Beruflich Dokumente

Kultur Dokumente

Figure 9.4-4 Spherical Shell or Dished End With Isolated Opening and Reinforcing Plate en 13445-3 - Figure 9.4-4

Hochgeladen von

met-calc0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

54 Ansichten4 SeitenFigure 9.4-4 Spherical Shell or Dished End With Isolated Opening and Reinforcing Plate en 13445-3

Originaltitel

Figure 9.4-4 Spherical Shell or Dished End With Isolated Opening and Reinforcing Plate en 13445-3_Figure 9.4-4

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenFigure 9.4-4 Spherical Shell or Dished End With Isolated Opening and Reinforcing Plate en 13445-3

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

54 Ansichten4 SeitenFigure 9.4-4 Spherical Shell or Dished End With Isolated Opening and Reinforcing Plate en 13445-3 - Figure 9.4-4

Hochgeladen von

met-calcFigure 9.4-4 Spherical Shell or Dished End With Isolated Opening and Reinforcing Plate en 13445-3

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

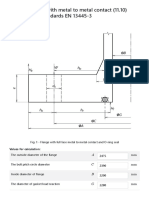

Figure 9.

4-4 Spherical shell or dished end with isolated opening and reinforcing plate

The calculation pressure: P 2,5 [Mpa]

The test pressure: Ptest 3,8 [Mpa]

The minimum yield strength or 0,2% proof strength at

calculation temperature: Rp0,2T 355 [Mpa]

The minimum tensile strength at 20°C: Rm/20 450 [Mpa]

The minimum yield strength or 0,2% proof strength at

calculation temperature reinforcing plate: Rp0,2Tp 250 [Mpa]

The minimum tensile strength at 20°C reinforcing

plate: Rm/20p 450 [Mpa]

Joint coefficient: z 1 []

The diameter of a hole, or the inside diameter of a

nozzle: d 400 [mm]

Inside radius of curvature of the shell at the opening

centre: ris 1000 [mm]

Analysis thickness of shell wall or mean analysis

thickness within the length l's and excluding the

thickness of the reinforcing pad if fitted: ea,s 30 [mm]

Assumed shell thickness of shell wall for checking of

reinforcement of an opening. The thickness may be

assumed by designer between the minimum required

shell thickness e and the shell analysis thickness ea,s.

This assumed thickness shall then be used consistently

in all requirements: ec,s 35 [mm]

Length of shell, from the edge of an opening or from

the external diameter of a nozzle, to a shell

discontinuity: ls 1500 [mm]

Analysis thickness of reinforcing plate: ea,p 10 [mm]

Width of reinforcing plate: lp 100 [mm]

Cross-sectional area of fillet weld between nozzle (or

plate) and shell: Afw 3,20E+01 [mm2]

Nominal design stress of shell material for normal

operating cases:

𝑅 , 𝑅 /

𝑓 = 𝑚𝑖𝑛 ;

1,5 2,4

𝑅 , 𝑅 /

𝑓 = 𝑚𝑖𝑛 ∗ 0,9; ∗ 0,9 : 𝑧 ≤ 0,7

1,5 2,4

fs 187,5 [Mpa]

Nominal design stress of shell material for test cases:

𝑅 ,

𝑓 =

1,05

fstest 338,1 [Mpa]

Nominal design stress of reinforcing plate material for

normal operating cases:

𝑅 , 𝑅 /

𝑓 = 𝑚𝑖𝑛 ;

1,5 2,4

𝑅 , 𝑅 /

𝑓 = 𝑚𝑖𝑛 ∗ 0,9; ∗ 0,9 : 𝑧 ≤ 0,7

1,5 2,4

fp 166,7 [Mpa]

Nominal design stress of reinforcing plate material for

test cases:

𝑅 ,

𝑓 =

1,05

fptest 238,1 [Mpa]

Minimal nominal design stress of reinforcing plate

material for normal operating cases:

𝑓 = 𝑚𝑖𝑛 𝑓 ; 𝑓

fop 166,7 [Mpa]

Minimal nominal design stress of reinforcing plate

material for test cases:

𝑓 = 𝑚𝑖𝑛 𝑓 ;𝑓

foptest 238,1 [Mpa]

