Beruflich Dokumente

Kultur Dokumente

High Solids Coal Tar Epoxy Product Specifications

Hochgeladen von

Abuhurairah MunshiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

High Solids Coal Tar Epoxy Product Specifications

Hochgeladen von

Abuhurairah MunshiCopyright:

Verfügbare Formate

BERGER PRODUCT SPECIFICATIONS

EPILUX 18HS

High Solids Coal Tar Epoxy

PRODUCT A two component, high solids coal tar epoxy anti-corrosive coating.

DESCRIPTION

DESIGN An anti-corrosive protective coating that is ideal for total, partial or intermittent submerged

structures such as pilings, pontoons, jetties, dock gates etc.

FEATURES

Outstanding anti-corrosive performance with excellent fresh and seawater resistance.

Compatible with cathodic protection.

Good abrasion resistance.

Able to withstand wet heat of up to 60°C.

Able to achieve 400 microns dry film build in a single coat application.

PHYSICAL Recommended Application Data Wet [µm] Dry [µm] m2/l

CHARACTERISTICS Theoretical Coverage 165 125 6.08

Volume solids 76 ± 2 % (based on ASTM D2697)

Dry Film Thickness Range 125 µm to 400 µm

Flash Point 36 °C

Finish Matt

Colour Range Brown / Black

Standard Packing Size 20 litres set (6.67 litres Base : 13.33 litres Hardener)

Mix Ratio ( by volume ) 1 Base : 2 Hardeners

APPLICATION AIRLESS SPRAY Tip Size : 0.58 – 0.63 mm ( 23 – 25 thou )

Recommended method of

METHOD application

Pressure : 140 –165 kg/cm2 (2000 - 2400 psi)

CONVENTIONAL AIR May be used. May require additional dilution to achieve good

SPRAY atomisation.

BRUSH OR ROLLER May be used. However, additional coats may be required to

achieve the recommended film thickness. Suitable for stripe

coating, weld-seams, edges, corners, rivets, etc.

DRYING &

CURING TIME Substrate Touch Dry Hard Dry Overcoating Interval Pot Life

Temperature Minimum Maximum

15 °C 4 hours 24 hours 24 hours 10 days 6 hours

25 °C 2 hours 12 hours 16 hours 5 days 3 hours

35 °C 1 hour 8 hours 12 hours 3 days 2 hours

USEFUL THINNER : SOLVALUX 7-45 or SOLVALUX 7-33 (Maximum 20% addition)

INFORMATION

CLEANER : SOLVALUX 7-77

STORAGE : Store in a cool dry shaded area.

EPILUX 18HS REVISION 03-2012

F3

BERGER PRODUCT SPECIFICATIONS

SURFACE The service life span and the service performance of EPILUX 18HS is directly related to the

PREPARATION degree of surface preparation.

STEEL

This product should be applied to a surface that has been blast cleaned. It can be applied either

directly to steel or to a suitably primed surface (e.g. with EPILUX 610 or ZINCANODE 685).

• Remove all wax, oil and grease in accordance with the guidelines given by SSPC-SP1.

• Where necessaries remove weld spatter and round off all rough weld seams and sharp

edges to a smooth surface.

• Abrasive blast clean to a minimum standard of Sa2½ (ISO 8501-1:1988) or SSPC-SP10.

• Any surface defects revealed by blast cleaning should be rectified in a suitable manner.

• An average surface profile of 50 - 75 microns is acceptable.

• Apply Epilux 18HS immediately after blasting to prevent oxidation and recontamination of

the steel surface. In case of oxidation or recontamination, re-blast to the required standard.

CONCRETE

• Ensure that the surface is sound. Remove laitence by thorough wire-brushing, acid etching

or sweep blasting. Blowholes and other defects should be filled with Solventless Epoxy

Filler. The first coat must be thinned by 20% for direct application to concrete.

