Beruflich Dokumente

Kultur Dokumente

Bell Restrainer - Tubo X Tubo

Hochgeladen von

JohanAndrésVillarrealCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bell Restrainer - Tubo X Tubo

Hochgeladen von

JohanAndrésVillarrealCopyright:

Verfügbare Formate

FOR: Restraint of 4” to 36” DIOD AWWAC900/905 PVC Pipe to Pipe Bell to Spigot Applications (Black Clamps)

Restraint of 4” to 12” IPS PVC Pipe to Pipe Bell to Spigot Applications (Grey Clamps)

FEATURES and ADVANTAGES:

•Available in sizes 4” through 36” (IPS PVC pipe restraints available in 4” – 12” only)

•Restraints rated at the listed pressure on the PVC pipe with a 2:1 safety factor

•Full 360° contact, no pipe distortion or point loading

•To ease installation, restraints and pipe can be assembled outside the trench

•Connecting rods, hex nuts, T-head bolts consist of low alloy high strength steel and comply with

applicable requirements of ANSI/AWWA C111/A21.11

•Clamping bolts are SAE Grade 5 and comply to applicable requirements of ANSI/AWWA C111/A21.11

•For easy identification, IPS pipe diameter clamps are GREY and DI pipe diameter clamps are BLACK

SAMPLE SPECIFICATIONS:

For use on water or wastewater piping systems subject to hydrostatic pressure and tested in accordance with

ASTM D2774 or AWWA C600. All sizes of clamps are made of high strength grade 65-45-12 ductile iron in

accordance with the requirements and specifications of ASTM A536. Restraint clamps internal serrations are

machined to exact tolerances. Restrainers approved per applicable requirements of ASTM F1674, current

revisions apply. Standard restraint is provided with an alkyd resin baking enamel coating. The 3000PP kit

includes, 1) 2 each 3000C restrainers, 2) hex head bolts and hex nuts for restrainer assembly, and 3) threaded

restrainer connecting rods with hex nuts and flat washers where applicable.

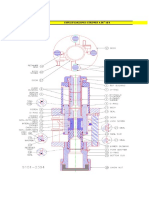

4” to 12” Assembly 14” to 36” Assembly

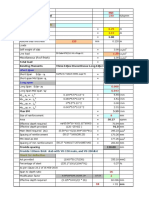

Nom Series 3000PP For Series 3000PP For *A *B *C Restraint Rods Quantity, Sizing and Torque WT

Size PVC Pipe With PVC Pipe With IPS Max. Connecting For Clamp Assembly Bolts

Ductile Pipe O.D. Pipe O.D. (Torque in Foot Pounds)

Pipe Dia. Part# Pipe Dia. Part# Qty Qty Size Qty Size Torque lbs.

4 4.80 462422 4.50 462477 9.12 1.12 12.0 2 3/4 X 17 4 5/8 X 3.5 100 15

6 6.90 462439 6.63 462484 11.12 1.12 13.0 2 3/4 X 17 4 5/8 X 3.5 100 19

8 9.05 462446 8.63 462491 14.74 1.25 15.0 2 3/4 X 17 4 3/4 X 5 150 31

10 11.10 462453 10.75 462507 16.81 1.38 16.0 4 3/4 X 24 4 7/8 X 5 150 51

12 13.20 462460 12.75 462514 19.45 1.38 18.0 4 3/4 X 24 4 7/8 X 5 150 55

14 15.30 488033 N/A N/A 22.54 4.00 24.0 6 3/4 X 30 8 7/8 X 6.5 150 138

16 17.40 488040 N/A N/A 24.66 4.00 28.0 6 3/4 X 30 8 7/8 X 6.5 150 148

18 19.50 488057 N/A N/A 26.64 5.06 28.0 8 3/4 X 30 8 1X8 175 207

20 21.60 488064 N/A N/A 28.76 5.06 34.0 8 3/4 X 36 8 1-1/8 X 8.5 200 265

24 25.80 488071 N/A N/A 33.98 5.20 34.0 12 3/4 X 36 8 1-1/8 X 8.5 225 407

30 32.00 498599 N/A N/A 40.90 10.0 34.0 12 1 X 40 16 1-1/8 X 8.5 250 605

36 38.30 498605 N/A N/A 48.00 10.0 34.0 12 1 X 40 16 1-1/8 X 8.5 250 670

Note: Approximate dimensions and weights

Tyler Union Waterworks Contact Information

Tyler: 11910 CR 492 ● Tyler, Texas 75706 ● (800) 527-8478 Elmira: 1021 East Water ● Elmira, NY 14902

Anniston: 1501 W 17th St. ● Anniston, AL 36201 ● (800) 226-7601 New Lenox: 2200 West Haven● New Lenox, IL 60451

Corona: 1001 El Camino Ave. ● Corona, CA 92879 ● (866) 527-8471 Portland: 6204 N. Marine Dr. ● Portland, OR 97203

www.tylerunion.com

Installation Instructions for Sizes 4” – 36” Series 3000PP:

Figure 1 Figure 2

Figure 3 Figure 4

Step (1): Assemble pipe per Figure 1 making sure the spigot end of the pipe is fully seated in the bell end of the

pipe.

Step (2): Assemble first restrainer on the bell end of the pipe joint and using one of the connecting rods

(included) as a guide, mark the location for the spigot restrainer per Figure 2.

Step (3): Assemble the spigot restrainer leaving sufficient threads on each end of the connecting rod to fully

install washer (where provided) and fully engage nut per Figure 3. Tighten the restrainer clamp

assembly bolts on each side evenly to the recommended torque maintaining even gaps between the

clamp pads.

Step (4): Connect both restrainers per Figure 4 utilizing the threaded restrainer connecting rods provided. Place a

flat washer (where provided) over onto connecting rods and against the restrainer ear. Install hex nuts

on the connecting rods and hand tighten all hex nuts to hand tight plus 1/2 turn. Do not over tighten

connecting rod retaining hex nuts thus forcing the spigot further into the joint.

Suggested hex head bolt and nut *torque recommendations for assembly of the 3000C restrainers is as provided

NOTE: For best results use the lower end of the recommended torque range for DR 41 and DR 51 PVC pipe

*4” – 6” – 100 ft. lbs. / 8” – 12” – 150 ft. lbs. / 14” – 16” – 150 – 200 ft. lbs.

18” 175 – 225 – ft. lbs. / 20” – 200 – 250 ft. lbs. / 24” – 225 – 275 ft. lbs. / 30” – 36” - 250 – 300 ft. lbs.

Tyler Union Waterworks Contact Information

Tyler: 11910 CR 492 ● Tyler, Texas 75706 ● (800) 527-8478 Elmira: 1021 East Water ● Elmira, NY 14902

Anniston: 1501 W 17th St. ● Anniston, AL 36201 ● (800) 226-7601 New Lenox: 2200 West Haven● New Lenox, IL 60451

Corona: 1001 El Camino Ave. ● Corona, CA 92879 ● (866) 527-8471 Portland: 6204 N. Marine Dr. ● Portland, OR 97203

www.tylerunion.com

Das könnte Ihnen auch gefallen

- Moto Case 845 PDFDokument693 SeitenMoto Case 845 PDFjose villegas100% (6)

- P08-1021-I-MN-1044 Rev 1 Simark - Flanged Turbine ManualDokument12 SeitenP08-1021-I-MN-1044 Rev 1 Simark - Flanged Turbine ManualrehanNoch keine Bewertungen

- Standarisasi KabelDokument44 SeitenStandarisasi Kabeladzan isaacNoch keine Bewertungen

- Pressure Pipe FittingsDokument52 SeitenPressure Pipe FittingslissandovalNoch keine Bewertungen

- Transicion C900 - Brida Tyler UnionDokument3 SeitenTransicion C900 - Brida Tyler UnionJohanAndrésVillarrealNoch keine Bewertungen

- Tools and Parts WGDokument35 SeitenTools and Parts WGSerNoch keine Bewertungen

- 0078Dokument1 Seite0078buddhansamratNoch keine Bewertungen

- Delco 28MTDokument4 SeitenDelco 28MTWilson BuenoNoch keine Bewertungen

- Another DWG of Vessel No 3Dokument1 SeiteAnother DWG of Vessel No 3Nomi KhanNoch keine Bewertungen

- Drip Line Fittings: Part No. Description PriceDokument3 SeitenDrip Line Fittings: Part No. Description PriceCamilo Sanchez RojasNoch keine Bewertungen

- Pressure Pipe Fittings PDFDokument64 SeitenPressure Pipe Fittings PDFmonkeyDivanNoch keine Bewertungen

- TorqueDokument2 SeitenTorquestaedtlerpNoch keine Bewertungen

- AMRI ISORIA Broad Market Type Series Booklet DataDokument12 SeitenAMRI ISORIA Broad Market Type Series Booklet Datarudiskw456Noch keine Bewertungen

- JIC-3 Injector Connector PDFDokument6 SeitenJIC-3 Injector Connector PDFmoorpvrNoch keine Bewertungen

- BTC Gate ValvesDokument26 SeitenBTC Gate ValvesCamilo Sanchez VanegasNoch keine Bewertungen

- Water Supply Scheme - MS PipesDokument6 SeitenWater Supply Scheme - MS PipesbalmahNoch keine Bewertungen

- Benchmark, DeWalt, Kuraidori, Chefman & CATDokument15 SeitenBenchmark, DeWalt, Kuraidori, Chefman & CATcristinaNoch keine Bewertungen

- TorqueDokument25 SeitenTorquesami4330100% (3)

- AMRI ISORIA 16 Type Series Booklet DataDokument20 SeitenAMRI ISORIA 16 Type Series Booklet Datarudiskw456Noch keine Bewertungen

- Despiece Filtro de ArenaDokument8 SeitenDespiece Filtro de Arenaluisote05Noch keine Bewertungen

- Stripper 4.06 10KDokument11 SeitenStripper 4.06 10KOswaldo VillarroelNoch keine Bewertungen

- Racetech CatalogueDokument23 SeitenRacetech CataloguecirclelineNoch keine Bewertungen

- PN. PartsindoDokument8 SeitenPN. PartsindoCandra VandraNoch keine Bewertungen

- Torch AsDokument9 SeitenTorch AsDaniel SantosNoch keine Bewertungen

- Grundfos Submersible JOCKEYDokument18 SeitenGrundfos Submersible JOCKEYdanilolabreNoch keine Bewertungen

- 1020 PDFDokument180 Seiten1020 PDFСергій XрестикNoch keine Bewertungen

- Caterpillar 3208 Diesel Engine SM Manual Copy OneDokument350 SeitenCaterpillar 3208 Diesel Engine SM Manual Copy Oneswoods71588% (25)

- 2ST Seated Leg Curl DiagramDokument10 Seiten2ST Seated Leg Curl DiagramJEREMEE MICHAEL TYLERNoch keine Bewertungen

- Jetter General EZ4040GDokument2 SeitenJetter General EZ4040GdiroperacionesNoch keine Bewertungen

- Model: P660 Series: Differential Pressure Gauge With Diaphragm ElementDokument6 SeitenModel: P660 Series: Differential Pressure Gauge With Diaphragm ElementTÀi VÕNoch keine Bewertungen

- Flange DimensionsDokument7 SeitenFlange DimensionsDave DonohueNoch keine Bewertungen

- Tubing Cutter Radial Cutting TorchDokument2 SeitenTubing Cutter Radial Cutting Torcharvandi_mahryNoch keine Bewertungen

- NPT ThreadsDokument4 SeitenNPT ThreadssatphoenixNoch keine Bewertungen

- 8010Dokument1.077 Seiten8010vut73 aNoch keine Bewertungen

- Mo GBX Sem 10Dokument10 SeitenMo GBX Sem 10RAY SANCHEZNoch keine Bewertungen

- 8 March 2022Dokument14 Seiten8 March 2022Kasarachi AmadiNoch keine Bewertungen

- Magasin Block 2Dokument686 SeitenMagasin Block 2Mohamed RigNoch keine Bewertungen

- EZ Series 44: General PumpDokument2 SeitenEZ Series 44: General PumpJorge M MNoch keine Bewertungen

- Actuador Masoneilan 87-88Dokument12 SeitenActuador Masoneilan 87-88montoya2333Noch keine Bewertungen

- MasterSeries 876V Specification SheetDokument4 SeitenMasterSeries 876V Specification SheetFEBCONoch keine Bewertungen

- Technical Data 37 FlaredDokument13 SeitenTechnical Data 37 FlaredhernychtNoch keine Bewertungen

- ST&R Duplex Piston PumpDokument2 SeitenST&R Duplex Piston Pump魏永涛Noch keine Bewertungen

- Torque Values Graphite Laminate (B16.5)Dokument2 SeitenTorque Values Graphite Laminate (B16.5)Gonçalo Cortez50% (2)

- DSI Underground SystemsDokument18 SeitenDSI Underground SystemsAntonio RamosNoch keine Bewertungen

- Manway Davits ZimmerlinCatalogDokument64 SeitenManway Davits ZimmerlinCatalogAnandKumarRavindranNoch keine Bewertungen

- 198 Faf2500 Flanged y Type StrainerDokument4 Seiten198 Faf2500 Flanged y Type Strainerinfo8176Noch keine Bewertungen

- 2200 SERIES: Jabiru Engine Parts BookDokument64 Seiten2200 SERIES: Jabiru Engine Parts BookEduardo BacilioNoch keine Bewertungen

- New Holland T8040 PartsDokument678 SeitenNew Holland T8040 PartsI PNoch keine Bewertungen

- Elastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsDokument6 SeitenElastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsAdhie_ginthinkNoch keine Bewertungen

- Remote Cotnrol Lines (Valve)Dokument4 SeitenRemote Cotnrol Lines (Valve)Eshopmanual BaruNoch keine Bewertungen

- Starter and AlternatorDokument2 SeitenStarter and AlternatorricardoNoch keine Bewertungen

- Pipe Dimensions: Nominal Pipe Size Pipe Schedule No. Pipe Outside Diameter Pipe Inside Diameter Wall ThicknessDokument2 SeitenPipe Dimensions: Nominal Pipe Size Pipe Schedule No. Pipe Outside Diameter Pipe Inside Diameter Wall ThicknessCool LikeNoch keine Bewertungen

- SimuLasi Opname GD KrangkengDokument52 SeitenSimuLasi Opname GD Krangkengwhs.oemNoch keine Bewertungen

- Field Welding InstructionsDokument6 SeitenField Welding InstructionsErickNoch keine Bewertungen

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerVon EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerBewertung: 5 von 5 Sternen5/5 (1)

- 579 081 PDFDokument78 Seiten579 081 PDFJohanAndrésVillarrealNoch keine Bewertungen

- Brochure Duyar ValveDokument32 SeitenBrochure Duyar ValveJohanAndrésVillarrealNoch keine Bewertungen

- Uniflange - Serie 900Dokument1 SeiteUniflange - Serie 900JohanAndrésVillarrealNoch keine Bewertungen

- Sample Specifications: Mechanical Joint C153 Ductile Iron Compact FittingsDokument8 SeitenSample Specifications: Mechanical Joint C153 Ductile Iron Compact FittingsJohanAndrésVillarrealNoch keine Bewertungen

- Tuf-Grip - Tubo X AccesorioDokument3 SeitenTuf-Grip - Tubo X AccesorioJohanAndrésVillarrealNoch keine Bewertungen

- PVC Pipe BrochureDokument12 SeitenPVC Pipe BrochureJohanAndrésVillarrealNoch keine Bewertungen

- Tyler Union Waterworks Catalog 2013Dokument103 SeitenTyler Union Waterworks Catalog 2013Brandon TrocNoch keine Bewertungen

- Blasting Guidance ManualDokument170 SeitenBlasting Guidance ManualJaviera AlejandraNoch keine Bewertungen

- Surface Driller Equipment Paper NO. 1.: All Questions Require Only ONE Answer Unless Otherwise StatedDokument22 SeitenSurface Driller Equipment Paper NO. 1.: All Questions Require Only ONE Answer Unless Otherwise StatedandrzemaNoch keine Bewertungen

- Tutorial 09Dokument2 SeitenTutorial 09秦瑋駿Noch keine Bewertungen

- 20222608332322tangazo Kazi TPDCDokument18 Seiten20222608332322tangazo Kazi TPDCJontelli SimonNoch keine Bewertungen

- Your Dream Home Awaits!: Rera Web Site - WWW - Rera.wb - Gov.in Rera Registration No. - WBRERA/P/SOU/2023/000281Dokument30 SeitenYour Dream Home Awaits!: Rera Web Site - WWW - Rera.wb - Gov.in Rera Registration No. - WBRERA/P/SOU/2023/000281discovernealNoch keine Bewertungen

- ELECT-TIC-2.1 - (Material Receiving Inspection For MV Power Cables & Accessories)Dokument2 SeitenELECT-TIC-2.1 - (Material Receiving Inspection For MV Power Cables & Accessories)Muhammad IrfanNoch keine Bewertungen

- Developing A Housing Microfinance Product - The First Microfinance Banks Experience in AfghanistanDokument32 SeitenDeveloping A Housing Microfinance Product - The First Microfinance Banks Experience in AfghanistanBhagyanath MenonNoch keine Bewertungen

- CHAPTER 2design Against Static LoadDokument33 SeitenCHAPTER 2design Against Static LoadmanishtopsecretsNoch keine Bewertungen

- Types of Stairs PDFDokument12 SeitenTypes of Stairs PDFAkshay Kumar100% (1)

- Floor Tiling Installation GuideDokument37 SeitenFloor Tiling Installation GuideGashi ArianitNoch keine Bewertungen

- Questions & Answers: Webinar: Leveraging Caesar Ii and Featools Featuring PRGDokument8 SeitenQuestions & Answers: Webinar: Leveraging Caesar Ii and Featools Featuring PRGMina MagdyNoch keine Bewertungen

- Arriostre de VigasDokument20 SeitenArriostre de VigasGonzalo Guerrero CáceresNoch keine Bewertungen

- Transmital Letter of Core Samples - JDT (South)Dokument1 SeiteTransmital Letter of Core Samples - JDT (South)Nscr GpiNoch keine Bewertungen

- Slab Code: Grade of Concrete Permissble Stress in SteelDokument1 SeiteSlab Code: Grade of Concrete Permissble Stress in Steeljuliyet strucNoch keine Bewertungen

- Updated Resume GR BIJUDokument5 SeitenUpdated Resume GR BIJUBiju GRNoch keine Bewertungen

- BAR CHART - Pert - CPM SampleDokument2 SeitenBAR CHART - Pert - CPM SampleLester Neil LomodNoch keine Bewertungen

- Construction Industry Intrnal AuditDokument129 SeitenConstruction Industry Intrnal AuditAlexandros Mavratsas100% (2)

- Wet Abrasive Blasting System and MethodDokument13 SeitenWet Abrasive Blasting System and MethodhainguyenbkvhvNoch keine Bewertungen

- Ch3 Fittinglist 05044 02 FDokument3 SeitenCh3 Fittinglist 05044 02 FZipronNoch keine Bewertungen

- Comparative Analysis of Green Building Rating Systems and Codes - 1Dokument46 SeitenComparative Analysis of Green Building Rating Systems and Codes - 1Rohit TirkeyNoch keine Bewertungen

- Concrete Cube Report - Parapets 21 August 2021 28 Day TestDokument1 SeiteConcrete Cube Report - Parapets 21 August 2021 28 Day Testakakak01Noch keine Bewertungen

- Housing Policies and Strategies in Libya - Brief An OverviewDokument5 SeitenHousing Policies and Strategies in Libya - Brief An OverviewsatgasppksNoch keine Bewertungen

- Why The BS 8500 Durability Tables Are The Way They Are-Concrete June2016Dokument4 SeitenWhy The BS 8500 Durability Tables Are The Way They Are-Concrete June2016Vipin Kumar ParasharNoch keine Bewertungen

- Repair & Rehab of Dams - Case Studies COEDokument263 SeitenRepair & Rehab of Dams - Case Studies COEchutton681Noch keine Bewertungen

- Table 13 Permitted Variations From A Flat Surface For Carbon Steel PlatesDokument1 SeiteTable 13 Permitted Variations From A Flat Surface For Carbon Steel PlatesamevaluacionesNoch keine Bewertungen

- Volvo Ew 180B VaDokument60 SeitenVolvo Ew 180B VaApexiNoch keine Bewertungen

- GI 298 010 Administration of Contractor Parks - 01022011Dokument44 SeitenGI 298 010 Administration of Contractor Parks - 01022011Kaif KhanNoch keine Bewertungen

- BIM in Middle EastDokument64 SeitenBIM in Middle EastAmarnathcbNoch keine Bewertungen

- Zhengzhou Huitong CatalogueDokument11 SeitenZhengzhou Huitong CatalogueweqefyteNoch keine Bewertungen

- Spec Sheet - American StandardDokument2 SeitenSpec Sheet - American StandardJohn Enrick ManuelNoch keine Bewertungen