Beruflich Dokumente

Kultur Dokumente

Single Stage Digital Controller With Timed Cycle: Installing and Operating Instructions

Hochgeladen von

vishadkapadiaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Single Stage Digital Controller With Timed Cycle: Installing and Operating Instructions

Hochgeladen von

vishadkapadiaCopyright:

Verfügbare Formate

dIXEL Installing and Operating Instructions 1592018000

4. TIMED CYCLE

XT420C 4.1 HOW TO SET THE TIMER

Single Stage Digital Controller 1. Push the CLOCK key, the bottom display shows the cycle duration, flashing, (h:mm or m:ss),

with timed cycle while the hourglass icons starts flahing..

2. Use the UP and DOWN keys to adjust it.

3. Confirm the value pushing again the CLOCK key or waiting 10s.

1. GENERAL WARNING

1.1 PLEASE READ BEFORE USING THIS MANUAL 4.2 HOW TO START A CYCLE

• This manual is part of the product and should be kept near the instrument for easy and quick reference. Push and release the START key.

• The instrument shall not be used for purposes different from those described hereunder. It cannot be used The bottom display shows the count down of the cycle duration and the cycle is started.

as a safety device.

• Check the application limits before proceeding.

4.3 CYCLE END

1.2 SAFETY PRECAUTIONS The end of the cycle is signalled by the “End” message on the display and by the activation of the buzzer.

• Check the supply voltage is correct before connecting the instrument. The buzzer go on noising till a key is pressed..

• Do not expose to water or moisture: use the controller only within the operating limits avoiding sudden

temperature changes with high atmospheric humidity to prevent formation of condensation

• Warning: disconnect all electrical connections before any kind of maintenance. 4.4 HOW TO MANUALLY STOP A CYCLE.

• The instrument must not be opened.

When a cycle is in progress push and release the START key. The controller come back to display

• In case of failure or faulty operation send the instrument back to the distributor or to “DIXELL S.p.A.” (see

address) with a detailed description of the fault. the temperature and the timer is erased.

• Consider the maximum current which can be applied to each relay (see Technical Data).

• Ensure that the wires for probes, loads and the power supply are separated and far enough from each

other, without crossing or intertwining. 4.5 HOW TO CHANGE THE TIMER WHEN A CYCLE IS RUNNING.

• In case of applications in industrial environments, the use of mains filters (our mod. FT1) in parallel with 1. Push and release the CLOCK key, the remaining time starts blinking.

inductive loads could be useful. 2. Use the UP and DOWN keys to adjust it.

3. Confirm the value pushing again the CLOCK key or waiting 10s.

2. GENERAL DESCRIPTION

The XT420C is a single-stage ON/OFF controller for temperature applications with direct or inverse

action and timed cycles. An additional relay is used to switch the light 4.6 POSSIBILITY OF SELECTING THE KIND OF REGULATION: CONTINUOS OR

The analogue input type can be set by parameter PTC or NTC. ONLY DURING THE CYCLE.

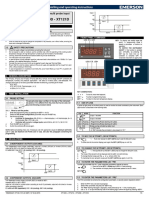

3. FRONT PANEL COMMANDS By means of the Ft parameter the kind of regulations is set::

With Ft = tMd the regulation is enabled only during the cycle.

LED1 LED2 With Ft = co the regulation is always active, the cycle consists of starting the timer and signalling when

this is expired.

4.7 TO ENTER THE PARAMETERS LIST “PR1

XT400

To enter the parameter list “Pr1” (user accessible parameters) operate as follows:

1. Push for 3s the SET + n keys (LED1 & 2 start blinking).

X----C

2. The controller will show the first parameter present in the Pr1 menu:

- Bottom menu: label

- Upper menu: value

4.8 TO ENTER IN PARAMETERS LIST “PR2”

To access parameters in “Pr2”:

LED3 1. Enter the “Pr1” level.

2. Select “Pr2” – “PAS” parameter and press the “SET” key.

SET: To display and modify target set point; in programming mode it selects a parameter or confirm an 3. The flashing value “0 - - ” is displayed. use o or n to input the security code and confirm the

operation. figure by pressing “SET” key.

TO SWITCH THE INSTRUMENT ON/OFF: If the function is enabled (par. onF=yES), by pressing

the SET key for more than 4s the controller is switched OFF. To switch the instrument on again

press the SET key. The security code is “321”.

/o UP / Light: to switch the light. In programming mode it browses the parameter codes or 4. If the security code is correct the access to “Pr2” is enabled by pressing “SET” on the last digit.

increases the displayed value. Hold it pressed for a faster change

Another possibility is the following:

/n DOWN / Start to start and stop the cycle. In programming mode it browses the parameter codes

After switching ON the instrument, within 30 seconds, push SET + n keys together for 3s: the Pr2 menu

or decreases the displayed value. Hold it pressed for a faster change

will be entered.

