Beruflich Dokumente

Kultur Dokumente

United States Patent (19) 11 Patent Number: 5,474,257: Fisher Et Al. (45. Date of Patent: Dec. 12, 1995

Hochgeladen von

1550 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

23 Ansichten11 Seiten4742

Originaltitel

Us 5474257

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument melden4742

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

23 Ansichten11 SeitenUnited States Patent (19) 11 Patent Number: 5,474,257: Fisher Et Al. (45. Date of Patent: Dec. 12, 1995

Hochgeladen von

1554742

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 11

||||||||||

USO054742.57A

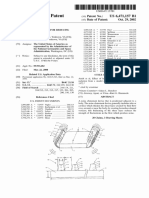

United States Patent (19) 11 Patent Number: 5,474,257

Fisher et al. (45. Date of Patent: Dec. 12, 1995

54) DEPLOYABLE WING 4,050,654 9/1977 Heckman ................................ 244190

4,116,406 9/1978 Hamilton .................................. 244f16

(75) Inventors: Jeffrey A. Fisher; Edward W. Miller, 4,116,407 9/1978 Murray ...................................... 244f16

both of Huntsville, Ala., Dennis Van 4,708,078 11/1987 Legaignoux et al. ... 14f102

4,742,977 5/1988 Crowell ........... ... 244/123

Dam, Chattanooga, Tenn. 4,846,423 7/1989 Reuter ..... ... 24.4/145

73) Assignee: USBI Co., Huntsville, Ala. 4,936,012 6/1990 Shepherd ................................. 29,845

FOREIGN PATENT DOCUMENTS

21 Appl. No.: 156,322 2310258 12A1976 France.

22 Filed: Nov. 23, 1993 2549393 5/1977 Germany.

2854939 7/1980 Germany.

5 Int. C. r. B64C 3/56 3119865 12/1982 Germany.

52 U.S. Cl. .......................... 244/49; 244/90 Rs 244/901; 3322047 12/1984 Germany.

2441904 1218 10/1984 U.S.S.R.

58) Field of Search ..................................... 244/900-904, 2050263 1/1981 United Kingdom.

244/16, 49, 138 R, 90R, 75R Primary Examiner Galen L. Barefoot

56 References Cited 57) ABSTRACT

U.S. PATENT DOCUMENTS The deployable wing of the present invention comprises an

Re. 26,427 7/1968 Jalbert .................................... 48/33.1 R t AE diverging ins g spars

2,764,375 9/1956 Lemoigne .. 244/45 attached to a keel spar and cross spars to form a delta wing

3,507,464 4/1970 Rogalla .......... 244190 configuration. This internal structure is enclosed within a

3,524,613 8/1970 Reuter et al. 244/42 volume defined by a fabric sail having an upper section, a

3,558,087 1/1971 Barish ............ 244f142 lower section, and fabric ribs disposed therebetween. This

3,599,904 8/1971 Condit et al... 244/49 fabric sail volume is internally pressurized through a ran air

3,679,157 7/1972 Roberts et al. 244f6 intake at the nose stagnation point. This deployable wing can

3,749,337 7/1973 Jalbert ....... 244f145 be folded and deployed in the air.

3,822,844 7/1974 Sutton 244/45

3,944,169 3/1976 Bede ..... 244/16

3,995,799 12/1976 Bartolini ................................... 244/16 17 Claims, 4 Drawing Sheets

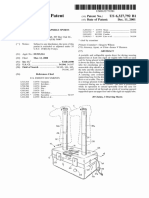

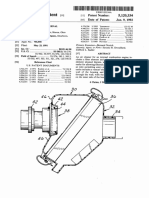

U.S. Patent Dec. 12, 1995 Sheet 1 of 4 5,474,257

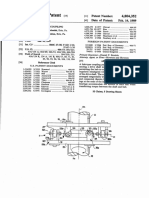

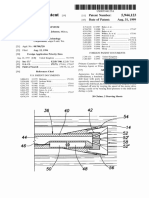

U.S. Patent Dec. 12, 1995 Sheet 2 of 4 5,474.257

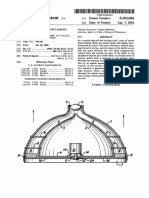

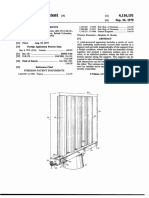

U.S. Patent Dec. 12, 1995 Sheet 3 of 4 5,474.257

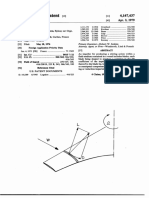

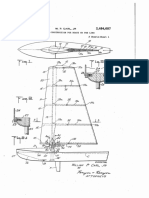

U.S. Patent Dec. 12, 1995 Sheet 4 of 4 5,474.257

5,474,257

1. 2

DEPLOYABLE WING keel to the keel spar; a plurality of fabric ribs disposed

between and connected to the upper section and the lower

TECHNICAL FIELD section, wherein said fabric ribs define a shape of the fabric

sail when inflated and have at least one slot through which

The present invention relates to a wing and especially to 5 the cross spars extend from the keel spar to the leading edge

a controllable, deployable wing. spars and ribs, and a ram air intake located on said leading

edge at the stagnation point of the wing during operation.

BACKGROUND OF THE INVENTION The foregoing and other features and advantages of the

Hang gliders allow manned flight without the expense or present invention will become more apparent from the

restrictions of powered flight. These gliders are aerodynami

O following description and accompanying drawings.

cally designed such that their lift-to-drag ratio (commonly BRIEF DESCRIPTION OF THE DRAWINGS

known as glide ratio) is greater than about 10:1 such that the

glider is capable of suspending a flyer for several hours FIG. 1 is a cut-away, side view of one embodiment of the

under the proper atmospheric conditions. Hang glider 15 deployable wing of the present invention.

designs range from the popular delta wing design commonly FIG. 2 is an exploded view of one embodiment of the

known as a Rogallowing and intermediate gliders with glide deployable wing of the present invention.

ratios of about 10:1 with docile characteristics to competi FIGS. 3A-3E are diagrammatical views of the opening

tion gliders with glide ratios as high as 13:1, but with less mechanism of one embodiment of the deployable wing of

stable characteristics. The original Rogallowing (about 45° 20 the present invention.

sweep) had a glide ratio of about 4:1, and modern Rogallo

wings (about 30° sweep) have a glide ratio of about 10:1. FIG. 4 is a cross-sectional view of one embodiment of the

The Rogallowing design largely resembles a traditional wing in its open position.

kite with a keel, cross members, and diverging leading edge FIG. 5 is a top view of one embodiment of the deployable

members. Another hang glider design generally similar to 25 wing attached to a payload.

the Rogallo wing is disclosed in U.S. Pat. No. 4,116,406 FIG. 6 is a side view of one embodiment of the deployable

which issued to Hamilton on Sep. 26, 1978. This glider has wing attached to a payload.

a double surface fabric airfoil forming an envelope, disposed FIG. 7 is a perspective view of one embodiment of the

around a Rogallo frame. This airfoil is inflated during flight deployable wing attached to a payload.

as air enters an opening in the nose and exhausts through 30 The figures are meant to further illustrate the present

nozzles in the underside along the trailing edge. Inflating the invention and not to limit the scope thereof.

