Beruflich Dokumente

Kultur Dokumente

711 Dissolution 1

Hochgeladen von

sohrabOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

711 Dissolution 1

Hochgeladen von

sohrabCopyright:

Verfügbare Formate

Stage 6 Harmonization

Official December 1, 2011 〈711〉 Dissolution 1

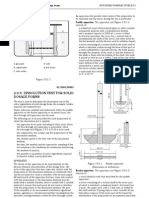

material1; a motor; a metallic drive shaft; and a cylindrical

〈711〉 DISSOLUTION basket. The vessel is partially immersed in a suitable water

bath of any convenient size or heated by a suitable device

such as a heating jacket. The water bath or heating device

This general chapter is harmonized with the correspond- permits holding the temperature inside the vessel at

ing texts of the European Pharmacopoeia and/or the Japanese 37 ± 0.5° during the test and keeping the bath fluid in con-

Pharmacopoeia. These pharmacopeias have undertaken not stant, smooth motion. No part of the assembly, including

to make any unilateral change to this harmonized chapter. the environment in which the assembly is placed, contrib-

Portions of the present general chapter text that are na- utes significant motion, agitation, or vibration beyond that

tional USP text, and therefore not part of the harmonized due to the smoothly rotating stirring element. An apparatus

text, are marked with symbols (✦✦) to specify this fact. that permits observation of the specimen and stirring ele-

This test is provided to determine compliance with the ment during the test is preferable. The vessel is cylindrical,

dissolution requirements ✦where stated in the individual with a hemispherical bottom and ✦with one of the following

monograph✦ for dosage forms administered orally. In this dimensions and capacities: for a nominal✦ capacity of 1 L,

general chapter, a dosage unit is defined as 1 tablet or 1 the height is 160 mm to 210 mm and its inside diameter is

capsule or the amount specified. ✦Of the types of apparatus 98 mm to 106 mm; ✦for a nominal capacity of 2 L, the

described herein, use the one specified in the individual height is 280 mm to 300 mm and its inside diameter is

monograph. Where the label states that an article is enteric- 98 mm to 106 mm; and for a nominal capacity of 4 L, the

coated, and where a dissolution or disintegration test that height is 280 mm to 300 mm and its inside diameter is

does not specifically state that it is to be applied to delayed- 145 mm to 155 mm✦. Its sides are flanged at the top. A

release articles is included in the individual monograph, the fitted cover may be used to retard evaporation.2 The shaft is

procedure and interpretation given for Delayed-Release Dos- positioned so that its axis is not more than 2 mm at any

age Forms is applied unless otherwise specified in the indi- point from the vertical axis of the vessel and rotates

vidual monograph. For hard or soft gelatin capsules and gel- smoothly and without significant wobble that could affect

atin-coated tablets that do not conform to the Dissolution the results. A speed-regulating device is used that allows the

specification, repeat the test as follows. Where water or a shaft rotation speed to be selected and maintained at the

medium with a pH of less than 6.8 is specified as the Me- specified rate ✦given in the individual monograph,✦ within

dium in the individual monograph, the same Medium speci- ±4%.

fied may be used with the addition of purified pepsin that Shaft and basket components of the stirring element are

results in an activity of 750,000 Units or less per 1000 mL. fabricated of stainless steel, type 316, or other inert mate-

For media with a pH of 6.8 or greater, pancreatin can be rial, to the specifications shown in Figure 1. A basket having

added to produce not more than 1750 USP Units of prote- a gold coating of about 0.0001 inch (2.5 µm) thick may be

ase activity per 1000 mL. used. A dosage unit is placed in a dry basket at the begin-

ning of each test. The distance between the inside bottom

USP Reference Standards 〈11〉—USP Chlorpheniramine of the vessel and the bottom of the basket is maintained at

Maleate Extended-Release Tablets RS. USP Prednisone Tablets 25 ± 2 mm during the test.

RS.✦ ■

1 The materials should not sorb, react, or interfere with the specimen being

Change to read: tested.

2 If a cover is used, it provides sufficient openings to allow ready insertion of

the thermometer and withdrawal of specimens.

APPARATUS

Apparatus 1 (Basket Apparatus)

The assembly consists of the following: a vessel, which

may be covered, made of glass or other inert, transparent

2011 The United States Pharmacopeial Convention All Rights Reserved.

Stage 6 Harmonization

2 〈711〉 Dissolution Official December 1, 2011

Figure 1. Basket Stirring Element

■2S (USP34) of 25 ± 2 mm between the bottom of the blade and the

inside bottom of the vessel is maintained during the test.

