Beruflich Dokumente

Kultur Dokumente

Hyundai electric cable specification and installation

Hochgeladen von

Tee Ping Hong0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

27 Ansichten1 SeiteThe document discusses electrical cable specifications and installation requirements. It states that cables must be rated to carry the total connected load while maintaining permissible voltage drop. Cable installation must comply with the requirements of this specification and the builder's approved electrical practice. Cable manufacturers must be on a preferred list agreed by the purchaser and builder, and cable specifications, installation, testing and tagging procedures must be approved.

Originalbeschreibung:

Cable spec

Originaltitel

Cable

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe document discusses electrical cable specifications and installation requirements. It states that cables must be rated to carry the total connected load while maintaining permissible voltage drop. Cable installation must comply with the requirements of this specification and the builder's approved electrical practice. Cable manufacturers must be on a preferred list agreed by the purchaser and builder, and cable specifications, installation, testing and tagging procedures must be approved.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

27 Ansichten1 SeiteHyundai electric cable specification and installation

Hochgeladen von

Tee Ping HongThe document discusses electrical cable specifications and installation requirements. It states that cables must be rated to carry the total connected load while maintaining permissible voltage drop. Cable installation must comply with the requirements of this specification and the builder's approved electrical practice. Cable manufacturers must be on a preferred list agreed by the purchaser and builder, and cable specifications, installation, testing and tagging procedures must be approved.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

HYUNDAI

10 - 4

10.1.3 ELECTRIC CABLES AND INSTALLATION

Cables must be sufficiently rated to carry the total connected load

considering the permissible voltage drop.

All cables to be installed in accordance with requirements of this

specification, the Class and the Builder's practice.

Builder’s practice must comply with the requirements of this specification,

and the Builder will submit “Electrical Practice” for approval before

installation is commenced.

Manufacturer of cables to be listed in the preferred maker list and mutually

agreed by Purchaser and Builder at contractual stage. The detail

specification of the cables, certification by Class, installation practice, testing

procedure and tagging system to be submitted to Purchaser for review and

approval. Installation inspection, testing and confirmation of tagging (at both

end) to be attended by Purchaser. Cable specification, record of tagging,

compilation of test record (if relevant) etc., to be included in the finished plan.

10.1.3.1 CABLE SPECIFICATION

*** Electric cable in general to be of HIS (High-quality IEC base simplified

Standard) marine cable, low smoke, low toxic emission type and enhanced oil

resistant type, oil resistance condition 100% x 96h and tested by IEEE 1580

Para 5.17.8) and flame retardant type tested according to IEC 60332-1 &

60332-3 Category A, which has been approved by Classification Society,

except special cable.

Current rating of cables to be at least 125% of the maximum current carried

under normal circumstances, to ensure that the voltage drop at the consumer

is less than 6% except for DC circuits which not to exceed 10% of the

nominal voltage.

Detailed specifications covering construction, installation and termination

methods to be submitted for Purchaser’s approval in respect of all cables

carrying voltages above 1000V and all cables intended for cryogenic service.

All cable routes to be carefully selected in order to minimize the adverse

effects of heat and moisture and those exposed to mechanical damage to be

suitably protected.

Cables on the open deck or passing through cofferdams to be installed in

glass reinforced plastic (GRP) pipe or trunks with sealed end boxes. Builder

can propose an alternative cable way or covered cable tray made of SUS

316. The supports of this alternative cable way or cable tray to be of SUS

316 and the height above deck to be 300mm.

Blue sheathed cables to be used for all cables for intrinsically safe circuits

and these to be run separate from non-IS cables.

All cables in the cargo machinery room to be located at least 300 mm above

floor plate level except cables which are directly come from bottom deck to

equipment.

All cable supplied by yard to be guaranteed for at least five (5) years.

LNMI150M(UST)-FS-P2-R7(Final)

Das könnte Ihnen auch gefallen

- MV and LV cable technical requirementsDokument5 SeitenMV and LV cable technical requirementsFor AppsNoch keine Bewertungen

- Wires and CablesDokument7 SeitenWires and CablessallammohamedNoch keine Bewertungen

- Npcil TSDokument10 SeitenNpcil TSBhavesh KeraliaNoch keine Bewertungen

- Medium Voltage Cable SpecDokument3 SeitenMedium Voltage Cable SpecOanh NguyenNoch keine Bewertungen

- Medium Voltage CablesDokument12 SeitenMedium Voltage Cableswafikmh4Noch keine Bewertungen

- 11.ACMV (Electrical) PDFDokument22 Seiten11.ACMV (Electrical) PDFIswadi Bin Zulkarnain100% (1)