CLOCK To set the timer and to start/stop a cycle

KEY COMBINATIONS: 4.9 HOW TO MOVE A PARAMETER FROM THE “PR2” MENU TO “PR1” AND

o +n To lock & unlock the keyboard. VICEVERSA.

SET + n To enter in programming mode. Each parameter present in “Pr2” MENU can be removed or put into “Pr1”, user level, by pressing “SET +

SET + o To return to the room temperature display. n”.

In “Pr2” when a parameter is present in “Pr1” the LED is on.

3.1 USE OF LEDS

A series of light points on the front panels is used to monitor the loads controlled by the instrument. Each 4.10 HOW TO CHANGE A PARAMETER

LED function is described in the following table. To change a parameter value operates as follows:

1. Enter the Programming mode

LED MODE FUNCTION 2. Select the required parameter.

ON Output relay enabled 3. Press the “SET” key to display its value.

4. Use “UP” or “DOWN” to change its value.

ON Light on

5. Press “SET” to store the new value and move to the following parameter.

LED1 Flashing - Programming Phase (flashing with LED2)

LED2 Flashing - Programming Phase (flashing with LED1) TO EXIT: Press SET + o or wait 15s without pressing a key.

ON - The cycle is running NOTE: the set value is stored even when the procedure is exited by waiting the time-out to expire.

ON - ALARM signal

- In “Pr2” indicates the parameter is also present in “Pr1” 4.11 HOW TO LOCK THE KEYBOARD

3.2 TO SEE AND CHANGE THE SETPOINT

1. Push and release the SET key: 1. Keep pressed for more than 3 s the o and n keys.

- the bottom display shows the label St1 2. The “POF” message will be displayed and the keyboard will be locked. At this point it will be

- the upper display shows the Set point value; possible only to see the set point or the MAX o Min temperature stored

2. To come back to the normal display push again the SET key or wait 10s.

3. If a key is pressed more than 3s the “POF” message will be displayed.

2. To change the Set value push the o or n arrows within 10s.

3. To memorise the new set point value push the SET key again or wait 10s.

1592018000 XT420C GB R.1.0 12.05.2005.doc XT420C 1/3

dIXEL Installing and Operating Instructions 1592018000

4.12 TO UNLOCK THE KEYBOARD 7. ELECTRICAL CONNECTIONS

Keep pressed together for more than 3s the o and n keys, till the “Pon” message will be displayed. The instruments are provided with screw terminal block to connect cables with a cross section up to 2,5

mm2. Before connecting cables make sure the power supply complies with the instrument’s requirements.

4.13 ON/OFF FUNCTION Separate the input connection cables from the power supply cables, from the outputs and the power

connections. Do not exceed the maximum current allowed on each relay, in case of heavier loads use a

TO SWITCH THE INSTRUMENT ON/OFF: If the function is enabled (par. onF=yES), by pressing the

suitable external relay.

SET key for more than 4s the controller is switched OFF. To switch the instrument on again press the

SET key.

8. SERIAL CONNECTIONS

5. LIST OF PARAMETERS All models can be connected to the monitoring and supervising system XJ500 using the serial port. The

external XJ485 serial module to interface the instrument with the monitoring and supervising system

REGULATION XJ500 is required.

Hy1 Differential: (-Full Sc. / Full Sc.) Intervention differential for set point. It can be set with positive The standard ModBus RTU protocol it is used.

value or with negative value. The kind of action (direct or inverse) depends on the S1C parameter

(in or di). 9. HOW TO USE THE HOT KEY

Ft Regulation setting

oFF the regulation is enabled only during the cycle.

on the regulation is always active, the cycle consists of starting the timer and signalling when this

9.1 HOW TO PROGRAM A HOT KEY FROM THE INSTRUMENT (UPLOAD)

has expired. 1. Program one controller with the front keypad.

odS Outputs activation delay at start up: (0÷255 min) This function is enabled at the initial start up of 2. When the controller is ON, insert the “Hot key” and push o key; the "uPL" message appears

the instrument and inhibits any output activation for the period of time set in the parameter. (Light followed a by flashing “End”

can work) 3. Push “SET” key and the End will stop flashing.

LS1 Minimum set point: (-50÷Set) Sets the minimum acceptable value for the set point. 4. Turn OFF the instrument remove the “Hot Key”, then turn it ON again.

US1 Maximum set point: (Set÷ 150°C) Sets the maximum acceptable value for set point.

Ac1 Anti-short cycle delay: (0÷250 sec) Minimum time between the switching off and the following NOTE: the “Err” message is displayed for failed programming. In this case push again o key if you want

switching on to restart the upload again or remove the “Hot key” to abort the operation.

con Output ON time with faulty probe: (0÷255 min) time during which the output is active in case of

faulty thermostat probe. With COn=0 compressor is always OFF. 9.2 HOW TO PROGRAM AN INSTRUMENT USING A HOT KEY (DOWNLOAD)

coF Output OFF time with faulty probe: (0÷255 min) time during which the output is off in case of 1. Turn OFF the instrument.

faulty thermostat probe. With COF=0 compressor is always active. 2. Insert a programmed “Hot Key” into the 5 PIN receptacle and then turn the Controller ON.

cH Action type: Ht= inverse action (heating); cL direct action (cooling). 3. Automatically the parameter list of the “Hot Key” is downloaded into the Controller memory, the

DISPLAY “doL” message is blinking followed a by flashing “End”.