To avoid condensation of moisture onto substrate prior to coating application, relative humidity

should not exceed 85% and substrate temperature should be more than 3 °C above Dew Point.

SUITABLE PRIMERS Epilux 610, Epilux 78, Zincanode 685, Zincanode 668

SUITABLE FINISH Epilux 18HS

COATS

NOTES • Coal Tar based products have tendency to bleed and hence can show darkening of colour

of finish coat applied on it.

• The coating specifications given above are typical. For specific recommendations to suit

individual applications, please refer to your Berger Paints representative.

• Common to all epoxies this product will experience chalking on prolonged exposure to

sunlight. However, this phenomenon is not detrimental to coating performance.

• Exposure to very low temperatures, high humidity or water ponding during and / or

immediately after application may result in incomplete cure and / or discolouration that may

compromise subsequent intercoat adhesion.

SAFETY This product contains coal tar pitch.

PRECAUTION Avoid contact with eyes and skin. Wear suitable protective clothing such as overalls, goggles,

dust mask and gloves. Use barrier cream.

Ensure that there is adequate ventilation in the area where the product is being applied. Do not

breathe in vapour or spray mist.

This product is flammable. Keep away from sources of ignition. Do not smoke.

Take precautionary measures against static discharge. In case of fire, blanket flames with foam,

carbon dioxide or dry chemicals.

FIRST AID Eyes : In the event of accidental splashes, flush eyes with warm water immediately

and seek medical advice.

Skin : Wash skin thoroughly with soap and water or approved industrial cleaner.

Do Not Use solvents or thinners.

Inhalation : Remove to fresh air, loosen collar and keep patient rested.

Ingestion : In case of accidental ingestion, DO NOT INDUCE VOMITING. Obtain

immediate medical attention.

For further safety information, please refer to our Material Safety Data Sheet (MSDS)

DISCLAIMER The information provided on this data sheet is not intended to be complete and is provided as general advice

only. It is the responsibility of the user to ensure that the product is suitable for the purpose for which he

wishes to use it. As we have no control over the treatment of the product, the standard of surface

preparation of the substrate, or other factors affecting the use of this product, we are not responsible for its

performance nor would we accept any liability whatsoever or howsoever arising from the use of this product

unless specifically agreed to in writing by us. The information contained in this data sheet may be modified

by us from time to time, and without notice, in the light of our experience and continuous product

development.

EPILUX 18HS REVISION 03-2012

F3

Das könnte Ihnen auch gefallen

- Coaltar Epoxy - Epilux5 - 0474Dokument2 SeitenCoaltar Epoxy - Epilux5 - 0474GautamNoch keine Bewertungen

- Microsoft Word - L3_Epilux82.docDokument2 SeitenMicrosoft Word - L3_Epilux82.docvitharvanNoch keine Bewertungen

- d2) Epilux218 4267Dokument2 Seitend2) Epilux218 4267Syed FaridNoch keine Bewertungen

- l2) Steelshield1200 3041Dokument2 Seitenl2) Steelshield1200 3041Syed FaridNoch keine Bewertungen

- High Build Epoxy Anti-Corrosive Primer SpecsDokument2 SeitenHigh Build Epoxy Anti-Corrosive Primer SpecsMuthuKumar100% (1)

- Epoxy Primer - Epilux610 - 4079Dokument2 SeitenEpoxy Primer - Epilux610 - 4079GautamNoch keine Bewertungen

- B B B Berger Erger Erger Erger: Product SpecificationsDokument2 SeitenB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaNoch keine Bewertungen

- Epilux 155 SFDokument2 SeitenEpilux 155 SFMohamed NasifNoch keine Bewertungen

- 19.abcolux18hs Content 237Dokument3 Seiten19.abcolux18hs Content 237MbimbikNoch keine Bewertungen

- Berger: Product SpecificationsDokument2 SeitenBerger: Product SpecificationsAabhas UpadhyayaNoch keine Bewertungen

