Beruflich Dokumente

Kultur Dokumente

Projector Dfma

Hochgeladen von

dwanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Projector Dfma

Hochgeladen von

dwanCopyright:

Verfügbare Formate

Boothroyd Dewhurst, Inc.

Design For Assembly Software

Case Study

Product Overhead Projector

Company 3M

Source "DFMA: Learning to Design for

Manufacture and Assembly"

Mechanical Engineering

May 1992

Improvements/Reductions

Product Development Cycle 45%

Summary

Redesign of overhead projector.

BDI Case Study # EQP5

Automakers and other manufacturers using design for manufacture

and assembly are relishing its fruits-shorter production times and improvements in

product quality-while saving money.

engineering. junction with a structural analysis of

While many automakers have the design for its overall efficiency

Joseph Constance embraced DFMA and benefited and suitability for the chosen assem-

most from this manufacturing ap- bly method.

Wyckoff, N.J. proach, it is also available to other DFMA runs on IBM PCs and on

industries. DFMA has enabled vari- Apple computers. The minimum cost

ous companies to design, manufac- of licensing either DFM or DFA soft-

D

esign for manufacture ture, and assemble products more ware, for a site with 250 employees,

and assembly (DFMA)-a efficiently and competitively. Mak- is $12,500.

management and software ers of aircraft, industrial and elec- The DFMA software is a method-

tool based on the premise trical machinery, pumps, and com- ology and data base system that al-

that about 70 percent of all pressors are among the growing lows a design engineer or cross-

product development, assembly, and number of manufacturers adopting functional manufacturing team to

production costs are built in during the method. analyze and rate product designs for

the design stage-has been saving However, DFMA has caused some ease of assembly and structural effi-

some companies production and la- disruptions. Under this system, ciency, as well as to predict assembly

bor costs for the last decade. The engineers and designers arc forced and manufacturing costs. The pro-

tool enables designers to consider a to work in teams rather than indi- gram allows for the selection of the

product’s material selection, design, vidually, and this occasionally cre- most feasible manufacturing process

manufacturability, and assembly up ates friction. Additionally, their at the concept stage, when product

front. It also increases productivity work is more closely scrutinized, as configurations are a rough sketch or

and quality. Approximately 400 com- DFMA often reveals that their ini- outline and before CAD/CAM activi-

panies and institutions use it tial ideas may not be the most ty has begun.

worldwide. effective.

At Ford Motor Co. (Dearborn, DFMA, developed by Boothroyd Putting DFMA to Use

Mich.), for example, executives Dewhurst Inc. (Wakefield, R.I.), The Portable Compressor division

saved $1.2 billion worldwide using calls for the development of de- of the Construction and Mining

design for assembly (DFA) in l987 tailed designs for each of a prod- Group was one of the first divisions

alone. And General Motors Corp. uct’s individual parts, based on the of Ingersoll-Rand Co. (Mocksville,

(Detroit) reportedly has reduced combination of various capabilities N.C.) to use the DFMA tool, accord-

manufacturing costs 30 to 60 per- and limitations inherent in the ma- ing to Don Gerhardt, manager of

cent on certain projects since it terials and processes used. That is, engineering and development. In

started to use DFMA in late l989. manufacturers must identify the the past, he explained, products

GM has implemented a large pro- most appropriate assembly system were designed and preproduction

gram using DFMA and concurrent for a new product design in con- units were built. Then 6 to 12

70 / MAY 1992 / MECHANICAL ENGINEERING

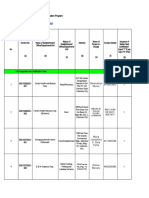

Instrument panel Screw, Control panel r Screw, nut

Relay _ r Control panel

Valve, 2-way

Decal-l

I. Lamp Rivet

Cable, choke- ,

Door, control panel

d Rivet

Combined control and instrument panel

Fewer parts. At Ingersoll-Rand, DFMA software was used on a control and instrument panel assembly. The number of parts was reduced 33 percent; the

number of fasteners used fell 38 percent; assembly operations decreased 33 percent; and assembly time improved 28 percent.