The metallic or suitably inert, rigid blade and shaft comprise

Apparatus 2 (Paddle Apparatus) a single entity. A suitable two-part detachable design may

be used provided the assembly remains firmly engaged dur-

Use the assembly from Apparatus 1, except that a paddle ing the test. The paddle blade and shaft may be coated

formed from a blade and a shaft is used as the stirring ele- with a suitable coating so as to make them inert. The dos-

ment. The shaft is positioned so that its axis is not more age unit is allowed to sink to the bottom of the vessel

than 2 mm from the vertical axis of the vessel at any point before rotation of the blade is started. A small, loose piece

and rotates smoothly without significant wobble that could of nonreactive material, such as not more than a few turns

affect the results. The vertical center line of the blade passes of wire helix, may be attached to dosage units that would

through the axis of the shaft so that the bottom of the otherwise float. An alternative sinker device is shown in Fig-

blade is flush with the bottom of the shaft. The paddle con- ure 2a. Other validated sinker devices may be used.

forms to the specifications shown in Figure 2. The distance

2011 The United States Pharmacopeial Convention All Rights Reserved.

Stage 6 Harmonization

Official December 1, 2011 〈711〉 Dissolution 3

Figure 2. Paddle Stirring Element

Figure 2a. Alternative sinker. All dimensions are expressed in mm.

Apparatus 3 (Reciprocating Cylinder) tings (stainless steel type 316 or other suitable material),

and screens that are made of suitable nonsorbing and

nonreactive material and that are designed to fit the tops

and bottoms of the reciprocating cylinders; and a motor

NOT ACCEPTED BY THE JAPANESE PHARMACOPOEIA and drive assembly to reciprocate the cylinders vertically in-

side the vessels and, if desired, index the reciprocating cylin-

The assembly consists of a set of cylindrical, flat-bottomed ders horizontally to a different row of vessels. The vessels are

glass vessels; a set of glass reciprocating cylinders; inert fit- partially immersed in a suitable water bath of any conven-

2011 The United States Pharmacopeial Convention All Rights Reserved.

Stage 6 Harmonization

4 〈711〉 Dissolution Official December 1, 2011

ient size that permits holding the temperature at 37 ± 0.5° of 4, 8, and 16 mL per minute. It must deliver a constant

during the test. No part of the assembly, including the envi- flow (±5% of the nominal flow rate); the flow profile is si-

ronment in which the assembly is placed, contributes signifi- nusoidal with a pulsation of 120 ± 10 pulses per minute. A

cant motion, agitation, or vibration beyond that due to the pump without pulsation may also be used. Dissolution test

smooth, vertically reciprocating cylinder. A device is used procedures using a flow-through cell must be characterized

that allows the reciprocation rate to be selected and main- with respect to rate and any pulsation.

tained at the specified dip rate ✦given in the individual The flow-through cell (see Figures 4 and 5), of transparent

monograph✦ within ±5%. An apparatus that permits obser- and inert material, is mounted vertically with a filter system

vation of the specimens and reciprocating cylinders is pref- (specified in the individual monograph) that prevents escape

erable. The vessels are provided with an evaporation cap of undissolved particles from the top of the cell; standard

that remains in place for the duration of the test. The com- cell diameters are 12 and 22.6 mm; the bottom cone is usu-

ponents conform to the dimensions shown in Figure 3 un- ally filled with small glass beads of about 1-mm diameter

less otherwise specified ✦in the individual monograph✦. with one bead of about 5 mm positioned at the apex to

protect the fluid entry tube; and a tablet holder (see Figures

4 and 5) is available for positioning of special dosage forms,

for example, inlay tablets. The cell is immersed in a water

bath, and the temperature is maintained at 37 ± 0.5°.

Figure 3. Apparatus 3 (reciprocating cylinder)

Apparatus 4 (Flow-Through Cell)

The assembly consists of a reservoir and a pump for the

Dissolution Medium; a flow-through cell; and a water bath

that maintains the Dissolution Medium at 37 ± 0.5°. Use the

specified cell size ✦as given in the individual monograph✦.

The pump forces the Dissolution Medium upwards through Figure 4. Apparatus 4, large cell for tablets and capsules

the flow-through cell. The pump has a delivery range be- (top), tablet holder for the large cell (bottom). (All measure-

tween 240 and 960 mL per hour, with standard flow rates ments are expressed in mm unless noted otherwise.)

2011 The United States Pharmacopeial Convention All Rights Reserved.

Stage 6 Harmonization

Official December 1, 2011 〈711〉 Dissolution 5

ture of the Dissolution Medium, rotation speed (Apparatus 1

and Apparatus 2), dip rate (Apparatus 3), and flow rate of

medium (Apparatus 4).

Determine the acceptable performance of the dissolution

test assembly periodically. ✦The suitability for the individual

apparatus is demonstrated by the Performance Verification

Test.

Performance Verification Test, Apparatus 1 and 2—

Test USP Prednisone Tablets RS according to the operating

conditions specified. The apparatus is suitable if the results

obtained are within the acceptable range stated in the tech-

nical data sheet specific to the lot used and the apparatus

tested.

Performance Verification Test, Apparatus 3—Test USP

Chlorpheniramine Maleate Extended-Release Tablets RS ac-

cording to the operating conditions specified. The apparatus

is suitable if the results obtained are within the acceptable

range stated in the technical data sheet specific to the lot

used.

