Beruflich Dokumente

Kultur Dokumente

Wps For Tank Vessel Rev3 (Site Fabricated) DT12.12.09 (IS2062)

Hochgeladen von

Salman KhanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Wps For Tank Vessel Rev3 (Site Fabricated) DT12.12.09 (IS2062)

Hochgeladen von

Salman KhanCopyright:

Verfügbare Formate

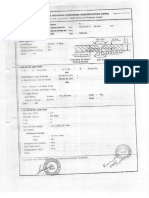

WELDING PROCEDURE SPECIFICATIONS WPS. NO.

: IEI/WPS/STD/01

(WPS)

Manufacturer’s NAME & ADDRESS OF MANU FACT URER

Logo REV. NO. 3

ION EXC HAN GE (INDIA ) LTD . REV. DATE: 21.12.09

R- 14 MTTC INDUS TRIAL AREA,

RA BALE , NAVI MU MBA I. PAGE : Page 1 of 4

Tre Dear

NTPC'S PROJECT :) VALLUR -STTP (3 X 500 MW)

Ref.: MAIN CONTRACTOR: ION EXCHANGE (I) LTD S PACKAGE: DESALINATION PLANT

ITEM : VESSELS&TANKS

PKG. NO.:0260-189-2

SUPPORTING PQR NO.___________________________DATE_________

WELDING PROCESS (ES)_______SMAW_____________TYPE(S)(AUTOMATIC, MANUAL, MACHINE, OR SEMI-AUTO.) MANUAL

INTS (QW-402)

Joint Design_________SINGLE “v” BUTT JOINT 70 deg groove angle

Backing (Yes/No)___________NO_____________

Backing Material (Type)_ NIL

Plate thk

(Refer to both backing and retainers)

12 mm

Metal Notfusing Metal

Nonmetallic Other

Sketches, Production Drawings, Welding Symbols or 1.6 TO

Written Root gap = 2mm 2 MM

Description should show the general arrangement of the

parts to be welded. Where applicable, the root spacing

and the details of welding grove may be specified.

(At the option of the Mfgr., sketches may be attached to

illustrate joint design, weld layers and bead sequence,

e.g. for notch toughness procedures, for multiple process

procedures, etc.)

*BASEMETALS (QW-403)

P.No. _____1_______Group No._______1_____________to P.No.________1_______Group No.________1 _____________

OR

Specification type & grade ____IS 2062________to specification type & grade ______________IS

2062________________

OR

Chem. Analysis & Mech. Prop.__________.____________ to Chem. Analysis & Mech.

Prop._________________________________

Thickness Range: Base Metal-Groove:_3 TO 24 MM__ Fillet _ALL__ Pipe Dia. Range: Groove 3/4” AND

ABOVE_ Fillet - ALL

Other __________________________________IS1239/IS3589

Approved subject to Satisfactory PQR

MANUFACTURER’S SIGN. DATE AND STAMP NTPC APPROVAL SIGN. DATE AND STAMP

PREPARED BY /REVIEWED BY NTPC DOC. NO. 9545-138(II)-QVM-Q-016

FORMAT NO. : QS-01-QAI-W-06 /F1-R0 1/2 ENGG. DIV./QA&I

WELDING PROCEDURE SPECIFICATIONS WPS. NO. : IEI/WPS/STD/01

(WPS)

Manufacturer’s NAME & ADDRESS OF MANU FACT URER

Logo REV. NO. 3

ION EXC HAN GE (INDIA ) LTD . REV. DATE: 21.12.09

R- 14 MTTC INDUS TRIAL AREA,

RA BALE , NAVI MU MBA I. PAGE : Page 2 of 4

*FILLER METALS (QW-404)

Spec. No. (SFA)

____________________5.1_______________________________________________________________________

AWS No. (Class)___________________________________E-6013__________

F.No.

______________________________________________2__________________________________________________

A.No.

_____________________________________________1___________________________________________________

Size of Filler Metals ________________________________2.5,3.15, 4__________________________________________

Weld Metal : Thickness Range : Groove ________3.15 MM TO 20 MM

Fillet ___ALL

Electrode-Flux (Class) ___N/A___________________________------________________________________________

Flux Trade Name

____N/A______________________________________________________________________________________

Consumable Insert

____N/A_____________________________________________________________________________________

Other ____ _________

* Each base metal-filler metal combination should be recorded individually.