MECHANICAL ENGINEERING / MAY 1992 / 71

months were spent obtaining input number of parts was reduced 33 per- perts into teams so that they would

from employees on how to optimize cent; the number of fasteners used communicate with each other read-

a prototype. But that all changed in fell 38 percent; assembly operations ily during implementation of

1987 when DFMA was adopted, said decreased 33 percent; and assembly DFMA. The most important ele-

Gerhardt. time improved 28 percent. ment in successfully applying DF-

“We have been able to reduce our To convince engineers of the value MA and concurrent engineering in-

new product development time from of the DFMA approach, Ingersoll- volves team building and proper

2 years to 12 months while maintain- Rand analyzed components not team selection, said Gerhardt. A

ing high-quality standards,” he said. made with DFMA and showed com- team leader must have the neces-

“DFMA has been an important tool pany designers firsthand how the sary technical skills, a sense of ur-

in uniting the project teams from technique could improve designs. gency and persistence, and the abil-

various departments into a cohesive Gerhardt said engineers were more ity to deal well with people.

group.” open to the concept once they were Ingersoll-Rand team leaders have

Ingersoll-Rand began seeing the given concrete examples of improved come from engineering, marketing,

benefits of DFMA as soon as it began designs. While it was good for the and purchasing groups.

its training period, said Gerhardt. In company as a whole to show its de- The company has learned that

a new radiator and oil cooler design signers how they could improve their early supplier involvement provides

used as a test, the number of parts work, management had to soothe the several benefits. The overall cost of

was reduced 64 percent from 80 to egos of engineers who found that a product can often be reduced by

29; the number of fasteners was cut they were not producing the opti- working with a supplier and incor-

47 percent from 38 to 20; assembly mum designs. The key here, Ger- porating simple changes in a com-

operations decreased from 159 to 40, hardt said, was to show how DFMA ponent, said Gerhardt. Ingersoll-

a reduction of 75 percent, and as- was not going to be used to criticize Rand has invited suppliers to

sembly time decreased from 18.5 the engineers’ work, but rather to partake in DFMA training sessions

minutes to 6.5 minutes, a 65 percent help them improve it. as the company relies on them to

improvement. take more of the design responsibil-

In another instance, the DFMA Teaming Up ity in areas in which they have the

software was used on a control and As soon as the training period expertise.

instrument panel assembly. Again, was over, Ingersoll-Rand combined Ingersoll-Rand’s Portable Com-

there were significant savings. The engineering and manufacturing ex- pressor division is currently using

72 / MAY 1992 / MECHANICAL ENGINEERING

DFMA concepts on several products:

air compressors, portable generators,

and portable construction lighting

equipment. “The DFMA concept is

becoming second nature to users,”

Gerhardt said. “Initial designs are

coming out with the best ratings

even before running them on the

software.”

At Precor USA Inc., a maker of

aerobic exercise equipment based in

Bothell. Wash.. DFMA--initiated last

year-is used to improve product

quality and productivity and to en-

able the firm to estimate competi-

tors’ overhead, labor, and material

costs as well as the type of produc-

tion process they use.

George Henry, vice president of

engineering at Precor explained that

the company began its business in

the early 1980s when there was not

much competition in aerobic exercise

equipment. But competition in-

creased in the mid-1980s after medi-

cal experts revealed that exercise af-

fecting the cardiovascular system

could help fight heart disease and

improve general health.

“We had to find a way to keep

our lead in the business, improve

our time to market and get better

products to market,” Henry said.

“We also needed a way to bench-

mark competing products. DFMA

enables us to design our products

better and more quickly using

lower-cost components. It gives us

quantitative assembly times up

front.”

Precor’s DFMA team includes

production, procurement, sales,

marketing. and financial personnel

as well as designers and manufactur-

ing engineers. Henry said that in-

volving employees outside the man-

ufacturing and design area is

important because if, for example,

purchasing managers learn that a

specific piece of tooling will be re-

quired for a new product, they can

order it well ahead of production

time.

Currently, DFMA is being applied

to about a dozen products under

development at Precor. For one

product, DFMA has enabled Precor

to reduce the number of fastener

types by 54 percent and total fabri-

cation and assembly time by 36 per-

cent. For another product, the

number of fastener types was re-

duced 75 percent and total fabrica-

tion and assembly time was cut 27

percent.

Improving Design

With DFMA, Fibercraft//DESCon

Inc. (Rochester, Mich.) was able to Less is more. Storage Technology Corp. used DFMA to reduce the number of par ts in this tape car-

eliminate about 120 parts and 109 tridge elevator from 95 (top) to 36 (bottom).