wing improves its lift at lower air speeds. This hang glider,

however, is manually controlled via a weight shift control BEST MODE FOR CARRYING OUT THE

bar by a flyer harnessed to the glider and is only useful for INVENTION

manned flights and not for operations such as air drops of 35

food, supplies, etc., where manned flights are either too The present invention is a deployable wing. Referring to

dangerous or impossible. FIGS. 1 and 2, in one embodiment of the present invention,

Parachutes, on the other hand, can and have been utilized the wing I has a fabric sail 3 disposed around both fabric ribs

for air drops of food, supplies, etc., in remote locations 5 and an internal structure. The internal structure comprises

where landing an airplane is either impossible or dangerous. 40 two leading edge spars 7 with retractable telescoping sec

Although these parachutes are useful in reducing the ground tions 7a, two cross spars 9, a keel spar 11, and a control

impact of the dropped load, it is difficult to ensure the device such as two elevon struts 23. The leading edge spars

parachute reaches the targeted area. Depending upon the 7 are pivotally attached at their foremost point 21 such that

precise parachute release time, the atmospheric conditions in the closed position (FIGS. 3A and 3B) leading edge spars

during release and flight, and release altitude, the parachute 45 7 rest substantially parallel to one another and in the open

may either reach its target or drift up to about 15 miles or position (FIGS.3E and 5) they diverge with an angle 0 (FIG.

more off course. 3E) therebetween. The keel spar 11 is similarly connected to

What is needed in the art is a remotely controlled device the two leading edge spars 7 at point 21 such that in the

for article recovery and delivery which can be collapsed, closed position the keel spar 11 rests substantially parallel to

deployed in motion, maneuvered, and which has an 50 and is disposed between the two leading edge spars 7 while

improved glide ratio. in the open position the keel spar 11 is disposed substantially

equidistant between the two leading edge spars 7, thereby

DISCLOSURE OF THE INVENTION bisecting the angle 6. The outboard ends 9a of the cross

spars 9 attach to the leading edge spars 7 while the inboard

The present invention relates to a deployable wing. This 55 ends 9b pivotally attach to the common slider 13 which

deployable wing comprises a double membrane fabric sail moves linearly along the keel spar 11. Finally an elevonstrut

having an upper section disposed above and joined to a 23 is connected to each leading edge spar 7 at the end

lower section, said sail having a leading edge with a front opposite their connection to the keel spar 11.

point, a trailing edge, and wing tips; an internal structure The internal structure provides structural integrity to the

disposed between the upper section and the lower section 60 wing 1, functioning as the main load carrying structure by

having two leading edge spars, each with a first end and a opening the fabric sail 3 to its wing-like form and main

second end, said first ends pivotally connected together at taining that form while in use and by directly connecting to

approximately the front point, a keel spar connected to and the payload. This structure opens and closes similar to an

disposed between the leading edge spars at the front point umbrella. (see FIGS. 3A-3E) In the open position, the

and extending rearward toward the trailing edge, and at least 65 leading edge spars 7 form the basic, swept-back, delta wing

two cross spars pivotally attached to both the leading edge commonly known in the aeronautical art. The cross spars 9

spars and a sliding mechanism which traverses along the lock the leading edge spars 7 into place, thereby preventing

5,474,257

3 4

the wing 1 from closing during operation, while the slider 3 more than the leeward wing, thereby correcting for the yaw.

allows the movement of the cross spars 9 from the closed Referring now to FIGS. 1-2 in conjunction with FIGS.

position to the open position. Consequently, all of these 3A-3E, connected to and disposed between the leading edge

spars have a sufficient diameter and are formed of a suitable spars 7, the keel spar 11 adds structural integrity to the fabric

material to attain a mechanical strength sufficient to main sail 3 by ensuring that the fabric sail 3 opens to and

tain the wing form while operating with a payload. In one maintains its full length from the leading edge 17 to the

embodiment, the leading edge spar length can be about 17.5 trailing edge 19, commonly known as the wing's chordwise

feet to about 18.5 feet for a 30 foot span wing with a length. As with the leading edge spars 7, the keel spar 11 can

diameter of about 2.5 inches to about 3.0 inches for use with

a payload up to about 1,500 pounds. Suitable spar materials O

have telescoping members (not shown) to decrease the keel

include, but are not limited to: aluminum and other light spar's overall length while in the closed position. The length

weight metals such as stainless steel and others, and com of the keel spar 11 is substantially equivalent to the chord

posites such as epoxy graphite and others commonly known wise length of the wing at the root (very centerline) which,

in the art. as with the leading edge spars 7 length, is determined on a

With continuing reference to FIGS. 1-2, the leading edge practical basis with aeronautical considerations effecting the

spars 7 located along the leading edge 17 of the fabric sails

15 ultimate size. The wing span corresponds to the greatest

3, join together at approximately the front most point 21 of length from one elevon strut 23 to the same point on the

the fabric sail 3 adjacent to the ram air intake 15 (discussed opposing elevon strut 23. A 30 foot span wing typically has

below). The length of each leading edge spar 7 is dependent a keel length of about 7 feet to about 14 feet, with a length

upon the desired size of the wing 1, which is only limited by 20

of about 9 feet to about 11 feet preferred. Generally, the wing

practical considerations: size once folded, size of the landing span to keel length is about 2:1 to about 4:1 with about 3:1

area, weight of the payload, etc. In order to reduce the closed preferred.

wing storage volume, each leading edge spar 7 can have The cross spars 9 similarly provide structural integrity to

telescoping members 7a such that in the closed position, the wing 1 by providing strength to the leading edge spars

each leading edge spar 7 extends to a portion of the length 25

7 to ensure that once the wing 1 is in the open position, the

of the leading edge 17 of the fabric sail 3, while in the open leading edge spars 7 remain therein. These cross spars 9 are

position, the leading edge spars 7 in conjunction with the pivotally connected to the leading edge spars 7 at point 9a

telescoping members 7a extend to the full length of the and are pivotally connected to the keel spar 11 via the slider

leading edge 17. These telescoping members 7a are typically mechanism 13 such that in the closed position, the cross

slidably located within the leading edge spars 7, and can be 30

spars 9 are folded, aligned coaxially with and substantially

hollow structures such as tube-like, D-shaped, or even parallel to the keel spar 11 and leading edge spars 7, and

C-shaped structures, among others. During deployment of disposed between the leading edge spars 7 and the keel spar

the wing 1, the telescoping members 7a are pulled from 11. In such a position, the slider mechanism 13 is located

within the leading edge spars 7 to form the full length of the adjacent to the front point 21 on the keel spar 11.

leading edge 17 of the wing. 35 With continuing reference to FIGS. 1-2in conjunction

Since the fabric sail 3 is disposed around the internal with FIGS.3A-3E, in the open position, the cross spars 9 are

structure and therefore the leading edge spars 7 and the fully extended and typically positioned at an angle Tt of

telescoping members 7a, the manner in which each tele about 90° or less. At greater than about 90°, the cut-outs 5a

scoping member 7a deploys, from the closed to the open in the fabric ribs 5 become excessively large due to the

position, is important. If the fabric sail 3 becomes twisted 40 increased amount of slider 13 travel, thereby reducing the

during deployment due to unexpected turning of the tele fabric ribs' 5 ability to properly define the wing's airfoil

scoping members 7a, the elevon trim position is effected, shape and reducing the mechanical strength of the fabric ribs

thereby decreasing the wings flight performance or even 5. Therefore, an angle at of less than 90° is preferred, with

preventing successful flight. Consequently, the telescoping Tt typically equal to about 65° to about 85°. Stops can be

members 7a are fabricated such that they deploy in a 45 employed to lock the cross spars 9 into place at the desired

predetermined fashion, i.e. straight without turning or by angle TL. Preferably, pins are located in the sliding mecha

turning a predetermined amount. Such deployment can be nism 13 and holes are located in the keel spar 11 such that

accomplished via the employment of a track V-shaped when the cross spars 9 reach the desired position, the pins

channel, cable within the leading edge spar 7 which the fall into the holes in the keel spar 11, thereby locking the

telescoping member 7a follows during deployment and/or a 50 cross spars 9 into position.

similar deployment scheme. Additionally, after deployment, The attachment point of the cross spars 9 to the leading

these telescoping members 7a lockinto the open position via edge spars 7 and the angle TC determines the cross spar 9's

conventional means. length. In one embodiment, the attachment point is typically

Referring now to FIGS. 3A-3E, once the leading edge between about 45% and about 80% of the leading edge spars

spars 7 are in the open position, they form an angle 0. The 55 7 length, with about 55% to 65% preferred, and about 57%

size of this angle 0 depends upon aerodynamic consider to about 62% especially preferred. Consequently, for a 30ft

ations including aspect ratio, yaw stability, and deployment wing span with a 17.5 ft leading edge spars and 12.25 ft

simplicity, among others. Typically, 0ranges from about 90 attachment point, a 85 angle TL, the cross spars 9 are about

to about 150 with about 105 to about 110 preferred due 9.5 ft long.

to simplicity of the deployment mechanism geometry. 60 Side cables 33 are attached to the leading edge spar's 7 at

Angles greater than about 150 result in more complex, and approximately 45% to 80% of the leading edge spar's

therefore less desirable, mechanical/structural geometry and length, typically at point 9a and extend downward and

decreasing yaw stability, while angles less than about 90 inward to attach to the payload below. The cables33 provide

result in decreasing glide ratio. Yaw stability is where wing support to each wing half and relieve cantileverloads which

sweep allows the wing to tend to maintain its flight directly 65 allow the structural components to be smaller and lighter.

into the wind, commonly known as maintaining the yaw The attachment point puts the cross spar 9 in compression

heading. As the wing yaws, the windward wing tends to drag without imposing further cantileverload on the leading edge

5,474,257

S 6

by providing a downward load path and reducing the length 3b which are joined around the perimeter to form an

of cantilevered load. envelope which can be filled with air to form the airfoil wing

With continued reference to FIGS. 1-2in conjunction with shape shown in FIG. 4. Although it is not required that the

FIGS. 3A-3E, the elevon struts 23, usually which provide fabric sail 3 be airtight, beside the ram air inlet 15, it is

structural integrity to the end of the wing 1 and tension along preferred that the upper and lower sections be completely

the sail trailing edge 19, are connected to the leading edge sealed around the periphery, particularly along the trailing

spars 7 at the second end 25a and 25b. For example, for a edge to ensure that the fabric sail 3 remains inflated and

30 ft wing span the keel spar 11 is about 10 ft with the elevon thereby rigid during flight. Internal pressure stiffens the

struts 23 being about 3 feet. As with the keel spar 11, these fabric sail 3 which forms the airfoil shape defined by the

10 fabric ribs 5, providing lift and reducing or eliminating sail

elevon struts 23 extend rearward from the leading edge 17 flutter which can increase drag and thereby reduce the glide

of the wing to the trailing edge 19 thereof, running parallel ratio.

to the keel spar 11. Depending upon the desired shape of the As can be clearly seen in FIG. 4, the size of lower section

wing tip, elevon struts 23 may be shortened or bowed. On a 3b of the wing corresponds to the amount of fabric required

30 ft wing, for example, the elevon struts can be about 35 to encapsulate the leading edge spar 7 and to extend there

inches to about 45 inches long with an outer diameter of 15

about 0.80".

from to the trailing edge 19 of the wing. Although it is not

necessary to encapsulate the leading edge spar 7 within the

In a configuration as shown in FIGS. 1 and 2, the elevon lower section 3b, such construction is preferred due to the

struts 23 are also employed for controlling the wing 1 during enhanced aerodynamic shape of the wing during operation.

operation. These elevonstruts 23 connect to a motor or fluid 20 The lower section 3b is patterned such that when the wing

actuator which in turn connects to the leading edge spar 7. is deployed, the lower sail section 3b is pulled taught,

During flight the elevon struts 23 are individually deflected extending rearward from the center of the leading edge spar

or rotated out of the plane of the sail as shown by arrows "A" 7. By maintaining tension in the lower section 3b, the

and "B" in FIG. 1, thereby controlling the flight of the wing. inflated airfoil shape can be better controlled. The lower

By rotating the elevon strut 23, the end of the sail (wing tip 25 section3b encapsulates the leading edge spar 7 and attaches

35a and 35b) is twisted up or down relative to the leading to itself at point 27 such that the remainder of the lower

edge. This helical twisting of the sail results in an aerody section 3b extends rearward and substantially aligns with the

namic force sufficient to pitch or roll the wing. Rotating or center of the leading edge spar 7. Preferably, the lower

deflecting the elevon struts 23 in unison generates an aero section 3b is patterned with a luff curve. In this embodiment,

dynamic force substantially behind the pressure center of the 30 the leading edge 17 is straight from the forward point 21 to

wing which is located at the point about 55% down the keel the cross spar junction 9a. (also see FIG. 2) From the cross

from the front point 21, thereby forming a moment force sparjunction 9a to the second end 25a and 25b of the leading

about the pressure center which is used for pitch control of edge spars 7, the lower section 3b curves toward the keel

the wing. By rotating or deflecting the elevon struts 23 spar 11 to flex the leading edge spar 7 and further tighten the

singularly or in opposite directions, aerodynamic forces at 35 lower section 3b, commonly known as a luff curve. In a 30

the wing tips 35a and 35b can be controlled in magnitude ft wing, for example, this luff curve can be a deflection (of

and direction, up or down. For example, if the right elevon the wing tip from point 9a) of up to 1 ft or more.

strut 23 is rotated up while the left is rotated down, a The envelope formed by the fabric sail 3 is completed

downward force is generated on the right tip 35a and an with the upper section 3a of the fabric sail 3 connecting to

upward force on the left tip 35b, resulting in a right roll or 40 the periphery of the lower section The size of the upper

turn. Other conventional devices can be employed such as section 3a of the fabric sail depends upon the size of the

pneumatic and hydraulic devices, among others. lower section 3b and the size of the fabric ribs 5 since the

These elevon struts 23, or other control devices, can be fabric ribs 5 define the desired lift shape of the inflated fabric

operated with any conventional motor capable of generating sail 3 (discussed below). This size can readily be determined

sufficient torque to overcome the aerodynamic forces at a 45 by artisans based upon conventional aeronautical consider

speed sufficient for control response. Factors important in ations. One airfoil shape which can be employed comprises

determining the required torque include wing area, wing the upper section 3a being about 5% to about 15% larger

loading, aspect ratio, and elevon strut length, among others. chordwise than the lower surface sail 3b, with about 8% to