CF Temperature measurement unit: °C = Celsius; °F = Fahrenheit. When the measurement unit is 4. After 10 seconds the instrument will restart working with the new parameters.

changed the SET point and the values of some parameters have to be modified. 5. Remove the “Hot Key”..

rES Resolution (for °C): (in = 1°C; de = 0,1°C) allows decimal point display. dE = 0,1°C; in = 1 °C

ALARMS NOTE the message “Err” is displayed for failed programming. In this case turn the unit off and then on if

you want to restart the download again or remove the “Hot key” to abort the operation.

ALC Temperature alarms configuration: it determines if alarms are relative to set point or referred to

absolute values: rE relative to set point; Ab absolute temperature

ALL Minimum alarm:

with ALC=rE: relative to set point, (0÷50°C) this value is subtracted from the set point. The alarm

10. DIGITAL INPUT

signal is enabled when the probe values goes below the “SET-ALL” value. XT420C has 1 free contact digital input. It is programmable in 4 different configurations by the “i1F”

with ALC=Ab absolute value, minimum alarm is enabled when the probe values goes below the parameter.

“ALL” value.

ALU Maximum alarm: 10.1 DOOR SWITCH INPUT

with ALC=rE: alarm relative to set point, (0÷50°C) Maximum alarm is enabled when the probe It signals the door status and the corresponding relay output status through the “odc” parameter:

values exceeds the “SET+ALU” value. no = normal (any change);

with ALC=Ab: absolute alarm, (Set÷Full Sc.) Maximum alarm is enabled when the probe values CPr and c_o= output OFF;

exceeds the “ALU” value. Since the door is opened, after the delay time set through parameter “doA”, the alarm output is enabled

ALH Differential for alarm recovery: (0,1÷Full scale) the alarm recovers when probe value is higher and the display shows the message “dA”. The alarm stops as soon as the external digital input is

than Alarm value + ALH. disabled again.

ALd Alarm delay:(0÷999 min) time interval between the detection of an alarm condition and alarm

signalling. 10.2 REMOTE ON/OFF (I1F = OFF)

dAO Delay of alarm at start-up: (0÷23.5h) time interval between the detection of the alarm condition

This function allows to switch ON and OFF the instrument.

after instrument power on and alarm signalling.

PROBES

10.3 GENERIC ALARM (I1F = EAL)

Pbc Kind of probe: Ptc = PTC; ntc = NTC

As soon as the digital input is activated the unit will wait for “did” time delay before signalling the “EAL”

oF1 Probe calibration: (-12÷12°C) allows to adjust possible offset of the probe.

alarm message. The outputs status don’t change. The alarm stops just after the digital input is de-

DIGITAL INPUT activated.

i1P Digital input polarity:

CL : the digital input is activated by closing the contact; 10.4 SERIOUS ALARM MODE (I1F = BAL)

OP : the digital input is activated by opening the contact

i1F Digital input operating mode: digital input function: When the digital input is activated, the unit will wait for “did” delay before signalling the “bAL” alarm

oFF = to switch the controller off.; EAL = generic external alarm; bAL = serious external alarm: it message. The relay outputs are switched OFF. The alarm will stop as soon as the digital input is de-

switches off the loads; dor = door switch function activated.

odc Output status with open door alarm:

no = normal; CPr or c_o= output OFF;

11. ALARM SIGNALS

rrd Regulation restart with door open alarm: Message Cause Outputs

YES = regulation restarts; no = regulation according to odc parameter. “PF1” Probe broken or absence Alarm output ON; Output according to parameter “con” and “coF”.

did Digital input alarm delay: (0÷255 min) delay between the detection of the external alarm condition “HA” Maximum alarm Alarm output ON; Other outputs unchanged.

(i1F= EAL or i1F = bAL) and its signalling. “LA” Minimum alarm Alarm output ON; Other outputs unchanged.

tcM Timer resolution: H-M = hour/minute; M-S = minute/second “EAL” External alarm Output unchanged.

OTHER “bAL” Serious external alarm Output OFF.

Adr RS485 serial address (0÷247) identifies the instrument within a control or supervising system. dA Door open According to rrd parameter

onF Switching ON/OFF enabling from keyboard: (no = disabled; yES=enabled) It permits the

switching ON/OFF of the instrument by pressing the SET key for more than 4s.

Ptb Parameters table: (read only) Shows the code of the parameters map.

11.1 SILENCING BUZZER

rEL Software release: (read only) Once the alarm signal is detected the buzzer, if present, can be disabled by pressing any key.

Pr2 To access the Pr2 parameter programming menu. The display signal remains as long as the alarm condition remains.