MECHANICAL ENGINEERING / MAY 1992 / 73

fasteners in the instrument panel turing engineering manager in the At NCR Corp.‘s engineering and

for the Oldsmobile line. Linda Hard Goods and Electric Support manufacturing facility in San Diego,

Shimkus, an instrument panel engi- division, said that some areas of the DFMA was used on the fourth gener-

neer at Fibercraft/DESCon, said that company have been able to reduce ation of its 9800 on-line transaction

while redesigning the instrument the time it takes to commercialize a processing and real-time computing

panel and related systems, her product by 40 to 50 percent. Part system. These products are used by

“team went through the DFA pro- counts have been reduced as well, banks in their automated teller

cess four times. The first time he said. The Hard Goods group has machines.

through we determined that the in- used DFMA to make overhead pro- Joe Fleming, senior principal in-

strument panel was not a stand- jectors and laser imagers used in dustrial engineer at NCR, said the

alone component but an integrated medical imaging. DFMA approach resulted in a 90 per-

system. The second time we went Enhancing a product by reducing cent reduction in continuing engi-

through the DFA process, we saw it the number of parts offers several neering efforts after the first test unit

as a complete system that crossed advantages, including fewer process- was built; a 66 percent reduction in

different technological areas.” ing steps, adjustments, mating points, continuing engineering efforts after

These included electrical engineer- tolerance stack-up problems, opera- product release; and no assembly er-

ing and design, as well as heating, tor frustrations, material control rors occurring on the first 10 units

ventilating, and air conditioning en- problems, and assembly fixtures, ac- built.

gineering and design. “The third cording to Moore. Also, 99 percent of all wire assem-

and fourth times through DFA, the Typically, designers do not have a bly labels were removed, resulting in

instrument panel was a totally inte- way to quickly evaluate the costs as- fewer labeling errors and lower part

grated highly functional system,” sociated with alternative designs. cost. The number of operation as-

she added. Current cost-estimating approaches sembly sheets was reduced 20 per-

Now there is less ergonomic require detailed engineering draw- cent. Moreover, improved CAD

stress on assembly plant opera- ings, creating excessive product costs drawings led to simpler written in-

tors-crawling in and out of cars and too many parts that end up be- structions on the products.

during assembly was reduced 60 ing quality and reliability problems, Fleming said NCR has given the

percent, and the number of times said Moore. DFMA technique its own name,

workers have to lie on their backs 3M assigns areas of expertise to “DFX,” as a way to make clear that

was halved. Also, the number of job members of the design team who efforts should be made to improve

stations at the assembly plant was have a specialty in a particular area, not only a product’s manufacturabili-

reduced from 36 to 18. such as electronics or design. These ty, but also its testability, repro-

Gerald Morrison, DFMA manag- specialists work concurrently with ducibility, marketability, and main-

er at Fibercraft/DESCon said the product designers to minimize manu- tainability. This NCR division is

key to implementing the system facturing costs and optimize the currently applying DFX to its model

was the creation of an atmosphere product. 3600 large on-line transaction pro-

that makes employees aware of In 1988, consultants recommended cessing system.

why the technique is being used that Storage Technology Corp.

and what its purpose is. “The ‘why’ (Louisville, Colo.), a manufacturer Failures Exist

was survival. In this business you of tape and disk peripheral comput- Not all of those who are intro-

have to fight for your existence,” er equipment, implement a quality- duced to DFMA find that it can help

Morrison said. Once the proper at- of-design program, said Arch Hig- them, however. After analyzing

mosphere is created, the DFMA gins, d i r e c t o r o f d e s i g n f o r some of their pen products with

group must perform as a team, he manufacturing at StorageTek. After DFMA, engineers and designers at

said. “It is necessary to lose one’s visiting the Ford facility to see the Bic Corp. (Milford, Conn.) found

identity and become part of the technique in action, about 1400 Stor- that, in many cases, the designs could

team and have a vision that is ageTek employees were trained in not be simplified. So while DFMA is

friendly to DFMA.” the process during 1989 and 1990. generally successful. there are in-

At the Codex division of Motorola Also trained were suppliers, since stances when it cannot help improve

Inc. Information Systems Group they can suggest ways to improve a the design efficiency or provide a

(Mansfield, Mass.), DFMA is used to design so that the optimum part can way for a company to gain addition-

optimize the design of the electro- be made. al cost savings.

mechanical enclosures on its line of Higgins said that by using DFMA, Henry Leo, product designer at

modems and networking systems. the company has streamlined compo- Bic, said the company’s pens contain

T.B. McMichen, principal engineer nents from about 90 parts down to many simple individual components

of new products manufacturing, said 36 parts. StorageTek is now imple- that cannot be combined into one

DFMA enabled the company to im- menting DFMA on all of its more unit. Moreover, the parts are not

prove assembly efficiency to 30 per- than 40 products. complex shapes or assemblies that

cent-previously it was at 15.9 per- “By going through a couple of it- could be streamlined or made less

cent-and decrease assembly time to erations on every product line complex by DFMA.