Maximum length of shell contributing to opening

reinforcement, taken on the mean surface of the shell

wall:

𝑙 = 2𝑟 + 𝑒 , ∗𝑒 ,

lso 266,9 [mm]

Effective length of shell for opening reinforcement:

𝑙 ´ = 𝑚𝑖𝑛 𝑙 ; 𝑙

l´s 266,9 [mm]

Medium radius of curvature of the shell at the opening

centre:

𝑟 = 𝑟 + 0,5 ∗ 𝑒 ,

rms 1015,0 [mm]

Coefficient:

𝑑

𝛿=

2∗𝑟

δ 0,20 []

Distance taken along the mid-thickness of the shell

between the centre of an opening and the external

edge of a nozzle or a ring; or, if no nozzle or ring is

present, a is the distance between the centre of the

hole and its bore:

𝑎=𝑟 ∗ 𝑎𝑟𝑐𝑠𝑖𝑛𝛿

a 201,3 [mm]

Pressure loaded area the shell:

𝑙´ + 𝑎

𝐴𝑝 = 0,5 ∗ 𝑟 ∗ +𝑎∗ 𝑒 , +𝑒 ,

0,5 ∗ 𝑒 , + 𝑟

Aps 2,39E+05 [mm2]

Stress loaded cross-sectional area effective as

reinforcement the shell:

𝐴𝑓 = 𝑙 ´ ∗ 𝑒 ,

Afs 9,34E+03 [mm2]

Effective width of reinforcing plate for reinforcement:

𝑙 ´ = 𝑚𝑖𝑛 𝑙 ; 𝑙

l´p 100,0 [mm]

Effective thickness of reinforcing plate for

reinforcement calculation:

𝑒 = 𝑚𝑖𝑛 𝑒 , ;𝑒 ,

ep 10,0 [mm]

𝑒 , ≤ 1,5 ∗ 𝑒 15 yes

Stress loaded cross-sectional area reinforcing plate

effective as reinforcement:

𝐴𝑓 = 𝑙 ´ ∗ 𝑒

Afp 1,00E+03 [mm2]

𝐴𝑓 + 𝐴𝑓 𝑓 − 0,5𝑃 + 𝐴𝑓 𝑓 − 0,5𝑃

≥1

𝑃 ∗ 𝐴𝑝

3,2 yes

𝐴𝑓 + 𝐴𝑓 𝑓 − 0,5𝑃 + 𝐴𝑓 𝑓 − 0,5𝑃

≥1

𝑃 ∗ 𝐴𝑝

3,7 yes

Das könnte Ihnen auch gefallen

- ASME BPVC.VIII.1 corrosion guidelinesDokument2 SeitenASME BPVC.VIII.1 corrosion guidelinescanizales70Noch keine Bewertungen

- Stress Analysis EssentialsDokument30 SeitenStress Analysis EssentialsDinesh SunderNoch keine Bewertungen

- PVP2016 Final ProgramDokument76 SeitenPVP2016 Final Programthaivinhtuy100% (1)

- On The Design of The Tubesheet and Tubesheet-To-Shell Junction of A Fixed Tubesheet Heat ExchangerDokument7 SeitenOn The Design of The Tubesheet and Tubesheet-To-Shell Junction of A Fixed Tubesheet Heat ExchangerEdgardo Chavez BelloNoch keine Bewertungen

- Understanding ASME UG-45Dokument3 SeitenUnderstanding ASME UG-45Ahmad DanielNoch keine Bewertungen

- Gear CalculationDokument58 SeitenGear CalculationSachin KubasadNoch keine Bewertungen

- Flange Input CalcDokument12 SeitenFlange Input CalcdharwinNoch keine Bewertungen

- Comparison ASME KTADokument7 SeitenComparison ASME KTAAndres_Pastor1987Noch keine Bewertungen

- EN13480-3 Chap12 ModificationsDokument37 SeitenEN13480-3 Chap12 ModificationsPrashant ChauhanNoch keine Bewertungen

- Design by AnalysisDokument22 SeitenDesign by AnalysisJEELE77Noch keine Bewertungen

- Pressure Vessel Fea Consulting Services - Asme Section Viii Division 2 Fatigue AnalysisDokument6 SeitenPressure Vessel Fea Consulting Services - Asme Section Viii Division 2 Fatigue AnalysisAbhay UpadhyayNoch keine Bewertungen

