Beruflich Dokumente

Kultur Dokumente

QA Job Responsibilty

Hochgeladen von

Abdullah AnsariCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

QA Job Responsibilty

Hochgeladen von

Abdullah AnsariCopyright:

Verfügbare Formate

Core Competencies

Development and maintenance of ‘Corporate QHSE Management System’.

Competency in ISO 9001, TS/ ISO 29001, ISO 14001 and OHSAS 18001standards.

Project specific QHSE plans, working methodologies, ITPs, HIRAC and JHAs etc.

Development of WPS, PQRs, Welding Inspections & NDT procedures

Internal, external, third parties QHSE, ASME (U & S Stamps) auditing.

BSC- (Balance Score Card) development, review monitoring and reporting.

Tender review and evaluation of DBSP, SOW, TP, BEDD and FEED’s

Evolution of project integrity requirements and QA review of Design

QHSE awareness and behaviors base safety programs (BBS, STOP, REACT)

Conversant with Saudi Aramco, ADNOC Group, QATAR Gas, QAFCO and QATAR Petroleum

requirements codes and practices.

Preparation of the company QUALITY MANUAL, control and supervision of all amendments and revisions

Verify contractor quality requirements are specified to vendors and contractor documentation submittals

Attend all pre-bid meetings and coordinate all project requirements with the project proposal department

The preparation and control of project quality system & documentation prior to project commencement

Planning and monitoring all quality related activities on the project from head office

Attend client quality management meetings for new and ongoing projects

Recommend and implement improvements when required as per INTEGRATED MANAGEMENT

SYSTEM

Preparation for Major Audits by INTERNATIONAL ORGANISATION FOR STANDARDISATION (ISO)

CLIENTS for INTEGRATED MANAGEMENT SYSTEM ( ISO 9001 , ISO 14001 , OSHAS 18001)

Perform all internal and external audits as per company audit procedure and clients procedure

Review quality inspection personnel qualifications and training requirements

Monitor the disposition of all issued non-conformance reports

Monitor the progress and effectiveness of the project quality management system

Conducting periodically & stage wise Audits on corporate level as well as Project level, Vendors &

Contractors

Certifying & qualifying new vendors for the company as well to clients

Coordinate all QA/QC activities with the site QC manager, QA/QC procurement manager

Coordinate all quality related correspondence with the customer’s & management representatives

Monitor statistical method reporting action and close all customer complaints

Monitor all archive documentation upon the completion of the project

Prepare, Review and implementation of Project Specification, ITP, Method Statement and Approved

Drawing

Preparation, witnessing and reviewing of WQT, WPS & PQR

Monitoring daily production activities and manpower reports

Attend weekly, monthly progress and review meetings

Conduct all stage-wise Inspection as per approved ITP with Client, Owner & TPI

Maintaining quality records as per quality management system requirements

Raising and close out of NCR, CAR & TECHNICAL QUERY

Materials (Base Materials/Consumables) inspection

Inspection of joints fit up, alignment and dimensional accuracy as per weld map

Inspection of welding visual examination

Offering NDT, conduct and evaluate non-destructive testing (RT, MPT, PT, UT) & interpretation of RT

films

Review of NDT Test Report with TPI or Client

Evaluation of pre & post weld heat treatment (PWHT) charts

Defect mapping & attaining the repair work

Inspection of Fit up , alignment ,dimensional and orientation of Glass-fiber Reinforced Epoxy Piping

(GRE/GRP) and underground Piping

Inspection of Bonding, lamination and Mechanical joints of GRE lines

Inspection of Fit up , alignment ,dimensional and orientation of HIGH DENSITY POLY ETHYLENE PIPE

(HDPE) and underground Piping

ELECTRO FUSION AND BUTT WELDING of HDPE pipes

Inspection of joints, Testing and quality check of various surface like checking of blast profiles, wet film

thickness, ambient condition, Dry film thickness, Holiday detection, Adhesion test, etc.

Maintaining welding inspection/NDT reports and record tracking

Preparation of welding inspection summary/Joint tracking log

Preparation & controlling Test Packages and submission, co-ordination with client, PMC, TPI or

Contractor

Checking the lines, marking punch list and Documentation of Test packs

Preparation, conducting and witnessing Leak Test, Hydro Test & Pneumatic test

To conduct sand blasting and HSS for underground Lines

Responsible for line checking after hydro test to complete the post punch list prior to sign-off the test

packages before signing the completion of piping / mechanical

Ensure hydro test reinstatement is done as per procedure

Ensure that all punch list items are resolved, client handover is satisfactorily concluded

Check hydro test package for completeness and traceability, Documentation related to the lines i.e. latest

isometric drawings or mark limits on P & ID and all RFI's records on the completed Lines

Conduction and reviewing overseas investigation, root cause analysis and lesson learnt

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- SAT 5000 Flash Card VocabularyDokument314 SeitenSAT 5000 Flash Card Vocabularymvocabulary100% (26)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- QAQC Organization Chart FormatDokument1 SeiteQAQC Organization Chart FormatAbdullah Ansari50% (2)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Daily Welding Progress ReportDokument1 SeiteDaily Welding Progress ReportAbdullah Ansari100% (1)

- WPS FormatDokument1 SeiteWPS FormatAbdullah AnsariNoch keine Bewertungen

- Asme Sec V - NDT GuidelinesDokument1 SeiteAsme Sec V - NDT GuidelinesAbdullah Ansari100% (1)

- Curriculum Vitae - Paul Joseph Sebastian..Dokument4 SeitenCurriculum Vitae - Paul Joseph Sebastian..Abdullah AnsariNoch keine Bewertungen

- Magnetic Particle Generic ProcedureDokument19 SeitenMagnetic Particle Generic ProcedureAbdullah AnsariNoch keine Bewertungen

- Hardness Generic ProcedureDokument9 SeitenHardness Generic ProcedureAbdullah AnsariNoch keine Bewertungen

- Viewing and Interpretation of RadiographsDokument30 SeitenViewing and Interpretation of RadiographsNatrajiNoch keine Bewertungen

- Roles of QA QC ManagerDokument3 SeitenRoles of QA QC ManagerAbdullah AnsariNoch keine Bewertungen

- The Temples of Karnak - Schwaller de LubiczDokument28 SeitenThe Temples of Karnak - Schwaller de LubiczDorian Taddei100% (4)

- ASME P Material NumbersDokument3 SeitenASME P Material NumbersTeodor EzaruNoch keine Bewertungen

- Quality Manager Job DescriptionDokument2 SeitenQuality Manager Job DescriptionAbdullah AnsariNoch keine Bewertungen

- Thesis Defense AljaberiDokument46 SeitenThesis Defense AljaberiJose TamayoNoch keine Bewertungen

- Hospital Design GuideDokument6 SeitenHospital Design Guidemdeenk0% (2)

- Ni 617 July 2014 PDFDokument46 SeitenNi 617 July 2014 PDFTi AnnelNoch keine Bewertungen

- The Right To A Balanced and Healthful Ecology by Antonio G.M. La ViñaDokument30 SeitenThe Right To A Balanced and Healthful Ecology by Antonio G.M. La Viñaellen joy chanNoch keine Bewertungen

- Warehouse Performance QuestionsDokument7 SeitenWarehouse Performance QuestionsjjjithendraNoch keine Bewertungen

- Application For New Learner's License (LL) (1/2)Dokument2 SeitenApplication For New Learner's License (LL) (1/2)Abdullah AnsariNoch keine Bewertungen

- ASME SEC IX Essential Variable Table Process WiseDokument35 SeitenASME SEC IX Essential Variable Table Process WiseAbdullah Ansari100% (1)

- Nickel Al Bronze Guide Engineers PDFDokument100 SeitenNickel Al Bronze Guide Engineers PDFSenakeNoch keine Bewertungen

- Master MLS 2500 3500 Operating Manual enDokument28 SeitenMaster MLS 2500 3500 Operating Manual enkamikazewuNoch keine Bewertungen

- Dorman Long 1960 HandbookDokument40 SeitenDorman Long 1960 HandbookAbdullah AnsariNoch keine Bewertungen

- Prayer Time - MayDokument1 SeitePrayer Time - MayAbdullah AnsariNoch keine Bewertungen

- ASME ChangesDokument1 SeiteASME ChangesAbdullah AnsariNoch keine Bewertungen

- Development of Quality Management System For Processes and Department in The CompanyDokument1 SeiteDevelopment of Quality Management System For Processes and Department in The CompanyAbdullah AnsariNoch keine Bewertungen

- World Strategic Management Process - Strategic Management InsightDokument9 SeitenWorld Strategic Management Process - Strategic Management InsightAbdullah AnsariNoch keine Bewertungen

- BV Rules 617 For Safety Guidelines For Design, Construction and Operation of TugsDokument38 SeitenBV Rules 617 For Safety Guidelines For Design, Construction and Operation of TugsAbdullah AnsariNoch keine Bewertungen

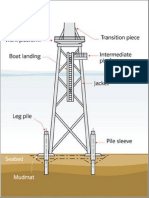

- Jacket AnatomyDokument1 SeiteJacket AnatomyAbdullah AnsariNoch keine Bewertungen

- United Arab Emirates Medicines Banned ListDokument15 SeitenUnited Arab Emirates Medicines Banned ListAbdullah AnsariNoch keine Bewertungen

- Job ResponsibiltyDokument2 SeitenJob ResponsibiltyAbdullah AnsariNoch keine Bewertungen

- ELife List of Basic and Free ChannelsDokument7 SeitenELife List of Basic and Free ChannelsAbdullah Ansari0% (1)

- Curriculum Vitae: Adari Yogeswara Rao Samsung Engineering Camp, Ghyathi Road. Abu-Dhabi - U A E Mob: 0569282901 BoyDokument2 SeitenCurriculum Vitae: Adari Yogeswara Rao Samsung Engineering Camp, Ghyathi Road. Abu-Dhabi - U A E Mob: 0569282901 BoyAbdullah AnsariNoch keine Bewertungen

- XA00048720 Stainless HandbookDokument92 SeitenXA00048720 Stainless HandbookThanis SurapapwongNoch keine Bewertungen

- Inspection Certifate 403-1Dokument1 SeiteInspection Certifate 403-1Abdullah AnsariNoch keine Bewertungen

- 16. SO2ndEdAAchTest5.doc - Google ДокументиDokument4 Seiten16. SO2ndEdAAchTest5.doc - Google ДокументиAlinaNoch keine Bewertungen

- 10.3 The Nerve ImpulseDokument20 Seiten10.3 The Nerve ImpulseazwelljohnsonNoch keine Bewertungen

- Recognition of Persisting Emotional Valence From EEG Using Convolutional Neural Networks PDFDokument6 SeitenRecognition of Persisting Emotional Valence From EEG Using Convolutional Neural Networks PDFMitchell Angel Gomez OrtegaNoch keine Bewertungen

- BureaucracyDokument19 SeitenBureaucracyJohnNoch keine Bewertungen

- Data Science CodealphaDokument11 SeitenData Science CodealphaSharef Eddine ArarNoch keine Bewertungen

- Aep Lesson Plan 3 ClassmateDokument7 SeitenAep Lesson Plan 3 Classmateapi-453997044Noch keine Bewertungen

- The Appreciative Inquiry - The Appreciative Inquiry BookDokument4 SeitenThe Appreciative Inquiry - The Appreciative Inquiry Book'Personal development program: Personal development books, ebooks and pdf100% (1)

- Seventh Grade Language Arts Letter of Introduction Frissora WillisDokument4 SeitenSeventh Grade Language Arts Letter of Introduction Frissora Willisapi-188248147Noch keine Bewertungen

- Distributed Flow Routing: Venkatesh Merwade, Center For Research in Water ResourcesDokument20 SeitenDistributed Flow Routing: Venkatesh Merwade, Center For Research in Water Resourceszarakkhan masoodNoch keine Bewertungen

- 125 25 AnalysisDokument8 Seiten125 25 AnalysismahakNoch keine Bewertungen

- Phywe Tess Che Lec enDokument108 SeitenPhywe Tess Che Lec enOlga Viviana Cardenas LunaNoch keine Bewertungen

- Ireu Top500 Ecommerce EuDokument36 SeitenIreu Top500 Ecommerce EuAnonymous 3YX9geNoch keine Bewertungen

- In Text CitationsDokument9 SeitenIn Text CitationsRey Allyson MartinezNoch keine Bewertungen

- Setting Advertising Objectives and Formulating StrategiesDokument12 SeitenSetting Advertising Objectives and Formulating StrategiesAnonymous bTh744z7E6Noch keine Bewertungen

- PT 2 Pracba1Dokument2 SeitenPT 2 Pracba1LORNA GUIWANNoch keine Bewertungen

- TSN Connections Tech CatalogDokument84 SeitenTSN Connections Tech CatalogkingdbmNoch keine Bewertungen

- The Truth Is A Thorny Issue'1 Lesbian Denial in Jackie Kay's TrumpetDokument12 SeitenThe Truth Is A Thorny Issue'1 Lesbian Denial in Jackie Kay's TrumpetTahir KhanNoch keine Bewertungen

- ROHR2 InterfacesDokument16 SeitenROHR2 InterfacesMarcia Akutsu MainardiNoch keine Bewertungen

- Dickinson CatreflectionDokument2 SeitenDickinson Catreflectionapi-240429775Noch keine Bewertungen

- Storeway FDA 2400 Disk Array Unit User's Guide: 86 A1 04ER 00 Order ReferenceDokument128 SeitenStoreway FDA 2400 Disk Array Unit User's Guide: 86 A1 04ER 00 Order ReferenceJorge Duran HerasNoch keine Bewertungen

- Human Flourishing ReducedDokument6 SeitenHuman Flourishing ReducedJanine anzanoNoch keine Bewertungen

- Wormhole: Topological SpacetimeDokument14 SeitenWormhole: Topological SpacetimeHimanshu GiriNoch keine Bewertungen

- Allegory of The CaveDokument2 SeitenAllegory of The CaveVanessa SantosNoch keine Bewertungen

- tmpC344 TMPDokument10 SeitentmpC344 TMPFrontiersNoch keine Bewertungen