160 seconds from 1720 seconds; that’s being developed, we’re seeing DFMA developers Geoffrey

part/operation count fell to 31 from a reduction in total assembly parts Boothroyd and Peter Dewhurst said

271; and the number of fasteners de- and assembly time,” said Paul that the next step in the develop-

creased to 12 from 171. Casey, a design applications engi- ment of DFMA is to expand its focus

Meanwhile, Minnesota Mining neer at StorageTek. “From the last- to include the assembly of large com-

and Manufacturing Co. (3M) in St. generation product line to the ponents; the assembly and installa-

Paul uses DFMA to move new prod- current-generation line, it’s very tion of electrical connections and

ucts to market in half the time it typical to see things such as part wire harnesses; and the design of

took before it implemented the sys- count and number of operations cut products that are easier to maintain

tem in 1989. Tom Moore, manufac- in half.” and recycle. n

74 / MAY 1992 I MECHANICAL ENGINEERING

Das könnte Ihnen auch gefallen

- Affidavit of DisclosureDokument1 SeiteAffidavit of DisclosureNatura Manila91% (11)

- Configuration Management for Senior Managers: Essential Product Configuration and Lifecycle Management for ManufacturingVon EverandConfiguration Management for Senior Managers: Essential Product Configuration and Lifecycle Management for ManufacturingNoch keine Bewertungen

- ADMS 2510 Sample Final ExamDokument11 SeitenADMS 2510 Sample Final ExamGrace 'Queen' IfeyiNoch keine Bewertungen

- Designing Rewad System at Disk DriveDokument5 SeitenDesigning Rewad System at Disk DriveLivia SafiraNoch keine Bewertungen

- Auditing Test Bank Chapter 9Dokument39 SeitenAuditing Test Bank Chapter 9MohammadYaqoob100% (5)

- Joint Venture ArrangementsDokument4 SeitenJoint Venture ArrangementsAnonymous 19hUyem0% (1)

- EY Tax Bulletin Oct 2013Dokument13 SeitenEY Tax Bulletin Oct 2013Wiann AngsiyNoch keine Bewertungen

- Strategy and Structure of International BusinessDokument33 SeitenStrategy and Structure of International BusinessSoumendra Roy67% (3)

- Application of Design For Manufacturing and Assembly (DFMA) Methodology in The Steel Furniture IndustryDokument5 SeitenApplication of Design For Manufacturing and Assembly (DFMA) Methodology in The Steel Furniture IndustrygandhiNoch keine Bewertungen

- G-DfAM A Methodological Proposal of Generative Design For Additive ManufacturingDokument12 SeitenG-DfAM A Methodological Proposal of Generative Design For Additive ManufacturingZeeshan HameedNoch keine Bewertungen

- Design For Manufacture and Assembly: The Boothroyd-Dewhurst ExperienceDokument22 SeitenDesign For Manufacture and Assembly: The Boothroyd-Dewhurst ExperienceGraham MooreNoch keine Bewertungen

- Problem: Solution:: Quality, Cost and ProductivityDokument3 SeitenProblem: Solution:: Quality, Cost and ProductivityArutprakash MaheswaranNoch keine Bewertungen

- DfmaDokument7 SeitenDfmaMAXNER10Noch keine Bewertungen

- Application of Design For Manufacturing and Assembly (DFMA) Methodology in The Steel Furniture IndustryDokument5 SeitenApplication of Design For Manufacturing and Assembly (DFMA) Methodology in The Steel Furniture IndustryanujNoch keine Bewertungen

- Case-Study 2 Fall2018 r1Dokument2 SeitenCase-Study 2 Fall2018 r1reginaldo joseNoch keine Bewertungen

- DFMAPaper FullDokument13 SeitenDFMAPaper FullahasimplemailNoch keine Bewertungen