- b3) Zincanode685 4586Dokument2 Seitenb3) Zincanode685 4586Syed FaridNoch keine Bewertungen

- Berger: Product SpecificationsDokument2 SeitenBerger: Product SpecificationsAabhas UpadhyayaNoch keine Bewertungen

- B B B Berger Erger Erger Erger: Product SpecificationsDokument2 SeitenB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaNoch keine Bewertungen

- E3) Epimastic5100 4292Dokument2 SeitenE3) Epimastic5100 4292Syed FaridNoch keine Bewertungen

- b6) Zincanode690 2886Dokument2 Seitenb6) Zincanode690 2886Anonymous XVEucVMsENoch keine Bewertungen

- Berger: Product SpecificationsDokument2 SeitenBerger: Product SpecificationsMuthuKumarNoch keine Bewertungen

- Berger: Product SpecificationsDokument2 SeitenBerger: Product SpecificationsAabhas UpadhyayaNoch keine Bewertungen

- l1) Steelshield1100 5833Dokument2 Seitenl1) Steelshield1100 5833Syed FaridNoch keine Bewertungen

- k1) Luxatherm1600 3171Dokument2 Seitenk1) Luxatherm1600 3171Syed FaridNoch keine Bewertungen

- g9) Berger Apcofine 905 - 8096Dokument2 Seiteng9) Berger Apcofine 905 - 8096Wasek SarkerNoch keine Bewertungen

- k2) Luxatherm5200 5219Dokument2 Seitenk2) Luxatherm5200 5219Syed FaridNoch keine Bewertungen

- LUXAPRIME 1400 Alkyd Zinc Phosphate Primer SpecsDokument2 SeitenLUXAPRIME 1400 Alkyd Zinc Phosphate Primer SpecsGurdeep Sungh AroraNoch keine Bewertungen

- B B B Berger Erger Erger Erger: Product SpecificationsDokument2 SeitenB B B Berger Erger Erger Erger: Product SpecificationsSanjeev Reddy KasulaNoch keine Bewertungen

- Luxaprime 1000 Alkyd Anti-Corrosive PrimerDokument2 SeitenLuxaprime 1000 Alkyd Anti-Corrosive PrimerGurdeep Sungh AroraNoch keine Bewertungen

- k3) Luxatherm5600 7954Dokument2 Seitenk3) Luxatherm5600 7954Syed FaridNoch keine Bewertungen

- LUXAPRIME 1200 Alkyd QD Primer SpecsDokument2 SeitenLUXAPRIME 1200 Alkyd QD Primer SpecsGurdeep Sungh AroraNoch keine Bewertungen

- Luxaprime1300 Alkyd Zinc Chromate PrimerDokument2 SeitenLuxaprime1300 Alkyd Zinc Chromate PrimerGurdeep Sungh AroraNoch keine Bewertungen

- b1) Zincanode330 6548Dokument2 Seitenb1) Zincanode330 6548Syed FaridNoch keine Bewertungen

- Berger: Product SpecificationsDokument2 SeitenBerger: Product SpecificationsAabhas UpadhyayaNoch keine Bewertungen

- I1) Luxol 1000Dokument2 SeitenI1) Luxol 1000Chan zxNoch keine Bewertungen

- ZINCANODE 330 PRODUCT SPECIFICATIONSDokument2 SeitenZINCANODE 330 PRODUCT SPECIFICATIONSDinesh ChouguleNoch keine Bewertungen

- b1) Zincanode330 6548Dokument2 Seitenb1) Zincanode330 6548chepurthiNoch keine Bewertungen

- d3) Epilux4 2763Dokument2 Seitend3) Epilux4 2763Salman KhanNoch keine Bewertungen

- Epilux 82: Product DescriptionDokument2 SeitenEpilux 82: Product DescriptionMoin AltafNoch keine Bewertungen

- Steel Shield 1200Dokument2 SeitenSteel Shield 1200Moin AltafNoch keine Bewertungen

- High Build Epoxy Coating for Steel and ConcreteDokument2 SeitenHigh Build Epoxy Coating for Steel and ConcreteTejinder KumarNoch keine Bewertungen

- PDS HEMPADUR 47183 en-USDokument2 SeitenPDS HEMPADUR 47183 en-USFreddy Carl Fredricksen0% (1)

- EPIMASTIC 5100-March 2019 Version 2Dokument2 SeitenEPIMASTIC 5100-March 2019 Version 2PraveenNoch keine Bewertungen

- EPILUX 850 SF VOC Jan-2017Dokument2 SeitenEPILUX 850 SF VOC Jan-2017PraveenNoch keine Bewertungen

- Luxaprime1801 Chromate Free Etch PrimerDokument2 SeitenLuxaprime1801 Chromate Free Etch PrimerGurdeep Sungh AroraNoch keine Bewertungen

- Berger Autocare Enamel Finish Product SpecificationsDokument2 SeitenBerger Autocare Enamel Finish Product SpecificationsvinodNoch keine Bewertungen

- Bergerlac Aluminium Finish PDFDokument2 SeitenBergerlac Aluminium Finish PDFMuthuKumarNoch keine Bewertungen

- 312 UkDokument4 Seiten312 UkAhmed IbrahimNoch keine Bewertungen

- Luxaprime1500 Etching Wash PrimerDokument2 SeitenLuxaprime1500 Etching Wash PrimerGurdeep Sungh AroraNoch keine Bewertungen

- Epilux 155Dokument2 SeitenEpilux 155Allana100% (1)

- Zincanode 402: Two Pack Zinc Rich Epoxy PrimerDokument2 SeitenZincanode 402: Two Pack Zinc Rich Epoxy PrimerlivefreakNoch keine Bewertungen

- Coating System Recommendation for Infrastructure ProjectDokument9 SeitenCoating System Recommendation for Infrastructure ProjectHariHaranNoch keine Bewertungen

- Luxaprime1501 Etch PrimerDokument2 SeitenLuxaprime1501 Etch PrimerGurdeep Sungh AroraNoch keine Bewertungen

- KANSAI PAINT Paralux - 15HBDokument2 SeitenKANSAI PAINT Paralux - 15HBYogalingam ArumugamNoch keine Bewertungen

- Rust O Cap: Surface Tolerant EpoxyDokument3 SeitenRust O Cap: Surface Tolerant EpoxySanthana SaravanaNoch keine Bewertungen

- Sherwin Williams Macropoxy M262 PDS Promain 05 09 2022Dokument2 SeitenSherwin Williams Macropoxy M262 PDS Promain 05 09 2022paNoch keine Bewertungen

- PARATHERM 600 HEAT RESISTING FINISHDokument2 SeitenPARATHERM 600 HEAT RESISTING FINISHyarth880% (1)

- Carboguard 635 Thinned 50% - Sealer PDSDokument5 SeitenCarboguard 635 Thinned 50% - Sealer PDSjakeNoch keine Bewertungen

- P3) Water Based Universal PrimerDokument2 SeitenP3) Water Based Universal PrimerBrandon LimNoch keine Bewertungen

- Epilux-78 HB PrimerDokument3 SeitenEpilux-78 HB PrimerIqra AngelsNoch keine Bewertungen

- Apcotherm Epn 200Dokument2 SeitenApcotherm Epn 200Moin AltafNoch keine Bewertungen

- Apcodur Ehb 500-VocDokument2 SeitenApcodur Ehb 500-VocMoin AltafNoch keine Bewertungen

- KCC DataSheet WH3350 (ENG)Dokument2 SeitenKCC DataSheet WH3350 (ENG)Trịnh Minh KhoaNoch keine Bewertungen

- Creative Resin: Easy techniques for contemporary resin artVon EverandCreative Resin: Easy techniques for contemporary resin artNoch keine Bewertungen

- Electric Installation ManualDokument47 SeitenElectric Installation ManualAbuhurairah MunshiNoch keine Bewertungen

- Miniature Circuit Breaker - Acti 9 xC60 MCBs - A9N2P06CDokument3 SeitenMiniature Circuit Breaker - Acti 9 xC60 MCBs - A9N2P06CKuenley TiNy OndeNoch keine Bewertungen

- Industrial Ethernet Switch - FL SWITCH 1008N: Your AdvantagesDokument15 SeitenIndustrial Ethernet Switch - FL SWITCH 1008N: Your AdvantagesAbuhurairah MunshiNoch keine Bewertungen

- Therapeutic Applications of Camels Milk and Urine PDFDokument12 SeitenTherapeutic Applications of Camels Milk and Urine PDFAbuhurairah MunshiNoch keine Bewertungen

- Kobelt Maneuvering SystemDokument1 SeiteKobelt Maneuvering SystemAbuhurairah MunshiNoch keine Bewertungen

- SMPV Second Amendment Rules 2018 GSR 1110 E Dated 13112018Dokument1 SeiteSMPV Second Amendment Rules 2018 GSR 1110 E Dated 13112018Abuhurairah MunshiNoch keine Bewertungen

- SKF Range of Housings and Accessories RSP Pricelist Effetive 15 January 2021Dokument16 SeitenSKF Range of Housings and Accessories RSP Pricelist Effetive 15 January 2021Abuhurairah MunshiNoch keine Bewertungen

- Garlock GSK 3-86 Strainer Gasket 04.2017 en-NADokument2 SeitenGarlock GSK 3-86 Strainer Gasket 04.2017 en-NAAbuhurairah MunshiNoch keine Bewertungen

- Garlock GSK 3-86 Strainer Gasket 04.2017 en-NADokument2 SeitenGarlock GSK 3-86 Strainer Gasket 04.2017 en-NAAbuhurairah MunshiNoch keine Bewertungen

- Welding Process Improvement in Pressure Vessel Fabrication Approach To DMAIC Methodology Case in Small and Medium Industries in IndonesiaDokument5 SeitenWelding Process Improvement in Pressure Vessel Fabrication Approach To DMAIC Methodology Case in Small and Medium Industries in IndonesiaAbuhurairah MunshiNoch keine Bewertungen

- Champtig 400 PDokument4 SeitenChamptig 400 PAbuhurairah MunshiNoch keine Bewertungen

- Champtig 400 P PDFDokument4 SeitenChamptig 400 P PDFAbuhurairah MunshiNoch keine Bewertungen

- 1 A 2 3 Appliance Handbook UKDokument0 Seiten1 A 2 3 Appliance Handbook UKVictor HugoNoch keine Bewertungen

- Typical Class 2 SystemDokument1 SeiteTypical Class 2 SystemAbuhurairah MunshiNoch keine Bewertungen

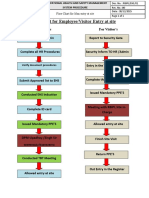

- fLOW CHART FOR WORKER'S ENTRYDokument2 SeitenfLOW CHART FOR WORKER'S ENTRYshamshad ahamedNoch keine Bewertungen

- Siemens MV Gas Insulated Switch GearDokument14 SeitenSiemens MV Gas Insulated Switch GearSajesh Thykoodan T VNoch keine Bewertungen

- FINALS REVIEWER ENVI ENGG Topic 1Dokument8 SeitenFINALS REVIEWER ENVI ENGG Topic 1As ReNoch keine Bewertungen

- UNICESS KR Consmetics Maeteria Nunssupjara 01apr23Dokument44 SeitenUNICESS KR Consmetics Maeteria Nunssupjara 01apr23ZB ChuaNoch keine Bewertungen

- 7 Surprising Cyberbullying StatisticsDokument4 Seiten7 Surprising Cyberbullying StatisticsJuby Ann Enconado100% (1)

- Workplace Hazard Analysis ProcedureDokument12 SeitenWorkplace Hazard Analysis ProcedureKent Nabz60% (5)

- TS4-F - Fire SafetyDokument2 SeitenTS4-F - Fire SafetyDominic SantiagoNoch keine Bewertungen

- Retail Management PPT1Dokument14 SeitenRetail Management PPT1Srilekha GubbalaNoch keine Bewertungen

- Reading and Listening 2Dokument4 SeitenReading and Listening 2Hải Anh TạNoch keine Bewertungen

- Module A Specimen Questions January2020 PDFDokument5 SeitenModule A Specimen Questions January2020 PDFShashi Bhusan SinghNoch keine Bewertungen

- ItilDokument11 SeitenItilNarendar P100% (2)

- InjectorDokument23 SeitenInjectorBac Nguyen100% (1)

- Case Report on Right Knee FuruncleDokument47 SeitenCase Report on Right Knee Furuncle馮宥忻Noch keine Bewertungen

- Hinduism Today April May June 2015Dokument43 SeitenHinduism Today April May June 2015jpmahadevNoch keine Bewertungen

- Species Diversity in Lentic and Lotic Systems of Lake Tamblyn and The Mcintyre RiverDokument21 SeitenSpecies Diversity in Lentic and Lotic Systems of Lake Tamblyn and The Mcintyre Riverapi-393048315Noch keine Bewertungen

- Pulsar2 User Manual - ENDokument83 SeitenPulsar2 User Manual - ENJanette SouzaNoch keine Bewertungen

- Esaote MyLabX7Dokument12 SeitenEsaote MyLabX7Neo BiosNoch keine Bewertungen

- Funds Flow Statement ExplainedDokument76 SeitenFunds Flow Statement Explainedthella deva prasad0% (1)

- Dr. Namrata Misra Head of Bioinnovations at KIIT UniversityDokument1 SeiteDr. Namrata Misra Head of Bioinnovations at KIIT Universitymanisha maniNoch keine Bewertungen

- Solution Manual of Physics by Arthur BeiserDokument145 SeitenSolution Manual of Physics by Arthur BeiserManuull71% (49)

- Endocrown Review 1Dokument9 SeitenEndocrown Review 1Anjali SatsangiNoch keine Bewertungen

- Rapid Cycling in Bipolar DisorderDokument1 SeiteRapid Cycling in Bipolar Disorderdo leeNoch keine Bewertungen

- Nicenstripy Gardening Risk AssessmentDokument38 SeitenNicenstripy Gardening Risk AssessmentVirta Nisa100% (1)

- Acc101Q7CE 5 3pp187 188 1Dokument3 SeitenAcc101Q7CE 5 3pp187 188 1Haries Vi Traboc MicolobNoch keine Bewertungen

- IMCI Chart 2014 EditionDokument80 SeitenIMCI Chart 2014 EditionHarold DiasanaNoch keine Bewertungen

- PERSONS Finals Reviewer Chi 0809Dokument153 SeitenPERSONS Finals Reviewer Chi 0809Erika Angela GalceranNoch keine Bewertungen

- Proper Operating Room Decorum: Lee, Sullie Marix P. Maderal, Ma. Hannah Isabelle JDokument15 SeitenProper Operating Room Decorum: Lee, Sullie Marix P. Maderal, Ma. Hannah Isabelle Jjoannamhay ceraldeNoch keine Bewertungen

- Synthesis, Experimental and Theoretical Characterizations of A NewDokument7 SeitenSynthesis, Experimental and Theoretical Characterizations of A NewWail MadridNoch keine Bewertungen

- OC - PlumberDokument6 SeitenOC - Plumbertakuva03Noch keine Bewertungen

- Base para Detectores de Humo y Temperatura KIDDE KI-SBDokument2 SeitenBase para Detectores de Humo y Temperatura KIDDE KI-SBAnderson CastañedaNoch keine Bewertungen