Performance Verification Test, Apparatus 4—[To

come.]✦

PROCEDURE

Apparatus 1 and Apparatus 2

IMMEDIATE-RELEASE DOSAGE FORMS

Place the stated volume of the Dissolution Medium (±1%)

in the vessel of the specified apparatus ✦given in the individ-

ual monograph✦, assemble the apparatus, equilibrate the

Dissolution Medium to 37 ± 0.5°, and remove the thermome-

ter. Place 1 dosage unit in the apparatus, taking care to

exclude air bubbles from the surface of the dosage unit, and

immediately operate the apparatus at the specified rate

✦given in the individual monograph . Within the time inter-

✦

val specified, or at each of the times stated, withdraw a

specimen from a zone midway between the surface of the

Dissolution Medium and the top of the rotating basket or

blade, not less than 1 cm from the vessel wall. [NOTE—

Where multiple sampling times are specified, replace the ali-

quots withdrawn for analysis with equal volumes of fresh

Dissolution Medium at 37° or, where it can be shown that

Figure 5. Apparatus 4, small cell for tablets and capsules replacement of the medium is not necessary, correct for the

(top), tablet holder for the small cell (bottom). (All measure- volume change in the calculation. Keep the vessel covered

ments are expressed in mm unless noted otherwise.) for the duration of the test, and verify the temperature of

the mixture under test at suitable times.] Perform the analy-

sis ✦as directed in the individual monograph✦ using a suita-

The apparatus uses a clamp mechanism and two O-rings ble assay method.3 Repeat the test with additional dosage

to assemble the cell. The pump is separated from the disso- form units.

lution unit in order to shield the latter against any vibrations If automated equipment is used for sampling or the appa-

originating from the pump. The position of the pump ratus is otherwise modified, verification that the modified

should not be on a level higher than the reservoir flasks. apparatus will produce results equivalent to those obtained

Tube connections are as short as possible. Use suitably inert with the standard apparatus described in this general chap-

tubing, such as polytef, with about 1.6-mm inner diameter ter is necessary.

and chemically inert flanged-end connections. Dissolution Medium—A suitable dissolution medium is

used. Use the solvent specified ✦in the individual

APPARATUS SUITABILITY monograph✦. The volume specified refers to measurements

made between 20° and 25°. If the Dissolution Medium is a

The determination of suitability of a test assembly to per- buffered solution, adjust the solution so that its pH is within

form dissolution testing must include conformance to the 0.05 unit of the specified pH ✦given in the individual

dimensions and tolerances of the apparatus as given above. 3 Test specimens are filtered immediately upon sampling unless filtration is

In addition, critical test parameters that have to be moni- demonstrated to be unnecessary. Use an inert filter that does not cause ad-

sorption of the active ingredient or contain extractable substances that would

tored periodically during use include volume and tempera- interfere with the analysis.

2011 The United States Pharmacopeial Convention All Rights Reserved.

Stage 6 Harmonization

6 〈711〉 Dissolution Official December 1, 2011

monograph✦. [NOTE—Dissolved gases can cause bubbles to ✦The procedure is specified in the individual monograph.

form, which may change the results of the test. If dissolved The test may be concluded in a shorter time period than

gases influence the dissolution results, dissolved gases that specified for the Buffer Stage if the requirement for the

should be removed prior to testing.4] minimum amount dissolved is met at an earlier time.✦

Time—Where a single time specification is given, the test Method B—

may be concluded in a shorter period if the requirement for Procedure ✦(unless otherwise directed in the individual

minimum amount dissolved is met. Specimens are to be monograph)✦—

withdrawn only at the stated times within a tolerance of ACID STAGE—Place 1000 mL of 0.1 N hydrochloric acid in

±2%. the vessel, and assemble the apparatus. Allow the medium

✦Procedure for a Pooled Sample for Immediate-

to equilibrate to a temperature of 37 ± 0.5°. Place 1 dosage

Release Dosage Forms—Use this procedure where Proce- unit in the apparatus, cover the vessel, and operate the ap-

dure for a Pooled Sample is specified in the individual mono- paratus at the rate specified ✦in the monograph✦. After 2

graph. Proceed as directed for Immediate-Release Dosage hours of operation in 0.1 N hydrochloric acid, withdraw an

Forms under Apparatus 1 and Apparatus 2 in the Procedure aliquot of the fluid, and proceed immediately as directed

section. Combine equal volumes of the filtered solutions of under Buffer Stage.

the six or twelve individual specimens withdrawn, and use Perform an analysis of the aliquot using a suitable assay

the pooled sample as the test specimen. Determine the av- method. ✦The procedure is specified in the individual

erage amount of the active ingredient dissolved in the monograph.✦

pooled sample.✦ BUFFER STAGE—[NOTE—For this stage of the procedure, use

buffer that previously has been equilibrated to a tempera-

EXTENDED-RELEASE DOSAGE FORMS ture of 37 ± 0.5°.] Drain the acid from the vessel, and add

to the vessel 1000 mL of pH 6.8 phosphate buffer, prepared

Proceed as directed for Immediate-Release Dosage Forms. by mixing 0.1 N hydrochloric acid with 0.20 M tribasic so-

dium phosphate (3 : 1) and adjusting, if necessary, with 2 N

Dissolution Medium—Proceed as directed for Immediate- hydrochloric acid or 2 N sodium hydroxide to a pH of

Release Dosage Forms. 6.8 ± 0.05. [NOTE—This may also be accomplished by re-

Time—The test-time points, generally three, are ex- moving from the apparatus the vessel containing the acid

pressed in hours. and replacing it with another vessel containing the buffer

and transferring the dosage unit to the vessel containing the

buffer.]