- Shell Thickness CalculationsDokument2 SeitenShell Thickness CalculationsskocogluNoch keine Bewertungen

- Figure 9.4-9 Cylindrical Shell With Isolated Opening, Increased Wall Thickness and Set-In Nozzle en 13445-3 - Figure 9.4-9Dokument4 SeitenFigure 9.4-9 Cylindrical Shell With Isolated Opening, Increased Wall Thickness and Set-In Nozzle en 13445-3 - Figure 9.4-9met-calcNoch keine Bewertungen

- Spence and Tooth Tube Sheet DesignDokument27 SeitenSpence and Tooth Tube Sheet DesignmakcodetechNoch keine Bewertungen

- Technical DataDokument48 SeitenTechnical Datashekhar2681Noch keine Bewertungen

- f201508151439617857 PDFDokument6 Seitenf201508151439617857 PDFh_alimohamNoch keine Bewertungen

- Skirt Support Analysis TransportDokument5 SeitenSkirt Support Analysis TransportHunnymijie NorNoch keine Bewertungen

- BS 5276-2Dokument20 SeitenBS 5276-2Ali Alizadeh100% (1)

- Analyzer Sample Systems Ver HappenDokument12 SeitenAnalyzer Sample Systems Ver HappenIñaki Eseberri100% (1)

- Figure 9.5-1 Cylindrical Shell With Nozzle Oblique in The Longitudinal Cross Section en 13445-3 - Figure 9.5-1Dokument5 SeitenFigure 9.5-1 Cylindrical Shell With Nozzle Oblique in The Longitudinal Cross Section en 13445-3 - Figure 9.5-1met-calcNoch keine Bewertungen

- Calculo de Brida Segun ASMEDokument29 SeitenCalculo de Brida Segun ASMEakarcz6731Noch keine Bewertungen

- Six Considerations For Proper Dust Collection System DesignDokument9 SeitenSix Considerations For Proper Dust Collection System DesignJoão CoelhoNoch keine Bewertungen

- 2400 Tema DCDokument7 Seiten2400 Tema DCMasoodMiyanNoch keine Bewertungen

- Channel Thickness Calculation: 1 Design Data: CO2 Condenser / Liquefier Design Code of ConstructionDokument6 SeitenChannel Thickness Calculation: 1 Design Data: CO2 Condenser / Liquefier Design Code of ConstructionGaurav BedseNoch keine Bewertungen

- Harmonic Analysis ExampleDokument32 SeitenHarmonic Analysis ExampleWendi JunaediNoch keine Bewertungen

- PROBLEMS Holtz and KovacsDokument3 SeitenPROBLEMS Holtz and KovacsDaniel L. Blanco Pérez0% (2)

- Figure 9.5-2 Cylindrical Shell With Nozzle Oblique in The Transverse Cross Section en 13445-3 - Figure 9.5-2Dokument5 SeitenFigure 9.5-2 Cylindrical Shell With Nozzle Oblique in The Transverse Cross Section en 13445-3 - Figure 9.5-2met-calcNoch keine Bewertungen

- Hydrodynamic Calculation Needle ValveDokument23 SeitenHydrodynamic Calculation Needle Valvemet-calcNoch keine Bewertungen

- Nuts (11.4.3.2) EN 13445-3Dokument1 SeiteNuts (11.4.3.2) EN 13445-3met-calcNoch keine Bewertungen

- Calculation Cover Sheet: ClientDokument8 SeitenCalculation Cover Sheet: Clientanamaria ursuNoch keine Bewertungen

- Hydrodynamic Calculation Butterfly Valve (Lattice Disc)Dokument18 SeitenHydrodynamic Calculation Butterfly Valve (Lattice Disc)met-calcNoch keine Bewertungen

- Figure 9.4-13 Conical Shell With Isolated Opening. Combined Reinforcement From Shell and Nozzle en 13445-3 - Figure 9.4-13Dokument4 SeitenFigure 9.4-13 Conical Shell With Isolated Opening. Combined Reinforcement From Shell and Nozzle en 13445-3 - Figure 9.4-13met-calcNoch keine Bewertungen