- 2007+ +Skills+&+Knowledge+of+Cost+Engineering1.61 88Dokument28 Seiten2007+ +Skills+&+Knowledge+of+Cost+Engineering1.61 88Naveen LopesNoch keine Bewertungen

- DFMPro BrochureDokument3 SeitenDFMPro Brochure2ymw6w4x45Noch keine Bewertungen

- Best Engineered PartDokument3 SeitenBest Engineered Partؤنييه ثهعغيNoch keine Bewertungen

- Research Paper On DfmaDokument4 SeitenResearch Paper On Dfmagz91rnat100% (1)

- Rapid Response Manufacturing For PlasticDokument4 SeitenRapid Response Manufacturing For PlasticYuxuan CaiNoch keine Bewertungen

- Additive ManufacturingDokument64 SeitenAdditive ManufacturingAnis HorNoch keine Bewertungen

- Sae Technical Paper Series: Meisen Li and Linjie HuangDokument8 SeitenSae Technical Paper Series: Meisen Li and Linjie HuangGopinath GopiNoch keine Bewertungen

- Engineering Edge Issue6 Vol1Dokument72 SeitenEngineering Edge Issue6 Vol1JocaNoch keine Bewertungen

- Design For Manufacturability SeminarDokument43 SeitenDesign For Manufacturability Seminarnagaraj mNoch keine Bewertungen

- Casting Process Modeling Rund-UpDokument6 SeitenCasting Process Modeling Rund-UpDarshak KamaniNoch keine Bewertungen

- DFMaint TutorialDokument4 SeitenDFMaint Tutorialpravit08Noch keine Bewertungen

- Sutherland Pracitcum Meltdown FinalDokument20 SeitenSutherland Pracitcum Meltdown FinalIshwinder BrarNoch keine Bewertungen

- 5 Steps To Start Building Digital InventoryDokument7 Seiten5 Steps To Start Building Digital InventoryAzhar PatelNoch keine Bewertungen

- Guide To 3D PrintingDokument6 SeitenGuide To 3D PrintingKomsa Csongor És AndreaNoch keine Bewertungen

- Fused Deposition Modeling - A Rapid Prototyping Technique For Product Cycle Time Reduction Cost Effectively in Aerospace ApplicationsDokument7 SeitenFused Deposition Modeling - A Rapid Prototyping Technique For Product Cycle Time Reduction Cost Effectively in Aerospace ApplicationssaurabhpetheNoch keine Bewertungen

- Sun Coast Product CatalogDokument39 SeitenSun Coast Product Catalogashraf elsayedNoch keine Bewertungen

- Design For Modular It yDokument4 SeitenDesign For Modular It yĐứcTrầnNoch keine Bewertungen

- Product Design and DevelopmentDokument16 SeitenProduct Design and DevelopmentTedy ThomasNoch keine Bewertungen

- Chapter 10 - Design For ManufacturingDokument21 SeitenChapter 10 - Design For Manufacturinghisham_eyesNoch keine Bewertungen

- Product Design and DevelopmentDokument16 SeitenProduct Design and DevelopmentTedy ThomasNoch keine Bewertungen

- The Integration of The Japanese Tear-Down Method With Design For Assembly and Value EngineeringDokument28 SeitenThe Integration of The Japanese Tear-Down Method With Design For Assembly and Value EngineeringAnonymous LhZEXJCj7Noch keine Bewertungen

- Implementation of Dmaic Approach To Minimize The Defects Rate of Product in Textile Plant IJERTCONV1IS02031Dokument4 SeitenImplementation of Dmaic Approach To Minimize The Defects Rate of Product in Textile Plant IJERTCONV1IS02031Aravind RajNoch keine Bewertungen

- Oil and Gas Special Report - SiemensDokument54 SeitenOil and Gas Special Report - SiemensSANJOYNoch keine Bewertungen

- DFMADokument12 SeitenDFMAbfazil100% (1)

- Dfma PDFDokument12 SeitenDfma PDFGelu BoneaNoch keine Bewertungen

- GS-0002D, Design FMEA Aug. 2009 Latest 1 C015464Dokument35 SeitenGS-0002D, Design FMEA Aug. 2009 Latest 1 C015464gouri67Noch keine Bewertungen

- What They Didn't Teach You in School About Heat Transfer: Mechanical AnalysisDokument9 SeitenWhat They Didn't Teach You in School About Heat Transfer: Mechanical AnalysisrajannplNoch keine Bewertungen