DELAYED-RELEASE DOSAGE FORMS NOT ACCEPTED BY THE Continue to operate the apparatus for 45 minutes, or for

JAPANESE PHARMACOPOEIA the specified time ✦given in the individual monograph✦. At

the end of the time period, withdraw an aliquot of the fluid,

Use Method A or Method B and the apparatus specified ✦in and perform the analysis using a suitable assay method.

the individual monograph✦. All test times stated are to be ✦The procedure is specified in the individual monograph.

observed within a tolerance of ±2%, unless otherwise The test may be concluded in a shorter time period than

specified. that specified for the Buffer Stage if the requirement for min-

Method A— imum amount dissolved is met at an earlier time.✦

Procedure ✦(unless otherwise directed in the individual

monograph)✦—

Apparatus 3 (Reciprocating Cylinder)

ACID STAGE—Place 750 mL of 0.1 N hydrochloric acid in

the vessel, and assemble the apparatus. Allow the medium

to equilibrate to a temperature of 37 ± 0.5°. Place 1 dosage

unit in the apparatus, cover the vessel, and operate the ap- NOT ACCEPTED BY THE JAPANESE PHARMACOPOEIA

paratus at the specified rate ✦given in the monograph✦. IMMEDIATE-RELEASE DOSAGE FORMS

After 2 hours of operation in 0.1 N hydrochloric acid,

withdraw an aliquot of the fluid, and proceed immediately Place the stated volume of the Dissolution Medium in each

as directed under Buffer Stage. vessel of the apparatus, assemble the apparatus, equilibrate

Perform an analysis of the aliquot using a suitable assay the Dissolution Medium to 37 ± 0.5°, and remove the ther-

method. ✦The procedure is specified in the individual mometer. Place 1 dosage-form unit in each of the six recip-

monograph.✦ rocating cylinders, taking care to exclude air bubbles from

BUFFER STAGE—[NOTE—Complete the operations of adding the surface of each dosage unit, and immediately operate

the buffer and adjusting the pH within 5 minutes.] the apparatus as specified ✦in the individual monograph✦.

With the apparatus operating at the rate specified ✦in the During the upward and downward stroke, the reciprocating

monograph✦, add to the fluid in the vessel 250 mL of cylinder moves through a total distance of 9.9 to 10.1 cm.

0.20 M tribasic sodium phosphate that has been equili- Within the time interval specified, or at each of the times

brated to 37 ± 0.5°. Adjust, if necessary, with 2 N hydro- stated, raise the reciprocating cylinders and withdraw a por-

chloric acid or 2 N sodium hydroxide to a pH of 6.8 ± 0.05. tion of the solution under test from a zone midway between

Continue to operate the apparatus for 45 minutes, or for the surface of the Dissolution Medium and the bottom of

the specified time ✦given in the individual monograph✦. At each vessel. Perform the analysis as directed ✦in the individ-

the end of the time period, withdraw an aliquot of the fluid, ual monograph✦. If necessary, repeat the test with addi-

and perform the analysis using a suitable assay method. tional dosage-form units.

4One method of deaeration is as follows: Heat the medium, while stirring Dissolution Medium—Proceed as directed for Immediate-

gently, to about 41°, immediately filter under vacuum using a filter having a Release Dosage Forms under Apparatus 1 and Apparatus 2.

porosity of 0.45 µm or less, with vigorous stirring, and continue stirring

under vacuum for about 5 minutes. Other validated deaeration techniques for Time—Proceed as directed for Immediate-Release Dosage

removal of dissolved gases may be used. Forms under Apparatus 1 and Apparatus 2.

2011 The United States Pharmacopeial Convention All Rights Reserved.

Stage 6 Harmonization

Official December 1, 2011 〈711〉 Dissolution 7

EXTENDED-RELEASE DOSAGE FORMS INTERPRETATION

Proceed as directed for Immediate-Release Dosage Forms

under Apparatus 3.

Dissolution Medium—Proceed as directed for Extended- Immediate-Release Dosage Forms

Release Dosage Forms under Apparatus 1 and Apparatus 2.

Unless otherwise specified ✦in the individual monograph✦,

Time—Proceed as directed for Extended-Release Dosage the requirements are met if the quantities of active ingredi-

Forms under Apparatus 1 and Apparatus 2. ent dissolved from the dosage units tested conform to Ac-

ceptance Table 1. Continue testing through the three stages

DELAYED-RELEASE DOSAGE FORMS unless the results conform at either S1 or S2. The quantity,

Q, is the amount of dissolved active ingredient ✦specified in

Proceed as described for Delayed-Release Dosage Forms, the individual monograph✦, expressed as a percentage of

Method B under Apparatus 1 and Apparatus 2 using one row the labeled content of the dosage unit; the 5%, 15%, and

of vessels for the acid stage media and the following row of 25% values in Acceptance Table 1 are percentages of the

vessels for the buffer stage media and using the volume of labeled content so that these values and Q are in the same

medium specified (usually 300 mL). terms.

Time—Proceed as directed for Immediate-Release Dosage

Forms under Apparatus 1 and Apparatus 2. Acceptance Table 1

Number

Stage Tested Acceptance Criteria

Apparatus 4 (Flow-Through Cell) S1 6 Each unit is not less than Q + 5%.

