Beruflich Dokumente

Kultur Dokumente

MS171 MS181 MS211 Service Manual REPAIR

Hochgeladen von

cosmin1991Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MS171 MS181 MS211 Service Manual REPAIR

Hochgeladen von

cosmin1991Copyright:

Verfügbare Formate

STIH)

STIHL MS 171, 181, 211 2007-05

Contents

1. Introduction 3 8. Engine 28 11. Servicing

the AV System 60

8.1 Muffler / Spark

2. Safety Precautions 4 Arresting Screen 28 11.1 AV Spring on Oil Tank 60

8.2 Leakage Test 29 11.2 AV Spring on

8.2.1 Preparations 29 Fuel Tank 60

3. Specifications 5 8.2.2 Vacuum Test 30 11.3 AV Spring on

8.2.3 Pressure Test 30 Cylinder 61

3.1 Engine 5 8.3 Oil Seals 31 11.4 Handle Frame 62

3.2 Fuel System 5 8.4 Removing and Installing

3.3 Ignition System 5 the Shroud 32

3.4 Chain Lubrication 5 8.5 Removing and Installing 12. Master Control Lever 64

3.5 Tightening Torques 6 the Engine 33

8.6 Crankshaft 34 12.1 Switch Shaft 64

8.7 Ball Bearings/ 12.1.1 Removing and

4. Troubleshooting 8 Crankshaft 36 Installing 64

8.8 Piston 37 12.2 Throttle Trigger /

4.1 Clutch 8 8.8.1 Piston Rings 39 Interlock Lever 66

4.2 Chain Drive,

Chain Brake,

Chain Tensioner 9 9. Ignition System 40 13. Chain Lubrication 68

4.3 Chain Lubrication 10

4.4 Rewind Starter 11 9.1 Ignition Module 40 13.1 Pickup Body 68

4.5 Ignition System 12 9.1.1 Removing and 13.2 Oil Suction Hose 68

4.6 Carburetor 14 Installing 40 13.3 Removing and Installing

4.7 Engine 17 9.2 Ignition Timing 42 the Oil Pump 69

9.3 Testing the Ignition 13.4 Valve 70

Module 42 13.5 Oil Tank Cap 71

5. Cutting Attachment 18 9.4 Spark Plug Boot 43

9.5 Flywheel 44

5.1 Chain Catcher 18 9.6 Short Circuit Wire 45

9.6.1 Testing 45

9.6.2 Removing and

6. Clutch 19 Installing 45

9.6.3 Ground Wire 47

6.1 Clutch Drum 21 9.6.4 Contact Spring 47

9.7 Ignition System

Troubleshooting 49

7. Chain Brake 22

7.1 Checking Operation 22 10. Rewind Starter 52

7.2 Removing and

Installing 10.1 General 52

the Brake Band 22 10.2 Removing and

7.3 Brake Lever 24 Installing 52

7.4 Flat Spring 26 10.3 Pawl 53

7.5 Pins 26 10.4 ErgoStart 53

7.6 Chain Tensioner 27 10.5 Rope Rotor 55

7.7 Bar Mounting Studs 27 10.6 Starter Rope / Grip 55

10.7 Tensioning

the Rewind Spring 57

10.8 Replacing

the Rewind Spring 58

RA_533_00_01_01

q

© ANDREAS STIHL AG & Co. KG, 2007

MS 171, MS 181, MS 211 1

Contents

14. Fuel System 72

14.1 Air Filter 72

14.2 Baffle / Filter Base 72

14.3 Removing and Installing

the Carburetor 73

14.3.1 Leakage Test 74

14.4 Servicing

the Carburetor 74

14.4.1 Metering Diaphragm 74

14.4.2 Inlet Needle 76

14.4.3 Fixed Jet 76

14.4.4 Valve Jet 77

14.4.5 Pump Diaphragm 77

14.4.6 Air Valve 79

14.4.7 Choke Shaft /

Choke Shutter 80

14.4.8 Throttle Shaft /

Throttle Shutter 82

14.4.9 Adjusting Screws 85

14.5 Adjusting

the Carburetor 86

14.5.1 Basic Setting 86

14.5.2 Standard Setting 87

14.6 Choke and

Throttle Rods 87

14.7 Removing and Installing

the Intake Manifold 89

14.7.1 Removing and Installing

the Carburetor Carrier 90

14.8 Tank Vent 92

14.8.1 Testing 92

14.8.2 Removing and

Installing 93

14.8.3 Manual Fuel Pump 93

14.9 Fuel Intake 94

14.9.1 Pickup Body 94

14.9.2 Fuel Intake Hoses 95

14.9.3 Fuel Hoses, Tank Vent /

Manual Fuel Pump 96

14.9.4 Fuel Tank Cap 97

15. Special Servicing

Tools 98

16. Servicing Aids 100

2 MS 171, MS 181, MS 211

1. Introduction

This service manual contains The special tools mentioned in the

detailed descriptions of all the descriptions are listed in chapter 1

typical repair and servicing "Special Servicing Tools" of this 3

procedures for this power tool. manual. Use the part numbers to

identify the tools in the "STIHL

You should make use of the Special Tools" manual which lists all 2

illustrated parts lists while carrying the special servicing tools currently

out repair work. They show the available from STIHL.

219RA000 TG

installed positions of the individual

components and assemblies. Symbols are included in the text and

pictures for greater clarity.

Refer to the latest edition of the The meanings are as follows:

relevant parts list to check the part Servicing and repairs are made

numbers of any replacement parts. In the descriptions: considerably easier if the machine

is mounted to assembly stand (3)

A fault on the machine may have : = Action to be taken as 5910 890 3100. To do this, secure

several causes. To help locate the shown in the illustration the mounting plate (2) 5910 850

fault, consult the chapter on (above the text) 1650 to the assembly stand with two

"Troubleshooting" and the "STIHL screws (1) and washers.

Service Training System" for all – = Action to be taken that is

assemblies. not shown in the illustration The screws must not project since

(above the text) they, depending on the machine,

Refer to the “Technical Information” may damage housings when the

bulletins for engineering changes machine is clamped in position.

IIn the illustrations:

which have been introduced since

publication of this service manual. The above operation is not

A Pointer

Technical information bulletins also necessary with the new assembly

supplement the parts list until an stand 5910 890 3101 since the

aDirection of movement

updated edition is issued. mounting plate is already fitted.

b 4.2 = Reference to another

chapter, i.e. chapter 4.2

in this example

Service manuals and technical

information bulletins are intended

exclusively for the use of properly

equipped repair shops. They must

not be passed to third parties.

MS 171, MS 181, MS 211 3

2. Safety Precautions

If the engine is started up in the

course of repairs or maintenance

work, observe all local and country-

specific safety regulations as well

as the safety precautions and

533RA000 TG

warnings in the instruction manual.

Gasoline is an extremely flammable

fuel and can be explosive in certain

After disengaging the chain brake conditions.

and removing the chain sprocket

cover, bar and chain, the Always wear suitable protective

powerhead’s bar stud is pushed gloves for operations in which

through the outer hole in the components are heated for

mounting plate and secured with the assembly or disassembly.

nut (arrow).

Improper handling may result in

The machine is held in position on burns or other serious injuries.

the mounting plate by the two screw

heads on the engine housing. Do not bring any fire, flame, spark or

other source of heat near the fuel.

Always use original STIHL All work with fuel must be performed

replacement parts. outdoors only. Spilled fuel must be

They can be identified by the wiped away immediately.

STIHL part number,

the STIH) logo and the Always perform leakage test after

STIHL parts symbol ( working on the fuel system and the

This symbol may appear alone on engine.

small parts.

Storing and disposing of oils and

fuels

Collect fuel or lubricating oil in a

clean container and dispose of it

properly in accordance with local

environmental regulations.

4 MS 171, MS 181, MS 211

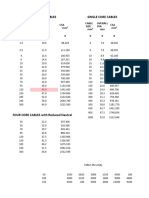

3. Specifications

3.1 Engine

MS 171 MS 181, MS 181 C MS 211, MS 211 C

Displacement: 30.1 cm3 31.8 cm3 35.2 cm3

Bore: 37 mm 38 mm 40 mm

Stroke: 28 mm 28 mm 28 mm

Engine power to ISO 7293: 1.3 kW (1.8 PS) 1.5 kW (2.0 PS) 1.7 kW (2.3 PS)

at 9,500 rpm at 9,500 rpm at 9,500 rpm

Max. permissible engine speed

with bar and chain: 13,500 rpm 13,500 rpm 13,500 rpm

Idle speed: 2,800 rpm 2,800 rpm 2,800 rpm

Clutch: Centrifugal clutch without linings

Clutch engages at: 5,100 rpm 5,100 rpm 5,100 rpm

Crankcase leakage test

at gauge pressure: 0.5 bar

under vacuum: 0.5 bar

3.2 Fuel System Carburetor leakage test 0.8 bar

at gauge pressure:

Operation of tank vent at gauge pressure: 0.5 bar

Fuel: as specified in instruction manual

3.3 Ignition System Air gap between ignition module and 0.15...0.35 mm

fanwheel:

Spark plug (suppressed): NGK CMR 6H

Electrode gap: 0.5 mm

3.4 Chain Lubrication Fully automatic, speed-controlled oil pump with reciprocating

piston

Oil delivery rate: 7.0 cm³/min at

10,000 rpm

MS 171, MS 181, MS 211 5

3.5 Tightening Torques

DG and P (Plastoform) screws are used in polymer and light metal components. These screws form a

permanent thread when they are installed for the first time. They can be removed and installed as often as

necessary without impairing the strength of the screwed assembly, providing the specified tightening torque is

observed.