- Insulator: PackingDokument8 SeitenInsulator: PackingZeeshan SubhaniNoch keine Bewertungen

- Insulator: PackingDokument8 SeitenInsulator: PackingZeeshan SubhaniNoch keine Bewertungen

- Part 10 Electrical Installations U15m CoDokument21 SeitenPart 10 Electrical Installations U15m CoIsaac ChitavatiNoch keine Bewertungen

- 1.1Kv Grade Power and Control Cables: SectionDokument9 Seiten1.1Kv Grade Power and Control Cables: SectionevjbalaNoch keine Bewertungen

- 16126Dokument13 Seiten16126uddinnadeemNoch keine Bewertungen

- TES-P-104.04-R0 Splices and Termination of Power CablesDokument9 SeitenTES-P-104.04-R0 Splices and Termination of Power CablesSalmanEjazNoch keine Bewertungen

- Technical Specifications For Aerial BunchedDokument5 SeitenTechnical Specifications For Aerial BunchedNazriNoch keine Bewertungen

- Medium Voltage Cable Installation StandardsDokument5 SeitenMedium Voltage Cable Installation Standardsesoares1990Noch keine Bewertungen

- Installation and Testing of Low-Voltage BuswaysDokument5 SeitenInstallation and Testing of Low-Voltage BuswaysuddinnadeemNoch keine Bewertungen

- Tech SpecificationsDokument47 SeitenTech Specificationssureshn829Noch keine Bewertungen

- Texas AM MV SpecificationDokument11 SeitenTexas AM MV SpecificationDavid BurgessNoch keine Bewertungen

- HT Cable RFQ Specifications PDFDokument7 SeitenHT Cable RFQ Specifications PDFAshil ThomasNoch keine Bewertungen

- SECTION 16126 Cables, High Voltage (Above 600 Volts) Part 1 - General 1.1 DescriptionDokument11 SeitenSECTION 16126 Cables, High Voltage (Above 600 Volts) Part 1 - General 1.1 Descriptionno nameNoch keine Bewertungen

- clark-public-utilities-ICEA S-94-649-AEIC CS8Dokument21 Seitenclark-public-utilities-ICEA S-94-649-AEIC CS8chrisNoch keine Bewertungen

- 12 SDMS 01rev1Dokument16 Seiten12 SDMS 01rev1sardarmkhanNoch keine Bewertungen

- Instrument Signal LineDokument62 SeitenInstrument Signal Linedewking198875% (4)

- 3D MV Cables SpecificationDokument10 Seiten3D MV Cables SpecificationPraveen KumarNoch keine Bewertungen

- XLPE Power Cable 11 & 33 KVDokument9 SeitenXLPE Power Cable 11 & 33 KVArjun M KumarNoch keine Bewertungen

- SEWA Regulations For Electrical ConnectionDokument5 SeitenSEWA Regulations For Electrical Connectionkidscv10Noch keine Bewertungen

- 06 Ele SpesificationDokument36 Seiten06 Ele Spesificationgreenicez10Noch keine Bewertungen

- Specification For Power Control & Earthing Cables PDFDokument17 SeitenSpecification For Power Control & Earthing Cables PDFg1kumar04100% (1)

- 16123-Wires and Cables For 600V CircuitsDokument5 Seiten16123-Wires and Cables For 600V Circuitstristan guarinoNoch keine Bewertungen

- Instrument Signal LineDokument62 SeitenInstrument Signal LineMerkoNoch keine Bewertungen

- B-03 LT Power CablesDokument8 SeitenB-03 LT Power Cablesrahul patraNoch keine Bewertungen

- Technical Specification For Aac / Acsr ConductorsDokument8 SeitenTechnical Specification For Aac / Acsr ConductorsDeepeshMaliNoch keine Bewertungen

- 14 +al-59+zebra+equivalent+conductor PDFDokument17 Seiten14 +al-59+zebra+equivalent+conductor PDFSandeep DhingraNoch keine Bewertungen

- EIL 6-51-0051 Rev. 6Dokument10 SeitenEIL 6-51-0051 Rev. 6Manish Sharma100% (1)

- XLPE Cable Technical SpecificationDokument18 SeitenXLPE Cable Technical SpecificationSandipNanawareNoch keine Bewertungen

- 4/11/2021 /conversion/tmp/scratch/518123760Dokument10 Seiten4/11/2021 /conversion/tmp/scratch/518123760DenyNoch keine Bewertungen

- CODES & STANDARDS FOR CABLESDokument4 SeitenCODES & STANDARDS FOR CABLESMutharasan VishnuNoch keine Bewertungen

- Control Cables SpecDokument15 SeitenControl Cables SpecnatbalNoch keine Bewertungen