6. INSTALLATION AND MOUNTING 11.2 ALARM RECOVERY

Instrument XT420C shall be mounted on vertical panel, in a 29x71 Probe alarms “P1” starts few seconds after the fault in the probe; they automatically stop few seconds

mm hole, and fixed using the special brackets supplied. To obtain after the probe restarts normal operation. Check connections before replacing the probe.

an IP65 protection grade use the front panel rubber gasket (mod. Max. and min. alarms “HA” and “LA” automatically stop as soon as the variable returns to normal values.

RG-C) as shown in figure. The temperature range allowed for Alarms “bAL” “dA”and “EAL” recover as soon as the digital input is disabled.

correct operation is 0÷60 °C. Avoid places subject to strong

vibrations, corrosive gases, excessive dirt or humidity. The same

recommendations apply to probes. Let air circulate by the cooling

holes.

1592018000 XT420C GB R.1.0 12.05.2005.doc XT420C 2/3

dIXEL Installing and Operating Instructions 1592018000

12. TECHNICAL DATA 14. DEFAULT SETTING VALUES

Housing: self extinguishing ABS; Case: frontal 32x74 mm; depth 60mm; COD °C/°F Lev Name Range

Mounting: panel mounting in a 71x29 mm panel cut-out. Set 3 - - - Set point LS1 ÷ uS1

Protection: IP20; Frontal protection: IP65 with frontal gasket RG-C (optional). Hy1 2 Pr1 Differential 0.1 ÷ 25.0 °C / 1 ÷ 45 °F

Connections: Screw terminal block ≤ 2,5 mm2 heat-resistant wiring. trM co Pr2 Regulation setting co = always / tMd = only

Power supply: 12Vac/dc, ±10% or: 24Vac/dc ± 10% during the cycle

or 230Vac ± 10%, 50/60Hz or 110Vac, ± 10%, 50/60Hz ods 0 Pr2 Output delay at power on 0÷255min

Power absorption: 3VA max.

LS1 -50 Pr2 Minimum set point -50.0 °C o -58°F ÷ St1

Display: Dual display with icons

uS1 110 Pr2 Maximum set point St1 ÷ 150 °C o 302 °F

Inputs: according to the order: NTC/PTC

Relay outputs: Load relay SPDT 8(3)A, 250Vac Ac1 0 Pr2 Anti-short cycle delay: 0 ÷ 30

Light: relay SPDT 8(3)A, 250Vac con 0 Pr2 output on time with faulty probe 0 ÷ 250

Other output: buzzer (optional) coF 0 Pr2 output of time with faulty probe 0 ÷ 250

Kind of action: 1B; Pollution grade: normal, Software class: A. cH Ht Pr2 Action type output Ht = heating/ cL = cooling

Data storing: on the non-volatile memory (EEPROM). CF °C Pr2 Measurement unit °C=°C; °F= °F;

Operating temperature: 0÷60 °C (32÷140°F). rES in Pr1 Resolution in= integer; dE = decimal

Storage temperature: -30÷85 °C (-22÷185°F). point

Relative humidity: 20÷85% (no condensing) ALC Ab Pr2 Alarm configuration rE=relat.; Ab= absolute

Measuring and regulation range: according to the probe ALL -50 Pr1 Minimum alarm (ALC=rE) 0 ÷ 50°C

Controller Accuracy a 25°C: better than ±0,5% of full scale (ALC=Ab) -50.÷ ALu

ALU 110 Pr1 Maximum alarm (ALC=rE) 0 ÷50°C

13. CONNECTIONS (ALC=Ab) ALL÷ 150°C

ALH 1 Pr2 Alarm recovery differential 0÷Full scale

13.1 XT420C – 230V AC OR 115V AC ALd 15 Pr1 Alarm delay 0÷999 min

dAO 1.3 Pr2 Alarm delay at start up 0÷23h 50min

Room

PbC ntc Pr2 Kind of probe Ptc = PTC / ntc = NTC

oF1 0 Pr2 Probe calibration -12 ÷ 12 °C / -22 ÷ 22 °F

6 7 8 9 i1P cL Pr2 Digital input polarity cL=closed; oP=open

8(3)A250V 8(3)A250V

i1F dor Pr2 Digital input configuration dor / EAL / bAL / oFF

odc no Pr2 Output status with door open no / cPr / c-o

1 2 3 4 5 11 12 rrd no Pr2 Output restart after door open alarm dA no = no / YES = yES

did 0 Pr2 Alarm delay for dig. input 0 ÷ 250 ( nu = 251 )

Hot Key

Line Line tcM H-M Pr2 Timer resolution H-M = h:m / M-S = m:s

Light OUT

Adr 1 Pr2 Serial address 0÷247

115Vac supply: connect to the 7-8 terminals.