- Cost Reduction of A Diesel Engine Using The DFMA MethodDokument10 SeitenCost Reduction of A Diesel Engine Using The DFMA MethodIng Raul OrozcoNoch keine Bewertungen

- Desktop Gear EngineeringDokument5 SeitenDesktop Gear EngineeringAdam FoltzNoch keine Bewertungen

- Engineering: AviamotiveDokument9 SeitenEngineering: Aviamotiveniranjan163Noch keine Bewertungen

- Prodcut CCDokument11 SeitenProdcut CCKrishna KumarNoch keine Bewertungen

- DFMA and Sustainability Analysis in Product DesignDokument9 SeitenDFMA and Sustainability Analysis in Product Designநளின் கான்Noch keine Bewertungen

- Design For Manufacturing and Assembly (Dfma) Technique Applicable For Cost Reduction - A ReviewDokument6 SeitenDesign For Manufacturing and Assembly (Dfma) Technique Applicable For Cost Reduction - A ReviewTJPRC PublicationsNoch keine Bewertungen

- 3D PrintingDokument54 Seiten3D PrintingMegha NeelgarNoch keine Bewertungen

- WP FDM JigsAndFixtures 0316a WebDokument8 SeitenWP FDM JigsAndFixtures 0316a WebAnish RayNoch keine Bewertungen

- Introduction To Robust Design (Taguchi Method)Dokument8 SeitenIntroduction To Robust Design (Taguchi Method)design_rajeevNoch keine Bewertungen

- Thermo Fluid Analysis SoftwareDokument32 SeitenThermo Fluid Analysis SoftwareWilly Thomas MrazNoch keine Bewertungen

- 14 PDFDokument7 Seiten14 PDFRamNocturnalNoch keine Bewertungen

- mgtCADCAM TAMAYODokument3 SeitenmgtCADCAM TAMAYONath ReyesNoch keine Bewertungen

- Maintainability), Followed by Sewing Machine Makers, and Then Textile, Farm MachineryDokument27 SeitenMaintainability), Followed by Sewing Machine Makers, and Then Textile, Farm MachineryAkshay AsNoch keine Bewertungen

- Dfa Analysis On Water PurifierDokument24 SeitenDfa Analysis On Water PurifierNshnthNoch keine Bewertungen

- Mitigating The High Cost of PCBDokument6 SeitenMitigating The High Cost of PCBDaveNoch keine Bewertungen

- Computers in EngineeringDokument4 SeitenComputers in EngineeringIvanNoch keine Bewertungen

- Design For Manufacturing and Assembly of A Connecting Rod 1362031980Dokument7 SeitenDesign For Manufacturing and Assembly of A Connecting Rod 1362031980addayesudasNoch keine Bewertungen

- Design For Manufacture and Assembly: The Boothroyd-Dewhurst ExperienceDokument2 SeitenDesign For Manufacture and Assembly: The Boothroyd-Dewhurst ExperienceAkshay PatilNoch keine Bewertungen

- Production Operation ManagementDokument3 SeitenProduction Operation ManagementGopi KrishnaNoch keine Bewertungen

- DFMADokument27 SeitenDFMAUsman Farooq Butt100% (1)

- Computer 2112Dokument12 SeitenComputer 2112zxcccz100% (2)

- Up and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsVon EverandUp and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsNoch keine Bewertungen

- Decision MakingDokument2 SeitenDecision MakingdwanNoch keine Bewertungen

- DeformDokument1 SeiteDeformdwanNoch keine Bewertungen

- FOC Column PDFDokument1 SeiteFOC Column PDFdwanNoch keine Bewertungen

- Molding Sand - Constituents, Types and PropertiesDokument8 SeitenMolding Sand - Constituents, Types and PropertiesdwanNoch keine Bewertungen

- Pressure Prism and Curved PlaneDokument12 SeitenPressure Prism and Curved PlaneAmeerul AzmieNoch keine Bewertungen

- 01ns Multivariable PDFDokument13 Seiten01ns Multivariable PDFdwanNoch keine Bewertungen

- Chapter 2 Hydro Static ForcesDokument28 SeitenChapter 2 Hydro Static ForcesApek SuasanaNoch keine Bewertungen