NOTE: QW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATION (WPS) AS PER

2001 ASME SECTION-IX Boiler and Pressure Vessel Code) (Refer QW 2001)

Approved subject to Satisfactory PQR

MANUFACTURER’S SIGN. DATE AND STAMP NTPC APPROVAL SIGN. DATE AND STAMP

PREPARED BY /REVIEWED BY NTPC DOC. NO. 9545-138(II)-QVM-Q-016

FORMAT NO. : QS-01-QAI-W-06 /F1-R0 2/2 ENGG. DIV./QA&I

WELDING PROCEDURE SPECIFICATIONS WPS. NO. : IEI/WPS/STD/01

(WPS)

Manufacturer’s NAME & ADDRESS OF MANU FACT URER

Logo REV. NO. 3

ION EXC HAN GE (INDIA ) LTD . REV. DATE: 21.12.09

R- 14 MTTC INDUS TRIAL AREA,

RA BALE , NAVI MU MBA I. PAGE : Page 3 of 4

POSITION (QW-405) POSTWELD HEAT TREATMENT (QW-407)

Position (s) Groove ___3G Temperature Range

Welding Progression : UP HILL __NA________________________________

Position(s) of Fillet _____________-------- Time Range ___NA_________________________________

___________________________________________________ _______________________________________________________

PREHEAT (QW-406) GAS (QW-408)

Preheat Temp. Min. ___NA Percent Composition

Inter-pass Temp. Max. _N/A Gas(es) (Mixture) Flow

Preheat Maintenance ___NA rate

(Continuous or special heating where applicable Shielding _____NA ______________ ___________

should be recorded) Trailing _____NA ______________ ___________

Backing _____NA ______________ ___________

ELECTRICAL CHARACTERISTICS (QW-409)

Current AC or DC : DC Polarity _____REVERSE (ELECTRODE +VE)

Amps (Range) ___70 –150 A Volts (Range) __20 – 28 V

(Amps and volts range should be recorded for each electrode size, position, and thickness, tec. This

information may be listed in a tabular form similar to that shown below.)

Tungsten Electrode Size and Type ____NA___________________________________________(Pure Tungsten, 2%

Thoriated, etc.)

Mode of Metal Transfer for GMAW __ NA_________________________________________(Spray arc, short circuiting

arc, etc.)

Electrodes Wire feed speed range

______NA_____________________________________________________________________

TECHNIQUE (QW-410)

String or Weave Bead __STRING & WEAVE BEAD

Orifice or Gas Cup Size ____NA_____________________________________

Initial and Interpass Cleaning (Brushing, Grinding, etc.) _ WIRE BRUSHING & GRINDING

____________________________________________________________________________________________________________

Method of Back Gouging __BY GRINDING._____________

Oscillation ___NIL____________________________

Contact Tube to Work Distance __ __ NA___

Multiple or Single Pass (per side) ___MULTIPLE_____

Multiple or Single Electrodes ______SINGLE________

Travel Speed (Range) ____________50 –150 MM / MIN___

Peening

_____________________________________________________________________________________________________

Other

_______________________________________________________________________________________________________

Filler Metal Current

Weld Process Class Dia POLARITY Amp. Volt Travel Other (e.g.

Layer(s) MM Range Range speed Remarks

Range Comments. Hot

mm/min Wire Addition.

. Technique, Torch

Angle, etc.

Approved subject to Satisfactory PQR

MANUFACTURER’S SIGN. DATE AND STAMP NTPC APPROVAL SIGN. DATE AND STAMP

PREPARED BY /REVIEWED BY NTPC DOC. NO. 9545-138(II)-QVM-Q-016

FORMAT NO. : QS-01-QAI-W-06 /F1-R0 3/2 ENGG. DIV./QA&I

WELDING PROCEDURE SPECIFICATIONS WPS. NO. : IEI/WPS/STD/01

(WPS)

Manufacturer’s NAME & ADDRESS OF MANU FACT URER

Logo REV. NO. 3

ION EXC HAN GE (INDIA ) LTD . REV. DATE: 21.12.09

R- 14 MTTC INDUS TRIAL AREA,

RA BALE , NAVI MU MBA I. PAGE : Page 4 of 4

Root Run SMAW E-6013 2.5/3.15 E(+VE) 60– 90 20 – 100–

24 150

SMAW DO 3.15 E(+VE) 80 – 120

1st Run

20 – 100–

SMAW DO 4 E(+VE) 8 0 - 150 24 150

2nd Run

SMAW DO 4.0 E(+VE) 90 - 150 20 – 100–

3rd Run

24 150

SMAW DO 3.15 E(+VE) 8 0 - 120

After

20 – 100–

Back-

24 150

Gauging

20 – 100 –

24 150

NOTE: QW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATION (WPS) AS PER

2001 ASME SECTION-IX Boiler and Pressure Vessel Code) (Refer QW 2001)

Approved subject to Satisfactory PQR

MANUFACTURER’S SIGN. DATE AND STAMP NTPC APPROVAL SIGN. DATE AND STAMP

PREPARED BY /REVIEWED BY NTPC DOC. NO. 9545-138(II)-QVM-Q-016

FORMAT NO. : QS-01-QAI-W-06 /F1-R0 4/2 ENGG. DIV./QA&I

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- DO - 036 - S2004 DPWH Equipt. RentalDokument8 SeitenDO - 036 - S2004 DPWH Equipt. RentalCharge EmotionNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- WeldingDokument9 SeitenWeldingkiraneluruNoch keine Bewertungen

