Beruflich Dokumente

Kultur Dokumente

The Cold Drawing Process For Bars and Coils

Hochgeladen von

quirogasOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

The Cold Drawing Process For Bars and Coils

Hochgeladen von

quirogasCopyright:

Verfügbare Formate

The Cold Drawing

Process for Bars

and Coils

• Raw Stock: Hot rolled steel bar or rod

coils are used as raw material. Because

the hot rolled products are produced at

elevated temperatures (1700 - 2200

Deg. F. i.e. hot rolling), they generally

have a rough and scaled surface and

may also exhibit variations in section

and size.

• Cleaning: Abrasive scale (iron oxide) on the surface of the hot rolled rough stock is removed.

• Coating: The surface of the bar or coil is coated with a drawing lubricant to aid cold drawing.

• Pointing: Several inches of the lead ends of the bar or coil are reduced in size by swaging or extruding

so that it can pass freely through the drawing die. Note: This is done because the die opening is

always smaller than the original bar or coil section size.

• Drawing: In this process, the material being drawn is at room temperature (i.e. Cold-Drawn). The

pointed/reduced end of the bar or coil, which is smaller than the die opening, is passed through the die

where it enters a gripping device of the drawing machine. The drawing machine pulls or draws the

remaining unreduced section of the bar or coil through the die. The die reduces the cross section of

the original bar or coil, shapes the profile of the product and increases the length of the original

product.

• Finished Product: The drawn product, which is referred to as Cold Drawn or Cold Finished, exhibits a

bright and/or polished finish, increased mechanical properties, improved machining characteristics and

precise and uniform dimensional tolerances.

• Multi-Pass Drawing: The cold drawing of complex shapes/profiles may require that each bar/coil be

drawn several times in order to produce the desired shape and

tolerances. This process is called multi-pass drawing and involves

drawing through smaller and smaller die openings. Material is

generally annealed between each drawing pass to remove cold work

and to increase ductility.

• Annealing: This is a thermal treatment generally used to soften the

material being drawn, to modify the microstructure, the mechanical

properties and the machining characteristics of the steel and/or to

remove internal stresses in the product. Depending on the desired

characteristics of the finished product, annealing may be used before,

during (between passes) or after the cold drawing operation,

depending on material requirements.

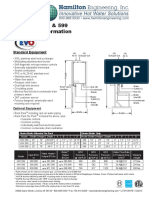

Example of Carbide Die Cross Section

BELL - ANGLE OR RADIUS

ENTRY ANGLE

APPROACH ANGLE

BEARING

HOT ROLLED BAR

DIAMETER COLD DRAWN BAR

DIAMETER

BACK RELIEF ANGLE

CLEANED (Iron Oxide Scale Removed)

HOT ROLLED BAR BAR CENTER LINE

COATED WITH DRAWING LUBRICANT COLD DRAWN BAR

COLD DRAWN BAR

SURFACE SMOOTH &

HOT ROLLED BAR HAS ROUGH BRIGHT AND NO

SURFACE AND IS OUT-OF- ROUND CARBIDE DIE OUT-OF-ROUND

CROSS SECTION PROFILE

Area of Die COLD DRAWING DIRECTION

(NOTE: As the hot rolled bar is pulled through the carbide die, the die compresses and enlogates the bar around the centerline.)

Customer Benefits of Cold Drawn Bar

and Wire vs. Hot Rolled Bar or Rod

Cold Drawn Product Features / Customer Benefits

• Improved Size and Section / Reduces machining losses

• Tighter size & section tolerances

• Dimensional consistency within each bar

• Dimensional consistency from bar to bar

• Improved Surface Finish / Reduces surface machining &

improves quality

• Cold drawn

• Ground and polished

• Surface Improvement (Shaving or turning to produce

"Defect Free" surface)

• Improved Straightness / Facilitates automatic bar feeding

• Increased Mechanical Properties / Can reduce the need for hardening

• Yield strength

• Tensile strength

• Hardness

• Improve Machinability and Productivity / Enables higher machining feeds & speeds and

improved machined finish.

• Increased machining rates

• Longer tool life

• Improved yield

• Improved Formability / Improves response to spheroidization Cold Drawn and Annealed

• Improved Cost Effectiveness / Optimizes machinability and reduces yield losses

Production of Precision Shapes to Precision Tolerances

Das könnte Ihnen auch gefallen

- Forging Operations - Machine Forging, Forging Dies and Special Forging OperationsVon EverandForging Operations - Machine Forging, Forging Dies and Special Forging OperationsNoch keine Bewertungen

- Rolling Mill DetailsDokument32 SeitenRolling Mill DetailsGovind RaoNoch keine Bewertungen

- Distortion in Weld JointDokument54 SeitenDistortion in Weld JointDiVik BhargAva100% (1)

- Aluminium Extrusion Training Aluminium EDokument68 SeitenAluminium Extrusion Training Aluminium EChitranjan Kumar100% (1)

- Quality Problems in Continuous Cast ProductsDokument47 SeitenQuality Problems in Continuous Cast Productsmanas burmaNoch keine Bewertungen

- EVO 299, 399, & 599 Technical Information: Standard EquipmentDokument2 SeitenEVO 299, 399, & 599 Technical Information: Standard EquipmentOscar GarayNoch keine Bewertungen

- G MadanPresnDokument32 SeitenG MadanPresnpulilathaNoch keine Bewertungen

- D SeriesDokument2 SeitenD SeriesRupesh ParaswarNoch keine Bewertungen

- KYOCERA CatalogueDokument95 SeitenKYOCERA CatalogueMANIT KUMAR BHOINoch keine Bewertungen

- Gas Turbine Fundamentals - 15mar2022 - R1Dokument35 SeitenGas Turbine Fundamentals - 15mar2022 - R1Chinelo GilbertNoch keine Bewertungen

- Welding DistortionDokument51 SeitenWelding DistortionRaj singhNoch keine Bewertungen

- Equipo Split Ducto YORK R22 Asia Manejadora YNSFXC060BBQ FXDokument4 SeitenEquipo Split Ducto YORK R22 Asia Manejadora YNSFXC060BBQ FXJheyson Maquera Mengoa0% (1)

- Basic Sheet and Coil Training Edit VersionDokument35 SeitenBasic Sheet and Coil Training Edit VersioncuongdcNoch keine Bewertungen

- 1441793840rbfatank Dada Sheet 50kl ss304Dokument1 Seite1441793840rbfatank Dada Sheet 50kl ss304Suaib VCSNoch keine Bewertungen

- JNF12 Hales 2380 PDFDokument18 SeitenJNF12 Hales 2380 PDFagilan89Noch keine Bewertungen

- Alfacond Range: Plate CondensersDokument2 SeitenAlfacond Range: Plate Condensersandres mNoch keine Bewertungen

- CRCA Technical Notes - 2018Dokument11 SeitenCRCA Technical Notes - 2018Sajib Chandra RoyNoch keine Bewertungen

- 2 - Flex Bellow Assembly 304 Stainless - 2 - Stainless Flex Pipe - Ace Race PartsDokument4 Seiten2 - Flex Bellow Assembly 304 Stainless - 2 - Stainless Flex Pipe - Ace Race Partsait oubella marouaneNoch keine Bewertungen

- Djei Opi Kahru Ioeg4Dokument1 SeiteDjei Opi Kahru Ioeg4P DNoch keine Bewertungen

- Shell Rolling ProcedureDokument26 SeitenShell Rolling ProcedureKingston Rivington100% (1)

- Albrecht Precision Drill Chucks: The World'S Most Consistently Accurate Drill ChucksDokument10 SeitenAlbrecht Precision Drill Chucks: The World'S Most Consistently Accurate Drill ChucksfgrefeNoch keine Bewertungen

- Shell Rolling For Pressure VesselsDokument26 SeitenShell Rolling For Pressure VesselsSHREEJINoch keine Bewertungen

- SABIC Flat ProductDokument15 SeitenSABIC Flat ProductAiman AliNoch keine Bewertungen

- High Static Ducted Split System (YSB)Dokument35 SeitenHigh Static Ducted Split System (YSB)Mai Hữu Nhân100% (4)

- AISI 8720 SteelDokument1 SeiteAISI 8720 SteelSIVASUTECH ENTERPRISESNoch keine Bewertungen

- PF Cfhe Coils enDokument2 SeitenPF Cfhe Coils enfeyza cebiNoch keine Bewertungen

- Hyundai Steel Products GuideDokument40 SeitenHyundai Steel Products GuidecarloNoch keine Bewertungen

- Annealing FundamentalsDokument41 SeitenAnnealing FundamentalsSuvro ChakrabortyNoch keine Bewertungen

- Double Regulating ValveDokument24 SeitenDouble Regulating ValveMohamed Rady33% (3)

- Technical Specification: Submersible Pump B 2066, 60 HZDokument8 SeitenTechnical Specification: Submersible Pump B 2066, 60 HZSebastian Amézaga ZegarraNoch keine Bewertungen

- Reinforcement Steel WorksDokument28 SeitenReinforcement Steel WorksPooja PawarNoch keine Bewertungen

- 9 Rolling, ForgingDokument103 Seiten9 Rolling, Forgingkagarwal3be23Noch keine Bewertungen

- Disbo-Extra: Innovative Design To Fit All InteriorsDokument5 SeitenDisbo-Extra: Innovative Design To Fit All Interiorsvimal alaberahNoch keine Bewertungen

- Carbon Steel Fact SheetDokument2 SeitenCarbon Steel Fact Sheettshepo hlakudiNoch keine Bewertungen

- Wet Beta Gamma Picoline TankDokument1 SeiteWet Beta Gamma Picoline Tanksushant_jhawerNoch keine Bewertungen

- RollingDokument22 SeitenRollingSahil JhambNoch keine Bewertungen

- Change !!: Change Change Change ChangeDokument20 SeitenChange !!: Change Change Change Changexmen norNoch keine Bewertungen

- Self-Drilling Dowel: Steel and AluminumDokument6 SeitenSelf-Drilling Dowel: Steel and AluminumLucas SeñaNoch keine Bewertungen

- Bar Basics and TerminologyDokument24 SeitenBar Basics and TerminologyEdwin MPNoch keine Bewertungen

- G100 Geneglace Brochure PremiumDokument2 SeitenG100 Geneglace Brochure Premiumtamphamdinh02Noch keine Bewertungen

- Product Catalogue Pt. GRDDokument40 SeitenProduct Catalogue Pt. GRDkrisna monicaNoch keine Bewertungen

- Ch4 SheetMetalDokument10 SeitenCh4 SheetMetalmaurya21Noch keine Bewertungen

- Remelting For Highest StandardsDokument12 SeitenRemelting For Highest StandardsX800XLNoch keine Bewertungen

- Welding Processes Welding KnowledgeDokument85 SeitenWelding Processes Welding KnowledgeIshtiaqNoch keine Bewertungen

- A Seminar Report On: Production of Ball BearingDokument25 SeitenA Seminar Report On: Production of Ball BearingParveen KumarNoch keine Bewertungen

- Cilindro BimbaDokument133 SeitenCilindro Bimbajuan apazaNoch keine Bewertungen

- Metal Seated Ball ValveDokument24 SeitenMetal Seated Ball Valvehiep nguyenNoch keine Bewertungen

- End Mill Basic TrainingDokument22 SeitenEnd Mill Basic TrainingChiao YunNoch keine Bewertungen

- Welcome To Honingcraft: Total Support in Hydraulic Cylinder ManufacturingDokument34 SeitenWelcome To Honingcraft: Total Support in Hydraulic Cylinder ManufacturingSHANENoch keine Bewertungen

- NSK - HPS Brochure FinalDokument8 SeitenNSK - HPS Brochure FinalRicardo PerezNoch keine Bewertungen

- Cold Rolling (DG Teori Detil)Dokument32 SeitenCold Rolling (DG Teori Detil)Baginda HamzahNoch keine Bewertungen

- ABCO - Hammer UnionsDokument2 SeitenABCO - Hammer UnionsOman Baptist ChurchNoch keine Bewertungen

- Technical Data Sheet For Shell and Tube Heat Exchager Design SpecificationDokument4 SeitenTechnical Data Sheet For Shell and Tube Heat Exchager Design SpecificationSakthi VelNoch keine Bewertungen

- TS PR Residential SeriesDokument2 SeitenTS PR Residential SeriesGégé di TPNoch keine Bewertungen

- 20160331071021-6541 23MnNiCrMo52Dokument1 Seite20160331071021-6541 23MnNiCrMo52rusf123Noch keine Bewertungen

- Rolling Mills and Strip Processing Lines: Capital Market Days 2007Dokument40 SeitenRolling Mills and Strip Processing Lines: Capital Market Days 2007Vikanshu bansalNoch keine Bewertungen

- Type 55b Ds Feb18Dokument3 SeitenType 55b Ds Feb18Suresh KumarNoch keine Bewertungen

- T GRP Catalogue 28102021Dokument80 SeitenT GRP Catalogue 28102021Muhammad FadhilNoch keine Bewertungen

- Yu13 EndmilDokument446 SeitenYu13 EndmilBrian FloresNoch keine Bewertungen

- The Effect of Different Vegetable Peelings and Additives/Chemicals Added To The Quality and Characteristics of BioplasticsDokument55 SeitenThe Effect of Different Vegetable Peelings and Additives/Chemicals Added To The Quality and Characteristics of BioplasticsAirielle MiotenNoch keine Bewertungen

- Separation of Ions by Fractional PrecipitationDokument45 SeitenSeparation of Ions by Fractional PrecipitationPrincess NavarroNoch keine Bewertungen

- Intrepid FBV15285 - Coil Damage ReportDokument10 SeitenIntrepid FBV15285 - Coil Damage ReportVIKTORNoch keine Bewertungen

- Science 5 q3 Module 3Dokument7 SeitenScience 5 q3 Module 3Alli SinaNoch keine Bewertungen

- Compressive Strength Modelling of Concrete Mixed With Fly Ash and Waste Ceramics Using K-Nearest Neighbor AlgorithmDokument6 SeitenCompressive Strength Modelling of Concrete Mixed With Fly Ash and Waste Ceramics Using K-Nearest Neighbor AlgorithmNewton GalileoNoch keine Bewertungen

- Sucker Rod Pump BasicsDokument76 SeitenSucker Rod Pump BasicsDumitrescu GabrielNoch keine Bewertungen

- NGL CT 1 0000 Pi SP 2013 D1 PDFDokument21 SeitenNGL CT 1 0000 Pi SP 2013 D1 PDFAnonymous cVnKDdhNoch keine Bewertungen

- GSTS Module-5Dokument14 SeitenGSTS Module-5Poison PinkNoch keine Bewertungen

- DOICT - Technical SpecificationsDokument6 SeitenDOICT - Technical Specificationsahmadmukit0Noch keine Bewertungen

- Cement BoardDokument5 SeitenCement BoardYsabella May Sarthou CervantesNoch keine Bewertungen

- Water Pollution, Causes and EffectsDokument28 SeitenWater Pollution, Causes and EffectsRuchir Gupta67% (3)

- 175 171500Dokument3 Seiten175 171500balajiNoch keine Bewertungen

- Materials Characterization: Iwona Sulima, Sonia Boczkal, Lucyna JaworskaDokument10 SeitenMaterials Characterization: Iwona Sulima, Sonia Boczkal, Lucyna JaworskaGunawan DarmaNoch keine Bewertungen

- Data Sheet: Experiment 1: Chemical ReactionsDokument17 SeitenData Sheet: Experiment 1: Chemical ReactionsLinh NguyễnNoch keine Bewertungen

- Mathalino: E N W S G S V V V V V W W W D Γ Γ Γ Γ Γ Γ Γ Γ Ll Pl Li Pi GiDokument8 SeitenMathalino: E N W S G S V V V V V W W W D Γ Γ Γ Γ Γ Γ Γ Γ Ll Pl Li Pi GiLovely Joy ArdanielNoch keine Bewertungen

- Astm C1567 - 13 PDFDokument6 SeitenAstm C1567 - 13 PDFAnonymous SBjNS7Gw0qNoch keine Bewertungen

- G 94 - 05 (2014)Dokument31 SeitenG 94 - 05 (2014)jose floresNoch keine Bewertungen

- F2 Chem Et2 QNDokument11 SeitenF2 Chem Et2 QNJOSEPH MWANGINoch keine Bewertungen

- 15 - Mangla Joshi PDFDokument22 Seiten15 - Mangla Joshi PDFSHIKHA SINGHNoch keine Bewertungen

- Safety Data Sheet Chemical Aquatrol - 275-1Dokument4 SeitenSafety Data Sheet Chemical Aquatrol - 275-1nikoNoch keine Bewertungen

- Trends in Period 3Dokument47 SeitenTrends in Period 3abby jacksonNoch keine Bewertungen

- The Effects of Mechanical Stress On Semiconductor DevicesDokument3 SeitenThe Effects of Mechanical Stress On Semiconductor Devicesvishnu vardhanNoch keine Bewertungen

- Method Statement For Stone Finish GRC Fabrication and ErectionDokument5 SeitenMethod Statement For Stone Finish GRC Fabrication and ErectionAnjo MolinaNoch keine Bewertungen

- What Is Column Chromatography?Dokument4 SeitenWhat Is Column Chromatography?rajeev KumarNoch keine Bewertungen

- Is 14745 1999 Thermic FluidsDokument8 SeitenIs 14745 1999 Thermic FluidsRajesh KumarNoch keine Bewertungen

- Laporan Material Teknik 2021Dokument23 SeitenLaporan Material Teknik 2021Rasendriya JettaNoch keine Bewertungen

- Smith Industries WaterBath Indirect Heater PDFDokument29 SeitenSmith Industries WaterBath Indirect Heater PDFcassindromeNoch keine Bewertungen

- Firestop: B-Line Series Cable Tray Systems EatonDokument6 SeitenFirestop: B-Line Series Cable Tray Systems EatonibharNoch keine Bewertungen

- Misumi OilFreeBushing p281 282Dokument1 SeiteMisumi OilFreeBushing p281 282Lutfi ArdiansyahNoch keine Bewertungen

- DVS Technical Codes On Plastics Joining TechnologiesDokument11 SeitenDVS Technical Codes On Plastics Joining TechnologiesjavierNoch keine Bewertungen