- Tugasan Solid 2aDokument2 SeitenTugasan Solid 2adwanNoch keine Bewertungen

- Tukar CHPTDokument1 SeiteTukar CHPTdwanNoch keine Bewertungen

- Pressure Prism and Curved PlaneDokument12 SeitenPressure Prism and Curved PlaneAmeerul AzmieNoch keine Bewertungen

- Chapter 2 Hydro Static ForcesDokument28 SeitenChapter 2 Hydro Static ForcesApek SuasanaNoch keine Bewertungen

- 1.1 Background StudyDokument4 Seiten1.1 Background StudydwanNoch keine Bewertungen

- Report-on-Safety-Seal-Certification-2021 (October 21-27, 2021)Dokument4 SeitenReport-on-Safety-Seal-Certification-2021 (October 21-27, 2021)Mecs NidNoch keine Bewertungen

- Joint Venture: Joint Venture Tecnology and Global Competition Harmandeep SinghDokument20 SeitenJoint Venture: Joint Venture Tecnology and Global Competition Harmandeep SinghHarman SidhuNoch keine Bewertungen

- Rejected BankDokument3 SeitenRejected Banksigitsutoko8765Noch keine Bewertungen

- What Is A SalnDokument18 SeitenWhat Is A SalnAnonymous EvbW4o1U7Noch keine Bewertungen

- PerpetualLicTransForm (EMEA) (ENG) (Jul2014) (CR)Dokument5 SeitenPerpetualLicTransForm (EMEA) (ENG) (Jul2014) (CR)Eliandro CardosoNoch keine Bewertungen

- Evidencia 10 Sentences Marketing PlanDokument3 SeitenEvidencia 10 Sentences Marketing PlanDayanna TowerNoch keine Bewertungen

- C7 8 Equity Portfolio ManagementDokument42 SeitenC7 8 Equity Portfolio ManagementRusa AlexandraNoch keine Bewertungen

- Chapter 2 SolutionsDokument5 SeitenChapter 2 SolutionskendozxNoch keine Bewertungen

- Vending Zone ProposedDokument30 SeitenVending Zone ProposedRishabh PrajapatiNoch keine Bewertungen

- Friendes FBDokument2 SeitenFriendes FBPang Jun LeeNoch keine Bewertungen

- Chapter13.Capital Budgeting & Revenue BudgetingDokument11 SeitenChapter13.Capital Budgeting & Revenue BudgetingUdhaya SundariNoch keine Bewertungen

- Fiit JeeDokument11 SeitenFiit JeeAnuj KansalNoch keine Bewertungen

- Corporate Governance.....Dokument10 SeitenCorporate Governance.....jyotsana vermaNoch keine Bewertungen

- Ifcb2009 18Dokument465 SeitenIfcb2009 18Praveen KumarNoch keine Bewertungen

- HCMP001818A - 2012 (SFC V Ernst & Young - Court of First Instance)Dokument89 SeitenHCMP001818A - 2012 (SFC V Ernst & Young - Court of First Instance)kfulleeNoch keine Bewertungen

- LAB AssignmentDokument28 SeitenLAB AssignmentMoh'ed A. KhalafNoch keine Bewertungen

- Invitation To BidDokument2 SeitenInvitation To BidMHack DhenVah VerdzNoch keine Bewertungen

- 28 Harpoon Marine Services, Inc., Et Al. v. Fernan H. Francisco, G.R. No. 167751, March 2, 2011Dokument9 Seiten28 Harpoon Marine Services, Inc., Et Al. v. Fernan H. Francisco, G.R. No. 167751, March 2, 2011AlexandraSoledadNoch keine Bewertungen

- CHA Press ReleaseDokument1 SeiteCHA Press ReleaseJoshua BostNoch keine Bewertungen

- MNC's Bane or BoonDokument5 SeitenMNC's Bane or Boonryan_dsouza501246Noch keine Bewertungen

- Agreed Upon Procedures vs. Consulting EngagementsDokument49 SeitenAgreed Upon Procedures vs. Consulting EngagementsCharles B. Hall100% (1)

- 1 SGD To Idr - Google SearchDokument2 Seiten1 SGD To Idr - Google SearchBachtiar M TaUfikNoch keine Bewertungen

- Key Word RecordDokument128 SeitenKey Word RecordJamie Jordan0% (1)

- Iberostar Grand Hotel Bavaro Inv #25468Dokument2 SeitenIberostar Grand Hotel Bavaro Inv #25468David ArteagaNoch keine Bewertungen