- Wps PQR GuideDokument40 SeitenWps PQR GuideBalakumar100% (10)

- Paint calculations: Determine DFT, WFT, spreading rate & consumptionDokument17 SeitenPaint calculations: Determine DFT, WFT, spreading rate & consumptionEkyharyans100% (17)

- What Every Engineer Should Know About Welding ProceduresDokument13 SeitenWhat Every Engineer Should Know About Welding Proceduresarash59_4uNoch keine Bewertungen

- LTCS Vs CSDokument2 SeitenLTCS Vs CSMuhammad ShahzadNoch keine Bewertungen

- LTCS Vs CSDokument2 SeitenLTCS Vs CSMuhammad ShahzadNoch keine Bewertungen

- Oracle Transportation Manager: Discover InsightsDokument27 SeitenOracle Transportation Manager: Discover Insightskkathiresan4998Noch keine Bewertungen

- Sample Portfolio As RPL EvidenceDokument33 SeitenSample Portfolio As RPL Evidenceapi-23985385750% (2)

- Engineering Unit Conversion PDFDokument5 SeitenEngineering Unit Conversion PDFBarcepandoNoch keine Bewertungen

- Microsoft General - EBCM - Business Continuity and Disaster Recovery Plan Validation Report (2022 Apr-June)Dokument8 SeitenMicrosoft General - EBCM - Business Continuity and Disaster Recovery Plan Validation Report (2022 Apr-June)Sammy DomínguezNoch keine Bewertungen

- PEFC Logo Usage ToolkitDokument25 SeitenPEFC Logo Usage ToolkitPEFC International75% (4)

- Stainless Steel Cladding and Weld Overlays PDFDokument13 SeitenStainless Steel Cladding and Weld Overlays PDFm5416Noch keine Bewertungen

- 16 Law of NegligenceDokument60 Seiten16 Law of NegligenceEliezer Charles Ngahyoma100% (1)

- Heat Exchanger InspectionDokument27 SeitenHeat Exchanger Inspectionglazetm100% (23)

- Asme B36.19Dokument13 SeitenAsme B36.19Salman KhanNoch keine Bewertungen

- Help Menu For BHEL UsersDokument2 SeitenHelp Menu For BHEL UsersSalman KhanNoch keine Bewertungen

- PO-00519 Amend-1-ETP BLOWERDokument4 SeitenPO-00519 Amend-1-ETP BLOWERSalman KhanNoch keine Bewertungen

- NTPC Circular DT 07-Mar-2017Dokument3 SeitenNTPC Circular DT 07-Mar-2017Salman KhanNoch keine Bewertungen

- Asme B36.19Dokument13 SeitenAsme B36.19Salman KhanNoch keine Bewertungen

- A Expensheet0001Dokument1 SeiteA Expensheet0001Salman KhanNoch keine Bewertungen

- Wps SsDokument12 SeitenWps SsSalman KhanNoch keine Bewertungen

- Daily Welding Check ListDokument14 SeitenDaily Welding Check ListSalman KhanNoch keine Bewertungen

- ANSI B16.25 Butt Welding Pipe DimensionsDokument4 SeitenANSI B16.25 Butt Welding Pipe DimensionsFernandoNoch keine Bewertungen

- Piping IsometricsDokument18 SeitenPiping IsometricsSalman KhanNoch keine Bewertungen

- Is Maintenance Manual PDFDokument13 SeitenIs Maintenance Manual PDFSalman KhanNoch keine Bewertungen

- Gaskets Ir Bhel BhadradriDokument2 SeitenGaskets Ir Bhel BhadradriSalman KhanNoch keine Bewertungen

- ASME InterpretationDokument4 SeitenASME Interpretationhrh_pogcNoch keine Bewertungen

- Fabrication and Inspection of PV and Columns PPMAI PDFDokument47 SeitenFabrication and Inspection of PV and Columns PPMAI PDFSalman KhanNoch keine Bewertungen

- Is 3502 2009 PDFDokument10 SeitenIs 3502 2009 PDFRajashekar.PNoch keine Bewertungen

- Astm A193Dokument13 SeitenAstm A193Joffre ValladaresNoch keine Bewertungen

- Development of SurfacesDokument8 SeitenDevelopment of SurfacesBhuban LimbuNoch keine Bewertungen

- Enll/ (-, 1.-I LL LLL ,: I L I (' J IDokument1 SeiteEnll/ (-, 1.-I LL LLL ,: I L I (' J ISalman KhanNoch keine Bewertungen

- Astm A 714 (1999) PDFDokument8 SeitenAstm A 714 (1999) PDFnisha_khanNoch keine Bewertungen