- Calculation of RC PAD2Dokument1 SeiteCalculation of RC PAD2m 418Noch keine Bewertungen

- Figure 9.5-3 Spherical Shell With A Non Radial Nozzle en 13445-3 - Figure 9.5-3Dokument5 SeitenFigure 9.5-3 Spherical Shell With A Non Radial Nozzle en 13445-3 - Figure 9.5-3met-calcNoch keine Bewertungen

- Conical Shells (7.6.4) EN 13445-3Dokument3 SeitenConical Shells (7.6.4) EN 13445-3met-calcNoch keine Bewertungen

- Conical Shells (7.6.4) EN 13445-3Dokument3 SeitenConical Shells (7.6.4) EN 13445-3met-calcNoch keine Bewertungen

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Dokument18 SeitenHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNoch keine Bewertungen

- Allowable Stress: R Mpa C SDokument1 SeiteAllowable Stress: R Mpa C Smet-calcNoch keine Bewertungen

- Spherical Shells (7.4.3) EN 13445-3Dokument3 SeitenSpherical Shells (7.4.3) EN 13445-3met-calcNoch keine Bewertungen

- Spherical Shells (7.4.3) EN 13445-3Dokument3 SeitenSpherical Shells (7.4.3) EN 13445-3met-calcNoch keine Bewertungen

- Contact Stress of The Cylinder in The Cylindrical SocketDokument3 SeitenContact Stress of The Cylinder in The Cylindrical Socketmet-calcNoch keine Bewertungen

- Stainless Steel Sightglass Din 28120 28121Dokument4 SeitenStainless Steel Sightglass Din 28120 28121Thoa Tran VanNoch keine Bewertungen

- Contact Stress of Cylinder On Flat SurfaceDokument3 SeitenContact Stress of Cylinder On Flat Surfacemet-calcNoch keine Bewertungen

- Threaded Holes (11.4.3.3) EN 13445-3Dokument1 SeiteThreaded Holes (11.4.3.3) EN 13445-3met-calcNoch keine Bewertungen

- Threaded Holes (11.4.3.3) EN 13445-3Dokument1 SeiteThreaded Holes (11.4.3.3) EN 13445-3met-calcNoch keine Bewertungen

- Hydrodynamic Calculation Howell-Bunger ValveDokument34 SeitenHydrodynamic Calculation Howell-Bunger Valvemet-calcNoch keine Bewertungen

- Hydrodynamic Calculation Butterfly Valve (Lenticular Disc)Dokument28 SeitenHydrodynamic Calculation Butterfly Valve (Lenticular Disc)met-calcNoch keine Bewertungen

- Hydrodynamic Calculation Needle Valve Closing Flow Against The Direction of Movement of The PistonDokument23 SeitenHydrodynamic Calculation Needle Valve Closing Flow Against The Direction of Movement of The Pistonmet-calcNoch keine Bewertungen

- Hydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)Dokument24 SeitenHydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)met-calcNoch keine Bewertungen

- Spherical Shells en 13445-3 - 7.4.3Dokument3 SeitenSpherical Shells en 13445-3 - 7.4.3met-calc100% (1)

- Rolled Shells (7.4.2) According To Standards EN 13445-3: Values For CalculationDokument3 SeitenRolled Shells (7.4.2) According To Standards EN 13445-3: Values For Calculationmet-calcNoch keine Bewertungen

- Full Face Flange With Metal To Metal Contact (11.10) EN 13445-3Dokument5 SeitenFull Face Flange With Metal To Metal Contact (11.10) EN 13445-3met-calcNoch keine Bewertungen

- Full Face Flange With Metal To Metal Contact (11.10) EN 13445-3Dokument5 SeitenFull Face Flange With Metal To Metal Contact (11.10) EN 13445-3met-calcNoch keine Bewertungen

- The Flow Characteristic On The Position of The DriveDokument7 SeitenThe Flow Characteristic On The Position of The Drivemet-calcNoch keine Bewertungen

- Etab RSM Eccc Basics SCMDokument2 SeitenEtab RSM Eccc Basics SCMsathiyaseelann.sNoch keine Bewertungen

- Hydrodynamic Calculation Butterfly Valve (Lattice Disc)Dokument31 SeitenHydrodynamic Calculation Butterfly Valve (Lattice Disc)met-calcNoch keine Bewertungen