A wing having a 30 foot wing span, for example, with a sail about 11% preferred. A larger upper section 3a forces the air

area of about 190 ft and a 700 lb load requires about 40 to 50 to travel a greater distance over the top of the sail, causing

about 80 ftlb torque while a 15ft wing span wing with an the air to spread out, forming a low pressure, and thereby

area of 45 ft' and a 90 lb load needs about 15 to about 25 causing lift.

ft. lb torque for control. Referring again to FIGS. 1-2, a plurality of fabric ribs 5

In addition to the leading edge spars 7, cross spars 9, which are disposed between and connect to the uppersection

elevonstruts 23, and the keel spar 11, upper rigging spars 30, 55 3a and the lower section 3b of the fabric sail 3, define and

31 and cables 32, can be used to provide additional support maintain the desired lift shape of the inflated fabric sail 3.

to the wing, particularly in negative (inverted flight) condi Consequently, the fabric ribs 5 have an airfoil shape. These

tions. (see FIGS. 6 and 7) Forward and aft spars 30 and 31 fabric ribs 5 connect to the lower section 3b near the front

pivotally attach external to the fabric sail 3 at the forward of the leading edge spar 7 such that the lower section 3b is

and aft ends of the keel spar 11 and join each other above the 60 disposed between the fabric rib 5 and the leading edge spar

keel spar 11 at the point where the cables 32 cross over the 7. From point 5b to the trailing edge 19, the lower portion

keel spar. The cables 32 attach at the junction of the forward of the fabric rib 5 conforms to the geometry of the lower

and aft spars 30 and 31, and at the junction 9a of each section3b. Since the upper portion of the fabric rib 5 defines

leading edge spar 7 and the cross spar 9. the airfoil shape of the inflated fabric sail 3, this portion

As stated above, the fabric sail 3 encompasses the leading 65 should conform to the desired inflated wing aerodynamic

edge spars 7, the keel spar 11, the cross spars 9, and the shape. Conventional aerodynamic shapes which can be

elevonstruts 23 with an upper section 3a and a lower section employed include: high lift/low speed airfoil sections, and

5,474.257

7 8

others conventionally known in the aerodynamic art such as The ram air pressurizes the envelope formed by the fabric

those described in the "Theory of Wing Sections” by Ira H. sail 3, stiffening the fabric sail 3, eliminating sail flutter, and

Abbott and Albert E. Von Doenhoff. The preferred upper causing the wing 1 to take on an airfoil shape and behave

portion rib shape is patterned after a Clark-Y airfoil section similar to a rigid wing. The size of the ram air intake 15,

with a maximum thickness of 12.2% of the chord length which can readily be determined by one skilled in the

with the maximum thickness occurring at 29.5% of the aerodynamic field, depends upon corresponding the time

chord length measured from the front of the fabric rib5. This required to fill and pressurize the wing with the time

preferred shape attains an improved glide ratio of about required for mechanical opening during deployment. Typi

13:1. Each fabric rib 5 allows opening and closing of the cally, the ram air intake 15 is about 0.5 ft to about 0.75 ft.

cross spars 9 via a cutout 5a where the cross spars 9 pass 10 for a 30 foot span wing. The ram air intake 15 must also be

from the keel spar 9 to the leading edge spars 7.(see FIGS. sufficiently large to allow in sufficient air to make up air for

1 and 2) The size of this cutout 5a substantially corresponds leakage.

to the chordwise travel area of the cross spars 9 from the Referring to FIGS. 3A-3E and 5-7, deployment com

closed position to the open position. prises dropping the closed wing from an aircraft, decelerat

In addition to defining and maintaining the desired 15

ing and stabilizing the wing nose-down, by deployment of a

inflated shape, the fabric ribs 5 also transfer the load from drogue parachute. Once stable, the parachute's suspended

the upper section 3a of the wing to the lower section 3b. It load is released from the payload and transferred to the slider

is commonly known that as an airfoil travels through the air, 13, thereby applying a rearward tension. This load transfer

a majority of the lifting force is obtained via a low pressure may be accomplished by a release mechanism initiated by

above the airfoil. By a spanwise distribution of fabric ribs 5 20

either a timer, an altimeter, or other signal. For example, the

this lifting force is transferred from the upper surface 3a to release mechanism can be a mechanical latch which when

the lower surface 3b at each fabric rib 5. Consequently, the tripped by an electrical signal, unlatches or releases the

preferred number of fabric ribs 5, which can readily be drogue parachute line from the payload, thereby causing

determined by an artisan, corresponds to the number nec tension on the line connected to the slider 13. Telescoping

essary to transfer a sufficient amount of the load and define 25

members can be extended by a similar parachute tension

and maintain the airfoil shape to allow efficient flight. force or by applying pneumatic pressure to an internal

With continuing reference to FIGS. 1-2, the fabric ribs 5 piston. As the internal structure extends to its open position,

spacing is determined by the number of fabric ribs 5 which, the wing inflates with ram air. The opened, inflated wing can

in turn, is a function of the criticality of airfoil definition then be guided to its desired destination.

versus weight and fabrication costs. A total of up to about 30 30 The rearward force applied to the slider 13 by the drogue

or more ribs can be utilized depending upon the size of the parachute causes the internal structure of the wing to deploy.

wing, with about 8 to about 25 fabric ribs preferred for wings (see FIG. 5) In one embodiment, this action accomplishes

having wing spans of about 15 ft to about 30 ft, and about the following mechanical actuation: the cross spars 9 push

14 to about 18 fabric ribs 5 especially preferred. Typically, against the leading edge spars 7 to move the leading edge

these fabric ribs 5 are aligned substantially parallel to one 35 spars 7 to the proper swept, delta geometry; the telescoping

another, Substantially equidistant apart from the keel spar 11 keel spar 11 retracts (shortens) causing the upper rigging

to the elevon struts 23, and coaxially with the keel spar 11. spars 30 and 31 to erect and a rearward movement of the

The two central ribs, however, can be employed to form a entire wing relative to the keel spar 11 attachment to the

pocket to contain the keel spar 11, and therefore are not payload. This rearward movement causes the wing to rotate

equidistant from both the keel spar 11 or one another (with 40 up (pitch up) about a pair of nose struts 34 to an angle of

relation to the other ribs). incidence relative to the payload. Once the keel spar 11 has

The sections of the fabric sail 3 can be formed of any retracted and the leading edge spars 7 have moved to the

conventional fabric which is sufficiently flexible to allow deployed geometry, the slider 13 aligns with holes in the

folding for packing, sufficiently elastic to dampen the shock keel spar 11 inner and outer tubes. A latching pin falls into

loads of deployment, yet not elastic to the point where shape 45 the aligned holes to lock the cross spars 9 and, therefore the

definition is lost, and possesses sufficient mechanical integ wing structure, into the deployed configuration. This latch

rity to withstand the deployment, operation loads, and ing action also releases the drogue parachute line, allowing

payloads. Normally, a nylon or dacron fabric can be the wing to begin flight. Note, whether to use nose struts 34

employed. Where high strength is needed, kevlar or spectra is dependent upon the flight geometry of the payload. If the

cloths can be used, typically resin coated cloth which has 50 payload flies more efficiently into the wind, the wing 1

decreased porosity such as polyurethane coated cloth is should be close-coupled to the payload, eliminating the need

preferred for the upper and lower sections 3a and 3b which for nose struts 34 and possibly eliminating the need for a

are preferably also substantially non-porous to contain the retractable keel spar 11. However, if the wing's flight ability

air when pressurized by ram air inflation. For example, since decreases when close-coupled to the payload, the nose struts

the fabric ribs 5 transfer the load from the upper section 3a 55 34 can be employed to change the angle between the wing

to the lower section 3b of the fabric sail 3, a light-weight and the payload.

fabric can be utilized for the upper section 3a with a heavier As is clear from the above description of the present

weight fabric utilized for the lower section 3b. Rip stop 1.25 invention, there are numerous advantages achieved with the

ozlyd’ (ounces/square yard) nylon can be utilized for the deployable wing. Unlike previous gliders and parachutes,

upper section 3a and for the fabric ribs 5 with 4.0 oz/yd? 60 the wing of the present invention is both deployable and

dacron used for the lower section 3b. Note, multiple layers remotely controllable or can be controlled by an onboard

can be employed at stress points such as at the trailing edge autopilot system. This wing can be folded, conveniently

and others. stored, deployed for an air drop, directed to the desired

The envelope formed by the fabric sail3 is inflated during location, and landed at the target area.

operation with air rammed into the wing through an intake 65 The deployable wing of the present invention attains a

opening 15 located at the nose stagnation point of the fabric glide ratio up to or exceeding about 12:1, and greater than

sail 3, commonly known as ram air and ram air intake 15. 8:1 with typical payloads of about 1,000 pounds for a 30 ft

5,474,257

9 10

wing, while gliding parachutes with payloads of about 1,000 Spars to said leading edge spars to said second ends of said

pounds typically have glide ratios of about 3:1 and hang leading edge spars.

gliders have glide ratios of about 10:1. The deployable wing 9. A deployable wing as in claim 1 further comprising a

is particularly useful in operations such as cargo delivery control device for twisting a portion of said leading edge

since the wing, with a cargo (payload), can be released from spars to control the flight of said wing by deforming the

an air-craft, deployed in motion, and safely maneuvered to shape of said wing.

the precise desired destination. 10. A deployable wing as in claim 1, wherein said fabric

It is also understood that the deployable wing of the ribs have a length and a thickness with a maximum thickness

present invention can be utilized for powered flight, particu of about 10% to about 15% of said length and occurring at

larly for retrieval of equipment and other objects from O about 27% to about 33% of said length.

locations whose distance is greater than the glide range of 11. A method for air dropping a payload, which com

the wing. prises:

Although the invention has been shown and described a. providing a deployable wing comprising:

with respect to detailed embodiments thereof, it will be i. a double membrane fabric sail having an upper

understood by those skilled in the art that various changes in 15 section disposed above and joined to a lower section,

form and detail thereof may be made without departing from Said sail having a leading edge, and wing tips,

the spirit and scope of the claimed invention. ii. an internal structure disposed between said upper

We claim: Section and Said lower section, said internal structure

1. A deployable wing, comprising: having,

20 a. two leading edge spars with a first end and a

a. a double membrane fabric sail having an upper section

disposed above and joined to a lower section, said sail second end, said first ends of said leading edge

having a leading edge with afront point, a trailing edge, spars pivotally connected together at approxi

and wing tips, mately said front point,

b. an internal structure disposed between said upper 25

b. a keel spar connected to and disposed between

section and said lower section, said internal structure said leading edge spars at said front point and

having, extending rearward toward said trailing edge, and

i. two leading edge spars, each of said leading edge c. at least two cross spars pivotally attached to said

spars having a first end and a second end, said first leading edge spars and to a sliding mechanism

ends of said leading edge spars pivotally connected which transverses along said keel spar;

30 iii. a plurality of fabric ribs disposed between and

together at approximately said front point,

ii. a keel spar connected to and disposed between said connected to said upper section and said lower

leading edge spars at said front point and extending Section, wherein said fabric ribs have at least one slot

rearward toward said trailing edge, and through which said cross spars extend from said keel

iii. at least two cross spars pivotally attached to said spar to said leading edge spars and said fabric ribs

35 define a shape of said fabric sail when inflated, and

leading edge spars and to a sliding mechanism which

transverses along said keel spar, iv, a ram air intake located on said leading edge at the

c. a plurality of fabric ribs disposed between and con stagnation point of the wing during operation,

nected to said upper section and said lower section, wherein said deployable wing is in a closed position

wherein said fabric ribs have at least one slot through such that said leading edge spars are aligned parallel

40 to said keel spar;

which said cross spars extend from said keel spar to b. attaching the payload to said deployable wing; and

said leading edge spars and said fabric ribs define a

shape of said fabric sail when inflated, and c. deploying said wing from an aircraft, wherein said

d. a ram air intake located on said leading edge at the leading edge spars open, said sliding mechanism moves

stagnation point of the wing during operation. 45 rearward toward the trailing edge and locks said cross

2. A deployable wing as in claim 1 further comprising at spars into place and air enters said wing through said

least one elevon strut attached to said second end of each of ran air intake to inflate said wing and form an airfoil

said leading edge spars wherein said elevon struts can be shape.

moved to thereby control the wing's flight. 12. A method as described in claim 11, wherein said

3. A deployable wing as in claim 2 further comprising an 50 leading edge spars have telescoping members which tele

actuator for moving said elevon struts such that said wing Scope to their open position during deployment.

tips move out of the plane of the wing. 13. A method as described in claim 11, wherein said

4. A deployable wing as in claim 1 further comprising deployable wing has an elevon strut connected to the second

external rigging, wherein said rigging comprises at least two end of each of said leading edge spars and is remotely

upper rigging spars pivotally joined together above said keel 55 controlled via said elevon struts.

spar, and at least two cables connecting from said upper 14. A method as described in claim 11, wherein said wing

rigging joint to said leading edge spars. is deployed utilizing a drogue parachute attached to said

5. A deployable wing as in claim 1, wherein each of said payload and said sliding mechanism.

leading edge spars have at least one telescoping member to 15. A remotely controllable wing, said wing having a

accommodate Small packaging constraints. 60 delta-wing geometry, comprising:

6. A deployable wing as in claim 1, wherein said lower a fabric sail having an upper section joined to a lower

Section extends rearward from and substantially aligns with section and including an intake opening;

the center of said leading edge spars. an internal structure disposed substantially between said

7. A deployable wing as in claim 6, wherein said lower upper Section and said lower section, said internal

section substantially encapsulates said leading edge spars. 65 structure including at least two leading edge spars

8. A deployable wing as in claim 7 wherein said lower connected together at approximately a front point, a

section forms a luff curve from said connection of said cross keel Spar connected to and disposed between said

5,474,257

11 12

leading edge spars at said front point and at least one ii. an internal structure disposed substantially between

cross spar attached to said leading edge spars; said upper section and said lower section, said inter

a plurality of elevon struts connected to the internal nal structure including at least two leading edge

structure and substantially enclosed within the fabric spars connected to either at approximately a front

sail; and 5 point, a keel spar connected to and disposed between

said leading edge spars at said front point and at least

a control device operatively connected to at least one of one cross spar attached to said leading edge spars;

said elevon struts, said control device being remotely iii. a plurality of elevon struts connected to the internal

operable to move at least one of said elevon struts structure and substantially enclosed within the fabric

between a first position substantially within a plane 10 sail;

defined by the wing and a second position substantially iv. a remotely operable control device operatively con

out of the plane of the wing. nected to at least one of said elevon struts; and

16. A remotely controllable wing as in claim 15, wherein . . signaling said control device to move at least one of

said control device is a motor or actuator. said elevon struts between a first position substantially

17. A method for remotely controlling a wing, which 15 within a plane defined by the deployable wing and a

comprises: second position substantially out of the plane of the

a. providing a deployable wing comprising: wing.

i. a fabric sail having an upper section joined to a lower

section and including an intake opening;

Das könnte Ihnen auch gefallen

- Progress in Aeronautical Sciences: Volume 3Von EverandProgress in Aeronautical Sciences: Volume 3Antonio FerriBewertung: 5 von 5 Sternen5/5 (1)

- Arnason TF-JFPDokument7 SeitenArnason TF-JFPIvan SABONoch keine Bewertungen

- Horizontal tail for aircraft generates increased pitch controlDokument9 SeitenHorizontal tail for aircraft generates increased pitch controlgorgiNoch keine Bewertungen

- US4624203Dokument11 SeitenUS4624203524Noch keine Bewertungen

- United States Patent (19) : A26%/A A2%2W2 Azaa2%2Dokument17 SeitenUnited States Patent (19) : A26%/A A2%2W2 Azaa2%2fitri auliyatinNoch keine Bewertungen

- United States PatentDokument15 SeitenUnited States PatentJjp ParmarNoch keine Bewertungen

- United States Patent (19) : Debarge Dec. 17, 1985Dokument9 SeitenUnited States Patent (19) : Debarge Dec. 17, 198563Noch keine Bewertungen

- United States Patent (19) : Chupka Et Al. 11) Patent Number: 5,078,275 (45) Date of PatentDokument10 SeitenUnited States Patent (19) : Chupka Et Al. 11) Patent Number: 5,078,275 (45) Date of PatentClaudinei MayerNoch keine Bewertungen

- Cloth Tow Target Sleeve (1991)Dokument25 SeitenCloth Tow Target Sleeve (1991)CAP History LibraryNoch keine Bewertungen

- US5918832Dokument8 SeitenUS5918832engine wangNoch keine Bewertungen

- United States PatentDokument13 SeitenUnited States Patent155Noch keine Bewertungen

- CGNCGFNDokument7 SeitenCGNCGFNfernando Ancaya AncayaNoch keine Bewertungen

- United States Patent (19) 5,022,984: Pimley Et Al. Jun. 11, 1991Dokument11 SeitenUnited States Patent (19) 5,022,984: Pimley Et Al. Jun. 11, 1991Claudinei MayerNoch keine Bewertungen

- United States Patent (10) Patent No.: US 6,170,421 B1: Ross (45) Date of Patent: Jan. 9, 2001Dokument8 SeitenUnited States Patent (10) Patent No.: US 6,170,421 B1: Ross (45) Date of Patent: Jan. 9, 2001155Noch keine Bewertungen

- Automated Flap and Cup Cleaner Water-Saving ToiletDokument41 SeitenAutomated Flap and Cup Cleaner Water-Saving ToiletAlex KattamisNoch keine Bewertungen

- US6276294Dokument12 SeitenUS6276294Văn Hiếu NguyễnNoch keine Bewertungen

- United States Patent (19) (11) Patent Number: 6,149,101: F'U-S'EL/IGE IDokument20 SeitenUnited States Patent (19) (11) Patent Number: 6,149,101: F'U-S'EL/IGE IgorgiNoch keine Bewertungen

- US4804352Dokument15 SeitenUS4804352雷黎明Noch keine Bewertungen

- United States Patent (19) : Aerospatiale, FranceDokument7 SeitenUnited States Patent (19) : Aerospatiale, Franceingeniomeca8800Noch keine Bewertungen

- United States Patent (19) : Gazalel, 72 8Dokument7 SeitenUnited States Patent (19) : Gazalel, 72 8Mihai RobertNoch keine Bewertungen

- United States Patent (19) : Saia, III Et Al. (45) Date of Patent: " Aug. 16, 1994Dokument18 SeitenUnited States Patent (19) : Saia, III Et Al. (45) Date of Patent: " Aug. 16, 1994Maulana IskhaqNoch keine Bewertungen

- United States Patent (19) : (21) Appl. No.: 927,123Dokument7 SeitenUnited States Patent (19) : (21) Appl. No.: 927,123155Noch keine Bewertungen

- Tow Target Line Reel (2005)Dokument19 SeitenTow Target Line Reel (2005)CAP History LibraryNoch keine Bewertungen

- United States Patent (19) : Peyman 45 Date of Patent: Aug. 15, 1989Dokument7 SeitenUnited States Patent (19) : Peyman 45 Date of Patent: Aug. 15, 1989155Noch keine Bewertungen

- United States Patent (10) Patent No.: US 6,282,863 B1: Christian Et Al. (45) Date of Patent: Sep. 4, 2001Dokument20 SeitenUnited States Patent (10) Patent No.: US 6,282,863 B1: Christian Et Al. (45) Date of Patent: Sep. 4, 2001Munir KadernaniNoch keine Bewertungen

- United States Patent (19) 11 Patent Number: 5,992,793: Perry Et Al. (45) Date of Patent: Nov.30, 1999Dokument8 SeitenUnited States Patent (19) 11 Patent Number: 5,992,793: Perry Et Al. (45) Date of Patent: Nov.30, 1999155Noch keine Bewertungen

- US7413145 - ChemtrailsDokument12 SeitenUS7413145 - ChemtrailsAlex Supertramp DantasNoch keine Bewertungen

- United States Patent (10) Patent No.: US 6,886,777 B2: Rock (45) Date of Patent: May 3, 2005Dokument24 SeitenUnited States Patent (10) Patent No.: US 6,886,777 B2: Rock (45) Date of Patent: May 3, 2005Ionel ConstantinescuNoch keine Bewertungen

- Flying Saucer Vehicle Controls Attitude With Pressurized Air JetsDokument8 SeitenFlying Saucer Vehicle Controls Attitude With Pressurized Air JetsSINGLE KIFNoch keine Bewertungen

- United States Patent (10) Patent No.: US 7,252,264 B2: Nattinger (45) Date of Patent: Aug. 7, 2007Dokument11 SeitenUnited States Patent (10) Patent No.: US 7,252,264 B2: Nattinger (45) Date of Patent: Aug. 7, 200712348Noch keine Bewertungen

- United States Patent (19) : Ginsberg 45 Date of Patent: Apr. 15, 1997Dokument26 SeitenUnited States Patent (19) : Ginsberg 45 Date of Patent: Apr. 15, 1997gorgiNoch keine Bewertungen

- United States Patent (19) : GravelineDokument15 SeitenUnited States Patent (19) : Graveline155Noch keine Bewertungen

- United States Patent 19Dokument9 SeitenUnited States Patent 19Claudinei MayerNoch keine Bewertungen

- Pop Top Inserton Indicator For Quick ConnectorsDokument12 SeitenPop Top Inserton Indicator For Quick ConnectorsTUNCAY GUMUSNoch keine Bewertungen

- Diseño de Impulsores para Mezcla de SuspensionesDokument9 SeitenDiseño de Impulsores para Mezcla de SuspensionesrwtoorresdNoch keine Bewertungen

- Us6111198 - Duplex Feedthrough and Method ThereforDokument9 SeitenUs6111198 - Duplex Feedthrough and Method ThereforNosfe Matingli DiazNoch keine Bewertungen

- Sai Gó: (5) (5) (5) (Sics211Dokument33 SeitenSai Gó: (5) (5) (5) (Sics211Dhrubajyoti BoraNoch keine Bewertungen

- Air Cleaner For Internal Combustion EngineDokument6 SeitenAir Cleaner For Internal Combustion EngineSirDeparnieux100% (1)

- Ihiiihiiihiiihihiiii: United States Patent (19) 11) Patent Number: 5,279,241Dokument10 SeitenIhiiihiiihiiihihiiii: United States Patent (19) 11) Patent Number: 5,279,24112348Noch keine Bewertungen

- Flat Glass Annealing LehrsDokument7 SeitenFlat Glass Annealing LehrsHồng ĐàoNoch keine Bewertungen

- United States Patent 19 11 Patent Number: 5,697,468: Russell, Jr. Et Al. (45) Date of Patent: Dec. 16, 1997Dokument8 SeitenUnited States Patent 19 11 Patent Number: 5,697,468: Russell, Jr. Et Al. (45) Date of Patent: Dec. 16, 1997155Noch keine Bewertungen

- United States Patent: (10) Patent No.: US 6,293,891 B1Dokument8 SeitenUnited States Patent: (10) Patent No.: US 6,293,891 B1Dejan ZdravkovskiNoch keine Bewertungen

- United States PatentDokument13 SeitenUnited States Patent63Noch keine Bewertungen

- Tad 2Dokument15 SeitenTad 2Reza IraniNoch keine Bewertungen

- United States Patent (19) : WalkerDokument8 SeitenUnited States Patent (19) : Walker155Noch keine Bewertungen

- Cloth Tow Target Sleeve (1992)Dokument26 SeitenCloth Tow Target Sleeve (1992)CAP History LibraryNoch keine Bewertungen

- Weighing Device for Apron FeederDokument13 SeitenWeighing Device for Apron Feederchannakeshava pandurangaNoch keine Bewertungen

- US5241749 Rod Baffle DesignDokument12 SeitenUS5241749 Rod Baffle Designashish.itbhuNoch keine Bewertungen

- United States Patent (10) Patent No.: US 8,919,272 B2Dokument10 SeitenUnited States Patent (10) Patent No.: US 8,919,272 B263Noch keine Bewertungen

- Autogyro Aircraft Adjusts Rotor Blade Pitch for Optimal LiftDokument50 SeitenAutogyro Aircraft Adjusts Rotor Blade Pitch for Optimal Liftwen longNoch keine Bewertungen

- United States Patent (19) 11 Patent Number: 5,937,665: Kiessel Et Al. (45) Date of Patent: Aug. 17, 1999Dokument9 SeitenUnited States Patent (19) 11 Patent Number: 5,937,665: Kiessel Et Al. (45) Date of Patent: Aug. 17, 1999hussainNoch keine Bewertungen

- United States Patent (10) Patent No.: US 6,216,982 B1: Pfennig Et Al. (45) Date of Patent: Apr. 17, 2001Dokument10 SeitenUnited States Patent (10) Patent No.: US 6,216,982 B1: Pfennig Et Al. (45) Date of Patent: Apr. 17, 2001Arthur HugenNoch keine Bewertungen

- US5304036Dokument24 SeitenUS5304036wen longNoch keine Bewertungen

- United States PatentDokument5 SeitenUnited States PatentAgil Dwy CahyoNoch keine Bewertungen

- Ulllted States Patent (19) (11) Patent Number: 5,944,123: Johnson (45) Date of Patent: Aug. 31, 1999Dokument8 SeitenUlllted States Patent (19) (11) Patent Number: 5,944,123: Johnson (45) Date of Patent: Aug. 31, 1999Cường Nguyễn QuốcNoch keine Bewertungen

- Us 6974123Dokument9 SeitenUs 6974123John MccloskeyNoch keine Bewertungen

- United States Patent (10) Patent No.: US 6,439,110 B1: Lin (45) Date of Patent: Aug. 27, 2002Dokument5 SeitenUnited States Patent (10) Patent No.: US 6,439,110 B1: Lin (45) Date of Patent: Aug. 27, 2002BobNoch keine Bewertungen

- Slide Gate Damper SystemDokument9 SeitenSlide Gate Damper SystemRohit BirajdarNoch keine Bewertungen

- United States Patent (19) : Helderle Et AlDokument14 SeitenUnited States Patent (19) : Helderle Et AlabodolkuhaaNoch keine Bewertungen

- United States Patent (19) 11 4,023,782: Eifer (45) May 17, 1977Dokument16 SeitenUnited States Patent (19) 11 4,023,782: Eifer (45) May 17, 1977liNoch keine Bewertungen

- United States Patent (19) : VicardDokument4 SeitenUnited States Patent (19) : Vicard155100% (1)

- United States Patent 19 11 Patent Number: 5,775,249: Samuel 45) Date of Patent: Jul. 7, 1998Dokument19 SeitenUnited States Patent 19 11 Patent Number: 5,775,249: Samuel 45) Date of Patent: Jul. 7, 1998155Noch keine Bewertungen

- EP0746495B1Dokument9 SeitenEP0746495B1155Noch keine Bewertungen

- United States Patent (19) : Peyman 45 Date of Patent: Aug. 15, 1989Dokument7 SeitenUnited States Patent (19) : Peyman 45 Date of Patent: Aug. 15, 1989155Noch keine Bewertungen

- EP2404820A1Dokument18 SeitenEP2404820A1155Noch keine Bewertungen

- United States Patent (19) : WalkerDokument8 SeitenUnited States Patent (19) : Walker155Noch keine Bewertungen

- United States Patent (19) : (76) Inventor: John Guthrie, Suite 1401-555-13th ST.Dokument10 SeitenUnited States Patent (19) : (76) Inventor: John Guthrie, Suite 1401-555-13th ST.155Noch keine Bewertungen

- Automatically Rotating Sail Rig for SloopsDokument18 SeitenAutomatically Rotating Sail Rig for Sloops155Noch keine Bewertungen

- Fied Feb. 5, 1967: 2. Sheets-Sheet LDokument5 SeitenFied Feb. 5, 1967: 2. Sheets-Sheet L155Noch keine Bewertungen

- Us 2484687Dokument7 SeitenUs 2484687155Noch keine Bewertungen

- United States Patent: (54) SailboatDokument5 SeitenUnited States Patent: (54) Sailboat155Noch keine Bewertungen

- United States Patent (19) : (21) Appl. No.: 927,123Dokument7 SeitenUnited States Patent (19) : (21) Appl. No.: 927,123155Noch keine Bewertungen

- Patent for improved sailing vessel with rotating masts and sailsDokument10 SeitenPatent for improved sailing vessel with rotating masts and sails155Noch keine Bewertungen

- Automatically Rotating Sail Rig for SloopsDokument18 SeitenAutomatically Rotating Sail Rig for Sloops155Noch keine Bewertungen

- Wells-Coates 1951 Patent for Sailing Craft with Adjustable Sail ArchDokument16 SeitenWells-Coates 1951 Patent for Sailing Craft with Adjustable Sail Arch155Noch keine Bewertungen

- United States PatentDokument6 SeitenUnited States Patent155Noch keine Bewertungen

- United States Patent (10) Patent No.: US 6,578,798 B1: Ave., #129, Anaheim, CA (US) 92801 S A 2: RegDokument24 SeitenUnited States Patent (10) Patent No.: US 6,578,798 B1: Ave., #129, Anaheim, CA (US) 92801 S A 2: Reg155Noch keine Bewertungen

- United States Design Patent (10) Patent No.:: USD639,239 SDokument9 SeitenUnited States Design Patent (10) Patent No.:: USD639,239 S155Noch keine Bewertungen

- United States Patent (19) 11 Patent Number: 5,992,793: Perry Et Al. (45) Date of Patent: Nov.30, 1999Dokument8 SeitenUnited States Patent (19) 11 Patent Number: 5,992,793: Perry Et Al. (45) Date of Patent: Nov.30, 1999155Noch keine Bewertungen

- United States Design Patent (10) Patent No.: US D478,598 SDokument5 SeitenUnited States Design Patent (10) Patent No.: US D478,598 S155Noch keine Bewertungen

- United States PatentDokument13 SeitenUnited States Patent155Noch keine Bewertungen

- W. Castles, JR: Filed Jan. 11, 1957Dokument3 SeitenW. Castles, JR: Filed Jan. 11, 1957155Noch keine Bewertungen

- United States Design Patent (10) Patent No .:: US D807, 823 SDokument9 SeitenUnited States Design Patent (10) Patent No .:: US D807, 823 S155Noch keine Bewertungen

- United States Patent: (10) Patent No.: US 6,168,383 B1Dokument17 SeitenUnited States Patent: (10) Patent No.: US 6,168,383 B1155Noch keine Bewertungen

- United States Patent 19 11 Patent Number: 5,697,468: Russell, Jr. Et Al. (45) Date of Patent: Dec. 16, 1997Dokument8 SeitenUnited States Patent 19 11 Patent Number: 5,697,468: Russell, Jr. Et Al. (45) Date of Patent: Dec. 16, 1997155Noch keine Bewertungen

- Us 5253828Dokument12 SeitenUs 5253828155Noch keine Bewertungen

- Us 5253828Dokument12 SeitenUs 5253828155Noch keine Bewertungen

- United States Patent (10) Patent No.: US 6,471,157 B1: Streett Et Al. (45) Date of Patent: Oct. 29, 2002Dokument8 SeitenUnited States Patent (10) Patent No.: US 6,471,157 B1: Streett Et Al. (45) Date of Patent: Oct. 29, 2002155Noch keine Bewertungen

- United States PatentDokument18 SeitenUnited States Patent155Noch keine Bewertungen

- Improved Bailey Batwing Sail GuideDokument2 SeitenImproved Bailey Batwing Sail GuideTom BeeNoch keine Bewertungen

- Master (3000gt Yacht) Orals Report - 2023-01 - Bates - PassDokument5 SeitenMaster (3000gt Yacht) Orals Report - 2023-01 - Bates - PassSachin JuyalNoch keine Bewertungen

- Cherub Rules2006rev2Dokument3 SeitenCherub Rules2006rev2Paul JamesNoch keine Bewertungen

- Genki Building Instructions CompleteDokument5 SeitenGenki Building Instructions CompleteluisvaygonbookNoch keine Bewertungen

- Lug Rig Rigging GuideDokument35 SeitenLug Rig Rigging Guidejancudak100% (1)

- Robotic Sailing 2014Dokument98 SeitenRobotic Sailing 2014aghannah93Noch keine Bewertungen

- PSY102 Assessment 3Dokument5 SeitenPSY102 Assessment 3Winda PutriNoch keine Bewertungen

- 360406Dokument276 Seiten360406Kidus Yado GirmaNoch keine Bewertungen

- Technical Writing Essentials 1563391738. - Print PDFDokument284 SeitenTechnical Writing Essentials 1563391738. - Print PDFVishnu VishnuNoch keine Bewertungen

- Boat Speed GuideDokument7 SeitenBoat Speed GuideErin HillierNoch keine Bewertungen

- Main Sail TwistDokument5 SeitenMain Sail TwistmadbakingNoch keine Bewertungen

- Euler-Ship Mast LocationDokument61 SeitenEuler-Ship Mast LocationzeldaikNoch keine Bewertungen

- Sadler SailmakingDokument212 SeitenSadler Sailmakinglhg900100% (2)

- USPS Sail-Part 01 Section 01, Sailboat RigsDokument23 SeitenUSPS Sail-Part 01 Section 01, Sailboat Rigsnacho363100% (1)

- The Kite: The History of Kites and How Kites Influenced TechnologyDokument35 SeitenThe Kite: The History of Kites and How Kites Influenced TechnologyanamNoch keine Bewertungen

- Mariner's DictionaryDokument238 SeitenMariner's DictionaryJeveelynvioleta TorreNoch keine Bewertungen

- 103 241 Elvstrřm Sails BroschyrDokument13 Seiten103 241 Elvstrřm Sails BroschyrBalint RoxanaNoch keine Bewertungen

- Melbourne Shade Sail BrochureDokument8 SeitenMelbourne Shade Sail BrochureParmiss Kia100% (2)

- Quantum TrimGuide CodeZeroDokument5 SeitenQuantum TrimGuide CodeZeroMarcelo MilicevickNoch keine Bewertungen

- Ka Sail 2011 PreviewDokument12 SeitenKa Sail 2011 Previewsy4milNoch keine Bewertungen

- ZF Sail Drive Series: Marine Propulsion SystemsDokument8 SeitenZF Sail Drive Series: Marine Propulsion SystemsAlbertoNoch keine Bewertungen

- North Sails Rigging Manual 2008 WaveDokument25 SeitenNorth Sails Rigging Manual 2008 Wavenorthsails100% (1)

- Migration Trade and PeoplesDokument195 SeitenMigration Trade and PeoplesRazvan DiaconescuNoch keine Bewertungen

- Hallberg-Rassy 372: Design: Germán FrersDokument12 SeitenHallberg-Rassy 372: Design: Germán Frersjwooden3Noch keine Bewertungen

- Beneteau Oceanis 473Dokument12 SeitenBeneteau Oceanis 473Denison Yacht Sales100% (1)

- Claughton HISWA 2013Dokument12 SeitenClaughton HISWA 2013Tiago CruzNoch keine Bewertungen

- The 19th Chesapeake Sailing Yacht SymposiumDokument16 SeitenThe 19th Chesapeake Sailing Yacht SymposiumjpsaliouNoch keine Bewertungen

- Everything You Need to Know About Cruise Ship Styles and FacilitiesDokument18 SeitenEverything You Need to Know About Cruise Ship Styles and FacilitiesRonajane BaelNoch keine Bewertungen

- Rigging Manual V4: Please Follow Rigging Manual in The Correct OrderDokument47 SeitenRigging Manual V4: Please Follow Rigging Manual in The Correct OrderFrancisco RodríguezNoch keine Bewertungen

- Chemistry An Atoms Focused Approach 2nd Edition Gilbert Test BankDokument35 SeitenChemistry An Atoms Focused Approach 2nd Edition Gilbert Test Bankclodprositd86ju100% (32)