Beruflich Dokumente

Kultur Dokumente

07 Bevel Technical

Hochgeladen von

aditOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

07 Bevel Technical

Hochgeladen von

aditCopyright:

Verfügbare Formate

Bevel Gears

Gears

Spur

MHP MBSG SBSG MBSA・MBSB SBS SBZG SB

High-Ratio Hypoid Gears Ground Spiral Bevel Gears Ground Spiral Bevel Gears Finished Bore Spiral Bevel Gears Spiral Bevel Gears Ground Zerol Bevel Gears Steel Bevel Gears

Gear Ratio 15 ~ 200 Gear Ratio Gear Ratio

Helical

Gear Ratio 2 Gear Ratio Gear Ratio 1.5, 2 Gear Ratio

Gears

1.5 ~ 3 1.5 ~ 3 1.5 ~ 4 1.5 ~ 4

m 1, 1.5 Page 288 m2 ~ 4 Page 290 m2 ~ 4 Page 292 m2 ~ 6 Page 294 m1 ~ 5 Page 298 m2 ~ 3 Page 302 m 1.5 ~ 6 Page 304

Internal

Gears

SBY SB SUB PB DB BB Nissei KSP

Steel Bevel Gears Steel Bevel Gears & Pinion Shafts Stainless Steel Bevel Gears Plastic Bevel Gears Injection Molded Bevel ears Sintered Metal Bushings Ground Spiral Bevel Gears

Gear Ratio 2 ~ 4 Gear Ratio 5 Gear Ratio Gear Ratio Gear Ratio 2 Gear Ratio 1.5 ~ 2

1.5 ~ 3 1.5 ~ 3

Racks

m5 ~ 8 Page 304 m 1.5 ~ 3 Page 308 m 1.5 ~ 3 Page 310 m1 ~ 3 Page 312 m 0.5 ~ 1 Page 314 φ5 ~ 8 Page 314 m2 ~ 5 Page 320

CP Racks

& Pinions

Gears

Miter

Gears

Bevel

Screw

Gears

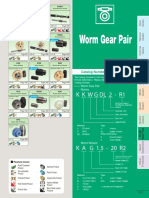

Products Gearboxes Gear Pair

Catalog Number of KHK Stock Gears

The Catalog Number for KHK stock gears is based on the simple formula listed below. Please order KHK gears by specifying the Catalog

Worm

Numbers.

(Example) Bevel Gears

Bevel

M BS G 2 - 40 20 R Material

S S45C

Type

B Straight Bevel Gears

M SCM415 BS Spiral Bevel Gears

SU SUS303 HP High Ratio Hypoid Gears

Direction of Spiral ( R )

P MC901

Other

No. of teeth of mating gear (20) D DURACON Other Information

No. of teeth (40) G Ground Gears

Module (2)

Others (Ground Gear)

Type (Spiral Bevel Gear)

Material (SCM415)

■ Feature Icons

RoHS Compliant Finished Product Ground Gear Resin Product Injection Molded

Product Product

Re-machinable Heat Treated Stainless Product Copper Alloy Black Oxide coat-

Product Product Product ed Product

281

catalog_usa.indb 281 15/05/21 15:23:31

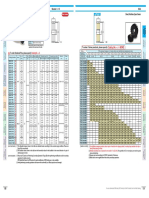

Bevel Gears

Characteristics

KHK stock bevel gears are available in two types, spiral and straight tooth, in gear ratios of 1.5 through 5, and are offered in a large

variety of modules, numbers of teeth, materials and styles. The following table lists the main features for easy selection.

Tooth Precision

Heat Treat- Secondary

Type

Catalog No. Module Gear Ratio Material Surface JIS B 1704 Features

ment Operations

Finish : 1978

Carburized High speed reduction ratio, high efficiency,

1 ~ 1.5 15 ~ 200 SCM415 Cut 3 △

Hypoid

MHP

Gear

Note 1 high rigidity and compact gear assembly.

Carburized High strength, abrasion-resistant and com-

MBSG 2~4 2 SCM415 Ground 1 △

Note 1 pact for high-speed & torque use.

Gear teeth Reasonably priced ground gear,

SBSG 2~4 1.5 ~ 3 S45C induction Ground 2 △

yet remachinable except for the gear teeth.

Spiral bevel gears

hardened

KSP F type Carburized ×

Superior performance with regard to high

1.5 ~ 5 20 ~ 30 SCM415 Ground 0

Carburized speed, low noise, and low vibration.

KSP U type Note 1

△

Ready to use without performing secondary

MBSA・MBSB 2~6 1.5 ~ 3 SCM415 Carburized Cut 4 ×

operations. Strong and abrasion resistant.

Gear teeth Large nos. of teeth and modules are offered

SBS 1~5 1.5 ~ 4 S45C induction Cut 4 △

hardened in these affordable spiral bevel gears.

Gear teeth A spiral bevel gears with a helix angle less than 10°.

2~3 1.5 ~ 2 S45C induction Ground 2 △

Gears

Bevel

Receives forces from the same directions straight bevel

Zerol

SBZG

hardened gears receive and have excellent precision.

Popular series of straight bevel gears for

SB・SBY 1~8 1.5 ~ 5 S45C ― Cut 3 ○

Straight bevel gears

many uses.

Suitable for food machinery due to SUS303's

SUB 1.5 ~ 3 1.5 ~ 3 SUS303 ― Cut 3 ○

rust-resistant quality.

MC nylon products are light and can be

PB 1~3 1.5 ~ 3 MC901 ― Cut 4 ○

used without lubricant.

Duracon Injection Injection molded, mass-produced produc-

DB 0.5 ~ 1 2 ― 6 △

(M90-44) Molded tions, suitable for office machines.

〔NOTE 1〕Although these are carburized products, secondary operations can be performed as

○ Possible △ Partly possible

the bore and the hub portions are masked during the carburization. However, as a

× Not possible

precaution, high hardness (HRC40 at maximum) occurs in some cases.

■ The chamfering of the corner gear tips for bevel gear

● For safe handling and to prevent damage such as deformation,

Module Outside edge R Inside edge R

KHK stock bevel gears have round chamfering at the corners, on

0.5 up to 1 0.5 All burrs removed

the top surface plane of a gear tooth.

1 up to 2.5 1 0.5

2.5 up to 5 2 1

Over 5 3 1.5

Integrated combination of cutting-edge technologies and know-how.

The popularity in our large selection of product lineups is estab-

lished by a production system integrated with advanced manufac-

turing technology and know-how, achieving quality products.

Gear cutting of Straight Bevel Gears Bevel Gear Grinding Machine (Gleason PH-275HG)

Gear cutting of Spiral Bevel Gears Bevel Gear Cutting Machine Equipments Inspection Equipment

282

catalog_usa.indb 282 15/05/21 15:23:36

KHK Technical Information

Selection Hints

Please select the most suitable products by carefully considering the characteristics of items and contents of the product ta-

bles. It is also important to read all applicable “CAUTION” notes shown below before the final selection.

1. Caution in Selecting the Mating Gears

Basically, KHK stock bevel gears should be selected as

shown in the catalog in pairs (e.g. MBSG2-4020R should

mate with MBSG2-2040L). But, for straight tooth bevel

gears, there is some interchangeability with different series.

For plastic bevel gears, we recommend metal mating gears

for good heat conductivity.

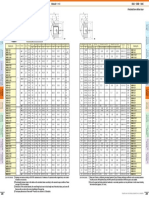

■ Selection Chart for Straight Bevel Gears ( ○ Allowable × Not allowable)

Gear Right(R) Left(L)

SB SUB PB DB

Pinion

SB ○ ○ ○ × ■ Selection Chart for Spiral Bevel Gears ( ○ Allowable × Not allowable)

SUB ○ ○ ○ × Gear MBSA

MBSG SBSG SBS

PB ○ ○ ○ ×

Pinion MBSB

DB × × × ○ MBSG ○ × × ×

SBSG × ○ × ×

■ Zerol Bevel Gears

MBSA・MBSB × × ○ ×

SBZG products are not interchangeable with products in

other series. SBS × × × ○

2. Caution in Selecting Gears Based on Gear Strength

The gear strength values shown in the product pages were computed by assuming a certain application environment. Therefore,

they should be used as reference only. We recommend that each user computes their own values by applying the actual usage

conditions. To learn more about strength calculation, please refer to the technical information contained in the “Bending Strength

of Bevel Gears” section on Page 87, and the “Surface Durability of Bevel Gears” section on Page 93.

■ Calculation assumptions for Bending Strength of Gears

Catalog No. MBSG SBSG

SB NOTE 3

MBSA SBZG SUB PB DB

SBY

Item MBSB SBS

Formula NOTE 1 Formula of bevel gears on bending strength(JGMA403-01) The Lewis formula

No. of teeth of mating gear No. of teeth of the mating gear of the set ---

Rotation 100rpm(600rpm for MBSG, SBSG and SBZG) 100rpm

Durability Over 107cycles ---

Impact from motor Uniform load Allowable bending stress(kgf/mm2)

Impact from load Uniform load m 0.5 4.0

Direction of load Bidirectional 1.15 m 0.8 4.0

(40℃ with No m 1.0 3.5

Allowable bending stress at root σFlim(kgf/mm2) NOTE 2 47 21 19(24.5) 10.5 Lubrication) (40℃ with Grease

Safety factor KR 1.2 Lubrication)

■ Calculation assumptions for Surface Durability (Except those in common with bending strength)

Formula NOTE 1 Formula of bevel gears on surface durability(JGMA404-01)

Kinematic viscosity of lubricant 100cSt(50℃)

Gear support Shafts & gear box have normal stiffness, and gears are supported on one end

Allowable Hertz stress σHlim(kgf/mm2) 166 90 49(62.5) 41.3

Safety factor CR 1.15

〔NOTE 1〕The gear strength formula is based on JGMA (Japanese Gear Manufacturers Association) specifications. “MC Nylon Technical Data” by Nippon

Polypenco Limited and “Duracon Gear Data” by Polyplastic Co. Also, the units (rpm) of number of rotations and unit (kgf/mm2) of stress are

adjusted to the units needed in the formula.

〔NOTE 2〕The allowable bending stress at the root σFlim is calculated from JGMA403-01, and set to 2/3 of the value in the consideration of the use of planetary-,

idler-, or other gear systems, loaded in both directions.

〔NOTE 3〕Since SB Bevel Pinion Shafts are thermally refined, the allowable tooth-root bending stress and allowable hertz stress are referred to the value

shown in parentheses.

283

catalog_usa.indb 283 15/05/21 15:23:36

Bevel Gears

Application Hints

In order to use KHK stock gears safely, carefully read the Appli- ⑧ For the handling conveniences, the SB and SBY series

cation Hints before proceeding. If there are questions or you listed below has the tapped holes (180 apart, 2 places)

o

require clarifications, please contact our technical department on the holding surface.

or your nearest distributor.

KHK USA Inc.

Catalog No. L(mm) Tap Size

PHONE: 516-248-3850 FAX: 516-248-4385 SB6-4515 130 M10 deep 15

E-mail info@khkgears.us SBY8-4020 160 M10 deep 15

SBY8-4515 210 M10 deep 15

1. Caution on Performing Secondary Operations SBY5-6015 160 M10 deep 15

① If you are reboring, it is important to pay special atten- SBY6-6015 220 M10 deep 15

tion to locating the center in order to avoid runout.

② The reference datum for gear cutting is the bore. There-

fore, it is best to use the bore for locating the center. If

it is too difficult to do for small bores, the alternative is

to use one spot on the bore and the runout of the side

2. Points of Caution in Assembling

surface.

③ If reworking using scroll chucks, we recommend the use ① Since bevel gears are cone shaped, they produce axial

of new or rebored jaws for improved precision. Please thrust forces. Especially for spiral bevel gears, the direc-

exercise caution not to crush the teeth by applying too tions of thrust changes with the hand of spiral and the

much pressure. Any scarring will cause noise during op- direction of rotation. This is illustrated below. The bear-

eration. ings must be selected properly to be able to handle these

thrust forces. For details, please refer to separate technical

reference book, section of “Gear Forces” (Page 108).

Direction of rotation and thrust force

Thrust Thrust

Drive

Thrust Thrust

Thrust

Thrust

Lathe operations

Drive

④ For items with induction hardened teeth, such as SBSG and

SBS series, the hardness is high near the tooth root. When ma-

chining the front end, the machined area should be 4 to 6mm Thrust Thrust

smaller than the dimension, J. [NOTE] Bevel gears with the gear ratio 1.57 or less, produce a thrust force which

has the same direction as miter gears. For details, see page 254.

② If a bevel gear is mounted on a shaft far from the bear-

ings, the shaft may bend. We recommend mounting

bevel gears as close to the bearings as possible. This is es-

pecially important since most bevel gears are supported

on one end. The bending of shafts will cause abnormal

noise and wear, and may even cause fatigue failure of the

shafts. Both shafts and bearings must be designed with

sufficient strength.

③ Due to the thrust load of bevel gears, the gears, shafts

and bearings have the tendency to loosen up during op-

⑤ For tapping and keyway operations, see the examples

given in “1. Caution on Performing Secondary Oper- eration. Bevel gears should be fastened to the shaft with

ations” in KHK Stock Spur Gear section. When cutting keys and set screws, taper pins, step shafts, etc.

keyways, to avoid stress concentration, always leave ④ When installing MBSA or MBSB spiral bevel gears in B7

radii on corners. style (ring type), al-

⑥ PB plastic bevel gears are susceptible to changes due Taper pin ways secure the gears

to temperature and humidity. Dimensions may change onto the mounting

between during and after remachining operations. base with taper pins to

absorb the rotational

Gear

⑦ When heat treating S45C products, it is possible to get

thermal stress cracks. It is best to subject them to pen- loads. It is dangerous

etrant inspection afterwards. While the teeth strength to secure with bolts

Mounting base

may increase four fold, the precision of the gear will only.

drop approximately one grade.

284

catalog_usa.indb 284 15/05/21 15:23:37

KHK Technical Information

⑤ KHK stock bevel gears are designed such that, when as-

Correct Tooth Contact

sembled according to the specified mounting distance

● When assembled correctly, the contact will occur

with a tolerance of H7 - H8, the backlash shown in the on both gears in the middle of the flank and center

table is obtained. Mounting distance error, offset error of face width but somewhat closer to the toe.

and shaft angle error must be minimized to avoid ex-

cessive noise and wear. For various conditions of teeth

contact, please see the following illustrations, "Correct

Tooth Contact" and "Incorrect Tooth Contact".

Center contact closer to toes

Incorrect Tooth Contact

■ Mounting Distance Error ■ Offset Error ■ Shaft Angle Error

● When the mounting distance of the ● When the pinion shaft is offset, the ● When there is an angular error of

pinion is incorrect, the contact will contact surface is near the toe of one shafts, the gears will contact at the

occur too high on the flank on one gear and near the heel of the other. toes or heels depending on whether

gear and too low on the other. the angle is greater or less than 90° .

Low contact Heel contact

High contact

Error

Error

Error

Toe contact

Toe contact

High contact Toe contact

Heel contact

Low contact

Error Error

Error

Heel contact

Application Examples

SB Bevel Gears are used in the automatic line-feeding of a machine part 2WD Bicycle by SHESCO

processing machine. SB Bevel Gears are used in the driving components in both the front and rear wheels.

285

catalog_usa.indb 285 15/05/21 15:23:39

MHP

High-Ratio Hypoid Gears

■ Features of MHP High Ratio Hypoid Gears

A pair of MHP high-ratio hypoid gears are able to produce an amazing reduction of speed of 200:1 in one stage.

Gears

Spur

1. Total-cost reduction

The MHP provides a compact gearing

body replacing several stages of reduction

Efficiency

Comparison of the efficiency of MHP High Ratio Hypoid Gear and Worm Gear

Helical

gears. This reduces the cost sharply.

Gears

2. High efficiency

Compared to worm gear drives, the MHP

has less sliding contact. The resulting MHP

MHP

Internal

higher efficiency allows the use of smaller

Gears

motors (See the graph on the right).

Worm Gear

3. High rigidity

The carburized hypoid gears lead to small-

Racks

er size than comparable worms gears.

4. Compact gear assembly

The size of the gear housing is nearly the

same as outer diameter of the large gear.

CP Racks

& Pinions

(See the diagrams below)

■ How to determine the radial and thrust loads

Before using the MHP high-ratio hypoid gears, be sure to confirm the

Gears

Miter

Comparison of MHP and Worm Gear direction of radial and thrust loads. Following equations are used to

compute these loads. The radial and thrust load coefficients are given

Worm Gear

on the product pages.

Gears

Bevel

Position

Reduction

Radial load calculation

WRP :Radial load on the pinion or L(N)

n

WRP = WKP × TG × z

Screw

Gears

Raw Material

WKP :Radial load coefficient of pinion or L (given on the product pages)

Strength

TG :Torque of gear or R(N.m)

Miniaturization n :Number of teeth of pinion or L

z :Number of teeth of gear or R

Products Gearboxes Gear Pair

of Main Body

+

Worm

Induction Hardened

+

Heat Treated WRG :Radial load on the gear or R(N)

WRG = WKG×TG

WKG :Radial load coefficient of gear or R (given on the product pages)

Efficiency

Reduced Mo- TG :Torque of gear or R(N.m)

Bevel

tor Capacity

ex,50W

Thrust load calculation

WXP :Thrust load on the pinion or L(N)

Other

n

ex,60W

WXP = WNP × TG × z

WNP :Thrust load coefficient of pinion or L (given on the product page)

TG :Torque of gear or R(N.m)

n :Number of teeth of pinion or L

z :Number of teeth of gear or R

WXG :Thrust load of gear or R(N)

WXG = WNG × TG

WNG :Thrust load coefficient of gear or R (given on the product pages)

TG :Torque of gear or R(N.m)

286

catalog_usa.indb 286 15/05/21 15:23:40

MHP

High-Ratio Hypoid Gears

■ Variations in tooth contact due to poor alignment of gears

If the gear engagement position is out of the normal position, variations in tooth contact, as illustrated below,

Gears

Spur

may appear.

Helical

(1) Tooth contact in case of a shaft-angle error (2) Tooth contact in case of a shaft-offset error

Gears

Toe contact

Internal

Gears

Toe Toe High heel

contact contact contact

Error

Toe Low toe

contact contact

High toe

contact

Racks

Error

Low heel (Offset is large)

contact

CP Racks

& Pinions

Low toe

contact

Error

Heel

contact

High toe

Heel contact

Gears

Heel

Miter

contact contact

Error

(Offset is small)

High heel

Gears

Low heel

Bevel

contact contact

Heel contact

(3) Tooth contact in case of a pinion set position error (4) Tooth contact in case of a gear set position error

Screw

Gears

Low heel

contact

Toe

contact

Products Gearboxes Gear Pair

High toe

Worm

contact Error

Toe

contact

High heel

Bevel

Low toe contact

contact Heel

contact Error

Heel

contact

Other

Heel

High toe contact

contact

Heel Error

Toe contact

Low toe contact

contact Low heel

contact

Error

Toe contact

High heel

contact

Inquiries are now being accepted on our website. 287

catalog_usa.indb 287 15/05/21 15:23:41

Das könnte Ihnen auch gefallen

- Catalogo Engranajes Conicos 2 PDFDokument36 SeitenCatalogo Engranajes Conicos 2 PDFwiiiNoch keine Bewertungen

- Bevel Gears PDFDokument21 SeitenBevel Gears PDFilijakljNoch keine Bewertungen

- Section 7Dokument44 SeitenSection 7aliNoch keine Bewertungen

- Spur Gears: Catalog Number of KHK Stock GearsDokument134 SeitenSpur Gears: Catalog Number of KHK Stock GearsaditNoch keine Bewertungen

- Spur IntroductionDokument3 SeitenSpur Introductionmanikantar15Noch keine Bewertungen

- Bevel GearsDokument21 SeitenBevel GearsZelalemNoch keine Bewertungen

- Screw Gears: Catalog Number of KHK Stock GearsDokument2 SeitenScrew Gears: Catalog Number of KHK Stock GearsDaniel FloresNoch keine Bewertungen

- Involute spline shafts and bushings guideDokument2 SeitenInvolute spline shafts and bushings guideJames TsaiNoch keine Bewertungen

- Spur Gears: Catalog Number of KHK Stock GearsDokument560 SeitenSpur Gears: Catalog Number of KHK Stock GearsJulian David SanabriaNoch keine Bewertungen

- Spur Gears PDFDokument75 SeitenSpur Gears PDFrahimi mohamadNoch keine Bewertungen

- 06 Miter GearsDokument17 Seiten06 Miter GearsNeogeo1234Noch keine Bewertungen

- Gear Boxes: P BX - 04 1 L KDokument16 SeitenGear Boxes: P BX - 04 1 L KAvhishek Rajan GuptaNoch keine Bewertungen

- Gear Types by KHK Gears p561-592Dokument32 SeitenGear Types by KHK Gears p561-592amir_fortunateNoch keine Bewertungen

- Spur GearsDokument75 SeitenSpur Gearstiko lolipopNoch keine Bewertungen

- GearboxesDokument7 SeitenGearboxesJohn Fake Last NameNoch keine Bewertungen

- Gear Boxes: P BX - 04 1 LDokument3 SeitenGear Boxes: P BX - 04 1 LThiago Scarso ScarsoNoch keine Bewertungen

- Ratchet & Pawl-1Dokument14 SeitenRatchet & Pawl-1Nilesh NarkhedeNoch keine Bewertungen

- Internal Gears: S I R 1 - 60 KDokument6 SeitenInternal Gears: S I R 1 - 60 KJuanNoch keine Bewertungen

- Especificaciones Tecnicos de Los EngranajesDokument1 SeiteEspecificaciones Tecnicos de Los EngranajesGary Hans Aüe AnteloNoch keine Bewertungen

- SRT SRTB SRT-C PDFDokument3 SeitenSRT SRTB SRT-C PDFKhaleel PashaNoch keine Bewertungen

- SRT SRTB SRT-C PDFDokument3 SeitenSRT SRTB SRT-C PDFKhaleel PashaNoch keine Bewertungen

- Worm GearsDokument31 SeitenWorm Gearsmohammad khoraminiaNoch keine Bewertungen

- 09 Worm GearsDokument31 Seiten09 Worm Gearsgermoal1468Noch keine Bewertungen

- Section 2Dokument18 SeitenSection 2Dhananjay SargarNoch keine Bewertungen

- GCU Gear Assembly KitDokument1 SeiteGCU Gear Assembly KitNagy ChristianNoch keine Bewertungen

- 02 Helical GearsDokument10 Seiten02 Helical Gearstepu msosaNoch keine Bewertungen

- Helical Gears: K H G 1 - 20 RDokument10 SeitenHelical Gears: K H G 1 - 20 RGILBERT YOEL DONATO ZAVALETANoch keine Bewertungen

- Gear SsaDokument4 SeitenGear Ssa3DSNoch keine Bewertungen

- Sma SMB SMCDokument1 SeiteSma SMB SMCKen MaglinteNoch keine Bewertungen

- Involute Spline Shafts & Bushings: FeaturesDokument4 SeitenInvolute Spline Shafts & Bushings: FeaturesSunilNoch keine Bewertungen

- Steel Rack Module SpecificationsDokument1 SeiteSteel Rack Module Specificationsindro wibowoNoch keine Bewertungen

- SH PDFDokument1 SeiteSH PDFchandraNoch keine Bewertungen

- 2019 Us 3826Dokument1 Seite2019 Us 3826Hormedo RodriguezNoch keine Bewertungen

- Reverse Gear Models SpecificationsDokument1 SeiteReverse Gear Models SpecificationsRicky WrightNoch keine Bewertungen

- Steel Helical Gears: Spur Gears Spur GearsDokument1 SeiteSteel Helical Gears: Spur Gears Spur GearsjaseNoch keine Bewertungen

- DVV TDokument6 SeitenDVV TLiviu ToaderNoch keine Bewertungen

- Caterpillar Curso de HidraulicaDokument2 SeitenCaterpillar Curso de Hidraulicamisaelandres1100% (1)

- Bearing Manual Vol2pg876Dokument1 SeiteBearing Manual Vol2pg876WilliamNilsenNoch keine Bewertungen

- Shafts precision standards and effective hardened layer depthsDokument1 SeiteShafts precision standards and effective hardened layer depthsJean AlexNoch keine Bewertungen

- Worm Gear Pair: K W G DL 2 - R1 KDokument56 SeitenWorm Gear Pair: K W G DL 2 - R1 KShuvam ShuvamNoch keine Bewertungen

- Link-Thyssenkrupp Rothe Erde Turntables BrochureDokument9 SeitenLink-Thyssenkrupp Rothe Erde Turntables BrochureBang TwoNoch keine Bewertungen

- 1,100 - 2,200# Dexter Torflex Axles Assembly #9: Made To OrderDokument1 Seite1,100 - 2,200# Dexter Torflex Axles Assembly #9: Made To OrderMAZM17Noch keine Bewertungen

- Stern Drive ModelsDokument1 SeiteStern Drive Modelsfreeze5959Noch keine Bewertungen

- Stripper Bolts Price and Delivery Time IndicationDokument3 SeitenStripper Bolts Price and Delivery Time Indicationmuhamad laaliNoch keine Bewertungen

- Ciaz SpecificationDokument2 SeitenCiaz SpecificationTeshomeNoch keine Bewertungen

- Kobe Works eDokument13 SeitenKobe Works eJagdish ShresthaNoch keine Bewertungen

- Maximized Performance with Metabo Abrasives for Angle Grinder TechnologyDokument2 SeitenMaximized Performance with Metabo Abrasives for Angle Grinder TechnologyJonathan DouglasNoch keine Bewertungen

- LEAD SCREW - p1 - 785Dokument1 SeiteLEAD SCREW - p1 - 785wawandev7Noch keine Bewertungen

- KSW Module 1.5 specifications for spur and helical gearsDokument5 SeitenKSW Module 1.5 specifications for spur and helical gearsmariamalloney1730Noch keine Bewertungen

- KSCP hardened steel spur and helical gears specificationsDokument1 SeiteKSCP hardened steel spur and helical gears specificationsqwerty 12345Noch keine Bewertungen

- CV-425 & CV-510: High Output. Reliable Workhorses!Dokument1 SeiteCV-425 & CV-510: High Output. Reliable Workhorses!Rachid DoumaNoch keine Bewertungen

- Daiwa Catalogo2011englishDokument52 SeitenDaiwa Catalogo2011englishdondepescasNoch keine Bewertungen

- SprocketDokument1 SeiteSprocketkoenNoch keine Bewertungen

- INTEGREX AG Series - Brochure - DigitalDokument7 SeitenINTEGREX AG Series - Brochure - Digitalrenilpeter89Noch keine Bewertungen

- SSR Steel Ring Gears (Spur Gears)Dokument1 SeiteSSR Steel Ring Gears (Spur Gears)dindo_waeNoch keine Bewertungen

- Please Use High-Tac EP (Industrial Gear Oil) - See P345 Use ExamplesDokument1 SeitePlease Use High-Tac EP (Industrial Gear Oil) - See P345 Use ExamplesHarshal TikekarNoch keine Bewertungen

- Telescopic CylinderDokument2 SeitenTelescopic CylinderReference mapiyeNoch keine Bewertungen

- Ashok Leyland Baba-Dost TrucksDokument6 SeitenAshok Leyland Baba-Dost TrucksmalikmotorsdostNoch keine Bewertungen

- ECT2011ECT28NEWDokument2 SeitenECT2011ECT28NEWambuenaflorNoch keine Bewertungen

- Gear TypeDokument7 SeitenGear Typetajju_121Noch keine Bewertungen

- Gear-Trains 1Dokument11 SeitenGear-Trains 1Sam DrakesNoch keine Bewertungen

- Perancangan Elevator Penumpang Pada Gedung Bertingkat Dengan Kapasitas 500 KG Di Yanglim Plaza MedanDokument11 SeitenPerancangan Elevator Penumpang Pada Gedung Bertingkat Dengan Kapasitas 500 KG Di Yanglim Plaza MedanWin ManikNoch keine Bewertungen

- Sona Koyo Summer Training Report on Steering Systems ManufacturingDokument35 SeitenSona Koyo Summer Training Report on Steering Systems ManufacturingRaja SinghNoch keine Bewertungen