- Scanned by CamscannerDokument1 SeiteScanned by CamscannerSalman KhanNoch keine Bewertungen

- Consolidation Workpaper for Piero SAADokument2 SeitenConsolidation Workpaper for Piero SAAAlya Sufi IkrimaNoch keine Bewertungen

- The Types of ArbitrationsDokument2 SeitenThe Types of Arbitrationsnupur jhodNoch keine Bewertungen

- Maintenance IntroductionDokument26 SeitenMaintenance IntroductionAlphaNoch keine Bewertungen

- Determinants of Mergers: A Case of Specified Purpose Acquisition Companies (Spacs)Dokument8 SeitenDeterminants of Mergers: A Case of Specified Purpose Acquisition Companies (Spacs)payal chaudhariNoch keine Bewertungen

- Project Report On Coca ColaDokument76 SeitenProject Report On Coca ColaFoo Shu FongNoch keine Bewertungen

- Elevator PitchDokument11 SeitenElevator PitchNancy JainNoch keine Bewertungen

- Organization and Management E-Book PDFDokument4 SeitenOrganization and Management E-Book PDFDomingo ManzoNoch keine Bewertungen

- Solidbank Corporation/ Metropolitan Bank and Trust Company, Petitioner, vs. SPOUSES PETER and SUSAN TAN, RespondentsDokument9 SeitenSolidbank Corporation/ Metropolitan Bank and Trust Company, Petitioner, vs. SPOUSES PETER and SUSAN TAN, RespondentsJoielyn Dy DimaanoNoch keine Bewertungen

- Ifrs Edition: Prepared by Coby Harmon University of California, Santa Barbara Westmont CollegeDokument79 SeitenIfrs Edition: Prepared by Coby Harmon University of California, Santa Barbara Westmont CollegeJhoni LieNoch keine Bewertungen

- Wholesale FBA Proposal TemplateDokument5 SeitenWholesale FBA Proposal Templateneeraj punjwaniNoch keine Bewertungen

- SAP Interview QuestionsDokument4 SeitenSAP Interview QuestionsAmaranathreddy YgNoch keine Bewertungen

- SJ-20120730093520-002-ZXUN ICX (MSCS) (V4.12.10) MSC Server Product DescriptionDokument70 SeitenSJ-20120730093520-002-ZXUN ICX (MSCS) (V4.12.10) MSC Server Product DescriptionDeepak JoshiNoch keine Bewertungen

- Unit 2 Capital Budgeting Decisions: IllustrationsDokument4 SeitenUnit 2 Capital Budgeting Decisions: IllustrationsJaya SwethaNoch keine Bewertungen

- Hexagon PPM Caesar II Fundamentals Info Sheet 1Dokument2 SeitenHexagon PPM Caesar II Fundamentals Info Sheet 1Muhammad Zahir ShahNoch keine Bewertungen

- The Effects of Background Music On Consumer Responses in A High End SupermarketDokument15 SeitenThe Effects of Background Music On Consumer Responses in A High End SupermarketAYFERNoch keine Bewertungen

- FINS5510 Quiz1题库Dokument3 SeitenFINS5510 Quiz1题库lbxxalbxxa1Noch keine Bewertungen

- 1 - Conceptual Framework Q PDFDokument6 Seiten1 - Conceptual Framework Q PDFandreamrieNoch keine Bewertungen

- Introduction To Cost Management Systems: Cost Accounting: Foundations and Evolutions, 9eDokument34 SeitenIntroduction To Cost Management Systems: Cost Accounting: Foundations and Evolutions, 9eGRACE ANN BERGONIONoch keine Bewertungen

- BABOR Phytoactive Combination in The Official BABOR Online Shop BABOR SkincareDokument1 SeiteBABOR Phytoactive Combination in The Official BABOR Online Shop BABOR SkincareDexterite Makeup ArtistNoch keine Bewertungen

- Gold in Ground and Near-Term Production Plan 43-101 Resources Over 3.3m GoldDokument2 SeitenGold in Ground and Near-Term Production Plan 43-101 Resources Over 3.3m GoldbimobimoprabowoNoch keine Bewertungen

- HRM HPCL NewDokument14 SeitenHRM HPCL NewYaramala Sai Venkata Rami ReddyNoch keine Bewertungen

- Environments (2 Days)Dokument5 SeitenEnvironments (2 Days)abhi74Noch keine Bewertungen

- Revised Corporation Code (RA No. 11232) - Title V - BylawsDokument3 SeitenRevised Corporation Code (RA No. 11232) - Title V - Bylawsshella vienNoch keine Bewertungen

- PWD Form 203A (Rev 1 - 2010)Dokument69 SeitenPWD Form 203A (Rev 1 - 2010)Jael YinianNoch keine Bewertungen