- BucklingDokument2 SeitenBucklingmet-calcNoch keine Bewertungen

- Hydrodynamic Calculation Gate Valve (Through Conduit)Dokument14 SeitenHydrodynamic Calculation Gate Valve (Through Conduit)met-calcNoch keine Bewertungen

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Dokument31 SeitenHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNoch keine Bewertungen

- Hydrodynamic Calculation Gate Valve (Through-Conduit)Dokument23 SeitenHydrodynamic Calculation Gate Valve (Through-Conduit)met-calcNoch keine Bewertungen

- Hydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)Dokument19 SeitenHydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)met-calcNoch keine Bewertungen

- Contact Stress Two CylindersDokument3 SeitenContact Stress Two Cylindersmet-calcNoch keine Bewertungen

- Hydrodynamic Calculation Spherical ValveDokument40 SeitenHydrodynamic Calculation Spherical Valvemet-calcNoch keine Bewertungen

- Flange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3Dokument4 SeitenFlange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3met-calcNoch keine Bewertungen

- Flange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3Dokument4 SeitenFlange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3met-calcNoch keine Bewertungen

- Hydrodynamic Calculation Howell-Jet ValveDokument17 SeitenHydrodynamic Calculation Howell-Jet Valvemet-calcNoch keine Bewertungen

- Multi-Stage ValveDokument2 SeitenMulti-Stage Valvemet-calcNoch keine Bewertungen

- Junction Between The Large End of A Cone and A Cylinder Without A Knuckle en 13445-3 - 7.6.6Dokument3 SeitenJunction Between The Large End of A Cone and A Cylinder Without A Knuckle en 13445-3 - 7.6.6met-calcNoch keine Bewertungen

- PD CR 12953-14-2002Dokument16 SeitenPD CR 12953-14-2002navaronefraNoch keine Bewertungen

- Flange calculation as per ASME Section VIIIDokument9 SeitenFlange calculation as per ASME Section VIIIDarshan PanchalNoch keine Bewertungen

- WHRB-265!08!00 Front and Rear Mirrors, Shell CalculationDokument2 SeitenWHRB-265!08!00 Front and Rear Mirrors, Shell CalculationmehmacarNoch keine Bewertungen

- Visual Vessel Design FAQDokument23 SeitenVisual Vessel Design FAQsierthinNoch keine Bewertungen

- In Elastic Buckling of Geometrically Imperfect TubesDokument16 SeitenIn Elastic Buckling of Geometrically Imperfect TubesSiva RajNoch keine Bewertungen

- Multi Layer Pressure VesselsDokument8 SeitenMulti Layer Pressure VesselsprivatehomeNoch keine Bewertungen

- Ccsviiid1 2260Dokument2 SeitenCcsviiid1 2260DieguitoOmarMoralesNoch keine Bewertungen

- Design and Static Analysis of Different Pressure Vessels and Materials Using Fem MethodDokument7 SeitenDesign and Static Analysis of Different Pressure Vessels and Materials Using Fem MethodSuryaprakashNoch keine Bewertungen

- En 13121-3 (2016) (E)Dokument10 SeitenEn 13121-3 (2016) (E)jasonNoch keine Bewertungen

- Contents Pages: W.U .Department of Mechanical Engineeringpage 1Dokument62 SeitenContents Pages: W.U .Department of Mechanical Engineeringpage 1Leta SK100% (1)

- Nozzle Load Check As Per TEMADokument2 SeitenNozzle Load Check As Per TEMAvm153748763Noch keine Bewertungen

- Figure 9.4-5 Cylindrical Shell With Isolated Opening and Reinforcing Ring, With External Blind Flange B en 13445-3 - Figure 9.4-5Dokument4 SeitenFigure 9.4-5 Cylindrical Shell With Isolated Opening and Reinforcing Ring, With External Blind Flange B en 13445-3 - Figure 9.4-5met-calcNoch keine Bewertungen

- U-Shaped Reinforced Bellows (Austenitic Steel)Dokument10 SeitenU-Shaped Reinforced Bellows (Austenitic Steel)met-calcNoch keine Bewertungen