- Differential components maintenance and working principle explained in detailDokument10 SeitenDifferential components maintenance and working principle explained in detailAskariz100% (1)

- Elements of Metric Gear TechnologyDokument234 SeitenElements of Metric Gear Technologyhrh_pogcNoch keine Bewertungen

- AGNEE HELICAL & BEVEL HELICAL GEAR BOX DIMENSIONSDokument41 SeitenAGNEE HELICAL & BEVEL HELICAL GEAR BOX DIMENSIONSgabisaNoch keine Bewertungen

- Gear Transmission Mechanisms ExplainedDokument4 SeitenGear Transmission Mechanisms ExplainedIbrahim HossainNoch keine Bewertungen

- Gear shaping and shaving process overviewDokument22 SeitenGear shaping and shaving process overviewSumesh Vijayan0% (1)

- Modeling and Simulation of Steering Rack & Pinion Gears: October 2017Dokument2 SeitenModeling and Simulation of Steering Rack & Pinion Gears: October 2017Everest Engineering Lead R&DNoch keine Bewertungen

- 210 Bevel Gear SetsDokument1 Seite210 Bevel Gear SetsFika PorieskaNoch keine Bewertungen

- Amp ProjectDokument15 SeitenAmp Projecttejas patil50% (2)

- Bevel - Gears Konik Dişli HesabıDokument6 SeitenBevel - Gears Konik Dişli HesabıserkanNoch keine Bewertungen

- GearsDokument3 SeitenGearsSridhar KanagarajNoch keine Bewertungen

- Bevel GearDokument22 SeitenBevel GearSamama khan100% (1)

- 1 Purpose of Revision 1. Purpose of Revision: Front Axle Assembly TransmissionDokument3 Seiten1 Purpose of Revision 1. Purpose of Revision: Front Axle Assembly TransmissionDmitryNoch keine Bewertungen

- Reading and Adjusting Ring and Pinion Tooth Patterns PDFDokument4 SeitenReading and Adjusting Ring and Pinion Tooth Patterns PDFMohammed gNoch keine Bewertungen

- Apltcl013 SGD L-01Dokument50 SeitenApltcl013 SGD L-01Ali AldameNoch keine Bewertungen

- Chapter 8 - Kinematics of GearsDokument41 SeitenChapter 8 - Kinematics of GearsRoberto AmryNoch keine Bewertungen

- 1.9 Contact Ratio and Specific SlidingDokument6 Seiten1.9 Contact Ratio and Specific SlidingShubh BhawsarNoch keine Bewertungen

- Gear & Gear TrainDokument20 SeitenGear & Gear Trainniaz kilamNoch keine Bewertungen

- GearsDokument51 SeitenGearsKasi Visweswar Rao100% (1)

- Zbook - Eaa8959c B9e9 40bb A30a f856d4 - 4d77c6Dokument20 SeitenZbook - Eaa8959c B9e9 40bb A30a f856d4 - 4d77c6gaelNoch keine Bewertungen

- Designing Involute Gear Teeth for Optimal PerformanceDokument11 SeitenDesigning Involute Gear Teeth for Optimal PerformanceVikas Mani TripathiNoch keine Bewertungen

- Planetary (Eng)Dokument10 SeitenPlanetary (Eng)naveenmg201Noch keine Bewertungen

- Theory of Machines - Final Exams2015Dokument2 SeitenTheory of Machines - Final Exams2015Dr-Nouby Mahdy GhazalyNoch keine Bewertungen

- PDF - Self Recorded - Lect-7 Unit - 3 Gear Trains - Problems On Epicyclic Gear TrainDokument15 SeitenPDF - Self Recorded - Lect-7 Unit - 3 Gear Trains - Problems On Epicyclic Gear TrainNikhil JadhavNoch keine Bewertungen

- GLDokument239 SeitenGLadrianstravitzNoch keine Bewertungen

- Dathan Tool and Gauge HandbookDokument32 SeitenDathan Tool and Gauge HandbooksamirkaminskyNoch keine Bewertungen

- PPT4 - Engineering Inspection and Quality Control PDFDokument22 SeitenPPT4 - Engineering Inspection and Quality Control PDFLOKESH NAYAK [BT20ME026]Noch keine Bewertungen