Beruflich Dokumente

Kultur Dokumente

Polymat User's Guide

Hochgeladen von

alejandroCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Polymat User's Guide

Hochgeladen von

alejandroCopyright:

Verfügbare Formate

Table of Contents

Using This Manual

1. The Contents of This Manual

2. The Contents of the ANSYS Polyflow Manuals

3. How to Use This Manual

3.1. For the Beginner

3.2. For the Experienced User

4. Typographical Conventions Used in This Manual

5. Contacting Technical Support

1. Getting Started

1.1. Introduction

1.2. Program Structure

1.3. Overview of Using ANSYS Polymat

1.3.1. Planning Your ANSYS Polymat Analysis

1.3.2. Steps for Fitting Material Parameters

1.4. Starting ANSYS Polymat

1.5. Starting ANSYS Polycurve

1.6. Sample Session

1.6.1. Problem Description

1.6.2. Outline of Procedure

1.6.3. Using the Non-Automatic Fitting Method

1.6.3.1. Defining the Experimental Data

1.6.3.2. Specifying the Curves to be Calculated

1.6.3.3. Defining Numerical Parameters

1.6.3.4. Defining the Type of Fluid Model

1.6.3.5. Fitting the Material Parameters

1.6.3.5.1. Finding the Value of K

1.6.3.5.1.1. Trying K=1

1.6.3.5.2. Trying Other Values of K

1.6.3.5.2.1. Finding the Value of n

1.6.3.6. Saving the Parameters to a Material Data File

1.6.3.7. Saving the Experimental Data to a File

1.6.3.8. Exiting from ANSYS Polymat

1.6.4. Using the Automatic Fitting Method

1.6.4.1. Defining the Type of Fluid Model

1.6.4.2. Fixing the Values of Parameters to Remain Constant

1.6.4.3. Reading in the Experimental Data

1.6.4.4. Drawing the Experimental Data Curve

1.6.4.5. Limiting the Range of the Fitting Calculation

1.6.4.6. Specifying a Name for the Material Data File

1.6.4.7. Performing the Automatic Fitting

2. User Interface

2.1. Polymat GUI Components

2.1.1. The Menu Bar

2.1.2. The Menu Buttons

2.1.3. The Menu

2.1.4. The Chart Buttons

2.1.5. The Chart Window

2.1.6. The Curve Buttons

2.1.7. The Curve List

2.1.8. The Curve Settings

2.1.9. The Output Text Window

2.2. Polycurve GUI Components

3. Reading and Writing Files

3.1. Files Written or Read by ANSYS Polymat and ANSYS Polycurve

3.2. Reading Experimental Data

3.2.1. Reading Experimental Data Curves for the Non-Automatic Fitting Method

3.2.2. Reading Experimental Data Curves for the Automatic Fitting Method

3.3. Saving Experimental Data

3.4. Reading and Writing Material Data

3.5. Reading CAMPUS Material Property Files

4. Unit Systems

4.1. Overview of Units

4.2. Converting to a New Unit System

4.3. Restrictions on Units

5. Fitting Material Parameters

5.1. Introduction

5.2. Non-Automatic Fitting

5.2.1. Steps for Non-Automatic Fitting

5.2.2. Specifying the Curves to be Calculated

5.2.3. Defining Numerical Parameters

5.2.4. Selecting the Type of Fluid Model

5.2.5. Defining Initial Values for the Material Parameters

5.2.6. Performing the Fitting Analysis

5.3. Automatic Fitting

5.3.1. Steps for Automatic Fitting

5.3.2. Selecting the Type of Fluid Model

5.3.3. Fixing Values for Selected Material Parameters

5.3.4. Defining Numerical Parameters

5.3.5. Drawing the Experimental Curves

5.3.6. Specifying a Name for the Material Data File

5.3.7. Performing the Automatic Fitting Analysis

6. Material Data Parameters

6.1. Overview of Fluid Properties and Flow Characteristics

6.2. Generalized Newtonian Flow

6.2.1. Introduction

6.2.1.1. Equations

6.2.1.2. Inputs

6.2.2. Shear-Rate Dependence of Viscosity

6.2.2.1. Constant

6.2.2.2. Bird-Carreau Law

6.2.2.3. Power Law

6.2.2.4. Bingham Law

6.2.2.5. Modified Bingham Law

6.2.2.6. Herschel-Bulkley Law

6.2.2.7. Modified Herschel-Bulkley Law

6.2.2.8. Cross Law

6.2.2.9. Modified Cross Law

6.2.2.10. Log-Log Law

6.2.2.11. Carreau-Yasuda Law

6.2.3. Temperature Dependence of Viscosity

6.2.3.1. Arrhenius Law

6.2.3.2. Approximate Arrhenius Law

6.2.3.3. Arrhenius Shear-Stress Law

6.2.3.4. Approximate Arrhenius Shear-Stress Law

6.2.3.5. Fulcher Law

6.2.3.6. WLF Law

6.2.3.7. WLF Shear-Stress Law

6.2.3.8. Mixed-Dependence Law

6.3. Differential Viscoelastic Flow

6.3.1. Introduction

6.3.1.1. Equations

6.3.1.2. Inputs

6.3.2. Differential Viscoelastic Models

6.3.2.1. Upper-Convected Maxwell Model

6.3.2.1.1. Equations

6.3.2.1.2. Inputs

6.3.2.1.3. Behavior Analysis

6.3.2.2. Oldroyd-B Model

6.3.2.2.1. Equations

6.3.2.2.2. Inputs

6.3.2.2.3. Behavior Analysis

6.3.2.3. White-Metzner Model

6.3.2.3.1. Equations

6.3.2.3.2. Guidelines for Fitting

6.3.2.3.3. Inputs

6.3.2.3.4. Behavior Analysis

6.3.2.4. Phan-Thien-Tanner Model

6.3.2.4.1. Equations

6.3.2.4.2. Inputs

6.3.2.4.3. Behavior Analysis

6.3.2.5. Giesekus Model

6.3.2.5.1. Equations

6.3.2.5.2. Inputs

6.3.2.5.3. Behavior Analysis

6.3.2.6. FENE-P Model

6.3.2.6.1. Equations

6.3.2.6.2. Inputs

6.3.2.6.3. Behavior Analysis

6.3.2.7. POM-POM Model [DCPP]

6.3.2.7.1. Inputs

6.3.2.7.2. Behavior Analysis

6.3.2.8. Leonov Model

6.3.2.8.1. Inputs

6.3.2.8.2. Identification of Model Parameters and Functions

6.3.2.8.3. Behavior Analysis

6.3.3. Temperature Dependence of Viscosity

6.3.4. Multiple Relaxation Times for Differential Viscoelastic Flows

6.4. Integral Viscoelastic Flow

6.4.1. Introduction

6.4.1.1. Equations

6.4.1.2. Inputs

6.4.2. Integral Viscoelastic Models

6.4.2.1. Doi-Edwards Model

6.4.2.2. KBKZ Model

6.4.2.3. Influence of Damping Functions and Their Parameters

6.4.2.3.1. Oscillatory Shear Flow

6.4.2.3.2. Simple Shear Flow

6.4.2.3.3. Extensional Flow

6.4.2.3.4. Transient Shear Flow

6.4.3. Temperature Dependence of Viscosity

6.5. Simplified Viscoelastic Model

6.5.1. Equations

6.5.2. Identification of Model Parameters and Functions

6.5.3. Inputs

6.5.4. Behavior Analysis

7. Rheological Properties

7.1. Steady Simple Shear Flow

7.2. Steady Extensional Flow

7.3. Oscillatory Shear Flow

7.4. Transient Shear Flow

7.5. Transient Extensional Flow

8. Defining and Plotting Curves

8.1. Overview

8.1.1. Definitions of Terms

8.2. Working with Curves

8.2.1. Defining Experimental Data Curves

8.2.2. Reading Curve Files

8.2.3. Deleting a Curve

8.2.4. Modifying a Curve Definition

8.2.5. Saving a Curve

8.2.6. Moving or Copying a Curve

8.2.7. Modifying Curve Display Attributes

8.3. Adding, Removing, and Modifying Charts

8.3.1. Adding and Removing a Chart

8.3.2. Modifying the Title and Legend

8.3.3. Modifying the Range and Scaling

8.3.4. Modifying the Axis Attributes

9. Guidelines for Viscoelastic Models

9.1. Introduction

9.2. The Weissenberg Number

9.3. Viscometric and Rheometric Measurements

9.3.1. Oscillatory Properties

9.3.2. Steady-State Shear Viscosity

9.3.3. First Normal-Stress Difference

9.3.4. Transient Uniaxial Elongational Viscosity

9.4. General Strategy for Fitting

9.4.1. Weighting Measured Data

9.4.2. Assigning a Value to a Parameter

9.4.3. Using Identical or Independent Nonlinear Parameters

9.4.4. Relaxation Time vs. Relaxation Spectrum in Extrusion, Fiber Spinning, and Film Casting

9.4.5. Relaxation Time vs. Relaxation Spectrum in Blow Molding and Thermoforming

9.4.6. Relaxation Time vs. Relaxation Spectrum in Pressing

9.5. Guidelines for Extrusion

9.5.1. Important Effects

9.5.1.1. 2D Extrusion

9.5.1.2. 3D Extrusion

9.5.2. Recommended Experimental Data

9.5.3. Recommended Models and Parameters

9.6. Guidelines for Fiber Spinning

9.6.1. Important Effects

9.6.1.1. 2D Fiber Spinning

9.6.1.2. 3D Fiber Spinning

9.6.2. Recommended Experimental Data

9.6.3. Recommended Models and Parameters

9.7. Guidelines for Film Casting

9.7.1. Important Effects

9.7.2. Recommended Experimental Data

9.7.3. Recommended Models and Parameters

9.8. Guidelines for Blow Molding and Thermoforming

9.8.1. Important Effects

9.8.2. Recommended Experimental Data

9.8.3. Recommended Models and Parameters

9.8.3.1. 2D and 3D Blow Molding and Thermoforming

9.8.3.2. Blow Molding and Thermoforming with Shell Models

9.9. Guidelines for Pressing

9.9.1. Important Effects

9.9.2. Recommended Experimental Data

9.9.3. Recommended Models and Parameters

9.10. Empirical Rules and Principles

9.10.1. Cox-Merz Rule

9.10.2. Gleissle Mirror Relationships

9.10.3. First Normal Stress Difference Relationships

9.10.4. Time-Temperature Equivalence

10. Examples

10.1. Example 1: Non-Isothermal Generalized Newtonian Model

10.1.1. Experimental Data

10.1.2. Fitting Procedure in ANSYS Polymat

10.1.2.1. Step 1: Define the Fluid Model Type

10.1.2.2. Step 2: Specify the Material Data Models and Fix Parameters

10.1.2.3. Step 3: Read in and Draw the Experimental Data Curves

10.1.2.4. Step 4: Run the Fitting Calculation

10.1.2.5. Results

10.2. Example 2: Non-Isothermal Differential Viscoelastic Model

10.2.1. Experimental Data

10.2.2. Fitting Procedure in ANSYS Polymat

10.2.2.1. Step 1: Define the Fluid Model Type

10.2.2.2. Step 2: Specify the Material Data Models and Fix Parameters

10.2.2.3. Step 3: Read in and Draw the Experimental Data Curves

10.2.2.4. Step 4: Set Numerical Options and Run the Fitting Calculation

10.2.2.5. Results

10.3. Example 3: Non-Isothermal Integral Viscoelastic Model

10.3.1. Experimental Data

10.3.2. Fitting Procedure in ANSYS Polymat

10.3.2.1. Step 1: Define the Fluid Model Type

10.3.2.2. Step 2: Specify the Material Data Models and Fix Parameters

10.3.2.3. Step 3: Read in and Draw the Experimental Data Curves

10.3.2.4. Step 4: Set Numerical Options and Run the Fitting Calculation

10.3.2.5. Results

10.4. Example 4: Isothermal Differential Viscoelastic Model

10.4.1. Experimental Data

10.4.2. Fitting Procedure in ANSYS Polymat

10.4.2.1. Step 1: Define the Fluid Model Type

10.4.2.2. Step 2: Specify the Material Data Models

10.4.2.3. Step 3: Read in and Draw the Experimental Data Curves

10.4.2.4. Step 4: Set Numerical Options and Run the Fitting Calculation

10.4.2.5. Results

Bibliography

Release 18.2 - © ANSYS, Inc. All rights reserved.

Das könnte Ihnen auch gefallen

- Flowgraph Models for Multistate Time-to-Event DataVon EverandFlowgraph Models for Multistate Time-to-Event DataNoch keine Bewertungen

- Regression Models for Time Series AnalysisVon EverandRegression Models for Time Series AnalysisBewertung: 2 von 5 Sternen2/5 (2)

- Applied Regression Including Computing and GraphicsVon EverandApplied Regression Including Computing and GraphicsBewertung: 5 von 5 Sternen5/5 (2)

- Population Harvesting (MPB-27), Volume 27: Demographic Models of Fish, Forest, and Animal Resources. (MPB-27)Von EverandPopulation Harvesting (MPB-27), Volume 27: Demographic Models of Fish, Forest, and Animal Resources. (MPB-27)Noch keine Bewertungen

- Generalized Linear Models: with Applications in Engineering and the SciencesVon EverandGeneralized Linear Models: with Applications in Engineering and the SciencesBewertung: 3.5 von 5 Sternen3.5/5 (1)

- Advanced Derivatives Pricing and Risk Management: Theory, Tools, and Hands-On Programming ApplicationsVon EverandAdvanced Derivatives Pricing and Risk Management: Theory, Tools, and Hands-On Programming ApplicationsNoch keine Bewertungen

- An Introduction to Time Series Analysis and Forecasting: With Applications of SAS® and SPSS®Von EverandAn Introduction to Time Series Analysis and Forecasting: With Applications of SAS® and SPSS®Bewertung: 5 von 5 Sternen5/5 (2)

- Aci 211Dokument38 SeitenAci 211Fabian MartnezNoch keine Bewertungen

- Aci 211Dokument38 SeitenAci 211Canberk ŞairNoch keine Bewertungen

- System Reliability Theory: Models and Statistical MethodsVon EverandSystem Reliability Theory: Models and Statistical MethodsNoch keine Bewertungen

- PycomDokument391 SeitenPycomAnnisa Nur ArifahNoch keine Bewertungen

- Electronic Design Automation: Synthesis, Verification, and TestVon EverandElectronic Design Automation: Synthesis, Verification, and TestNoch keine Bewertungen

- Arcsie: User'S GuideDokument120 SeitenArcsie: User'S GuideSergio Diaz BaezNoch keine Bewertungen

- Verilog Bhaskar .JDokument230 SeitenVerilog Bhaskar .JSuraj GhaleNoch keine Bewertungen

- Sample CollectionDokument188 SeitenSample CollectionmlakkissNoch keine Bewertungen

- SAS for Forecasting Time Series, Third EditionVon EverandSAS for Forecasting Time Series, Third EditionNoch keine Bewertungen

- Artificial Intelligence and Causal InferenceDokument253 SeitenArtificial Intelligence and Causal InferenceHektor Saavedra Music100% (1)

- 1997 (Jack Johnston, John Dinardo) Econometric Methods PDFDokument514 Seiten1997 (Jack Johnston, John Dinardo) Econometric Methods PDFtitan10084% (19)

- Wa0002 PDFDokument3 SeitenWa0002 PDFpatrickNoch keine Bewertungen

- Bayes Rules (Johnson, Alicia A.ott, Miles Q.dogucu, Mine)Dokument713 SeitenBayes Rules (Johnson, Alicia A.ott, Miles Q.dogucu, Mine)Cris BadilloNoch keine Bewertungen

- Regression Problems in Python PDFDokument34 SeitenRegression Problems in Python PDFmathewNoch keine Bewertungen

- AlgorithmicsDokument381 SeitenAlgorithmicsArn Jrn100% (2)

- January 2015 - V 2.0: (Revised August 2019)Dokument164 SeitenJanuary 2015 - V 2.0: (Revised August 2019)Mukovhe MuvhaliNoch keine Bewertungen

- DAMBRKDokument250 SeitenDAMBRKWidyan MursyiantoNoch keine Bewertungen

- Model Building, Diagnostics and Remedial Measures 6.1. 6.2. 6.2.2. 6.2.3. Mallows Cpcriterion 6.2.4. Aic and SBC Criteria 6.2.5. P ResspcriterionDokument1 SeiteModel Building, Diagnostics and Remedial Measures 6.1. 6.2. 6.2.2. 6.2.3. Mallows Cpcriterion 6.2.4. Aic and SBC Criteria 6.2.5. P ResspcriterionmuralidharanNoch keine Bewertungen

- Prediction of The Risk of Capsize of Small ShipsDokument299 SeitenPrediction of The Risk of Capsize of Small ShipsDina ANDRIAMAHEFAHERYNoch keine Bewertungen

- Carpenter's Complete Guide to the SAS Macro Language, Third EditionVon EverandCarpenter's Complete Guide to the SAS Macro Language, Third EditionNoch keine Bewertungen

- Queueing Networks and Markov Chains: Modeling and Performance Evaluation with Computer Science ApplicationsVon EverandQueueing Networks and Markov Chains: Modeling and Performance Evaluation with Computer Science ApplicationsBewertung: 5 von 5 Sternen5/5 (1)

- Fea For Design EngineersDokument2 SeitenFea For Design EngineersOmer HayatNoch keine Bewertungen

- Simulation Modeling and Analysis: Averill M. LawDokument9 SeitenSimulation Modeling and Analysis: Averill M. LawSg EliNoch keine Bewertungen

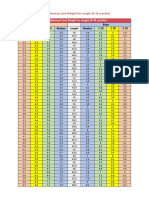

- WHO Reference Card WHZDokument6 SeitenWHO Reference Card WHZDevkota SujataNoch keine Bewertungen

- Structural Health MonitoringVon EverandStructural Health MonitoringDaniel BalageasNoch keine Bewertungen

- QM, MBA, 2, 7 Basic Quality ToolsDokument28 SeitenQM, MBA, 2, 7 Basic Quality ToolsYousab KaldasNoch keine Bewertungen

- Rapt 1Dokument8 SeitenRapt 1tailieuxaydung2019Noch keine Bewertungen

- Machine Learning in Non Stationary Environments Ab00 PDFDokument263 SeitenMachine Learning in Non Stationary Environments Ab00 PDFHellowNoch keine Bewertungen

- Jason M. Kinser - Modeling and Simulation in Python-Chapman & Hall (2022)Dokument333 SeitenJason M. Kinser - Modeling and Simulation in Python-Chapman & Hall (2022)Thigpen FockspaceNoch keine Bewertungen

- Statistical HydrologyDokument39 SeitenStatistical HydrologyMeryNoch keine Bewertungen

- Optimal Seismic Deconvolution: An Estimation-Based ApproachVon EverandOptimal Seismic Deconvolution: An Estimation-Based ApproachNoch keine Bewertungen

- Xtext TutorialDokument124 SeitenXtext TutorialAmit KumarNoch keine Bewertungen

- Open Assignment - 2022Dokument79 SeitenOpen Assignment - 2022Harshad PrajapatiNoch keine Bewertungen

- OpenFoam8 UserGuideDokument223 SeitenOpenFoam8 UserGuideAnonymous DehXfSd4xMNoch keine Bewertungen

- (Birkhauser Advanced Texts) Pavel Drabek, Jaroslav Milota - Methods of Nonlinear Analysis - Applications To Differential Equations-Birkhäuser (2007)Dokument575 Seiten(Birkhauser Advanced Texts) Pavel Drabek, Jaroslav Milota - Methods of Nonlinear Analysis - Applications To Differential Equations-Birkhäuser (2007)Omar Guzman0% (1)

- How Plants SurviveDokument16 SeitenHow Plants SurviveGilbertNoch keine Bewertungen

- Gender Inequality and Its Impact On Mental HealthDokument20 SeitenGender Inequality and Its Impact On Mental Healthbanipreet kaurNoch keine Bewertungen

- Symbolic Interaction Theory: Nilgun Aksan, Buket Kısac, Mufit Aydın, Sumeyra DemirbukenDokument3 SeitenSymbolic Interaction Theory: Nilgun Aksan, Buket Kısac, Mufit Aydın, Sumeyra DemirbukenIgor Dutra BaptistaNoch keine Bewertungen

- AADE Review of Lost Circulation Materials and Treatments With An Updated ClassificationDokument9 SeitenAADE Review of Lost Circulation Materials and Treatments With An Updated ClassificationMuhamad IrfanNoch keine Bewertungen

- GE Elec 7 UNIT-3 NoDokument22 SeitenGE Elec 7 UNIT-3 NoLyleNoch keine Bewertungen

- Youth and Moral ValuesDokument6 SeitenYouth and Moral ValuesAlka SinghNoch keine Bewertungen

- Characteristics of Victorian BritainDokument3 SeitenCharacteristics of Victorian BritainmwaqasenggNoch keine Bewertungen

- Solution Manual For Understanding Business 12th Edition William Nickels James Mchugh Susan MchughDokument36 SeitenSolution Manual For Understanding Business 12th Edition William Nickels James Mchugh Susan Mchughquoterfurnace.1ots6r100% (51)

- DRUG STUDY (Erythromycin)Dokument3 SeitenDRUG STUDY (Erythromycin)Avianna CalliopeNoch keine Bewertungen

- Syllabus ClinPhar143Dokument2 SeitenSyllabus ClinPhar143Angel GoNoch keine Bewertungen

- Inner DriveDokument51 SeitenInner DriveShaurya VajhulaNoch keine Bewertungen

- Algorithm Design TechniquesDokument24 SeitenAlgorithm Design TechniquespermasaNoch keine Bewertungen

- Manual Safety Installation Operations Tescom en 123946Dokument23 SeitenManual Safety Installation Operations Tescom en 123946Karikalan JayNoch keine Bewertungen

- April FoolDokument179 SeitenApril FoolrogeraccuraNoch keine Bewertungen

- Science9 Q3 SLM1Dokument15 SeitenScience9 Q3 SLM1Zandra Musni Delos ReyesNoch keine Bewertungen

- Berghahn Dana ResumeDokument2 SeitenBerghahn Dana ResumeAnonymous fTYuIuK0pkNoch keine Bewertungen

- Infoblatt Skischulen Trends Port eDokument18 SeitenInfoblatt Skischulen Trends Port eAustrian National Tourism BoardNoch keine Bewertungen

- Vallen AE AccesoriesDokument11 SeitenVallen AE AccesoriesSebastian RozoNoch keine Bewertungen

- JamPlay 30 Minute Guitar Pratice TemplateDokument23 SeitenJamPlay 30 Minute Guitar Pratice TemplateSunkilr Sönny100% (4)

- Diagnostic Report: Patient Name: Pranav Chauhan PRANM050319990B 0009VA060799Dokument2 SeitenDiagnostic Report: Patient Name: Pranav Chauhan PRANM050319990B 0009VA060799pranav chauhanNoch keine Bewertungen

- Stacy Frysinger - Him ExperienceDokument2 SeitenStacy Frysinger - Him Experienceapi-250552115Noch keine Bewertungen

- Allowable Nozzle LoadsDokument6 SeitenAllowable Nozzle Loads김동하Noch keine Bewertungen

- Quiz Application in Visual BasicDokument20 SeitenQuiz Application in Visual BasicShivangi SahaNoch keine Bewertungen

- Power - of - Suffering 2Dokument21 SeitenPower - of - Suffering 2jojiNoch keine Bewertungen

- FinancialAccountingTally PDFDokument1 SeiteFinancialAccountingTally PDFGurjot Singh RihalNoch keine Bewertungen

- Ga-Ta10 (LHH)Dokument181 SeitenGa-Ta10 (LHH)Linh T.Thảo NguyễnNoch keine Bewertungen

- Steve Talbott Getting Over The Code DelusionDokument57 SeitenSteve Talbott Getting Over The Code DelusionAlexandra DaleNoch keine Bewertungen

- CSMP77: en Es FRDokument38 SeitenCSMP77: en Es FRGerson FelipeNoch keine Bewertungen

- PMP Exam Questions and Answers PDFDokument12 SeitenPMP Exam Questions and Answers PDFAshwin Raghav SankarNoch keine Bewertungen

- Compuware DCRUM Intro 2012 Version 12.00Dokument142 SeitenCompuware DCRUM Intro 2012 Version 12.00JanNoch keine Bewertungen