S2 6 Average of 12 units (S1 + S2) is equal to or

greater than Q, and no unit is less than

IMMEDIATE-RELEASE DOSAGE FORMS Q − 15%.

S3 12 Average of 24 units (S1 + S2 +S3) is equal to

Place the glass beads into the cell specified ✦in the or greater than Q, not more than 2 units

monograph✦. Place 1 dosage unit on top of the beads or, if are less than

specified ✦in the monograph✦, on a wire carrier. Assemble Q − 15%, and no unit is less than Q −

the filter head, and fix the parts together by means of a 25%.

suitable clamping device. Introduce by the pump the Disso-

lution Medium warmed to 37 ± 0.5° through the bottom of ✦Immediate-Release Dosage Forms Pooled Sample—

the cell to obtain the flow rate specified ✦in the individual Unless otherwise specified in the individual monograph, the

monograph✦ and measured with an accuracy of 5%. Collect requirements are met if the quantities of active ingredient

the eluate by fractions at each of the times stated. Perform dissolved from the pooled sample conform to the accompa-

the analysis as directed ✦in the individual monograph✦. Re- nying Acceptance Table for a Pooled Sample. Continue testing

peat the test with additional dosage-form units. through the three stages unless the results conform at either

Dissolution Medium—Proceed as directed for Immediate- S1 or S2. The quantity, Q is the amount of dissolved active

Release Dosage Forms under Apparatus 1 and Apparatus 2. ingredient specified in the individual monograph, expressed

Time—Proceed as directed for Immediate-Release Dosage as a percentage of the labeled content.

Forms under Apparatus 1 and Apparatus 2.

Acceptance Table for a Pooled Sample

EXTENDED-RELEASE DOSAGE FORMS Number

Stage Tested Acceptance Criteria

Proceed as directed for Immediate-Release Dosage Forms S1 6 Average amount dissolved is not less than

under Apparatus 4. Q + 10%.

Dissolution Medium—Proceed as directed for Immediate- S2 6 Average amount dissolved (S1 + S2) is equal

Release Dosage Forms under Apparatus 4. to or greater than Q + 5%.

Time—Proceed as directed for Immediate-Release Dosage S3 12 Average amount dissolved (S1 + S2 + S3) is

Forms under Apparatus 4. equal to or greater than Q.

DELAYED-RELEASE DOSAGE FORMS ✦

Proceed as directed for Delayed-Release Dosage Forms Extended-Release Dosage Forms

under Apparatus 1 and Apparatus 2, using the specified

media. Unless otherwise specified ✦in the individual monograph✦,

Time—Proceed as directed for Delayed-Release Dosage the requirements are met if the quantities of active ingredi-

Forms under Apparatus 1 and Apparatus 2. ent dissolved from the dosage units tested conform to Ac-

ceptance Table 2. Continue testing through the three levels

unless the results conform at either L1 or L2. Limits on the

amounts of active ingredient dissolved are expressed in

terms of the percentage of labeled content. The limits em-

brace each value of Qi, the amount dissolved at each speci-

fied fractional dosing interval. Where more than one range

is specified ✦in the individual monograph✦, the acceptance

criteria apply individually to each range.

2011 The United States Pharmacopeial Convention All Rights Reserved.

Stage 6 Harmonization

8 〈711〉 Dissolution Official December 1, 2011

through all levels unless the results of both acid and buffer

stages conform at an earlier level.

Acceptance Table 2

Number

Acceptance Table 3

Level Tested Criteria

L1 6 No individual value lies outside each of the Number

stated ranges and no individual value is Level Tested Criteria

less than the stated amount at the final A1 6 No individual value exceeds 10% dissolved.

test time. A2 6 Average of the 12 units (A1 +A2) is not

L2 6 The average value of the 12 units (L1 + L2) more than 10% dissolved, and no individ-

lies within each of the stated ranges and ual unit is greater than 25% dissolved.

is not less than the stated amount at the A3 12 Average of the 24 units (A1 + A2 +A3) is not

final test time; none is more than 10% of more than 10% dissolved, and no individ-

labeled content outside each of the stated ual unit is greater than 25% dissolved.

ranges; and none is more than 10% of

labeled content below the stated amount

at the final test time. Buffer Stage—Unless otherwise specified ✦in the individ-

L3 12 The average value of the 24 units (L1 + L2 +

ual monograph✦, the requirements are met if the quantities

L3) lies within each of the stated ranges,

of active ingredient dissolved from the units tested conform

and is not less than the stated amount at

to Acceptance Table 4. Continue testing through the three

the final test time; not more than 2 of the

levels unless the results of both stages conform at an earlier

24 units are more than 10% of labeled

level. The value of Q in Acceptance Table 4 is 75% dissolved

content outside each of the stated ranges;

unless otherwise specified ✦in the individual monograph✦.

not more than 2 of the 24 units are more

The quantity, Q ✦specified in the individual monograph✦ is

than 10% of labeled content below the

the total amount of active ingredient dissolved in both the

stated amount at the final test time; and

Acid and Buffer Stages, expressed as a percentage of the la-

none of the units is more than 20% of

beled content. The 5%, 15%, and 25% values in Acceptance

labeled content outside each of the stated

Table 4 are percentages of the labeled content so that these

ranges or more than 20% of labeled con-

values and Q are in the same terms.

tent below the stated amount at the final

test time.

Acceptance Table 4

Number

Level Tested Criteria

Delayed-Release Dosage Forms B1 6 Each unit is not less than Q + 5%.

B2 6 Average of 12 units (B1 + B2) is equal to or

greater than Q, and no unit is less than

NOT ACCEPTED BY THE JAPANESE PHARMACOPOEIA. Q – 15%.

B3 12 Average of 24 units (B1 + B2 + B3) is equal

Acid Stage—Unless otherwise specified ✦in the individual to or greater than Q, not more than 2

monograph✦, the requirements of this portion of the test units are less thanQ – 15%, and no unit is

are met if the quantities, based on the percentage of the less than Q – 25%.

labeled content, of active ingredient dissolved from the

units tested conform to Acceptance Table 3. Continue testing

2011 The United States Pharmacopeial Convention All Rights Reserved.

Das könnte Ihnen auch gefallen

- QCtabletDokument9 SeitenQCtabletapi-3742263100% (3)

- Assignment Brief HNHM301 The Contemporary Hospitality IndustryDokument6 SeitenAssignment Brief HNHM301 The Contemporary Hospitality IndustryTanjum Tisha100% (1)

- USP40 711 DissolutionDokument13 SeitenUSP40 711 Dissolutionsean_goh_8Noch keine Bewertungen

- 0295-0301 (711) DissolutionDokument7 Seiten0295-0301 (711) DissolutionsudermanfitoNoch keine Bewertungen

- Change To ReadDokument15 SeitenChange To ReadMin Thura OoNoch keine Bewertungen

- Change To ReadDokument15 SeitenChange To Readandev RnDNoch keine Bewertungen

- General Chapters 711 DISSOLUTION UspDokument17 SeitenGeneral Chapters 711 DISSOLUTION UspAndrew TurnerNoch keine Bewertungen

- 711 Dissolution PDFDokument15 Seiten711 Dissolution PDFRajesh AkkiNoch keine Bewertungen

- Change To Read:: USP Reference Standards 11Dokument14 SeitenChange To Read:: USP Reference Standards 11riniNoch keine Bewertungen

- Dissolution Test-2554700864Dokument12 SeitenDissolution Test-2554700864Aanchal DeviNoch keine Bewertungen

- Dissolution Test For Solid Oral Dosage FormsDokument8 SeitenDissolution Test For Solid Oral Dosage FormsPedro Marcelo Alva PlasenciaNoch keine Bewertungen

- Appendix XII B. DissolutionDokument17 SeitenAppendix XII B. Dissolutionqd2bnjdthsNoch keine Bewertungen

- 711 USP Dissolution PDFDokument11 Seiten711 USP Dissolution PDFAnnisaIndahPNoch keine Bewertungen

- General Chapters - 711 - DISSOLUTIONDokument11 SeitenGeneral Chapters - 711 - DISSOLUTIONFitri WahyuningsihNoch keine Bewertungen

- Á701Ñ Disintegration: 584 Á699ñ Density of Solids / Physical Tests USP 40Dokument3 SeitenÁ701Ñ Disintegration: 584 Á699ñ Density of Solids / Physical Tests USP 40Long ManNoch keine Bewertungen

- 2.9. 3. Dissolution Test For Solid Dosage Forms 20903eDokument10 Seiten2.9. 3. Dissolution Test For Solid Dosage Forms 20903eSantosh kumar BatchuNoch keine Bewertungen

- 〈711〉 DISSOLUTION - 221117 - 130956Dokument15 Seiten〈711〉 DISSOLUTION - 221117 - 130956Maheen TariqNoch keine Bewertungen

- Dissolution TestingDokument37 SeitenDissolution Testingampay ayubNoch keine Bewertungen

- 2.9.3. Dissolution Test For Solid Dosage FormsDokument3 Seiten2.9.3. Dissolution Test For Solid Dosage FormsHiren J PatelNoch keine Bewertungen

- 〈711〉 DissolutionDokument17 Seiten〈711〉 DissolutionViridiana VázquezNoch keine Bewertungen

- GUID - 3 en-USDokument18 SeitenGUID - 3 en-USunicahayNoch keine Bewertungen

- Electrolab PDFDokument4 SeitenElectrolab PDFtechwithbiswasNoch keine Bewertungen

- USP Chapter 711 DissolutionDokument17 SeitenUSP Chapter 711 DissolutionQC MahakamNoch keine Bewertungen

- About ApparaatusDokument18 SeitenAbout Apparaatusachi_cantikNoch keine Bewertungen

- 2040 Disintegration and DissolutionDokument6 Seiten2040 Disintegration and DissolutionWillian SilvaNoch keine Bewertungen

- Usp 2040 Disintegration and Dissolution of Dietary SupplementsDokument4 SeitenUsp 2040 Disintegration and Dissolution of Dietary SupplementsKenneth Vergil de GuzmanNoch keine Bewertungen

- Assignment Title: Submitted To: Submitted byDokument18 SeitenAssignment Title: Submitted To: Submitted bySyed UmairNoch keine Bewertungen

- 183-711 - DissolutionDokument11 Seiten183-711 - DissolutionLong ManNoch keine Bewertungen

- C 305 Â " 99 QZMWNS05OQDokument3 SeitenC 305 Â " 99 QZMWNS05OQSebastián RodríguezNoch keine Bewertungen

- ASTM C 305 Standard Practice For Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic ConsistencyDokument3 SeitenASTM C 305 Standard Practice For Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic ConsistencyPaola Vargas100% (1)

- Clau Astm PDFDokument3 SeitenClau Astm PDFLezlie Berenice Serrano GalindoNoch keine Bewertungen

- Astm C305-MixingDokument3 SeitenAstm C305-MixingFolik AsitNoch keine Bewertungen

- Cpms College of Nursing: Assignment ON Setting, Use and Maintainance of Centrifuge MachineDokument6 SeitenCpms College of Nursing: Assignment ON Setting, Use and Maintainance of Centrifuge MachineAmy Lalringhluani ChhakchhuakNoch keine Bewertungen

- TPH (Total Petroleum Hydrocarbons) : Immunoassay Method 10050Dokument10 SeitenTPH (Total Petroleum Hydrocarbons) : Immunoassay Method 10050Cindy Valenzuela RuedaNoch keine Bewertungen

- DNA From Soft TissuesDokument4 SeitenDNA From Soft TissuesCosmin ValentinNoch keine Bewertungen

- Activity #3Dokument9 SeitenActivity #3PrincessNoch keine Bewertungen

- USP 2040 Disol y Desint SotaxDokument4 SeitenUSP 2040 Disol y Desint Sotaxpatricia MedinaNoch keine Bewertungen

- In Vitro Dissolution Testing ModelsDokument13 SeitenIn Vitro Dissolution Testing ModelsSai Charan Varma KucharlapatiNoch keine Bewertungen

- Agilent Hi-Plex Ligand Exchange Columns: Installation Column ConnectionsDokument4 SeitenAgilent Hi-Plex Ligand Exchange Columns: Installation Column ConnectionsNGUYỄN VĂN QUÝNoch keine Bewertungen

- VETERINARY NEUROPHARMACOLOGY Practical ManualDokument40 SeitenVETERINARY NEUROPHARMACOLOGY Practical ManualSunil100% (1)

- AFPX 617: High Capacity Solids-Ejecting Centrifuge For The Animal and Fish Processing IndustriesDokument2 SeitenAFPX 617: High Capacity Solids-Ejecting Centrifuge For The Animal and Fish Processing IndustriesMARCO VERAMENDINoch keine Bewertungen

- Physical Pharmacy - Dissolution and DiffusionDokument87 SeitenPhysical Pharmacy - Dissolution and DiffusionPriyasriNoch keine Bewertungen

- Rehardening FinalDokument11 SeitenRehardening FinalGemmyl YsatamNoch keine Bewertungen

- Astm C305Dokument4 SeitenAstm C305Rafael Bolivar Diaz GranadosNoch keine Bewertungen

- Lab ManualDokument76 SeitenLab ManualKrishnan Mohan0% (1)

- Content Uniformity, Dissolution Test and QC of CaPsDokument48 SeitenContent Uniformity, Dissolution Test and QC of CaPsgul rehmanNoch keine Bewertungen

- DISSOLUTIONDokument61 SeitenDISSOLUTIONSujit DasNoch keine Bewertungen

- SMR 001799USP Guideline On MQ and PVT DPVS FinalDokument15 SeitenSMR 001799USP Guideline On MQ and PVT DPVS FinalNimsi levíNoch keine Bewertungen

- Liflus: Operating ManualDokument41 SeitenLiflus: Operating ManualausfliegeNoch keine Bewertungen

- D 3279 - 97 - RdmynzktotcDokument3 SeitenD 3279 - 97 - RdmynzktotcHans AbantoNoch keine Bewertungen

- Owners' Manual PRO Sprayers 996P and 997P: Screw Cap WandDokument2 SeitenOwners' Manual PRO Sprayers 996P and 997P: Screw Cap WandmbkNoch keine Bewertungen

- Astm C 1262Dokument2 SeitenAstm C 1262Miguelina NRNoch keine Bewertungen

- CTM 217 Jun2008 A11yDokument11 SeitenCTM 217 Jun2008 A11yeyong philiceNoch keine Bewertungen

- Analytical Chemistry: A Decreases Thus, Overheating of The Dry ResidueDokument1 SeiteAnalytical Chemistry: A Decreases Thus, Overheating of The Dry Residuewan nur mursyidahNoch keine Bewertungen

- Cross Flow Filtration HandbookDokument21 SeitenCross Flow Filtration Handbooksahar vahdatifarNoch keine Bewertungen

- AppendicesDokument169 SeitenAppendicesSai PrasadNoch keine Bewertungen

- Dissolution TestDokument5 SeitenDissolution TestAlecza Mae SavellaNoch keine Bewertungen

- M (V) - 4 FW Rehardening FilterDokument10 SeitenM (V) - 4 FW Rehardening Filtererkan aksoyNoch keine Bewertungen

- PSTC 9Dokument4 SeitenPSTC 9Soo SeoNoch keine Bewertungen

- Lab+Manual+2014 Cbe 2207Dokument63 SeitenLab+Manual+2014 Cbe 2207Krishnan Mohan100% (1)

- Section Cutting and Staining: A practical introduction to histological methods for students and practitionersVon EverandSection Cutting and Staining: A practical introduction to histological methods for students and practitionersNoch keine Bewertungen

- Basic CommandsDokument40 SeitenBasic CommandsPrashant RaiNoch keine Bewertungen

- GB Programme Chart: A B C D J IDokument2 SeitenGB Programme Chart: A B C D J IRyan MeltonNoch keine Bewertungen

- SDS enDokument6 SeitenSDS enAnup BajracharyaNoch keine Bewertungen

- Manaloto V Veloso IIIDokument4 SeitenManaloto V Veloso IIIJan AquinoNoch keine Bewertungen

- DS - LWT300 - SF - A4 EN Rev BDokument4 SeitenDS - LWT300 - SF - A4 EN Rev BZts MksNoch keine Bewertungen

- Tapspp0101 PDFDokument119 SeitenTapspp0101 PDFAldriel GabayanNoch keine Bewertungen

- Notes in Judicial AffidavitDokument11 SeitenNotes in Judicial AffidavitguibonganNoch keine Bewertungen

- Pas 38 Pas 41 Pas 40Dokument12 SeitenPas 38 Pas 41 Pas 40Leddie Bergs Villanueva VelascoNoch keine Bewertungen

- Flexi Multiradio Introduction - Sharing SessionDokument96 SeitenFlexi Multiradio Introduction - Sharing SessionRobby MiloNoch keine Bewertungen

- 2.1 Article On Reasonable Compensation Job Aid 4-15-2015Dokument3 Seiten2.1 Article On Reasonable Compensation Job Aid 4-15-2015Michael GregoryNoch keine Bewertungen

- Media DRIVEON Vol25 No2Dokument21 SeitenMedia DRIVEON Vol25 No2Nagenthara PoobathyNoch keine Bewertungen

- Oil and Gas Reloaded: Offshore ArgentinaDokument9 SeitenOil and Gas Reloaded: Offshore ArgentinaMuhammad Fahmi AnbNoch keine Bewertungen

- PepsiCo Strategic Plan Design PDFDokument71 SeitenPepsiCo Strategic Plan Design PDFdemereNoch keine Bewertungen

- Ems Accounting Term 2Dokument39 SeitenEms Accounting Term 2Paballo KoopediNoch keine Bewertungen

- EC1002 Commentary 2022Dokument32 SeitenEC1002 Commentary 2022Xxx V1TaLNoch keine Bewertungen

- IEC947-5-1 Contactor Relay Utilization CategoryDokument1 SeiteIEC947-5-1 Contactor Relay Utilization CategoryipitwowoNoch keine Bewertungen

- St10 Flasher DLL: Stmicroelectronics ConfidentialDokument10 SeitenSt10 Flasher DLL: Stmicroelectronics Confidentialeshwarp sysargusNoch keine Bewertungen

- Motorola Droid 2Dokument11 SeitenMotorola Droid 2Likith MNoch keine Bewertungen

- Editing Packs I Maybe Will NeedDokument3 SeitenEditing Packs I Maybe Will NeedMijo SusićNoch keine Bewertungen

- Mid Semester Question Paper Programming in CDokument8 SeitenMid Semester Question Paper Programming in CbakaNoch keine Bewertungen

- Apples-to-Apples in Cross-Validation Studies: Pitfalls in Classifier Performance MeasurementDokument9 SeitenApples-to-Apples in Cross-Validation Studies: Pitfalls in Classifier Performance MeasurementLuis Martínez RamírezNoch keine Bewertungen

- 5 Axis Lesson 2 PDFDokument36 Seiten5 Axis Lesson 2 PDFPC ArmandoNoch keine Bewertungen

- National School Building Inventory (NSBI) Encoding For SY 2021-2022Dokument31 SeitenNational School Building Inventory (NSBI) Encoding For SY 2021-2022Renato Rivera100% (1)

- Quick Commerce:: The Real Last MileDokument9 SeitenQuick Commerce:: The Real Last MileChhavi KhandujaNoch keine Bewertungen

- The US Navy - Fact File - MQ-8C Fire ScoutDokument2 SeitenThe US Navy - Fact File - MQ-8C Fire ScoutAleksei KarpaevNoch keine Bewertungen

- Retail Scenario in IndiaDokument10 SeitenRetail Scenario in IndiaSeemaNegiNoch keine Bewertungen

- Hydraulic Power Unit: RE 51057, Edition: 2020-11, Bosch Rexroth AGDokument20 SeitenHydraulic Power Unit: RE 51057, Edition: 2020-11, Bosch Rexroth AGHanzil HakeemNoch keine Bewertungen

- River Planning AetasDokument4 SeitenRiver Planning AetasErika ReyesNoch keine Bewertungen

- UNDCO Disability Inclusion Strategy 2022 - 2025Dokument28 SeitenUNDCO Disability Inclusion Strategy 2022 - 2025Nelson MichmeNoch keine Bewertungen