OnF no Pr2 oFF function enabling no=not enabled;

yES=enabled

Ptb -- Pr2 Parameter table Readable only

rEL --- Pr2 Software release Readable only

Pr2 321 Pr1 To access the Pr2 Readable only

Dixell S.p.A. Z.I. Via dell’Industria, 27

32010 Pieve d’Alpago (BL) ITALY

tel. +39 - 0437 - 98 33 - fax +39 - 0437 - 98 93 13

E-mail: dixell@dixell.com - http://www.dixell.com

1592018000 XT420C GB R.1.0 12.05.2005.doc XT420C 3/3

Das könnte Ihnen auch gefallen

- XT210C - XT211C: Single Stage Digital Controller With Multi Probe InputDokument3 SeitenXT210C - XT211C: Single Stage Digital Controller With Multi Probe InputJennifer Eszter Sárközy100% (1)

- Dixell XR20CXDokument4 SeitenDixell XR20CXionut ciobanuNoch keine Bewertungen

- XR20C - XR20D: Installing and Operating InstructionsDokument4 SeitenXR20C - XR20D: Installing and Operating InstructionsJennifer Eszter SárközyNoch keine Bewertungen

- XR30CX: Installing and Operating InstructionsDokument4 SeitenXR30CX: Installing and Operating InstructionsD GraymanNoch keine Bewertungen

- XR30CX: Installing and Operating InstructionsDokument4 SeitenXR30CX: Installing and Operating InstructionsImmorthalNoch keine Bewertungen

- dIXEL Installing and Operating Instructions Rel.2.0 - Cod. 1598002170, Manual XW60LDokument4 SeitendIXEL Installing and Operating Instructions Rel.2.0 - Cod. 1598002170, Manual XW60LAlexey IvanovNoch keine Bewertungen

- XT110C - XT111C - XT110D - XT111D: Single Stage Digital Controller With Multi Probe InputDokument4 SeitenXT110C - XT111C - XT110D - XT111D: Single Stage Digital Controller With Multi Probe InputHoàngViệtAnhNoch keine Bewertungen

- Installing and Operating Instructions: DixellDokument4 SeitenInstalling and Operating Instructions: Dixellmartinfood100% (1)

- XR30C - XR30D: Digital Controller With Off Cycle DefrostDokument4 SeitenXR30C - XR30D: Digital Controller With Off Cycle DefrostJennifer Eszter SárközyNoch keine Bewertungen

- XR50CX GBDokument4 SeitenXR50CX GBEmilia CocioNoch keine Bewertungen

- Dixell XR60CDokument4 SeitenDixell XR60CCarlos0% (1)

- XR20C - XR20D: Digital Controller With Off Cycle DefrostDokument4 SeitenXR20C - XR20D: Digital Controller With Off Cycle DefrostJennifer Eszter SárközyNoch keine Bewertungen

- Hướng dẫn sử dụng bộ điều khiển nhiệt độ Dixell-XR72CXDokument4 SeitenHướng dẫn sử dụng bộ điều khiển nhiệt độ Dixell-XR72CXVĩnhNoch keine Bewertungen

- XW60LS GB Rel.1.0 27.10.06Dokument4 SeitenXW60LS GB Rel.1.0 27.10.06Jennifer Eszter SárközyNoch keine Bewertungen

- XR30C - XR30D: Installing and Operating InstructionsDokument4 SeitenXR30C - XR30D: Installing and Operating InstructionsJennifer Eszter SárközyNoch keine Bewertungen

- B 812 CFC 59Dokument15 SeitenB 812 CFC 59Alberto OrtizNoch keine Bewertungen

- XR40CX GBDokument4 SeitenXR40CX GBmoosaNoch keine Bewertungen

- XR20C - XR20D: Digital Controller With Off Cycle DefrostDokument4 SeitenXR20C - XR20D: Digital Controller With Off Cycle DefrostJennifer Eszter SárközyNoch keine Bewertungen

- Universal-Xr60Cx: 1. General DescriptionDokument17 SeitenUniversal-Xr60Cx: 1. General DescriptionNikola NikolovNoch keine Bewertungen

- XT120C - XT121C - XT120D - XT121D: Two Stages Digital Controllers With Multi Probe InputDokument4 SeitenXT120C - XT121C - XT120D - XT121D: Two Stages Digital Controllers With Multi Probe InputaliNoch keine Bewertungen

- Dixell 121C ControllerDokument4 SeitenDixell 121C ControllerDorin50% (2)

- Dixell xw260lDokument4 SeitenDixell xw260lMiftakhul KhoirNoch keine Bewertungen

- XR70C - XR70D - XR72C: Installing and Operating InstructionsDokument4 SeitenXR70C - XR70D - XR72C: Installing and Operating InstructionsJennifer Eszter SárközyNoch keine Bewertungen

- XW263LDokument4 SeitenXW263L270cdi aaNoch keine Bewertungen

- XT141C-D GB r1.0 06.03.2007Dokument4 SeitenXT141C-D GB r1.0 06.03.2007Jennifer Eszter SárközyNoch keine Bewertungen

- XW60L VDokument4 SeitenXW60L VGilles LE NOUVELNoch keine Bewertungen

- TAEevo Tech 015 - 1002 Manual enDokument96 SeitenTAEevo Tech 015 - 1002 Manual encarlos quispe laymeNoch keine Bewertungen

- Dixel: Instruction ManualDokument38 SeitenDixel: Instruction ManualDavid SilvaNoch keine Bewertungen

- Freezer&Fridge KeypadDokument21 SeitenFreezer&Fridge Keypadjohnwayne314Noch keine Bewertungen

- Ik3 enDokument7 SeitenIk3 enEsteban Calixto CrisoloNoch keine Bewertungen

- Manual Dixell x120Dokument4 SeitenManual Dixell x120Alejandro AlomotoNoch keine Bewertungen

- Vdocuments - MX Horno Secado Dhg9140a LuzerenDokument8 SeitenVdocuments - MX Horno Secado Dhg9140a LuzerenAdrian Desiderio Mendoza BaureNoch keine Bewertungen

- XC10CX and XC30CX: Digital Controller For CDU ManagementDokument4 SeitenXC10CX and XC30CX: Digital Controller For CDU ManagementJennifer Eszter SárközyNoch keine Bewertungen

- Tec40 User v2Dokument45 SeitenTec40 User v2sebastian100% (1)

- Installing and Operating Instructions: DixelDokument4 SeitenInstalling and Operating Instructions: DixelJennifer Eszter SárközyNoch keine Bewertungen

- Xr70cx RTC GB DixellDokument4 SeitenXr70cx RTC GB DixellTeknik1 sultengNoch keine Bewertungen

- XT220C - XT221C:, Qvwdoolqj DQG 2shudwlqj, QvwuxfwlrqvDokument4 SeitenXT220C - XT221C:, Qvwdoolqj DQG 2shudwlqj, QvwuxfwlrqvJennifer Eszter SárközyNoch keine Bewertungen

- 9IS44315 - ICPlus 902 - EN-IT-ES-DE-FR - 0716Dokument124 Seiten9IS44315 - ICPlus 902 - EN-IT-ES-DE-FR - 0716Nanda KrisbiantoNoch keine Bewertungen

- XR20CX GBDokument4 SeitenXR20CX GBเปลวเพลิง นิรนามNoch keine Bewertungen

- 6rshudwlqjlqvwuxfwlrqv: Multifunction Digital Controller For RefrigerationDokument4 Seiten6rshudwlqjlqvwuxfwlrqv: Multifunction Digital Controller For RefrigerationJennifer Eszter SárközyNoch keine Bewertungen

- ETKL8 3atpDokument15 SeitenETKL8 3atpFrancisco MedinaNoch keine Bewertungen

- Installing and Operating Instructions: DixelDokument4 SeitenInstalling and Operating Instructions: Dixeldorin stoicuNoch keine Bewertungen

- User'S Manual: Portable High Current Test Set Model Number Hc1Dokument17 SeitenUser'S Manual: Portable High Current Test Set Model Number Hc1Victor Jose Romero FernandezNoch keine Bewertungen

- XJM60D: I/O Management ModuleDokument6 SeitenXJM60D: I/O Management ModuleTIAGO LIMANoch keine Bewertungen

- DATAKOM DK40 Installation ManualDokument45 SeitenDATAKOM DK40 Installation ManualVykintas ImbrasasNoch keine Bewertungen

- DataKom 040 USERDokument45 SeitenDataKom 040 USERsebastianNoch keine Bewertungen

- XR80CX: Milk Tank ControllersDokument4 SeitenXR80CX: Milk Tank ControllersArvind WaghNoch keine Bewertungen

- XT110C - XT111C - XT110D - XT111D: Single Stage Digital Controller With Multi Probe InputDokument4 SeitenXT110C - XT111C - XT110D - XT111D: Single Stage Digital Controller With Multi Probe InputJennifer Eszter SárközyNoch keine Bewertungen

- XJM60D EN r1.1 29.11.2013Dokument6 SeitenXJM60D EN r1.1 29.11.2013Jennifer Eszter SárközyNoch keine Bewertungen

- Manual Danfoss Erc211 PDFDokument152 SeitenManual Danfoss Erc211 PDFSanllyNoch keine Bewertungen

- XC10CX and XC30CX: Digital Controller For CDU ManagementDokument5 SeitenXC10CX and XC30CX: Digital Controller For CDU ManagementJennifer Eszter SárközyNoch keine Bewertungen

- Dixell XR40CDokument4 SeitenDixell XR40Cminhdung76np100% (1)

- XR70CX: Digital Controller With Defrost and Fan ManagementDokument5 SeitenXR70CX: Digital Controller With Defrost and Fan ManagementZackyExlipzNoch keine Bewertungen

- Bulletin 4008 Gas Detectors Ver 1.30 O&M Manual Rev 01-17-2011Dokument12 SeitenBulletin 4008 Gas Detectors Ver 1.30 O&M Manual Rev 01-17-2011Docente 361 UMECITNoch keine Bewertungen

- Safety: 1. Stuff You Do Most OftenDokument52 SeitenSafety: 1. Stuff You Do Most OftenGil GarciaNoch keine Bewertungen

- Brivis DRC Inverter ControllerDokument35 SeitenBrivis DRC Inverter ControllerNeamat AliNoch keine Bewertungen

- True :dixell TS InstructionsDokument4 SeitenTrue :dixell TS InstructionsFred Smif100% (1)

- Manual NSGP Plus1 Global TraderDokument26 SeitenManual NSGP Plus1 Global TraderALEJANDRO NOLASCO JUANNoch keine Bewertungen

- XR30C - XR30D: Digital Controller With Off Cycle DefrostDokument4 SeitenXR30C - XR30D: Digital Controller With Off Cycle DefrostJennifer Eszter SárközyNoch keine Bewertungen

- Automatic Controls for Heating and Air Conditioning: Principles and ApplicationsVon EverandAutomatic Controls for Heating and Air Conditioning: Principles and ApplicationsBewertung: 4 von 5 Sternen4/5 (2)

- Data Sheet 6ES7417-4XL04-0AB0: General InformationDokument10 SeitenData Sheet 6ES7417-4XL04-0AB0: General InformationvishadkapadiaNoch keine Bewertungen

- DatasheetDokument1 SeiteDatasheetvishadkapadiaNoch keine Bewertungen

- Product Data Sheet: Alarmline II Analogue LHD Cable W/ PVC Sheath, 100mDokument2 SeitenProduct Data Sheet: Alarmline II Analogue LHD Cable W/ PVC Sheath, 100mvishadkapadiaNoch keine Bewertungen

- Data Sheet 6ES7952-1AM00-0AA0: MemoryDokument1 SeiteData Sheet 6ES7952-1AM00-0AA0: MemoryvishadkapadiaNoch keine Bewertungen

- Aacusp: Product Data SheetDokument2 SeitenAacusp: Product Data SheetvishadkapadiaNoch keine Bewertungen

- Translation of Figure Captions EtcDokument5 SeitenTranslation of Figure Captions EtcvishadkapadiaNoch keine Bewertungen

- By Pass Rotameter PDFDokument6 SeitenBy Pass Rotameter PDFvishadkapadiaNoch keine Bewertungen

- PID110 Temprature ControllersDokument2 SeitenPID110 Temprature ControllersvishadkapadiaNoch keine Bewertungen

- Converter, Inverter, Brake: SKIIP 12NAB126V1Dokument4 SeitenConverter, Inverter, Brake: SKIIP 12NAB126V1vishadkapadiaNoch keine Bewertungen

- DS Gas Lab Q1 ENDokument2 SeitenDS Gas Lab Q1 ENvishadkapadiaNoch keine Bewertungen

- DSFG Gateways C1 and C2 Series 2: Technical Documentation Function, Operation, Commissioning and MaintenanceDokument54 SeitenDSFG Gateways C1 and C2 Series 2: Technical Documentation Function, Operation, Commissioning and MaintenancevishadkapadiaNoch keine Bewertungen

- Installing and Configuring The MBSerial DA ServerDokument9 SeitenInstalling and Configuring The MBSerial DA ServervishadkapadiaNoch keine Bewertungen

- Whitepaper Repair Hydr ActuatorsDokument6 SeitenWhitepaper Repair Hydr ActuatorsvishadkapadiaNoch keine Bewertungen

- Hygiene Gauges - 100mm & 150mm DialDokument4 SeitenHygiene Gauges - 100mm & 150mm DialvishadkapadiaNoch keine Bewertungen

- Manual n2000 v30x H EnglishDokument11 SeitenManual n2000 v30x H EnglishvishadkapadiaNoch keine Bewertungen

- 3RN10112CB00 Datasheet en PDFDokument3 Seiten3RN10112CB00 Datasheet en PDFvishadkapadiaNoch keine Bewertungen

- 6826 Gruhn SafetyDokument28 Seiten6826 Gruhn SafetyvishadkapadiaNoch keine Bewertungen

- FDT/DTM Framework For New Field Device Tools: TAKEUCHI TetsuoDokument4 SeitenFDT/DTM Framework For New Field Device Tools: TAKEUCHI TetsuovishadkapadiaNoch keine Bewertungen

- Specify The Right Solution For Vacuum Applications: Technical NoteDokument4 SeitenSpecify The Right Solution For Vacuum Applications: Technical NotevishadkapadiaNoch keine Bewertungen

- 300W 3RU DC-DC Converter Brochure With DistributionDokument4 Seiten300W 3RU DC-DC Converter Brochure With DistributionvishadkapadiaNoch keine Bewertungen

- Wonderware InTouch 10.1 Readme PDFDokument10 SeitenWonderware InTouch 10.1 Readme PDFvishadkapadiaNoch keine Bewertungen

- Refillable PH Probe: Model PHC30101 or PHC30103: Safety InformationDokument14 SeitenRefillable PH Probe: Model PHC30101 or PHC30103: Safety InformationvishadkapadiaNoch keine Bewertungen

- Television: Operating InstructionsDokument2 SeitenTelevision: Operating InstructionsvishadkapadiaNoch keine Bewertungen

- Specifying FDT Technology: Putting Your Assets To Work!Dokument6 SeitenSpecifying FDT Technology: Putting Your Assets To Work!vishadkapadiaNoch keine Bewertungen

- Cause List 2.1.2023Dokument4 SeitenCause List 2.1.2023あいうえおかきくけこNoch keine Bewertungen

- DbmsDokument5 SeitenDbmsRohit KushwahaNoch keine Bewertungen

- Iso 16232 10 2007 en PDFDokument8 SeitenIso 16232 10 2007 en PDFyağmurNoch keine Bewertungen

- PC2000-8 Spec SheetDokument20 SeitenPC2000-8 Spec SheetNeeraj ChauhanNoch keine Bewertungen

- Proac Studio 100: Monitor Level Performance From An Established Compact DesignDokument2 SeitenProac Studio 100: Monitor Level Performance From An Established Compact DesignAnonymous c3vuAsWANoch keine Bewertungen

- Ofsaai Ic 72 E22351 01Dokument312 SeitenOfsaai Ic 72 E22351 01Mohamed AbrarNoch keine Bewertungen

- MAPEH-Arts: Quarter 3 - Module 2Dokument24 SeitenMAPEH-Arts: Quarter 3 - Module 2Girlie Oguan LovendinoNoch keine Bewertungen

- Introduction of Woman Role in SocietyDokument12 SeitenIntroduction of Woman Role in SocietyApple DogNoch keine Bewertungen

- Bo Sanchez-Turtle Always Wins Bo SanchezDokument31 SeitenBo Sanchez-Turtle Always Wins Bo SanchezCristy Louela Pagapular88% (8)

- GTAG-14 Edited With Ad 05-20-20101 PDFDokument32 SeitenGTAG-14 Edited With Ad 05-20-20101 PDFpiornelNoch keine Bewertungen

- WTSDA2021 TSDBlack Belt ManualDokument160 SeitenWTSDA2021 TSDBlack Belt ManualJesus HernandezNoch keine Bewertungen

- Volcanic SoilsDokument14 SeitenVolcanic SoilsVictor Hugo BarbosaNoch keine Bewertungen

- The Senior High School in The Phillipines: The Way To The WorldDokument5 SeitenThe Senior High School in The Phillipines: The Way To The WorldRodel Ramos DaquioagNoch keine Bewertungen

- Procedure For Non Hazardous Waste ManagementDokument6 SeitenProcedure For Non Hazardous Waste ManagementPaddyNoch keine Bewertungen

- Auditing BasicsDokument197 SeitenAuditing BasicsMajanja AsheryNoch keine Bewertungen

- Operations Management Stevenson 11th Edition Test BankDokument10 SeitenOperations Management Stevenson 11th Edition Test BankAries Gonzales Caragan50% (2)

- FBDokument27 SeitenFBBenjaminNoch keine Bewertungen

- Curriculum Vitae: Career ObjectiveDokument3 SeitenCurriculum Vitae: Career ObjectiveRākesh Rakhi100% (1)

- Environmental and Chemical Policy Module3Dokument47 SeitenEnvironmental and Chemical Policy Module3jahazi1Noch keine Bewertungen

- Calculating Staff Strength:: Find Latest Hospitality Resources atDokument8 SeitenCalculating Staff Strength:: Find Latest Hospitality Resources atPriyanjali SainiNoch keine Bewertungen

- ISA Guidelines PPF 1Dokument19 SeitenISA Guidelines PPF 1Vasu DevanNoch keine Bewertungen

- Chemistry Previos Papaer 313Dokument19 SeitenChemistry Previos Papaer 313Ashu GuptaNoch keine Bewertungen

- 2012 Karshaniya YavaguDokument4 Seiten2012 Karshaniya YavaguRANJEET SAWANTNoch keine Bewertungen

- 4040 SERIES: Hinge (Pull Side) (Shown) Top Jamb (Push Side) Parallel Arm (Push Side)Dokument11 Seiten4040 SERIES: Hinge (Pull Side) (Shown) Top Jamb (Push Side) Parallel Arm (Push Side)Melrose FabianNoch keine Bewertungen

- Bach Polonaise G Min BWV 119 A4Dokument1 SeiteBach Polonaise G Min BWV 119 A4vincenzovaiaNoch keine Bewertungen

- Differentiating Language Difference and Language Disorder - Information For Teachers Working With English Language Learners in The Schools PDFDokument23 SeitenDifferentiating Language Difference and Language Disorder - Information For Teachers Working With English Language Learners in The Schools PDFIqra HassanNoch keine Bewertungen

- Ericsson AXE 810: Switch (ROTD)Dokument4 SeitenEricsson AXE 810: Switch (ROTD)Kao Sun HoNoch keine Bewertungen

- Lay Planning TypesDokument1 SeiteLay Planning TypesGaurav Shakya100% (1)