- DEWA Instrumentation Cable SpecsDokument12 SeitenDEWA Instrumentation Cable SpecsFlavioNoch keine Bewertungen

- Tech - Spec. 1.1KV Grade Control Cable-2008Dokument4 SeitenTech - Spec. 1.1KV Grade Control Cable-2008Pratik SarkarNoch keine Bewertungen

- Sec-09 Electrical Works and InstallationDokument6 SeitenSec-09 Electrical Works and InstallationOmer HayatNoch keine Bewertungen

- EPR Insulated EVA Sheathed Copper Cable NPCIL SpecificationDokument23 SeitenEPR Insulated EVA Sheathed Copper Cable NPCIL SpecificationVarun ThakurNoch keine Bewertungen

- Ddugjy 3 Phase DTsDokument32 SeitenDdugjy 3 Phase DTspraveenkumarNoch keine Bewertungen

- 12SDMS01Dokument14 Seiten12SDMS01hafezasadNoch keine Bewertungen

- Literature ReviewDokument2 SeitenLiterature ReviewJanaka JayakodyNoch keine Bewertungen

- Bus Duct Technical SpecificationsDokument15 SeitenBus Duct Technical SpecificationsAshish Mulik100% (1)

- Safety For Wiring Methods: By: Komarul FausiyahDokument16 SeitenSafety For Wiring Methods: By: Komarul FausiyahJeffrey ArandiaNoch keine Bewertungen

- Powell Electrical Systems, Inc. Guide Specification: Low and Medium Voltage Metal-Enclosed Cable BusDokument4 SeitenPowell Electrical Systems, Inc. Guide Specification: Low and Medium Voltage Metal-Enclosed Cable BuslongnguyenNoch keine Bewertungen

- Section-6 Chapter-1 Part-I Technical Specification For 66 KV (Cross Linked Polyethylene Insulated Power Cable: 1.1 SCOPEDokument5 SeitenSection-6 Chapter-1 Part-I Technical Specification For 66 KV (Cross Linked Polyethylene Insulated Power Cable: 1.1 SCOPESandeep SharmaNoch keine Bewertungen

- Package SubstationDokument9 SeitenPackage SubstationuddinnadeemNoch keine Bewertungen

- MV Cable InstallationDokument10 SeitenMV Cable Installationjesus marquez arvaezNoch keine Bewertungen

- FEWA LV Joints & TerminationsDokument13 SeitenFEWA LV Joints & TerminationsMuhammad RazaNoch keine Bewertungen

- Sandwhich BusductDokument5 SeitenSandwhich BusductHarmandeep Ahluwalia100% (1)

- 16122-Power Cable Rated 15kV Copper Tape ShieldedDokument3 Seiten16122-Power Cable Rated 15kV Copper Tape Shieldedrafael velardeNoch keine Bewertungen

- Power Transformer Manual PDFDokument82 SeitenPower Transformer Manual PDFamulya00428Noch keine Bewertungen

- 3 9031-11KV-Composite Polymer - Disc-Insulator Specifications GTPDokument24 Seiten3 9031-11KV-Composite Polymer - Disc-Insulator Specifications GTPAnonymous 4kYNmixNoch keine Bewertungen

- Intruduction Final LVDokument37 SeitenIntruduction Final LVmealysrNoch keine Bewertungen

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

- Insulation Co-ordination in High-voltage Electric Power SystemsVon EverandInsulation Co-ordination in High-voltage Electric Power SystemsBewertung: 4.5 von 5 Sternen4.5/5 (5)

- W W W W W W: February March JanuaryDokument2 SeitenW W W W W W: February March JanuaryTee Ping HongNoch keine Bewertungen

- PI WorkshopDokument1 SeitePI WorkshopTee Ping HongNoch keine Bewertungen

- Energy Management: Programme Structure and Modules by SemesterDokument2 SeitenEnergy Management: Programme Structure and Modules by SemesterTee Ping HongNoch keine Bewertungen

- OMTS Telemetry SystemDokument2 SeitenOMTS Telemetry SystemTee Ping HongNoch keine Bewertungen

- Benoi Yard Layout GuideDokument1 SeiteBenoi Yard Layout GuideTee Ping HongNoch keine Bewertungen

- TemBreak MCCB operating characteristicsDokument24 SeitenTemBreak MCCB operating characteristicsTee Ping HongNoch keine Bewertungen

- Simlab 2Dokument85 SeitenSimlab 2Wilson BotchaNoch keine Bewertungen

- Performance of A Small Wind Powered Water Pumping SystemDokument13 SeitenPerformance of A Small Wind Powered Water Pumping SystemKhaled AbdusamadNoch keine Bewertungen

- Electric Fields and Magnetism - Practice TestDokument5 SeitenElectric Fields and Magnetism - Practice Testharkeerat singhNoch keine Bewertungen

- Substation Main Functions and Classification - EEPDokument6 SeitenSubstation Main Functions and Classification - EEPAbhishek DasNoch keine Bewertungen

- Electric Wire Winch Operation ManualDokument43 SeitenElectric Wire Winch Operation ManualPedro Estay OlivaresNoch keine Bewertungen

- Try Test 1Dokument6 SeitenTry Test 1Theophilus AmponsahNoch keine Bewertungen

- Operation PDFDokument64 SeitenOperation PDFArjunroyEdwardNoch keine Bewertungen

- 2.IR Wireless Underwater Communication SystemDokument4 Seiten2.IR Wireless Underwater Communication SystemRamsathaya71% (7)

- Selpact To Masterpact PDFDokument2 SeitenSelpact To Masterpact PDFDave PotterNoch keine Bewertungen

- Electrical Data: (Basta)Dokument2 SeitenElectrical Data: (Basta)Anonymous ZlPONG100% (2)

- 003 Meteostation - X-Serie - Outdoor - en - V1 - 00 - PN818031Dokument21 Seiten003 Meteostation - X-Serie - Outdoor - en - V1 - 00 - PN818031cristobal valderramaNoch keine Bewertungen

- St. Louis Review Center TLE Basic Electricity GuideDokument16 SeitenSt. Louis Review Center TLE Basic Electricity GuideWilson AgustinNoch keine Bewertungen

- Hm-Dcmo-Ul DS 081902Dokument2 SeitenHm-Dcmo-Ul DS 081902Mickie MayorNoch keine Bewertungen

- Edm PowerexplanationDokument8 SeitenEdm Powerexplanationapi-3711466Noch keine Bewertungen

- Power Electronics Concept in Power SystemsDokument9 SeitenPower Electronics Concept in Power SystemsT.l. SelvamNoch keine Bewertungen

- Electric Equipment Proposal: A Solution Beyond The ElectricityDokument56 SeitenElectric Equipment Proposal: A Solution Beyond The ElectricityJermaine PeñaNoch keine Bewertungen

- Output Module FCM-1Dokument2 SeitenOutput Module FCM-1Irwan RamdaniNoch keine Bewertungen

- Aic23 DatasheetDokument44 SeitenAic23 DatasheetBalacescu ClaudiuNoch keine Bewertungen

- Targa Instruction ManualDokument18 SeitenTarga Instruction ManualPedro Elias SantanaNoch keine Bewertungen

- Olution AnualDokument207 SeitenOlution Anualmrgummy2013Noch keine Bewertungen

- Ep1c Manual-EnDokument120 SeitenEp1c Manual-Encarlos alfonso calderonNoch keine Bewertungen

- Effect of Change in Frequency On Operation and Performance of Three Phase Induction MotorDokument4 SeitenEffect of Change in Frequency On Operation and Performance of Three Phase Induction MotorIDES100% (1)

- AQR Daughter Board (HTG - AQRDBa)Dokument9 SeitenAQR Daughter Board (HTG - AQRDBa)William PeeleNoch keine Bewertungen

- Operacion PMMDokument28 SeitenOperacion PMMalio0oNoch keine Bewertungen

- Effective Properties of Carbon Fiber CompositesDokument6 SeitenEffective Properties of Carbon Fiber CompositesMladenNoch keine Bewertungen

- L&T Electrical & Automation: (+VE) (-VE) (+VE) (-VE)Dokument1 SeiteL&T Electrical & Automation: (+VE) (-VE) (+VE) (-VE)Sivachandran RNoch keine Bewertungen

- Guide For Application of IEC 62271-100 AND IEC 62271-1: Making and Breaking TestsDokument186 SeitenGuide For Application of IEC 62271-100 AND IEC 62271-1: Making and Breaking TestsJosé Alejandro RangelNoch keine Bewertungen

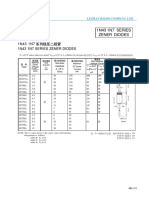

- 1N43 1N7 1N43 1N7 Series Zener DiodesDokument2 Seiten1N43 1N7 1N43 1N7 Series Zener DiodesAllan Souza SantanaNoch keine Bewertungen

- Ion Source Operation ManualDokument19 SeitenIon Source Operation ManualPitarsaNoch keine Bewertungen

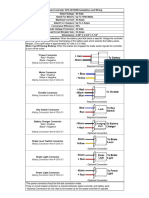

- SPD-481000B Installation and WiringDokument2 SeitenSPD-481000B Installation and WiringMNoch keine Bewertungen