine Bewertungen

- MiniQAR MK IIDokument4 SeitenMiniQAR MK IIChristina Gray0% (1)

- Sop EcuDokument11 SeitenSop Ecuahmed saeedNoch keine Bewertungen

- Programme Report Light The SparkDokument17 SeitenProgramme Report Light The SparkAbhishek Mishra100% (1)

- Introduction To Succession-1Dokument8 SeitenIntroduction To Succession-1amun dinNoch keine Bewertungen

- Proposal Semister ProjectDokument7 SeitenProposal Semister ProjectMuket AgmasNoch keine Bewertungen

- DHPL Equipment Updated List Jan-22Dokument16 SeitenDHPL Equipment Updated List Jan-22jairamvhpNoch keine Bewertungen

- Tata Chemicals Yearly Reports 2019 20Dokument340 SeitenTata Chemicals Yearly Reports 2019 20AkchikaNoch keine Bewertungen

- Nature of ConversionDokument18 SeitenNature of ConversionKiranNoch keine Bewertungen

- SyllabusDokument4 SeitenSyllabusapi-105955784Noch keine Bewertungen

- OBHR Case StudyDokument8 SeitenOBHR Case StudyYvonne TanNoch keine Bewertungen

- Denial and AR Basic Manual v2Dokument31 SeitenDenial and AR Basic Manual v2Calvin PatrickNoch keine Bewertungen

- Janapriya Journal of Interdisciplinary Studies - Vol - 6Dokument186 SeitenJanapriya Journal of Interdisciplinary Studies - Vol - 6abiskarNoch keine Bewertungen