For this reason it is essential to use a torque wrench.

Fastener Thread size For component Torque Remarks

Nm

Screw P 4x12 Cover plate, chain sprocket cover 2.5

Screw B 3.9x13 Cover plate (special accessory) 1.0

Screw D 4x15 Chain tensioner cover/engine housing 2.5

Collar screw D 8x18 Collar screw, engine housing/guide bar, 16.0 1)

rear

Collar screw D 8x18 Collar screw engine housing/guide bar, 16.0 1)

front

Screw P 4x16 Cover, chain brake/engine housing 2.0

(repair solution)

Screw D 5x16 Cover, chain brake/engine housing 2.0

(repair solution)

Countersunk screw M 6x14 Replacement chain catcher (repair 4.0

solution)

Screw P 5x20 Filter base/engine housing 4.0

Screw P 5x20 Filter base/engine housing/carburetor 4.0

carrier

Screw D 5x16 Spiked bumper/engine housing 3.5

Screw D 4x12 Manifold/cylinder 4.0

Screw P 5x20 AV bearing plug, front bottom/engine 4.0

housing

Screw P 5x20 AV bearing plug, rear bottom/handle 4.0

frame

Screw P 5x20 AV bearing plug, rear bottom/engine 4.0

housing

Screw D 5x18 AV bearing plug/cylinder 8.0

Screw P 5x25 Fan housing/hand guard/engine 4.0

housing

Screw P 5x20 Fan housing/engine housing 4.0

M 12x1 L Clutch/crankshaft 50.0

Screw D 5.3x41 Crankcase/engine pan/cylinder 11.0

Collar nut M5 Baffle/filter base/collar screw, 3.5

carburetor

Screw D 5x18 Muffler/cylinder 8.0

Nut M 8x1 Flywheel/crankshaft 28.0 2)

M 10x1 Spark plug 12.0

Screw D 4x18 Ignition module/cylinder 4.0

6 MS 171, MS 181, MS 211

Remarks:

1) Loctite 243 medium strength

2) Degrease crankshaft/flywheel faces and mount oil-free

Use the following procedure when refitting a DG or P screw in an existing thread:

Place the screw in the hole and rotate it counterclockwise until it drops down slightly.

Tighten the screw clockwise to the specified torque.

This procedure ensures that the screw engages properly in the existing thread and does not form a new thread

and weaken the assembly.

Power screwdriver setting for polymer: DG and P screws max. 500 rpm

Do not use a impact wrench for releasing or tightening screws.

Do not mix up screws with and without binding head

MS 171, MS 181, MS 211 7

4. Troubleshooting

4.1 Clutch

Condition Cause Remedy

Saw chain stops under load at full Clutch shoes badly worn Install new clutch

throttle

Clutch drum badly worn Install new clutch drum

Saw chain rotates at idle speed Engine idle speed too high Readjust with idle speed screw

(LA) (counterclockwise)

Clutch springs stretched or fatigued Replace the clutch springs or install

new clutch

Clutch spring hooks broken Replace the clutch springs

Clutch shoe bores worn Replace clutch shoes or install new

clutch

Loud noises Clutch springs stretched or fatigued Replace all clutch springs

Needle cage damaged Fit new needle cage

Clutch shoe retainer broken Fit new retainer

Clutch shoes and carrier worn Install new clutch

8 MS 171, MS 181, MS 211

4.2 Chain Drive, Chain Brake, Chain Tensioner

Condition Cause Remedy

Chain sprocket wears rapidly Chain not properly tensioned Tension chain as specified

Wrong chain pitch Fit chain of correct pitch

Insufficient chain lubrication Check chain lubrication

Chain sprocket worn Fit new chain sprocket

Saw chain stops under load at full Clutch shoes badly worn Install new clutch

throttle

Clutch drum badly worn Install new clutch drum

Brake band blocked Check freedom of movement and

operation of brake band

Saw chain does not stop Brake spring stretched or broken Fit new brake spring

immediately when brake is

activated

Brake band stretched or worn Fit new brake band

Clutch drum worn Fit new clutch drum

MS 171, MS 181, MS 211 9

4.3 Chain Lubrication

In the event of trouble with the

chain lubrication system, check and .

rectify other sources of faults

before disassembling the oil pump.

Condition Cause Remedy

Chain receives no oil Oil tank empty Fill up with oil, check oil pump

Oil inlet hole in guide bar is Clean oil inlet hole

blocked

Intake hose or pickup body clogged Fit new intake hose and pickup

or intake hose ruptured body

Valve in oil tank blocked Clean or replace valve

Teeth on worm worn Install new worm

Oil pump damaged or worn Install new oil pump

Oil intake hose not properly fitted or Fit oil intake hose properly or install

damaged new hose

Machine losing chain oil Oil pump body (engine housing) Check engine housing and oil

damaged pump and replace if necessary

Oil pump damaged or worn Install new oil pump

Oil intake hose connector damaged Install new oil intake hose

Oil intake hose not properly fitted or Fit oil intake hose properly or install

damaged new hose

Oil pump delivers insufficient oil Oil pump worn Install new oil pump

Oil intake hose not properly fitted or Fit oil intake hose properly or install

damaged new hose

Unsuitable chain lubricant has been Drain unsuitable chain lubricant

used from oil tank and fill up with

recommended chain lubricant

10 MS 171, MS 181, MS 211

4.4 Rewind Starter

Condition Cause Remedy

Starter rope broken Rope pulled out too vigorously as Fit new starter rope

far as stop or over edge, i.e. not

vertically

Normal wear Fit new starter rope

Starter rope does not rewind Very dirty or corroded Clean or replace rewind spring

Insufficient spring tension Check rewind spring and increase

tension

Rewind spring worn Fit new rewind spring

Starter rope cannot be pulled out Spring overtensioned Check rewind spring and reduce

far enough tension

Starter rope can be pulled out Guide peg on pawl or pawl itself is Fit new pawl

almost without resistance worn

(crankshaft does not turn)

Spring clip on pawl fatigued Fit new spring clip

Versions with ErgoStart Spring worn or fatigued Fit new ErgoStart spring housing

Carriers or pawls on flywheel faulty Install new ErgoStart carriers or

pawls

Starter rope is difficult to pull Starter mechanism is very dirty Thoroughly clean complete starter

and rewinds very slowly mechanism

Lubricating oil on rewind spring Coat rewind spring with a little

becomes viscous at very low standard solvent-based degreasant

outside temperatures (spring (containing no chlorinated or

windings stick together) halogenated hydrocarbons), then

pull rope carefully several times

until normal action is restored

MS 171, MS 181, MS 211 11

4.5 Ignition System

Exercise extreme caution while

carrying out maintenance and

repair work on the ignition system.

The high voltages which occur can

cause serious or fatal accidents!.

Condition Cause Remedy

Engine runs roughly, misfires, Spark plug boot is loose Press boot firmly onto spark plug

temporary loss of power and fit new spring if necessary

Spark plug sooted, smeared Clean the spark plug or replace if

with oil necessary

Fuel/oil mixture Use correct mixture of fuel and oil

– too much oil

Incorrect air gap between ignition Set air gap correctly

module and flywheel

Flywheel cracked or has other Install new flywheel

damage or pole shoes have turned

blue

Ignition timing wrong, flywheel out Install new flywheel

of adjustment, key in flywheel has

sheared off

Weak magnetization in flywheel – Install new flywheel

pole shoes have turned blue

Irregular spark Check operation of switch shaft/

contact springs and ignition

module.

Faulty insulation or break in ignition

lead or short circuit wire. Check

ignition lead/ignition module and

replace ignition module if

necessary.

Check operation of spark plug,

clean spark plug and replace if

necessary.

A problem with the carburetor or the engine can also be the reason for erratic running behavior.

12 MS 171, MS 181, MS 211

Condition Cause Remedy

No spark Spark plug faulty Install new spark plug

Faulty insulation or short in short Check short circuit wire for short

circuit wire circuit to ground

Break in ignition lead or insulation Check ignition lead, replace ignition

damaged module if necessary

Ignition module faulty Install new ignition module

MS 171, MS 181, MS 211 13

4.6 Carburetor

Condition Cause Remedy

Carburetor floods; Inlet needle not sealing. Foreign Remove and clean or replace the

engine stalls matter between valve seat and inlet needle, clean the carburetor,

cone or cone worn replace inlet needle if necessary

Inlet control lever sticking on Clean inlet control lever, replace if

spindle necessary

Helical spring not located on nipple Remove the inlet control lever and

of inlet control lever refit it correctly

Perforated disc on diaphragm is Fit a new metering diaphragm

deformed and presses constantly

against the inlet control lever

Poor acceleration Setting of low speed screw too lean Check basic carburetor setting,

correct if necessary

High speed screw too rich Check basic carburetor setting,

correct if necessary

Inlet needle sticking to valve seat Remove inlet needle, clean and

refit

Diaphragm gasket leaking Fit new diaphragm gasket

Metering diaphragm damaged or Fit new metering diaphragm

shrunk

Manifold damaged Install new manifold

14 MS 171, MS 181, MS 211

Condition Cause Remedy

Engine will not idle, Throttle shutter opened too wide by Reset idle speed screw (LA)

idle speed too high idle speed screw (LA) correctly

Oil seals/engine leaking Seal or replace oil seals/

engine

Air valve contaminated Clean air valve, replace if

– does not close necessary

Air valve stiff Check air valve, replace if

necessary

Throttle rod stiff Replace throttle rod and lever

– throttle shutter does not close

Engine stalls at idle speed Idle jet bores or ports blocked Clean the carburetor

Idle jet too rich or too lean Set low speed screw (L)

correctly

Setting of idle speed (LA) Set idle speed screw (LA)

incorrect – throttle shutter correctly

completely closed

MS 171, MS 181, MS 211 15

Condition Cause Remedy

Engine speed drops quickly under Air filter dirty Clean the air filter

load – low power

Throttle shutter not opened fully Check throttle rod

Tank vent faulty Replace tank vent

Fuel pickup body dirty Install new pickup body

Fuel strainer dirty Clean fuel strainer in carburetor,

replace if necessary

Leak in fuel line between tank and Install new fuel line

fuel pump

Setting of high speed screw (H) too Check basic carburetor setting,

rich correct if necessary

Main jet bores or ports blocked Clean the carburetor

Pump diaphragm damaged or Fit new pump diaphragm

fatigued

Engine running extremely rich, no Air valve does not open Check lever on air valve and

power and very low maximum replace if necessary

speed

Engine running too rich, low power Air valve does not open fully in full Check lever on air valve and

and low maximum speed throttle position replace if necessary

Erratic idle – too lean Air valve does not close properly Check lever on air valve and

replace if necessary

16 MS 171, MS 181, MS 211

4.7 Engine

Always check and, if necessary,

repair the following parts before

looking for faults on the engine:

- Air filter

- Fuel system

- Carburetor

- Ignition system

Condition Cause Remedy

Engine does not start easily, stalls Oil seals in engine damaged Replace the oil seals

at idle speed, but operates normally

at full throttle

Engine leaking or damaged Seal or replace the engine

(cracks)

Engine does not deliver full power Piston rings worn or broken Fit new piston rings

or runs erratically

Muffler / spark arresting screen Clean the muffler (inlet and

carbonized exhaust), replace spark arresting

screen, replace muffler if necessary

Air filter element dirty Replace air filter element

Fuel hose severely kinked or Fit new hose or position it free from

damaged kinks

Tank vent faulty Check tank vent and replace if

necessary

Air valve does not open Check air valve and replace if

necessary

Engine overheating Insufficient cylinder cooling. Air Thoroughly clean all cooling air

inlets in fan housing blocked or openings and the cylinder fins

cooling fins on cylinder very dirty

MS 171, MS 181, MS 211 17

5. Cutting Attachment

When installing the adjusting wheel,

3 check that its teeth face the cover

plate.

– Reassemble in the reverse

sequence.

2 1

533RA001 TG

165RA006 TG

5.1 Chain Catcher

1 A replacement chain catcher can be

fitted if the integral chain catcher on

Wear gloves to protect your hands : Apply screwdriver to side (1) of the chain sprocket cover is worn.

from injury. wing nut and pry it out of its seat.

– Remove the chain sprocket

: Unscrew the hex nut (1). – Check the wing nut and replace if cover, bar and chain, b 5

necessary.

: Remove the chain sprocket – File down the damaged chain

cover (2). catcher on the chain sprocket

cover.

: Remove the bar (3) and chain.

– Install in the reverse sequence.

1

Machines with quick chain

tensioner

165RA007 TG

3

3 4

533RA006 TG

– Open up the wing nut.

1 2

: Push the wing nut (1), thin side

first (arrow), into the opening and : Position the replacement chain

press it home until it snaps into catcher (1) in the guides (arrows).

position.

533RA002 TG

2 – Push the countersunk screw (2)

1 through the bore in the engine

housing and fit the locknut (3) at

Wear gloves to protect your hands 1 the other side.

from injury.

– Tighten down the countersunk

: Open up the wing nut (1) and 2 screw firmly – the locknut butts

unscrew it counterclockwise. against the engine housing and

need not be held.

: Remove the chain sprocket cover

533RA005 TG

(2) and tensioning gear (3) with – Reassemble all other parts in the

guide bar (4). reverse sequence.

– Install in the reverse sequence. : Remove the screw (arrow). – Tightening torques, b 3.5

– Remove the cover plate (1) and

adjusting wheel (2).

18 MS 171, MS 181, MS 211

6. Clutch

– Troubleshooting, b 4.1

1 1

– Remove the chain sprocket

cover, bar and chain, b 5

– Remove the clutch drum, b 6.1

533RA009 TG

533RA012 TG

1

: Push the locking strip (1) – Pull the clutch shoes off the

0000 893 5904 into the spark carrier.

plug hole until it butts against the

cylinder wall (arrow) as shown. : Pull the retainers (1) off the clutch

shoes.

533RA007 TG

– Remove the shroud, b 8.4

TOP

– The spring may be preloaded on

machines with ErgoStart. It is

therefore necessary to remove

1

the fan housing, b 10.1 and

533RA010 TG

b 10.2

533RA013 TG

: Pull off the spark plug boot (1).

: Unscrew the clutch (1).

– Clean all parts, b 16

Note that the clutch has a left-hand

1 thread. – Replace any damaged parts.

2

1

1

533RA008 TG

533RA011 TG

: Unscrew the spark plug (1).

533RA014 TG

Disassembling

: Slip the retainers (1) onto the

clutch shoes.

– Clamp the clutch in a vise.

: Use hook (2) 5910 890 2800 to

remove the clutch springs (1).

MS 171, MS 181, MS 211 19

2 1

TOP

1

533RA015 TG

533RA018 TG

533RA021 TG

: Fit the clutch shoes (1) over the : Check the clutch – all springs : Use the hexagon (arrow) to

arms (2). (arrows) must be properly screw the clutch (1) onto the

attached. crankshaft stub. Check the

position of the locking strip and

then tighten down the clutch

firmly – left-hand thread.

– Tightening torques, b 3.5

TOP

1

– Remove the locking strip from the

cylinder.

533RA016 TG

– Reassemble all other parts in the

533RA019 TG

reverse sequence.

: Clamp the clutch in a vise

(arrow). – Cover washer (1) must be in

position.

It is correctly fitted when “TOP”

(arrow) faces outwards.

2

1

TOP

533RA017 TG

Attach the springs to the side with

533RA020 TG

the raised hexagon (arrow).

: Attach one end of each spring (1)

to the clutch shoes. : Position the clutch on the

crankshaft stub so that the raised

: Use the hook (2) 5910 890 2800 hexagon (arrow) faces outwards.

to attach the other ends of the

springs and press them firmly into

the clutch shoes – do not

overstretch the springs.

20 MS 171, MS 181, MS 211

6.1 Clutch Drum

1 1

TOP TOP

533RA024 TG

533RA025 TG

2

533RA022 TG

: Pull off the needle cage (1). The notch (arrow) in the clutch drum

must engage the worm’s spring (1).

– On machines with ErgoStart, – Clean the needle cage and

crankshaft stub, b 16 Use the mark (2) for alignment.

relieve spring tension, b 10.4

– Apply thin coating of oil to the

– Remove the chain sprocket – Lubricate the needle cage and

outside of the clutch drum and

cover, bar and chain, b 5 crankshaft stub, b 16

the brake band.

: Pull the hand guard (1) towards – Reassemble all other parts in the

the front handle. reverse sequence.

1

R

1

100%

148RA101 VA

TOP

80% !

– Inspect the clutch drum (1) for

533RA023 TG

signs of wear.

If there are signs of serious wear on

Remove and install the clutch drum the inside diameter of the clutch

(1), see instruction manual. drum (1), check the remaining wall

thickness. If it is less than about

80% of the original thickness, install

a new clutch drum.

MS 171, MS 181, MS 211 21

7. Chain Brake

7.1 Checking Operation 7.2 Removing and Installing

the Brake Band

The chain brake is one of the most

important safety devices on the

chainsaw. Its efficiency is measured

in terms of the chain braking time,

i.e. the time that elapses between

activating the brake and the saw

533RA027 TG

chain coming to a complete 1

standstill. 1

533RA022 TG

Contamination (with chain oil, chips, : Pry the brake band (1) out of its

fine particles of abrasion, etc.) and seat (arrow).

smoothing of the friction surfaces of

the brake band and clutch drum

impair the coefficient of friction. – Troubleshooting, b 4.2

This, in turn, reduces the frictional

forces and thus prolongs the – Remove the chain sprocket

braking time. A fatigued or stretched cover, bar and chain, b 5

brake spring has the same negative

effect. : Disengage the chain brake by

pulling the hand guard (1)

– Start the engine towards the front handle – the

brake band is loose.

533RA028 TG

1

– With the chain brake activated

(locked), open the throttle wide – Remove the clutch drum, b 6.1

for a brief period (max. 3

seconds) – the chain must not : Swing the brake band (1)

– Push the hand guard (1) towards

rotate. outwards.

the guide bar – the brake band is

tensioned.

– With the chain brake released, Do not over-stretch the brake band.

open the throttle wide and

To reduce the risk of injury, do not

activate the brake manually – the

activate the chain brake while the

chain must come to an abrupt

chain brake cover is open.

stop.

The braking time is in order if

deceleration of the saw chain is 1

imperceptible to the eye. 1

If the chain brake does not operate

533RA029 TG

properly, refer to troubleshooting,

b 4.2. TOP

533RA356 TG

: Turn the brake band (1) slightly to

one side and disconnect it from

the brake lever (arrow).

: Use a screwdriver to ease the

cover (1) away at the points

shown (arrows).

– Remove and inspect the cover

(1), service or replace if

necessary.

22 MS 171, MS 181, MS 211

1 2

533RA030 TG

533RA059 TG

533RA033 TG

1

Install a new brake band if there are : Push the brake band (1) into its If the pegs have broken off, the

noticeable signs of wear (large guides (arrows). cover can be serviced.

areas on inside diameter and/or

parts of outside diameter) and its – Drill out the recesses exactly in

remaining thickness is less than the center (arrow):

0.6 mm. a (1) = o 4.5 mm

b (2) = o 5.5 mm

– If a peg is stuck in the engine

housing, remove it by pushing it

inwards.

533RA027 TG

1

1 3 1 2

533RA031 TG

: Push the brake band (1) into its

seat (arrow) as far as stop.

TOP

: Attach the brake band (1) to the

brake lever (arrow) from the side 1

533RA034 TG

and then turn it in the direction of

its seat.

TOP

– Place the cover (1) in position.

– Fit D 5x16 screw (2) and P 4x16

533RA026 TG

screw (3) and tighten down firmly.

– Tightening torques, b 3.5

– Engage pegs on cover (1) in the

holes (arrows) and push it fully – Install the clutch drum,

533RA032 TG

home. b 6.1

– Reassemble all other parts in the

reverse sequence.

: Swing the brake band into the

guide (arrow) first.

– Check operation.

MS 171, MS 181, MS 211 23

7.3 Brake Lever

2

1

533RA035 TG

533RA037 TG

533RA040 TG

1

– Troubleshooting, b 4.2 : Remove the E-clip (arrow). : Pull the brake lever (2) out of the

hand guard (1).

– Remove the brake band, b 7.2

– Inspect the brake lever and hand

– Push the hand guard away from

1 guard and replace if necessary.

the front hand to relax the brake

spring.

: Use the assembly tool (2)

1

1117 890 0900 to disconnect the

brake spring (1) from the anchor 533RA038 TG

pin (arrow) – the spring may pop

out during this operation.

– Disconnect the brake spring from : Lift and turn the strap (1) a little,

533RA041 TG

the brake lever. then push it to the left as far as

the hole (arrow) and remove it.

– Remove the spacer sleeve from – Inspect the pivot pins and replace

the brake lever. if necessary, b 7.5

1 – Inspect the flat spring and

replace if necessary., b 7.4

1

– Clean all disassembled parts,

b 16

533RA036 TG

– Position the brake lever so that

the hook (arrow) for the brake

: Take out the screw. spring is at the top.

533RA039 TG

: Pry the hand guard (1) off the fan 2 : Push the brake lever (1) into the

housing (arrow). hand guard recess and line up

: Pull the hand guard (1) and brake the holes.

– To ease assembly, remove the lever (2) off the pivot pins

rewind starter, b 10.2 (arrows) together.

– Remove the hand guard and

brake lever.

24 MS 171, MS 181, MS 211

– Locate the hand guard at the

starter side and fit the screw. 1

1 2

533RA042 TG

533RA047 TG

– Lubricate the pivot pins, b 16 : Attach brake spring (1) to the

533RA045 TG

brake lever (arrow).

: Push the hand guard and brake

lever over the machine until they

butt against the pivot pins. – Push on the spacer sleeve.

1

– Fit the strap (1).

: Fit the E-clip (2).

2

533RA048 TG

533RA043 TG

: Use assembly tool (2)

1117 890 0900 to attach the

brake spring (1) to the anchor pin

: Lift the bearing boss of the hand (arrow).

533RA046 TG

guard and the brake lever a little

and position them on the pivot – Reassemble all other parts in the

pins (arrows). reverse sequence.

: The turns of brake spring must be

tightly against one another in the – Tightening torques, b 3.5

relaxed condition. If this is not the

case, replace the brake spring. – Lubricate the brake lever, b 16

If the groove in the brake spring

anchor pin is worn, install a new pin,

2

b 7.5

533RA044 TG

: Ease the cam (arrow) of the hand

guard (2) past the flat spring (1).

– Push the hand guard and brake

lever onto the pivot pins, moving

the hand guard to and fro at the

same time.

MS 171, MS 181, MS 211 25

7.4 Flat Spring 7.5 Pins

2 1

The flat spring and hand guard cam The anchor pins secure the springs.

hold the hand guard in position. Worn pins must be replaced.

– Remove the brake lever, b 7.3 All parts have been removed from

the pins in the following illustrations

for greater clarity.

3

533RA053 TG

1

3 2 1

: Drive home pins (1+2+3) to

specified lengths.

b

533RA049 TG

533RA051 TG

2

: Pull out the flat spring (1), check

it and replace if necessary. 1

– Remove the engine, b 8.5

a

3

533RA054 TG

: Use a suitable punch to drive out

1 the pins (1+2) in the direction of c

the engine – use suitable

support. View from air filter side.

: Use a suitable punch to drive out : Carefully tap home the pins

the pin (3) in the direction of the squarely to obtain the following

clutch – use suitable support. dimensions:

533RA050 TG

Pin (1) a = 8.9 mm

Pin (2) b = 12.1 mm

Pin (3) c = 4.0 mm

1

: Push the flat spring (1) into the

– Reassemble all other parts in the

guides (arrows).

reverse sequence.

– Lubricate the flat spring, b 16

– Tightening torques, b 3.5

– Reassemble all other parts in the

– Lubricate the brake lever and flat

533RA052 TG

reverse sequence.

spring, b 16

– Tightening torques, b 3.5

– Before installing the new pin (1),

coat its knurled shank with

Loctite, b 16

: Position the new pin (1) in the

bore (arrow) so that the knurling

on the pin meshes with the

existing knurling in the bore. Turn

pin back and forth as necessary.

26 MS 171, MS 181, MS 211

7.6 Chain Tensioner 7.7 Bar Mounting Studs

1 2

For machines with quick chain

tensioner see b 5 3 2

– Remove the chain sprocket

cover, bar and chain, b 5

533RA057 TG

– Troubleshooting, b 4.2

533RA003 TG

: Remove the spur gear (1) and 1

2 tensioner slide (2).

– Remove the chain sprocket

cover, bar and chain, b 5

2 2 4

: Push stud puller 5910 893 0501

(1) over the collar stud (2) as far

as it will go. Unscrew the stud.

533RA055 TG

1 : Unscrew collar stud (3).

: Turn the spur gear (2) clockwise

533RA058 TG

until the tensioner slide (1) butts

against the right-hand end and 1 3

the screw (arrow) is visible.

: Inspect the cover (1), spur gear

assembly (2), tensioner slide (3)

and thrust pad (4) and replace if

necessary.

533RA004 TG

– Clean all disassembled parts,

b 16

– Lubricate the chain tensioner

: Before installing, coat threads

with STIHL multipurpose grease,

(arrows) of collar studs with

533RA056 TG

b 16

Loctite, b 16

– Install in the reverse sequence. – Fit the collar studs and tighten

: Remove the screw (arrow). them down firmly.

– Tightening torques, b 3.5

– Reassemble all other parts in the

reverse sequence.

MS 171, MS 181, MS 211 27

8. Engine

8.1 Muffler / Spark Arresting

Screen

Always check and, if necessary,

1 1

repair the fuel system, carburetor,

air filter and ignition system before

looking for faults on the engine.

533RA062 TG

533RA065 TG

– Troubleshooting, b 4

: Remove the heat shield (1). : Place the heat shield (1) in

position and use the recesses

(arrows) to line it up on the

Spark arresting screen sealing face of the exhaust port.

1

533RA060 TG

: Pry the plugs out of the muffler by

means of the tabs (arrows).

533RA063 TG

533RA066 TG

1 : Use suitable pliers to pull out the

spark arresting screen (1) (if – Care place the muffler (1) in

fitted). position.

– Clean the spark arresting screen : Fit the screws (arrows) and check

(1) and replace if necessary. correct position of heat shield

again.

533RA061 TG

– Install in the reverse sequence.

– Tighten down the screws

(arrows) firmly.

: Take out the screws (arrows).

– Remove the muffler (1), check

and replace if necessary.

533RA064 TG

533RA060 TG

: Inspect and clean the sealing

faces (arrows), b 16

: Push home the plugs (arrows).

– Position machine vertically.

– Tightening torques, b 3.5

28 MS 171, MS 181, MS 211

8.2 Leakage Test The sealing plate must completely

fill the space between the two

screws.

Defective oil seals and gaskets or

cracks in castings are the usual

causes of leaks. Such faults allow – Remove the carburetor, b 14.3

supplementary air to enter the

engine and upset the fuel-air

mixture.

533RA060 TG

This makes adjustment of the

prescribed idle speed difficult, if not

impossible. : Pry the plugs (arrows) out of the

muffler.

Moreover, the transition from idle 1

speed to part or full throttle is not

– Take out the screws.

533RA069 TG

smooth.

Always perform the vacuum test – Remove the muffler.

first.

: Check that the sleeve (1) is in

place.

The engine can be checked

thoroughly for leaks with the pump

0000 850 1300.

8.2.1 Preparations 1

533RA116 TG

1 1

533RA070 TG

– Fit the flange (1) 1123 855 4200.

: Insert the screws (arrows).

: Fit the test flange 1139 893

533RA008 TG

2500 (1).

– Remove the shroud, b 8.4

1

: Unscrew the spark plug (1).

– Set the piston to top dead center.

This can be checked through the

533RA067 TG

inlet port.

533RA071 TG

: Fit spark plug (1) and tighten it

down firmly. : Fit the sealing plate (1)

0000 855 8106 between the

: Fit the nuts (arrows) and tighten

– Tightening torques, b 3.5 cylinder exhaust port and flange

them down firmly.

and tighten down the screws

moderately.

MS 171, MS 181, MS 211 29

8.2.2 Vacuum Test If the vacuum reading remains

constant, or rises to no more than

0.3 bar within 20 seconds, it can be

Oil seals tend to fail when subjected

to a vacuum, i.e. the sealing lip lifts assumed that the oil seals are in

away from the crankshaft during the good condition. However, if the

pressure continues to rise (reduced 2

piston's induction stroke because

vacuum in the engine), the oil seals

there is no internal counterpressure.

must be replaced, b 8.3

533RA075 TG

A test can be carried out with pump

– After finishing the test, push the

0000 850 1300 to detect this kind of 1

fault. ring to the right to vent the pump.

: Push the ring (1) to the right.

– Continue with pressure test,

b 8.2.3

1 : Operate the lever (2) until the

pressure gauge (arrow) indicates

a pressure of 0.5 bar. If this

8.2.3 Pressure Test

pressure remains constant for at

least 20 seconds, the engine is

airtight.

1

– If the pressure drops, the leak

533RA072 TG

must be located and the faulty

part replaced.

: Connect suction hose (1) of To find the leak, coat the suspect

pump 0000 850 1300 to area with oil and pressurize the

533RA072 TG

nipple (arrow). engine. Bubbles will appear if a leak

exists.

Carry out the same preparations as – After finishing the test, push the

for the vacuum test, b 8.2.2 ring to the left to vent the pump –

disconnect the hose.

– Always carry out the vacuum test

before the pressure test, b 8.2.2 – Remove the test flange.

2

: Connect pressure hose (1) of – Install the carburetor, b 14.3

pump 0000 850 1300 to nipple

533RA073 TG

(arrow). – Loosen the muffler and remove

1 the sealing plate.

: Push ring (1) to the left. – Tighten down the muffler firmly.

: Operate the lever (2) until the – Reassemble all other parts in the

pressure gauge (arrow) indicates reverse sequence.

a vacuum of 0.5 bar.

– Tightening torques, b 3.5

30 MS 171, MS 181, MS 211

8.3 Oil Seals – Clamp the puller arms. Clutch side

– Pull out the oil seal. – Remove the chain sprocket

cover, bar and chain, b 5

Take care not to damage the

crankshaft stub. – Remove the clutch, b 6

2

– Cleaning the sealing face, b 16 – Remove the oil pump, b 13.3

1 – Lubricate sealing lips of new oil

217RA085 TG

seal with grease, b 16

Use oil seal (1) 9638 003 1581 if the

engine is not opened.

Install oil seal (2) 9639 003 1585 if

the engine has been opened up.

2 1

533RA074 TG

It is not necessary to disassemble

the complete engine to replace the

oil seals. 1

533RA077 TG

: Remove and inspect the worm

Ignition side (1), and replace if necessary.

– Remove the fan housing, b 10.1

and b 10.2 – Apply thin coating of sealant,

b 16, to the outside diameter of

the oil seal.

– Remove the flywheel, b 9.5

– Slip the oil seal, closed side

facing the engine, over the

crankshaft stub.

1

1 : Use press sleeve (2)

533RA078 TG

1123 893 2400 to install the oil

seal (1).

The seating face must be flat and : Remove the retaining ring (1).

free from burrs.

533RA076 TG

– Wait about one minute, then

rotate the crankshaft several

– Free off the oil seal in its seat by times.

tapping it with a suitable tube or a

punch. – Degrease the crankshaft taper,

b 16

: Apply puller (1) 5910 890 4400

with No. 3.1 jaws 0000 893 3706. – Reassemble all other parts in the

reverse sequence.

MS 171, MS 181, MS 211 31

– Slip the oil seal, closed side

facing the engine, over the

1 installing sleeve.

– Remove the installing sleeve (1).

533RA087 TG

533RA079 TG

1

– Free off the oil seal in its seat by : Push the worm (1) onto the

tapping it with a suitable tube or a crankshaft stub as far as stop – it

punch. must engage the oil pump pinion.

2

533RA081 TG

: Apply puller (1) 5910 890 4400 – Reassemble all other parts in the

with No. 3.1 jaws 0000 893 3706. reverse sequence.

– Clamp the puller arms. : Use press sleeve (1)

1123 893 2400 to install the oil 8.4 Removing and Installing

– Pull out the oil seal. seal (2). the Shroud

Take care not to damage the

crankshaft stub. 1

– Cleaning the sealing face, b 16

– Lubricate sealing lips of new oil

seal with grease, b 16 1

533RA083 TG

533RA082 TG

: Push slide lock (1) in direction of

– Wait about one minute, then rear handle.

1 rotate the crankshaft several

times.

: Fit the retaining ring (1). 1

533RA080 TG

– Install the oil pump, b 13.3

: Fit the installing sleeve (1) – Lubricate the worm with grease,

1118 893 4602. b 16

533RA088 TG

– Apply thin coating of sealant,

b 16, to the outside diameter of

the oil seal.

: Lift the shroud (1) a little and pull

it off in the direction of the rear

handle.

32 MS 171, MS 181, MS 211

1 2

1 1

533RA085 TG

533RA074 TG

: Apply screwdriver above the 533RA084 TG : Push the shroud (1) down as far : Remove the worm (1).

spindle (arrow) and push it into as stop and secure in position

the slide (1). with the slide lock (2).

– Remove the slide (1).

8.5 Removing and Installing

– Inspect the slide and spindle and the Engine

replace if necessary.

533RA091 TG

1

2 : Remove the cylinder mounting

screws (arrows) from the

533RA090 TG

underside of the engine housing

– engine pan is also loose.

533RA089 TG

The complete engine has to be

removed before removing either the

: Push the slide (1) into the guides piston or cylinder.

(arrows) until it snaps into

position in the spindle (2). – Remove the shroud, b 8.4

– Remove the chain sprocket

cover, bar and chain, b 5 1

– Remove the muffler, b 8.1

533RA092 TG

– Remove the clutch, b 6

1 – Remove the ignition module,

b 9.1

– Remove the wiring harness, : Take the engine (1) out of the

b 9.6.2 engine housing.

– Remove the flywheel, b 9.5

533RA086 TG

– Remove the handle frame, After loosening the engine pan,

b 11.4 always clean the sealing faces and

– Remove the throttle rod, b 14.6 apply fresh sealant, b 16

: Push the bearing lugs of shroud – If necessary, also remove the

(1) into the guides (arrows) until The carburetor carrier can be also

carburetor carrier, b 14.7.1

they snap into position. be removed after the engine has

been removed.

MS 171, MS 181, MS 211 33

533RA093 TG

533RA091 TG

533RA097 TG

– Clean the sealing faces on the – Position the engine in the engine : Lift the crankshaft out of the

cylinder, engine pan and oil housing and hold it there bearing seats (arrows).

seals, remove gasket residue if – the holes in the engine housing,

necessary, b 16 engine pan and cylinder must line : Carefully pull the crankshaft and

up. piston out of the cylinder.

– Apply fresh sealant to sealing

faces, b 16 : Fit and tighten down the cylinder – Inspect the crankshaft and ball

mounting screws (arrows). bearings and replace if

– Install new oil seals, b 8.6 necessary, b 8.7

– Install the worm, b 8.3

: Make sure the oil seals are – Inspect piston and piston rings

properly seated – Reassemble all other parts in the and replace if necessary, b 8.8,

– they must be installed flush reverse sequence. b 8.8.1

(arrow).

– Tightening torques, b 3.5

– Carry out leakage test, b 8.2

1

1

8.6 Crankshaft

533RA098 TG

533RA094 TG

: Remove the retaining ring (1).

: Pass the clutch end of the 1

crankshaft (1) through the

opening (arrow) in the engine

533RA096 TG

housing.

– Carefully place the engine in the

engine housing – Remove the engine, b 8.5

– support engine pan from below

with one hand. : Pry the engine pan (1) away from

the engine at the lugs (arrows).

533RA099 TG

– Remove the engine pan.

: Pull the oil seals (arrows) off the

crankshaft stub.

34 MS 171, MS 181, MS 211

2

217RA085 TG

533RA102 TG

533RA104 TG

– Inspect the cylinder and clean the Use oil seal (1) 9638 003 1581 if the – Lubricate the piston, piston rings

sealing faces (arrows), remove engine is not opened. and cylinder wall with oil.

gasket residue if necessary, Install oil seal (2) 9639 003 1585 if

b 16 the engine has been opened up. : Position the piston rings so that

the radii at the ring gap meet at

The sealing faces must be clean the fixing pin in the piston groove

and show no signs of damage. (arrows) – there is otherwise a

Parts with damaged sealing faces risk of ring breakage.

must be replaced.

533RA107 TG

1 1

: Push the installing sleeve (1)

533RA105 TG

1118 893 4602 onto the

533RA101 TG

crankshaft.

: Push the new oil seals, open side – Align the piston and crankshaft

– Check the intake manifold (1) and facing the crankshaft, onto the before installing in the cylinder.

replace if necessary, b 14.7 crankshaft stubs.

Viewed from the exhaust port, the

If a new cylinder is installed, transfer long crankshaft stub (1) must be on

the intake manifold (if it is still the right.

serviceable) from the old cylinder. 1

533RA098 TG

: Fit the retaining ring (1).

MS 171, MS 181, MS 211 35

– Clean the crankshaft stub, b 16

– Install the engine, b 8.5

– Reassemble all other parts in the

reverse sequence.

533RA106 TG

533RA110 TG

8.7 Ball Bearings/Crankshaft

– Remove the engine, b 8.5

The pistons rings are compressed – Inspect and clean the mating face

by the inner taper of the cylinder. on the engine pan, remove

gasket residue if necessary, – Remove the crankshaft and oil

: Carefully push the piston with b 16 seals, b 8.6

crankshaft into the cylinder

(arrow). The mating faces must be perfectly – Remove the piston, b 8.8

clean and not be damaged in any

way. Replace parts with damaged

mating faces.

: Apply sealant along the groove,

b 16

Sealant must not get into the 1

recesses (arrows) – the transfer

ports must not be obstructed.

533RA108 TG

533RA113 TG

: Apply thin coating of sealant to 1 : Pull the ball bearing (1) off the

the outside diameter (arrows) of ignition end of the crankshaft.

the oil seals, b 16

533RA111 TG

1

: Place the engine pan (1) on the

cylinder.

533RA114 TG

533RA109 TG

Apply slight pressure to the engine

pan so that the sealant is evenly

distributed .

: Pull the ball bearing (1) off the

: Position the crankshaft with clutch end of the crankshaft.

Take care not to damage the

bearings and oil seals in the

crankshaft stubs.

bearing seats in the cylinder,

making sure the oil seals are

properly seated (arrows) in the

housing.

36 MS 171, MS 181, MS 211

1

3 1

2 2

1

533RA115 TG

533RA121 TG

533RA119 TG

: The crankshaft (1), connecting Use a firm support (2) to protect the : Position the small diameter of

rod (2) and needle bearing (3) are crankshaft. assembly drift (1) 1110 893 4700

an inseparable unit. This means against the piston pin.

the crankshaft must always be : Apply a suitable sleeve (1) to the

replaced as a complete unit. inner race to press home the ball

bearing at the ignition side as far

When fitting a replacement as stop. 1 2

crankshaft, always install new ball

bearings and oil seals. – Lubricate the needle bearing with

oil.

– Clean the crankshaft before

installing, b 16 – Install the piston, b 8.8

533RA122 TG

– Install the crankshaft and oil

seals, b 8.6

1 – Install the engine, b 8.5 : Use the assembly drift (2)

1110 893 4700 to push the piston

2 pin (1) out of the piston.

8.8 Piston

If the piston pin is stuck, release it

by tapping the end of the drift with a

533RA117 TG

– Remove the engine, b 8.5

hammer. Hold the piston steady

during this process to ensure that

– Remove the crankshaft, b 8.6 no jolts are transmitted to the

Use a firm support (2) to protect the connecting rod..

crankshaft.

: Apply a suitable sleeve (1) to the

inner race to press home the ball

bearing at the clutch side as far

as stop. 1

533RA120 TG

533RA123 TG

: Use a suitable tool to ease the

hookless snap rings out of the : Remove the piston (1) from the

grooves in the piston bosses connecting rod.

(arrow).

– Inspect the piston rings and

replace if necessary, b 8.8.1

MS 171, MS 181, MS 211 37

1

533RA130 TG

533RA124 TG

533RA127 TG

1

– Lubricate needle cage with oil. : Remove the sleeve (1) from the : Press the installing tool

installing tool 5910 890 2210. downwards into the sleeve until

: Line up the piston as shown in the magnet butts against the end

the illustration so that the mark of the guide slot.

(arrow) points to the rear and the

long crankshaft stub (1) is on the Use a suitable base (wooden

right. board).

– Position the piston on the

connecting rod.

533RA128 TG

1 2 1

: Attach the snap ring (1) to the

magnet (2) so that the snap ring

533RA131 TG

gap is on the flat side of the tool's

shank (arrow).

533RA125 TG

: Remove the sleeve and slip it

onto the other end of the shank.

3 2 1

: Push the assembly drift (1) Inner pin (arrow) must point toward

1110 893 4700, small diameter flat face.

first, through the piston and small

end (needle cage) and line up the

piston.

533RA129 TG

1 2

: Push the large slotted diameter of

the sleeve (1) 5910 893 1707

over the magnet and snap ring.

The inner pin (2) must point towards

the flat face (3) of tool's shank.

533RA126 TG

: Fit the piston pin (2) on the

assembly drift (1) and slide it into

the piston.

38 MS 171, MS 181, MS 211

533RA132 TG

533RA136 TG

533RA134 TG

– Install the snap rings at both – Check the piston rings and : Install the new piston rings in the

sides. replace if necessary., b 8.8.1 grooves so that the radii face

upward (arrows).

: Apply the installing tool – Check the oil seals and ball

5910 890 2210 with the sleeve’s bearings and replace if

taper against the piston boss, necessary., b 8.7

hold the piston steady, center the

tool shank exactly and press – Install the crankshaft, b 8.6

home until the snap ring slips into

the groove.

– Install the engine, b 8.5

8.8.1 Piston Rings

533RA137 TG

– Remove the piston, b 8.8

: Position the piston rings so that

– Remove the piston rings from the the radii at the ring gap meet at

1 piston – the MS 171 has only one the fixing pin in the piston groove

piston ring. (arrows).

533RA133 TG

2 – Check correct installed position

of the piston rings (arrows).

Fit the snap ring (1) so that its gap

(arrow) points up. It must not be – Install the piston, b 8.8

near the recess (2).

– Check position and security of

both snap rings.

533RA135 TG

: Use a piece of old piston ring to

scrape the grooves clean.

MS 171, MS 181, MS 211 39

9. Ignition System

Exercise extreme caution when – the high voltage output with

troubleshooting and carrying out ignition lead (1)

maintenance or repair work on the

ignition system. The high voltages – the connector tag (2) for the short 1

which occur can cause serious or circuit wire

even fatal accidents.

Testing in the workshop is limited to

Troubleshooting on the ignition

a spark test.

533RA140 TG

system should always begin at the

A new ignition module must be

spark plug, b 4.5

installed, b 9.1, if no ignition spark

is obtained (after checking that

– Remove the fan housing, b 10.1

wiring and stop switch are in good : Pull the ignition lead (1) out of the

and b 10.2

condition). retainer (arrow).

Ignition timing is fixed and cannot

be adjusted during repair work.

2 Since there is no mechanical wear

in these systems, ignition timing

cannot get out of adjustment. 1

2

9.1.1 Removing and Installing

1

533RA138 TG

533RA141 TG

– Remove the shroud, b 8.4

The electronic (breakerless) ignition – Remove the fan housing, b 10.1

system basically consists of an : Pull off the short circuit wire (1).

and b 10.2

ignition module (2) and flywheel (1).

: Take out the screws (arrows).

9.1 Ignition Module 1 : Remove the ground wire (2).

533RA007 TG

1

2

1

533RA139 TG

: Pull off the spark plug boot (1).

533RA142 TG

The ignition module accommodates

all the components required to : Remove the ignition module (1).

control ignition timing. There are

two electrical connections on the

coil body:

40 MS 171, MS 181, MS 211

1

2 2

2

1

533RA143 TG

533RA146 TG

533RA118 TG

The ignition module (1) and ignition – Fit the insulator (1) so that the : Fit the ground wire (2) in the

lead (2) are an assembly. stop (2) is against the upper hole. retainer (1) – ground wire must

face the cylinder (arrow).

– Check the ignition module (1) and : Secure the insulator (1) with the

ignition lead and replace the lugs (arrows) on the bosses.

ignition module if necessary.

2 2 N

S

533RA149 TG

1

1 533RA147 TG

533RA144 TG

– Push the ignition module (1) back

– the flywheel must turn freely.

: Position the ignition module (1)

: Remove the insulator (1) and pull so that the ignition lead (2) is on : Rotate the flywheel until the

off the retainer (2). the left and insert the screw magnet poles (arrows) are next to

(arrow) with washer the ignition module.

– Check the retainer and insulator – do not tighten down yet.

and replace if necessary.

– Check the spark plug boot and

replace if necessary, b 9.4

– Troubleshooting, b 4.5

1

533RA148 TG

: Fit the wire terminal (1) so that it

is against the stop (arrow) and

insert the screw – do not tighten

533RA145 TG

down yet.

: Fit the retainer (1).

MS 171, MS 181, MS 211 41

1

533RA150 TG

533RA152 TG

212RA209 VA

1 1 2 3

: Slide the setting gauge (1) : Push the ignition lead (1) into the Using the ZAT 4 ignition tester

4118 890 6400 between the retainer (arrow) and pull it a little 5910 850 4503

arms of the ignition module and in the direction of the air filter.

the flywheel magnet. – Before starting the test, install a

– Fit the boot on the spark plug. new spark plug in the cylinder

– Press the ignition module against and tighten it down firmly.

the setting gauge. – Reassemble all other parts in the

reverse sequence. – Tightening torques, b 3.5

– Hold the ground wire terminal

and tighten down the screws : Connect spark plug boot to the

firmly. 9.2 Ignition Timing input terminal (1). Push the

tester’s output terminal (3) onto

– Tightening torques, b 3.5 the spark plug

Ignition timing is fixed and cannot

be adjusted during repair work.

– Remove the setting gauge. High voltage – risk of electric shock.

Since there is no mechanical wear

in these systems, ignition timing : Crank the engine quickly with the

– Check operation

cannot get out of adjustment.. rewind starter and check spark in

– rotate the flywheel and make

the tester’s window (2).

sure it does not touch the ignition

module.

9.3 Testing the Ignition The engine may start and

Module accelerate during the test.

If a spark is visible, the ignition

To test the ignition module, use system is in order.

either the ZAT 4 ignition system

tester 5910 850 4503 or the ZAT 3 If no spark is visible in the window

1 ignition system tester (2), check the ignition system with

5910 850 4520. the aid of the troubleshooting chart,

b 9.7

The ignition test refers only to a

533RA151 TG

spark test, not to ignition timing.

: Fit the short circuit wire (1) in the

retainer (arrow) and reconnect it.

Short circuit and ground wires must

be next to one another in the

retainer – ground wire must face the

cylinder.

42 MS 171, MS 181, MS 211

High voltage – risk of electric shock.

– Crank the engine quickly with the mm

rewind starter and check spark in 95,6

the tester’s window (3).

1

The engine may start and

accelerate during the test.

533RA186 TG

533RA375 TG

2 3 If a spark is visible, the ignition

system is in order.

Using ZAT 3 ignition tester – Use a pointed tool to pierce the

If no spark is visible in the window

5910 850 4520 center of the ignition lead’s

(3), check the ignition system with

insulation, 95.6 mm from the end

the aid of the troubleshooting

– Before starting the test, install a of the lead.

chart, b 9.7

new spark plug in the cylinder

and tighten it down firmly

9.4 Spark Plug Boot

– Tightening torques, b 3.5

The ignition module and ignition

– Connect spark plug boot to the

lead are an assembly. If the ignition

terminal (2). lead is damaged, install a new

ignition module.

: Attach ground terminal (1) to the

spark plug. – Remove the shroud, b 8.4

376RA136 TG

: Use adjusting knob (3) to set – Pull the boot off the spark plug.

spark gap to about 2 mm.

: Pinch the hook of the leg spring

into the center of the lead (arrow).

1

533RA153 TG

376RA135 TG

2 34 533RA154 TG

: Use suitable pliers to pull the leg

While using the ZAT 3, hold it only spring out of the spark plug boot.

by the handle (4) or position it in a

safe place. Keep fingers or other – Coat inside of spark plug boot

– Unhook the leg spring from the

parts of your body at least 1 cm with Press Fluid, b 16

ignition lead.

away from the spark window (3),

high voltage connection (2), ground : Hold the ignition lead and leg

connection (5) and the ground – Pull the boot off the ignition lead.

spring together and push them

terminal (1). into the spark plug boot.

MS 171, MS 181, MS 211 43

Inspect flywheel (1) and magnet

poles (2) for cracks or other

damage. If it is damaged or has

turned blue, install a new flywheel.

The flywheel bore and crankshaft

stub must be free from grease,

b 16.

533RA155 TG

533RA157 TG

– On machines with ErgoStart,

check the pawls and replace if

necessary, b 10.4

: Make sure the leg spring (arrow) : Unscrew the flywheel nut (arrow).

locates properly inside the spark

plug boot. If the flywheel is stuck, use the

puller.

Do not use either graphite grease or

silicone insulating paste.

– Reassemble all other parts in the

reverse sequence.

533RA160 TG

9.5 Flywheel

1

533RA158 TG

: Make sure the key (arrow)

1 engages the slot in the crankshaft

stub.

: Screw on the puller (1)

– Check air gap between ignition

1116 893 0800 clockwise as far

module and flywheel and adjust if

as stop and then turn it back a

necessary, b 9.1.1

quarter turn.

533RA156 TG

– Reassemble all other parts in the

– Tap the end of the puller a few

reverse sequence.

times to release the flywheel.

– Remove the shroud, b 8.4 – Tightening torques, b 3.5

– Block the piston with the locking

strip (1), b 6

533RA159 TG

– Unscrew the puller and remove

the flywheel.

44 MS 171, MS 181, MS 211

9.6 Short Circuit Wire 9.6.2 Removing and Installing : Disconnect short circuit wire (1).

9.6.1 Testing

The short circuit and ground wires – Pull the short circuit and ground

are combined in a wiring harness. If wires out of the retainer (arrow).

damaged, the complete wiring

harness must be replaced.

1 When cleaning the machine, take

care not to disconnect wires. 1

– Remove the shroud, b 8.4

533RA161 TG

– Remove the fan housing, b 10.1

533RA164 TG

and b 10.2

If the spark plug, ignition lead and – Remove the carburetor, b 14.3

spark plug boot are in order, check

the short circuit wire. : Remove the wiring harness (1)

from the guide (arrow) – do not

– Remove the shroud, b 8.4 move the cable tie.

1 – Remove the carburetor carrier,

– Remove the fan housing, b 10.1

and b 10.2 b 14.7.1

: Disconnect short circuit wire (1).

533RA162 TG

– Connect the ohmmeter to ground

(arrow) and the short circuit (1).

– Set the Master Control lever to : Pull off the spark plug boot (1). 1

“0”.

: Pull the ignition lead out of the

533RA165 TG

The resistance measured must be retainer (arrow). 2

about 0 Ω. If it is much higher, the

reason is a break and the wire has

to be replaced, b 9.6.2

– Pull the short circuit and ground

– Set the Master Control lever “#“. wires out of the guides (arrows).

The resistance measured must be : Disconnect connectors of short

infinitely high. If not, fit a new short circuit wire (1) and ground wire

circuit wire, b 9.6.2 1 (2).

If no fault can be found, check the – Remove the wiring harness.

533RA163 TG

ignition system with the aid of the

troubleshooting chart, b 9.7 2

– Check ground wire for continuity. : Take out the screw and remove

the ground wire (2).

– Install in the reverse sequence.

MS 171, MS 181, MS 211 45

2 1

533RA166 TG

533RA168 TG

533RA171 TG

1 1

: Check the short circuit wire (1) : Fit the wiring harness (1) along : Press the wires into the guides

and ground wire (2) and replace the housing and push it, ground (1) first, then into the guides

wiring harness if necessary. wire first, completely into the (arrows).

guide (arrow).

A faulty ground wire can impair or The wires must be against the

prevent operation of the short circuit housing and must not cross each

wire. For this reason also check the other.

ground wire for contact and

continuity.

Installing 1 533RA169 TG

1 2

2

533RA172 TG

: Push ground wire connector with

protective tube (2) onto the

contact spring (1).

533RA167 TG

The short circuit wire must be

looped (arrow) so that it can move

with the switch shaft.

The following steps are shown

without the manifold for greater

clarity.

: Push the wiring harness, short

1

circuit wire (1) first, into the guide

(arrow).

533RA170 TG

The cable tie (2) must rest on the 1

guide and point in the direction of

533RA173 TG

the cylinder – do not move the cable

tie on the wiring harness. : Push short circuit wire connector

(1) into receptacle on switch shaft

(arrow) as far as stop.

: Position the ground wire (1)

against the protective rib (arrow)

– to avoid unintentional

disconnection.

46 MS 171, MS 181, MS 211

9.6.3 Ground Wire

1

A faulty ground wire can impair or

prevent operation of the short circuit

wire. Always check ground wire for

contact and continuity.

The short circuit and ground wires

533RA177 TG

533RA174 TG

are combined in a wiring harness. If

damaged, the complete wiring

harness must be replaced.

: Check operation : Ease the contact spring (1) over

– the short circuit wire’s – Check for contact and continuity the lug (arrow) and pull it out.

connector must touch the contact and replace wiring harness if

spring (arrow) in position “0“. necessary, b 9.6.1

– Check contact spring and replace

if necessary.

– Install the carburetor carrier, – Remove and install wiring

b 14.7.1 harness, b 9.6.2

1

9.6.4 Contact Spring

533RA178 TG

533RA175 TG

: Push the contact spring (1) into

533RA176 TG

the guide so that it lines up with

: Attach the wires, short circuit wire 1 the recess (arrows).

first, to the guide (arrow)

– the protective tube (1) must – Remove the switch shaft, b 12.1

engage the guide.

: Disconnect the ground wire (1). 1

– Fit the ground and short circuit

wires in the retainer and connect

them up, b 9.1.1

– Install the ignition lead, b 9.1

533RA179 TG

– Check air gap on ignition module

and adjust if necessary, b 9.1.1

– Reassemble all other parts in the : Push the contact spring (1) into

reverse sequence. its seat until the lug (arrow) snaps

into position.

– Tightening torques, b 3.5

MS 171, MS 181, MS 211 47

1

533RA169 TG

533RA174 TG

2

– Install the switch shaft, b 12.1 : Check operation

– the short circuit wire’s

: Push ground wire connector with connector must touch the contact

protective tube (2) onto the spring (arrow) in position “0“.

contact spring (1).

– The ground and short circuit

wires must be laid close to the

housing and properly seated in

the guides, b 9.6.2

– Reassemble all other parts in the

reverse sequence.

1 – Tightening torques, b 3.5

533RA173 TG

: Position the ground wire (1)

against the protective rib (arrow)

– to avoid unintentional

disconnection

48 MS 171, MS 181, MS 211

9.7 Ignition System Troubleshooting

Engine does not run

Switch shaft:

– in position ”#“?

Check the spark plug:

– Smeared with oil, black?

– Sooted?

– Electrode gap correct?

– Contacts shorted?

– Clean or replace the plug,

b 9.3

Check spark plug boot:

– Firmly seated on plug (leg spring)?

– Leg spring hook in center of ignition lead?

– Boot damaged?

– If necessary, install new spark plug boot

and/or leg spring,

b 9.4

Test ignition system:

with ZAT 3 or ZAT 4

(use ZAT 3 as main spark gap

– see TI 32.94),

b 9.3

MS 171, MS 181, MS 211 49

1

Powerful yes

spark?

no

Air gap:

– Check ignition module/flywheel,

– reset if necessary, b 9.1.1

Check flywheel:

– Have pole shoes turned blue?

– Install new flywheel if necessary,

b 9.5

Check ground and short circuit wires:

– Wire damaged?

– Connectors firmly seated?

– Check continuity, replace wiring harness if

necessary, b 9.6.1

Check ignition lead:

– Severe chafing?

– Spark plug boot: Holes/cracks?

– Resistance: spark plug boot to ground:

spec. 1.5 – 12 kΩ

If necessary, install new spark plug boot

and/or ignition lead with ignition module,

b 9.4

2 3

50 MS 171, MS 181, MS 211

2 3

Check operation

of switch shaft:

– Short circuit wire chafed?

– Does contact spring make contact

with short circuit wire in position “#“?

– If necessary, install new

wiring harness,

b 9.6.2

Powerful yes

spark?

no

Install new

ignition module,

b 9.1.1

yes Engine no

runs

Machine runs trouble-free, –Look for fault in fuel system

no further action necessary or carburetor

– Check engine for leaks

– Check position of flywheel on

crankshaft,

b 8.2, b 9.5

MS 171, MS 181, MS 211 51

10. Rewind Starter

10.1 General 10.2 Removing and Installing – Check the fan housing and

segment and replace if

necessary.

If the action of the starter rope

becomes very stiff and the rope

rewinds very slowly or not

completely, it can be assumed that

the starter mechanism is in order

1

but plugged with dirt. At very low

outside temperatures the lubricating

oil on the rewind spring may thicken

533RA180 TG

and cause the spring windings to

stick together. This has a

detrimental effect on the function of

533RA183 TG

the starter mechanism.

– Remove the shroud, b 8.4

In such a case it is sufficient to apply

a few drops of a standard solvent- : Turn the starter grip sideways

based degreasant (containing no and take out the screws (arrows). : Fit the segment (1) in the slots

(arrows) in the fan housing, then

chlorinated or halogenated

push it into the locking tab until it

hydrocarbons) to the rewind spring.

snaps into position.

Carefully pull out the starter rope

several times and allow it to rewind

until its normal smooth action is

restored.

1 1

Before installing, lubricate the

rewind spring and starter post with 2

STIHL special lubricant.

533RA181 TG

If clogged with dirt or pitch, the

533RA184 TG

entire starter mechanism, including

the rewind spring, must be removed – Use a screwdriver to pry the hand

and disassembled. Take particular guard (1) off the boss (arrow) and

care when removing the spring. remove the fan housing (2).

: Fit and tighten down the screws

(arrows) firmly – the hand guard

– Clean all components, b 16

is secured with the screw (1) and

1 washer.

Machines with ErgoStart

– Relieve tension of spring, – Tightening torques, b 3.5

b 10.4

533RA182 TG

: Push the locking tab (arrow) to

one side and take out the

segment (1).

52 MS 171, MS 181, MS 211

10.3 Pawl : Push the straight part of the

spring clip over the starter post

until it snaps into the groove.

– Reassemble all other parts in the 1

reverse sequence.

1

3 Machines with ErgoStart

533RA189 TG

2

533RA185 TG

: Position the spring clip (1) so that

its loops engage the pegs on the

1 pawls and its curved part (arrow)

– Remove the fan housing, b 10.1

is in the starter post’s groove.

and b 10.2 2

2

: Push the straight part of the

533RA189 TG

: Grip the straight end of the spring

spring clip over the starter post

clip (1) and ease it off the starter

post – the rewind spring may pop 3 until it snaps into the groove.

out during this operation.

– Remove the ErgoStart, b 10.4 – Reassemble all other parts in the

– Remove and inspect the pawl (2), reverse sequence.

clean or replace if necessary. : Grip the straight part of the spring

clip (1), ease it out of the groove

and pull the spring clip off the 10.4 ErgoStart

– Lubricate seat of new pawl with

starter post – the rewind spring

grease, b 16

may pop out during this

The spring may still be under

operation. tension. Always relieve tension of

– Fit the new pawl and lubricate its