Beruflich Dokumente

Kultur Dokumente

Pattern of Holes: Objectives

Hochgeladen von

David Bumbalough0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

11 Ansichten2 Seitencnc

Originaltitel

27 00 Introduction

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldencnc

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

11 Ansichten2 SeitenPattern of Holes: Objectives

Hochgeladen von

David Bumbaloughcnc

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

27 PATTERN OF HOLES

Objectives

The main objective of these projects is to calculate rectangular coordinates (XY points) of various hole patterns.

All patterns share some order - randomly spaced series of holes do not qualify as true patterns. The most common

hole patterns are linear and circular.

Overview and Applications

A pattern of holes is an orderly arrangement of holes located on a part, typically equally spaced. Typical patterns

are linear (horizontal, vertical and angular) and circular - those arranged along an arc (arc and bolt hole patterns).

The holes in such patterns may used for a wide variety of industrial purposes.

One of the most common applications of hole patterns are those used for fastening two parts together, for exam-

ple flanges. In such cases, the patterns of both parts must be identical. Flanges commonly use an even number of

equally spaced holes (6, 8, 12, for example), arranged on a bolt circle diameter. Odd number of equally spaced

holes can be found on flanges where the pattern orientation is important. Arc patterns share many characteristics of

bolt hole pattern, but are contained within a certain angle that is smaller than 360 degrees. Holes in such patterns

are also equally spaced.

Another common pattern is an octagonal series of holes (in rows within an octagon) that is used for holding pipes

in heat exchangers. An example of such a pattern is one of the projects in this series of project (27-05).

Hole patterns arranged in a linear direction could be single horizontal or vertical rows, frames (two horizontal

and two vertical holes combined) or a full matrix (array of rows and columns).

Many modern CNC lathes support the third axis (milling axis or live tooling), which also can be used for machin-

ing various patterns. These are some common patterns of holes that are machined on CNC machining centers:

Peter Smid CNC Programming Handbook Chapter 27 [ 1 ]

Programming Methods

Programming methods vary for each pattern, and there could be a number of variations. The longest programs

are the result of programming XY coordinates individually, for each hole and each tool. Typical programming

methods used for shortening the program length include incremental mode G91, subprograms, and even macros

(this subject is not covered here). Combining one programming method with another, for example, an incremental

mode and subprograms, results in even shorter programs. Keep in mind, however, that a short program developed

at all costs just to be short, is not always the best approach.

Many circular array holes (arc and bolt circle) have a defined center at a location other than X0Y0 (part zero). The

required program can be simplified by using the Local Coordinate System, identified by the G52 command. Also,

a datum shift command G10 can be used, if the control system supports it.

Using polar coordinates for circular patterns can save a great amount of time, but the majority of CNC systems

do not have this feature available as a standard specification. If such a feature is available, polar coordinates can be

defined by the pattern center point and the arc radius.

References

& CNC Programming Handbook - Chapter 27 Pattern of Holes

Chapter 27 Bolt Circle Formula (explanation)

Chapter 27 Polar Coordinates

Chapter 26 Machining Holes

Chapter 40 Local Coordinate System (G52)

Chapter 40 Data Setting (G10)

Chapter 53 Polygon calculations

Peter Smid CNC Programming Handbook Chapter 27 [ 2 ]

Das könnte Ihnen auch gefallen

- CAD/CAM Viva-Voce Questions (SVSCE Edition)Dokument4 SeitenCAD/CAM Viva-Voce Questions (SVSCE Edition)goldencometNoch keine Bewertungen

- Department of Mechanical Engineering Me1355 - Cad/Cam Lab Year: III Year Semester: VIDokument6 SeitenDepartment of Mechanical Engineering Me1355 - Cad/Cam Lab Year: III Year Semester: VIT.V.B.BabuNoch keine Bewertungen

- Cad Cam Lab VivaDokument9 SeitenCad Cam Lab VivaAnonymous dYDY4Eha100% (2)

- CNC Programming Handbook Smid 195 - 293Dokument99 SeitenCNC Programming Handbook Smid 195 - 293Răzvan Iordache100% (1)

- Development of Canned Cycle For CNC Milling Machine: AbstractDokument9 SeitenDevelopment of Canned Cycle For CNC Milling Machine: AbstractandreNoch keine Bewertungen

- Computer-Aided CNC Programming For The Machining of Non-Typical PartsDokument16 SeitenComputer-Aided CNC Programming For The Machining of Non-Typical PartsPham LongNoch keine Bewertungen

- QuestionsDokument4 SeitenQuestionsOsama MohammedNoch keine Bewertungen

- G-code Programming Language GuideDokument16 SeitenG-code Programming Language GuideArnold NagyNoch keine Bewertungen

- Lab Manual CNC LatheDokument10 SeitenLab Manual CNC LatheSai Naga Sri Harsha100% (1)

- Manual of Engineering Drawing: British and International StandardsVon EverandManual of Engineering Drawing: British and International StandardsBewertung: 3.5 von 5 Sternen3.5/5 (4)

- Flexible FixturingDokument24 SeitenFlexible FixturingAbhishek KaushikNoch keine Bewertungen

- Chapter 6Dokument56 SeitenChapter 6gashawletaNoch keine Bewertungen

- Drill ModelingDokument13 SeitenDrill Modelingantonio87Noch keine Bewertungen

- Examples of CNC Machines: Punched Tape Servomechanisms MachiningDokument5 SeitenExamples of CNC Machines: Punched Tape Servomechanisms MachiningTushar KhorateNoch keine Bewertungen

- 1.0 Introduction of CNC Turning MachineDokument9 Seiten1.0 Introduction of CNC Turning Machineeizhar50% (4)

- CNC Project FullDokument22 SeitenCNC Project FullDebabrata NandaNoch keine Bewertungen

- Unit - III CNC Part ProgrammingDokument39 SeitenUnit - III CNC Part ProgrammingNarayana PerumalNoch keine Bewertungen

- G Code WikiDokument19 SeitenG Code WikiShaukat Ali ShahNoch keine Bewertungen

- CNC Part ProgrammingDokument17 SeitenCNC Part ProgrammingGptc ChekkanuraniNoch keine Bewertungen

- CNC Milling Machine GuideDokument19 SeitenCNC Milling Machine GuidesumanthNoch keine Bewertungen

- Mini Project PresentationDokument22 SeitenMini Project PresentationTechnology SinghNoch keine Bewertungen

- Me 473 - Unit 4 - 1Dokument70 SeitenMe 473 - Unit 4 - 1Ama Serwaa YeboahNoch keine Bewertungen

- CNC Work TheoryDokument16 SeitenCNC Work TheoryMeet technicalsNoch keine Bewertungen

- CST Training Core ModuleDokument141 SeitenCST Training Core ModuleAnonymous U6Q0f5L100% (1)

- CNC02 - DAY9-11 - Basic Turning ProgrammingDokument26 SeitenCNC02 - DAY9-11 - Basic Turning Programmingmohammadarif afgan100% (1)

- Jm201 - CNC MillingDokument24 SeitenJm201 - CNC MillingMuhd Zulhusni Ag Jaludin100% (1)

- G-Code - Wikipedia, The Free EncyclopediaDokument21 SeitenG-Code - Wikipedia, The Free Encyclopediabeta2009Noch keine Bewertungen

- CNC TURNING MachineDokument14 SeitenCNC TURNING MachineFaiz AhmedNoch keine Bewertungen

- 71 Bosnjakovic Selir CIM2015 Article OKDokument6 Seiten71 Bosnjakovic Selir CIM2015 Article OKmladbos6065Noch keine Bewertungen

- Department of Mechanical Engineering IAT - 1 Me8691 Computer Aided Design Manufacturing Q.NoDokument18 SeitenDepartment of Mechanical Engineering IAT - 1 Me8691 Computer Aided Design Manufacturing Q.NoSaravana Kumar MNoch keine Bewertungen

- G-code Interpolator for Real-Time Contour Machining of Free-Form SurfacesDokument30 SeitenG-code Interpolator for Real-Time Contour Machining of Free-Form SurfacesMusadiq MalikNoch keine Bewertungen

- Introduction To CNC MachiningDokument36 SeitenIntroduction To CNC MachiningNavya VelagaNoch keine Bewertungen

- Numerical Control: Instructor: DR Haris Aziz TA: Mian WasifDokument55 SeitenNumerical Control: Instructor: DR Haris Aziz TA: Mian WasifarunNoch keine Bewertungen

- Tool Path Generation For CNC Milling Based On STL File: Nadia Sami Hasan Dr. Laith Abdullah MohammedDokument12 SeitenTool Path Generation For CNC Milling Based On STL File: Nadia Sami Hasan Dr. Laith Abdullah MohammedAvinashNoch keine Bewertungen

- CATIA Module Descriptions for 3D Design, Machining & AssemblyDokument57 SeitenCATIA Module Descriptions for 3D Design, Machining & AssemblyvinothNoch keine Bewertungen

- Program solutions for complex contour grinding on flat grinding machinesDokument11 SeitenProgram solutions for complex contour grinding on flat grinding machinesa.chernjiNoch keine Bewertungen

- Unigraphics Interview Question A IreDokument5 SeitenUnigraphics Interview Question A Ireyuvarajtalele100% (2)

- CourseDokument2 SeitenCoursepc100xohmNoch keine Bewertungen

- Numerical ControlDokument36 SeitenNumerical ControlsaishvNoch keine Bewertungen

- A Parametric Programming Technique For Efficient CNC Machining Op PDFDokument4 SeitenA Parametric Programming Technique For Efficient CNC Machining Op PDFpocerilloNoch keine Bewertungen

- UG Interview QuestionsDokument16 SeitenUG Interview Questionsharsharg6_8Noch keine Bewertungen

- FullDokument35 SeitenFullsumanth100% (1)

- G-Code: ImplementationsDokument19 SeitenG-Code: Implementationsfedek2810Noch keine Bewertungen

- 27418-Article Text-48519-1-10Dokument8 Seiten27418-Article Text-48519-1-10rizukiwonderwallNoch keine Bewertungen

- G-Code Table Explains Numerical Control AddressingDokument3 SeitenG-Code Table Explains Numerical Control AddressingBradley VidañaNoch keine Bewertungen

- Process Engineering Chapter 2 Preliminary Part Print AnalysisDokument12 SeitenProcess Engineering Chapter 2 Preliminary Part Print AnalysisSaksham SarkarNoch keine Bewertungen

- Computer Aided Design 2 Mark Questions With AnswersDokument18 SeitenComputer Aided Design 2 Mark Questions With AnswersM.Thirunavukkarasu100% (4)

- CNC Manual enDokument41 SeitenCNC Manual enbeast manNoch keine Bewertungen

- Catia Software QuestionsDokument51 SeitenCatia Software Questionsdevil rocksNoch keine Bewertungen

- Cad Lab Viva QuestionDokument9 SeitenCad Lab Viva QuestionSms RajaNoch keine Bewertungen

- The Geometrical Tolerancing Desk Reference: Creating and Interpreting ISO Standard Technical DrawingsVon EverandThe Geometrical Tolerancing Desk Reference: Creating and Interpreting ISO Standard Technical DrawingsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- CAD Systems in Mechanical and Production EngineeringVon EverandCAD Systems in Mechanical and Production EngineeringBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Complete PCB Design Using OrCAD Capture and PCB EditorVon EverandComplete PCB Design Using OrCAD Capture and PCB EditorBewertung: 5 von 5 Sternen5/5 (1)

- Design Guidelines for Surface Mount TechnologyVon EverandDesign Guidelines for Surface Mount TechnologyBewertung: 5 von 5 Sternen5/5 (1)

- Production Engineering: Jig and Tool DesignVon EverandProduction Engineering: Jig and Tool DesignBewertung: 4 von 5 Sternen4/5 (9)

- Autodesk Inventor 2019 For Beginners - Part 1 (Part Modeling)Von EverandAutodesk Inventor 2019 For Beginners - Part 1 (Part Modeling)Noch keine Bewertungen

- Modeling and Problem Solving Techniques for EngineersVon EverandModeling and Problem Solving Techniques for EngineersNoch keine Bewertungen

- This Little Weed Is One of The Most Useful Medicines On The PlanetDokument6 SeitenThis Little Weed Is One of The Most Useful Medicines On The PlanetDavid BumbaloughNoch keine Bewertungen

- How To Become Untrackable - Part 1 - SurvivopediaDokument12 SeitenHow To Become Untrackable - Part 1 - SurvivopediaDavid Bumbalough100% (1)

- 12 Plants You'Ll Want in Your SHTF Garden - SurvivopediaDokument21 Seiten12 Plants You'Ll Want in Your SHTF Garden - SurvivopediaDavid BumbaloughNoch keine Bewertungen

- HK94, MP5, Parts KitsDokument6 SeitenHK94, MP5, Parts KitsDavid BumbaloughNoch keine Bewertungen

- Scaling Function Q+A: # Answer 1Dokument2 SeitenScaling Function Q+A: # Answer 1David BumbaloughNoch keine Bewertungen

- Tomato Fertilizer - How To Feed Your Plants For The Ultimate HarvestDokument11 SeitenTomato Fertilizer - How To Feed Your Plants For The Ultimate HarvestDavid BumbaloughNoch keine Bewertungen

- The Complete Guide To Growing Corn in Containers - Garden and HappyDokument17 SeitenThe Complete Guide To Growing Corn in Containers - Garden and HappyDavid BumbaloughNoch keine Bewertungen

- Tortort Manufacturing 80% Milled Receivers AK47Dokument6 SeitenTortort Manufacturing 80% Milled Receivers AK47David BumbaloughNoch keine Bewertungen

- Gun Control and The Founding Fathers Intent - The - Truth - and - JusticeDokument9 SeitenGun Control and The Founding Fathers Intent - The - Truth - and - JusticeDavid BumbaloughNoch keine Bewertungen

- Exercises After Abdominal SurgeryDokument5 SeitenExercises After Abdominal SurgeryDavid BumbaloughNoch keine Bewertungen

- Providers - PrivacytoolsDokument7 SeitenProviders - PrivacytoolsDavid BumbaloughNoch keine Bewertungen

- Feedrate Q+A: # Answer 1Dokument2 SeitenFeedrate Q+A: # Answer 1David BumbaloughNoch keine Bewertungen

- Verifying Programs Q+A: # Answer 1Dokument2 SeitenVerifying Programs Q+A: # Answer 1David BumbaloughNoch keine Bewertungen

- 44-01 Machining With TailstockDokument1 Seite44-01 Machining With TailstockDavid BumbaloughNoch keine Bewertungen

- 15-01 Reference Points - MillDokument1 Seite15-01 Reference Points - MillDavid BumbaloughNoch keine Bewertungen

- Calculating XY Points of a Blend Arc Dimensioned to its CenterDokument1 SeiteCalculating XY Points of a Blend Arc Dimensioned to its CenterDavid BumbaloughNoch keine Bewertungen

- Scaling Exercise: Use T01 Ø20 End MillDokument1 SeiteScaling Exercise: Use T01 Ø20 End MillDavid BumbaloughNoch keine Bewertungen

- 46-01 Horizontal MachiningDokument1 Seite46-01 Horizontal MachiningDavid BumbaloughNoch keine Bewertungen

- 53-04 Contour Points 2Dokument1 Seite53-04 Contour Points 2David BumbaloughNoch keine Bewertungen

- 49-01 Documenting Programs Q+A PDFDokument1 Seite49-01 Documenting Programs Q+A PDFDavid BumbaloughNoch keine Bewertungen

- CNC Machining Q+A: Major Criteria for Running First PartDokument2 SeitenCNC Machining Q+A: Major Criteria for Running First PartDavid BumbaloughNoch keine Bewertungen

- 49-01 Documenting Programs Q+ADokument1 Seite49-01 Documenting Programs Q+ADavid BumbaloughNoch keine Bewertungen

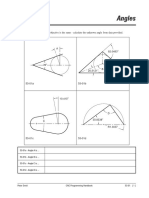

- Angles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDokument1 SeiteAngles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDavid BumbaloughNoch keine Bewertungen

- Calculating XY Points of a Blend Arc Dimensioned to its CenterDokument1 SeiteCalculating XY Points of a Blend Arc Dimensioned to its CenterDavid BumbaloughNoch keine Bewertungen

- 53-02 Locators PDFDokument1 Seite53-02 Locators PDFDavid BumbaloughNoch keine Bewertungen

- Trig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDokument1 SeiteTrig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDavid BumbaloughNoch keine Bewertungen

- Calculate Contour Change Points 1Dokument1 SeiteCalculate Contour Change Points 1David BumbaloughNoch keine Bewertungen

- 19-01 Tool LengthDokument1 Seite19-01 Tool LengthDavid BumbaloughNoch keine Bewertungen

- Unknown Radius: Chine Shop MagazineDokument1 SeiteUnknown Radius: Chine Shop MagazineDavid BumbaloughNoch keine Bewertungen

- 20-02 Rapid Motion FormulasDokument2 Seiten20-02 Rapid Motion FormulasDavid BumbaloughNoch keine Bewertungen

- For Coin & Blood (2nd Edition) - SicknessDokument16 SeitenFor Coin & Blood (2nd Edition) - SicknessMyriam Poveda50% (2)

- Empowerment Technology Reviewer: First SemesterDokument5 SeitenEmpowerment Technology Reviewer: First SemesterNinayD.MatubisNoch keine Bewertungen

- JD - Software Developer - Thesqua - Re GroupDokument2 SeitenJD - Software Developer - Thesqua - Re GroupPrateek GahlanNoch keine Bewertungen

- 00 CCSA TestDokument276 Seiten00 CCSA TestPedro CubillaNoch keine Bewertungen

- Module 2Dokument42 SeitenModule 2DhananjayaNoch keine Bewertungen

- ExpDokument425 SeitenExpVinay KamatNoch keine Bewertungen

- Instagram Dan Buli Siber Dalam Kalangan Remaja Di Malaysia: Jasmyn Tan YuxuanDokument13 SeitenInstagram Dan Buli Siber Dalam Kalangan Remaja Di Malaysia: Jasmyn Tan YuxuanXiu Jiuan SimNoch keine Bewertungen

- Feasibility StudyDokument47 SeitenFeasibility StudyCyril Fragata100% (1)

- Electrosteel Castings Limited (ECL) - Technology That CaresDokument4 SeitenElectrosteel Castings Limited (ECL) - Technology That CaresUjjawal PrakashNoch keine Bewertungen

- 'K Is Mentally Ill' The Anatomy of A Factual AccountDokument32 Seiten'K Is Mentally Ill' The Anatomy of A Factual AccountDiego TorresNoch keine Bewertungen

- IntroductionDokument34 SeitenIntroductionmarranNoch keine Bewertungen

- Distinguish Between Tax and FeeDokument2 SeitenDistinguish Between Tax and FeeRishi Agarwal100% (1)

- Amul ReportDokument48 SeitenAmul ReportUjwal JaiswalNoch keine Bewertungen

- 5505 SW 138th CT, Miami, FL 33175 ZillowDokument1 Seite5505 SW 138th CT, Miami, FL 33175 Zillowlisalinda29398378Noch keine Bewertungen

- Master of Commerce: 1 YearDokument8 SeitenMaster of Commerce: 1 YearAston Rahul PintoNoch keine Bewertungen

- DSE61xx Configuration Suite Software Manual PDFDokument60 SeitenDSE61xx Configuration Suite Software Manual PDFluisNoch keine Bewertungen

- TransistorDokument1 SeiteTransistorXhaNoch keine Bewertungen

- PW CDokument4 SeitenPW CAnonymous DduElf20ONoch keine Bewertungen

- Environmental Assessment of Sewer ConstructionDokument32 SeitenEnvironmental Assessment of Sewer ConstructionKaleab TadesseNoch keine Bewertungen

- 5 Important Methods Used For Studying Comparative EducationDokument35 Seiten5 Important Methods Used For Studying Comparative EducationPatrick Joseph63% (8)

- Timely characters and creatorsDokument4 SeitenTimely characters and creatorsnschober3Noch keine Bewertungen

- Investigatory Project Pesticide From RadishDokument4 SeitenInvestigatory Project Pesticide From Radishmax314100% (1)

- Yanmar America publication listing for engine parts, service, and operation manualsDokument602 SeitenYanmar America publication listing for engine parts, service, and operation manualsEnrique Murgia50% (2)

- Clogging in Permeable (A Review)Dokument13 SeitenClogging in Permeable (A Review)Chong Ting ShengNoch keine Bewertungen

- Rhodes Motion For Judicial NoticeDokument493 SeitenRhodes Motion For Judicial Noticewolf woodNoch keine Bewertungen

- Embryo If Embryonic Period PDFDokument12 SeitenEmbryo If Embryonic Period PDFRyna Miguel MasaNoch keine Bewertungen

- Test Bank For Core Concepts of Accounting Information Systems 14th by SimkinDokument36 SeitenTest Bank For Core Concepts of Accounting Information Systems 14th by Simkinpufffalcated25x9ld100% (46)

- The Changing Face of War - Into The Fourth GenerationDokument5 SeitenThe Changing Face of War - Into The Fourth GenerationLuis Enrique Toledo MuñozNoch keine Bewertungen

- Product CycleDokument2 SeitenProduct CycleoldinaNoch keine Bewertungen

- Statement of Compulsory Winding Up As On 30 SEPTEMBER, 2008Dokument4 SeitenStatement of Compulsory Winding Up As On 30 SEPTEMBER, 2008abchavhan20Noch keine Bewertungen