- Junction Between The Large End of A Cone and A Cylinder With A Knuckle en 13445-3 - 7.6.7Dokument4 SeitenJunction Between The Large End of A Cone and A Cylinder With A Knuckle en 13445-3 - 7.6.7met-calcNoch keine Bewertungen

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryVon EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNoch keine Bewertungen

- Cylindrical Compression Helix Springs For Suspension SystemsVon EverandCylindrical Compression Helix Springs For Suspension SystemsNoch keine Bewertungen

- Allowable Hertz PressureDokument1 SeiteAllowable Hertz Pressuremet-calcNoch keine Bewertungen

- Multi-Hole CageDokument7 SeitenMulti-Hole Cagemet-calcNoch keine Bewertungen

- Outline For PhotosynthesisDokument6 SeitenOutline For Photosynthesiswitzy11Noch keine Bewertungen

- Xperia™Z: Environmental Declaration ForDokument4 SeitenXperia™Z: Environmental Declaration ForandreskalikasansaraNoch keine Bewertungen

- Organic Rankine Cycle (ORC) ExplainedDokument1 SeiteOrganic Rankine Cycle (ORC) ExplaineddolphinNoch keine Bewertungen

- ACT Reading Practice TestsDokument81 SeitenACT Reading Practice TestsYann VautrinNoch keine Bewertungen

- Points For PPT On AdmixturesDokument9 SeitenPoints For PPT On AdmixturesAvinash MaratheNoch keine Bewertungen

- LM Product BrochureDokument20 SeitenLM Product BrochurekashishNoch keine Bewertungen

- Boscoseal Torch OnDokument3 SeitenBoscoseal Torch OnjbonvierNoch keine Bewertungen

- Ball PistonDokument15 SeitenBall PistonNm5793100% (1)

- The Solar DynamoDokument29 SeitenThe Solar Dynamoanizha_nNoch keine Bewertungen

- 1 ph-1Dokument17 Seiten1 ph-1soonaNoch keine Bewertungen

- Re91001 01 X b2 - 2016 04Dokument30 SeitenRe91001 01 X b2 - 2016 04Bernardo Orozco LariosNoch keine Bewertungen

- R311 Catalyst 06.2004 msds3434Dokument6 SeitenR311 Catalyst 06.2004 msds3434rawaronteksNoch keine Bewertungen

- Assignment 1Dokument4 SeitenAssignment 1Nur AfiqahNoch keine Bewertungen

- Gcse 239/01 Additional Science: Foundation Tier Biology 2 A.M. THURSDAY, 13 January 2011 45 MinutesDokument12 SeitenGcse 239/01 Additional Science: Foundation Tier Biology 2 A.M. THURSDAY, 13 January 2011 45 MinutessureshthevanNoch keine Bewertungen

- Research Programmes: EligibilityDokument14 SeitenResearch Programmes: Eligibilitysatyakrishna1234Noch keine Bewertungen

- QIAexpress Detection and Assay HandbookDokument104 SeitenQIAexpress Detection and Assay HandbookghadbaneNoch keine Bewertungen

- Millman Halkias - Integrated ElectronicsDokument14 SeitenMillman Halkias - Integrated ElectronicsSushruti Richaa KashyapNoch keine Bewertungen

- Process Modeling Using Aspen HYSYSDokument2 SeitenProcess Modeling Using Aspen HYSYSLinton WongNoch keine Bewertungen

- Soal BIOKIM Nomor 3Dokument4 SeitenSoal BIOKIM Nomor 3Siti RositahNoch keine Bewertungen

- ENSCO DS6 - Unit320P04DS6 - SNDS6320D - Mud Pump D - Abnormal - 25506970Dokument5 SeitenENSCO DS6 - Unit320P04DS6 - SNDS6320D - Mud Pump D - Abnormal - 25506970mohamed hamedNoch keine Bewertungen

- MOF Part 2-1-100Dokument100 SeitenMOF Part 2-1-100Tayyaba BibiNoch keine Bewertungen

- VERTEX Epoxy Self LevellingDokument2 SeitenVERTEX Epoxy Self LevellingSheikh BeryalNoch keine Bewertungen

- METALLODRUGSDokument21 SeitenMETALLODRUGSAditya Verma100% (1)

- