Beruflich Dokumente

Kultur Dokumente

4597-AAB-SC-09 R0v1 28

Hochgeladen von

danieldumapitOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

4597-AAB-SC-09 R0v1 28

Hochgeladen von

danieldumapitCopyright:

Verfügbare Formate

One Za'abeel | 4597-AAB-SC-09

4-3 Typical End Mullion Bracket.xmct

Section Page 5 of 17

Design and Engineering Dept.

______________________________________________________________________________________________________________________________

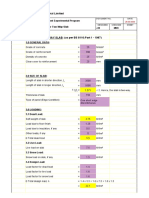

Code Based Checking BS 5950 Sec on 6.3.3.2 / 6.3.3.3

( )

ρ bb := 0.7 Ub + Yb = 805.00⋅ MPa

ρ bs := 0.67( Us + Ys) = 472.35⋅ MPa

k bs := 1.0

Ρbs_f := ϕ⋅ tp⋅ ρ bb = 128.80⋅ kN ← Design Bearing Resistance of Fastener

( )

Ρbs_cm := min k bs⋅ ϕ⋅ tp⋅ ρ bs , 0.5k bs edf⋅ tp⋅ ρ bs = 75.58⋅ kN ← Design Bearing Resistance of Connected Material

(

Ρbsc := min Ρbs_f , Ρbs_cm = 75.58⋅ kN ) ← Design Bearing Resistance of Connec on

Design Criteria : F bs ≤ Ρbsc Code Check : Safe! ; Utilization Ratio = 7.60%

▄▄▄

⌂ This subsec on verifies the tensile failure of bolt material in axial loading.

≡

Design Parameters / Analysis

nf = 2.00

edf := 50.00⋅ mm

Direct Tensile Force per Fastener

Pzf_d := F3 ÷ nf = 0.00⋅ kN

Tensile Force Due to Moment

Pzf_m1 := 0.00⋅ kN

( )

Pzf_m2 := M2 ÷ 2 ÷ 3⋅ edf ÷ nf = 11.60⋅ kN

PR f := Pzf_d + Pzf_m1 + Pzf_m2 = 11.60⋅ kN ← Design Tensile Force on the Most

Stressed Fastener

Code Based Checking BS 8118 Sec on 6.4.3

γm := 1.2

( )

ρ f := min 0.50 Yb + Ub , 1.2⋅ Yb = 540.00⋅ MPa ← Limi ng Stress of Fastener

αt := 1.0 Note: For steel/stainless steel bolts

αt⋅ ρ f⋅ As ← Design Tensile Resistance of Fastener

PRTf := = 70.50⋅ kN Material

γm

Design Criteria : PR f ≤ PRTf Code Check : Safe! ; Utilization Ratio = 16.45%

▄▄▄

⌂ This subsec on verifies the combined shear and tensile failure of bolt material.

≡

Code Based Checking BS 8118 Sec on 6.4.5

Combined Stress Ra o

Design Criteria : 2 2

VRf PR f Code Check : Safe! ; Utilization Ratio = 4.58%

▄▄▄

+ ≤ 1.0

VRSf PRTf

≡

28 of 72

TempVer20.0_012018 | Engineer: D. Dumapit | Checked: S.M. Lomboy Jr.

Das könnte Ihnen auch gefallen

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionVon EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNoch keine Bewertungen

- 4597-AAB-SC-09 R0v1 33Dokument1 Seite4597-AAB-SC-09 R0v1 33danieldumapitNoch keine Bewertungen

- 4597-AAB-SC-09 R0v1 34Dokument1 Seite4597-AAB-SC-09 R0v1 34danieldumapitNoch keine Bewertungen

- 4597-AAB-SC-09 R0v1 27Dokument1 Seite4597-AAB-SC-09 R0v1 27danieldumapitNoch keine Bewertungen

- 4597-AAB-SC-09 R0v1 32Dokument1 Seite4597-AAB-SC-09 R0v1 32danieldumapitNoch keine Bewertungen

- 4597-AAB-SC-09 R0v1 29Dokument1 Seite4597-AAB-SC-09 R0v1 29danieldumapitNoch keine Bewertungen

- 4597-AAB-SC-09 R0v1 31Dokument1 Seite4597-AAB-SC-09 R0v1 31danieldumapitNoch keine Bewertungen

- 4597-AAB-SC-09 R0v1 40Dokument1 Seite4597-AAB-SC-09 R0v1 40danieldumapitNoch keine Bewertungen

- 4597-AAB-SC-09 R0v1 36Dokument1 Seite4597-AAB-SC-09 R0v1 36danieldumapitNoch keine Bewertungen

- 4597-AAB-SC-09 R0v1 37Dokument1 Seite4597-AAB-SC-09 R0v1 37danieldumapitNoch keine Bewertungen

- 4597-AAB-SC-09 R0v1 35Dokument1 Seite4597-AAB-SC-09 R0v1 35danieldumapitNoch keine Bewertungen

- Glass Check 550mm X 1550mmDokument7 SeitenGlass Check 550mm X 1550mmAniket InarkarNoch keine Bewertungen

- Design of Steel I-Section (BS5950)Dokument3 SeitenDesign of Steel I-Section (BS5950)gertjaniNoch keine Bewertungen

- Inverted-T Capacity Calculation@Phase1v2Dokument11 SeitenInverted-T Capacity Calculation@Phase1v2satyaNoch keine Bewertungen

- ACI 318M-11 RC Bracket and Corbel Design - v0.03 - 2017-04-10Dokument5 SeitenACI 318M-11 RC Bracket and Corbel Design - v0.03 - 2017-04-10arken123Noch keine Bewertungen

- Design Example - Bonded AnchorsDokument6 SeitenDesign Example - Bonded AnchorsmetropodikasNoch keine Bewertungen

- 6 Verification On Anchor Bolt: References CalculationsDokument1 Seite6 Verification On Anchor Bolt: References CalculationsAzahar Bin HashimNoch keine Bewertungen

- Base Plate TopDokument7 SeitenBase Plate TopUpendra WalinjkarNoch keine Bewertungen

- Inspection of Bolt Connection For BearingDokument3 SeitenInspection of Bolt Connection For Bearinghoang KhieuNoch keine Bewertungen

- Plenary Paper No 2 - KC TsaiDokument67 SeitenPlenary Paper No 2 - KC TsaikrtNoch keine Bewertungen

- Appendix A5Dokument4 SeitenAppendix A5Thomas StephenNoch keine Bewertungen

- Isolated Foundation Calculation (ACI) : CheckingDokument2 SeitenIsolated Foundation Calculation (ACI) : CheckingSher AfganNoch keine Bewertungen

- VMH AnchorDokument4 SeitenVMH Anchormohamed rafiNoch keine Bewertungen

- Corbel Design Using Strut and Tie Method and According To AS3600Dokument3 SeitenCorbel Design Using Strut and Tie Method and According To AS3600Jay Ryan SantosNoch keine Bewertungen

- Padeye DesignDokument32 SeitenPadeye DesignMuhammad Iqbal100% (1)

- Single Tension Fastener Away From Edges Based On ACI 318-02Dokument2 SeitenSingle Tension Fastener Away From Edges Based On ACI 318-02civixxNoch keine Bewertungen

- Plate Girder Design ExampleDokument14 SeitenPlate Girder Design ExampleWaleed KhalidNoch keine Bewertungen

- Design of Square HSS in Combined Axial Compression and Biaxial FlexureDokument12 SeitenDesign of Square HSS in Combined Axial Compression and Biaxial FlexureJorge Vega JNoch keine Bewertungen

- Software Verification: AISC DG02 Example 001Dokument5 SeitenSoftware Verification: AISC DG02 Example 001f tshNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 32Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 32danieldumapitNoch keine Bewertungen

- Handrail Coring Check (Calculation)Dokument56 SeitenHandrail Coring Check (Calculation)Rey GonzalesNoch keine Bewertungen

- ReportDokument9 SeitenReportShafeeq KTNoch keine Bewertungen

- S.No Description Page No 1 Load Calculations 1 To 3 2 Anchor Bolt Design 4 To 17 3 Star Column Design 18 To 27 4 Deflection Check 28Dokument29 SeitenS.No Description Page No 1 Load Calculations 1 To 3 2 Anchor Bolt Design 4 To 17 3 Star Column Design 18 To 27 4 Deflection Check 28Chandrasekhar ReddyNoch keine Bewertungen

- Design of BeamDokument14 SeitenDesign of BeamheheloveNoch keine Bewertungen

- Gantry ExampleDokument4 SeitenGantry ExamplechrisNoch keine Bewertungen

- Design of Coping Beam (Portal) : A. Basic DataDokument7 SeitenDesign of Coping Beam (Portal) : A. Basic DataUzziel Abib GabiolaNoch keine Bewertungen

- JEROME M. GUETA QUIZ 3 - Advance Steel DesignDokument105 SeitenJEROME M. GUETA QUIZ 3 - Advance Steel DesignJerome M. GuetaNoch keine Bewertungen

- ShearkeyDokument3 SeitenShearkeyRama Subramanyam ManepalliNoch keine Bewertungen

- AISC360-16 LRFD Check of Single Plate Shear Connection - Rev 0.02 - 2017!11!17Dokument9 SeitenAISC360-16 LRFD Check of Single Plate Shear Connection - Rev 0.02 - 2017!11!17Vietanh PhungNoch keine Bewertungen

- ShearReinfCalc01 09 07Dokument6 SeitenShearReinfCalc01 09 07n5i4s3h2a1Noch keine Bewertungen

- AISC360-16 LRFD Check of Single Plate Shear Connection - Rev 0.02 - 2017!11!17Dokument9 SeitenAISC360-16 LRFD Check of Single Plate Shear Connection - Rev 0.02 - 2017!11!17Vietanh PhungNoch keine Bewertungen

- Alr - ACI Presentation 4-02Dokument24 SeitenAlr - ACI Presentation 4-02Marcos LópezNoch keine Bewertungen

- Two Way Slab Design.Dokument9 SeitenTwo Way Slab Design.tuansteelsNoch keine Bewertungen

- Mathcad - Column Base Plate CheckDokument12 SeitenMathcad - Column Base Plate CheckValentinNoch keine Bewertungen

- ACI 318M-11 RC Beam Ledge Design - v0.04 - 2020-07-23Dokument5 SeitenACI 318M-11 RC Beam Ledge Design - v0.04 - 2020-07-23Vietanh PhungNoch keine Bewertungen

- Villanueva Residence - Two-Way Slab Design S3 PDFDokument11 SeitenVillanueva Residence - Two-Way Slab Design S3 PDFMcKen FloresNoch keine Bewertungen

- Position 2 - HZA 4127Dokument10 SeitenPosition 2 - HZA 4127mapuphamNoch keine Bewertungen

- Aisc Asd-89 Example 001Dokument5 SeitenAisc Asd-89 Example 001gusla7Noch keine Bewertungen

- Etabs 2016 16.2Dokument6 SeitenEtabs 2016 16.2kervinarmasNoch keine Bewertungen

- ACI 318M-11 RC Bracket and Corbel Design - v0.03 - 2017!04!10Dokument11 SeitenACI 318M-11 RC Bracket and Corbel Design - v0.03 - 2017!04!10Muhammad Imran ZafarNoch keine Bewertungen

- Diagonal MemDokument2 SeitenDiagonal MemchannajayamangalaNoch keine Bewertungen

- Basic Design Parameters:: Loads: 1 1Dokument9 SeitenBasic Design Parameters:: Loads: 1 1ahmedhusseinkamelNoch keine Bewertungen

- Ii. Analysis and Design Verifica On: A) Connec On On Typical MullionDokument1 SeiteIi. Analysis and Design Verifica On: A) Connec On On Typical MulliondanieldumapitNoch keine Bewertungen

- BRBFDokument5 SeitenBRBFtonyNoch keine Bewertungen

- Natural Bend Radius Cal Rev. C PDFDokument3 SeitenNatural Bend Radius Cal Rev. C PDFhamid sobirin100% (2)

- 21 Lifting Lugs - CalculatorDokument3 Seiten21 Lifting Lugs - CalculatorMbalekelwa Mpembe100% (1)

- Stud Bolt CheckDokument2 SeitenStud Bolt CheckUpendra WalinjkarNoch keine Bewertungen

- Sstruc Ctur Flyo Ral de Ver A Esign AT 0+ N Rep + Port 950 (LHS)Dokument70 SeitenSstruc Ctur Flyo Ral de Ver A Esign AT 0+ N Rep + Port 950 (LHS)Chandra prakash AndhwanNoch keine Bewertungen

- Columns DesignDokument60 SeitenColumns DesignifsrebraNoch keine Bewertungen

- JLG X 430 - Arrivals SlabCalcs - GOODDokument29 SeitenJLG X 430 - Arrivals SlabCalcs - GOODKailin JuNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 18Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 18danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 41Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 41danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 44Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 44danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 40Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 40danieldumapitNoch keine Bewertungen

- Par Al Plan View of Structure: Ii. Structural SystemDokument1 SeitePar Al Plan View of Structure: Ii. Structural SystemdanieldumapitNoch keine Bewertungen

- C.4 Torsional Strength, Chapter H: Nominal Axial Strength, Sec On E7 Nominal Axial StrengthDokument1 SeiteC.4 Torsional Strength, Chapter H: Nominal Axial Strength, Sec On E7 Nominal Axial StrengthdanieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 43Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 43danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 36Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 36danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 34Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 34danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 39Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 39danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 63Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 63danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 35Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 35danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 17Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 17danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 32Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 32danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 42Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 42danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 60Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 60danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 61Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 61danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 31Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 31danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 38Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 38danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 30Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 30danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 55Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 55danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 37Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 37danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 54Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 54danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 80Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 80danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 62Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 62danieldumapitNoch keine Bewertungen

- 8 Installation Data: Profis Anchor 2.8.8Dokument1 Seite8 Installation Data: Profis Anchor 2.8.8danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 48Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 48danieldumapitNoch keine Bewertungen

- Annex B - Extracts From Project Specificaons / Standards / Codes / Design Reports / Product CatalogueDokument1 SeiteAnnex B - Extracts From Project Specificaons / Standards / Codes / Design Reports / Product CataloguedanieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 57Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 57danieldumapitNoch keine Bewertungen

- 4597 AAB SC 07 Addendum 2 R0v0 53Dokument1 Seite4597 AAB SC 07 Addendum 2 R0v0 53danieldumapitNoch keine Bewertungen

- Kaylee Mccracken - Simulation - Forces and Motion - PhetDokument3 SeitenKaylee Mccracken - Simulation - Forces and Motion - Phetapi-534781715Noch keine Bewertungen

- Aerodynamic Modeling & Simulation of HGVDokument26 SeitenAerodynamic Modeling & Simulation of HGVManjunath PattarNoch keine Bewertungen

- Problems in Electrostatics, Current ElectricityDokument14 SeitenProblems in Electrostatics, Current ElectricityThayumanavar SachithananthamNoch keine Bewertungen

- CFD Simulation of Multicomponent Gas Flow Through Porous MediaDokument77 SeitenCFD Simulation of Multicomponent Gas Flow Through Porous Mediachethan_mk07Noch keine Bewertungen

- Tesis PDFDokument120 SeitenTesis PDFdaniel sernaNoch keine Bewertungen

- Vocabulary 1Dokument1 SeiteVocabulary 1api-260932599Noch keine Bewertungen

- Broek - The Practical Use of Fracture Mechanics PDFDokument266 SeitenBroek - The Practical Use of Fracture Mechanics PDFIan Kelly100% (1)

- Bouncy ChudinovDokument8 SeitenBouncy Chudinovthefallenghost6108Noch keine Bewertungen

- 2 20Dokument29 Seiten2 20slv_prasaadNoch keine Bewertungen

- Kinematics Problems With SolutionDokument17 SeitenKinematics Problems With SolutionApril ClaireNoch keine Bewertungen

- Full Configuration Drag Estimation: Virginia Polytechnic Institute and State University, Blacksburg, Virginia, 24061-0203Dokument24 SeitenFull Configuration Drag Estimation: Virginia Polytechnic Institute and State University, Blacksburg, Virginia, 24061-0203dewantaraakbarNoch keine Bewertungen

- AS 3600-2009 Ex001Dokument8 SeitenAS 3600-2009 Ex001Antonius AjalahNoch keine Bewertungen

- Lecture 2 - Chap 1Dokument15 SeitenLecture 2 - Chap 1Muneer AhmedNoch keine Bewertungen

- Lecture IX (Welded Joint - Eccentric Loading)Dokument13 SeitenLecture IX (Welded Joint - Eccentric Loading)Bikalpa khadkaNoch keine Bewertungen

- Solving Motion ProblemsDokument5 SeitenSolving Motion ProblemsAkshat Kumar AgarwalNoch keine Bewertungen

- Footing Design Joseph Sent To BentleyDokument15 SeitenFooting Design Joseph Sent To BentleyfarrukhNoch keine Bewertungen

- TP B 47 13118220 Alifia Rahmannida MachendraDokument3 SeitenTP B 47 13118220 Alifia Rahmannida MachendraglennNoch keine Bewertungen

- Defense - Intelligence - Reference - Document - Advanced - Space - Propulsion - Based - On - Vacuum - (Spacetime Metric) - Engineering (Spacetime Metric) - EngineeringDokument14 SeitenDefense - Intelligence - Reference - Document - Advanced - Space - Propulsion - Based - On - Vacuum - (Spacetime Metric) - Engineering (Spacetime Metric) - EngineeringalexandrecpcNoch keine Bewertungen

- Appplied Physics AnesthesiaDokument38 SeitenAppplied Physics AnesthesiaBogdan CarabasNoch keine Bewertungen

- Agitator Design 11 PDF FreeDokument9 SeitenAgitator Design 11 PDF FreeMeisam MomeniNoch keine Bewertungen

- Rotational Equilibrium and Rotational DynamicsDokument12 SeitenRotational Equilibrium and Rotational DynamicsCG AmonNoch keine Bewertungen

- Thermodynamics 1 Basic Principles, Concepts and DefinitionDokument8 SeitenThermodynamics 1 Basic Principles, Concepts and DefinitionHENRICK IGLENoch keine Bewertungen

- MS101 Egypt AssignmentDokument16 SeitenMS101 Egypt Assignmentrofaman100% (5)

- Lab#3 Compression TestDokument7 SeitenLab#3 Compression TestLarisaVladNoch keine Bewertungen

- Lecture 3 Bending and Shear in Beams PHG A8 Oct17 PDFDokument30 SeitenLecture 3 Bending and Shear in Beams PHG A8 Oct17 PDFEvi32Noch keine Bewertungen

- Science 6.5Dokument6 SeitenScience 6.5Nestlee ArnaizNoch keine Bewertungen

- Fundamentals of AerodynamicsDokument25 SeitenFundamentals of AerodynamicsPaul Timothy Hao100% (3)

- Trans RotDokument5 SeitenTrans RotFazriah UlfahNoch keine Bewertungen

- Ce2 Sample2Dokument5 SeitenCe2 Sample2ParZiValNoch keine Bewertungen

- KIneTic THeory of GassEsDokument14 SeitenKIneTic THeory of GassEsVail LunorNoch keine Bewertungen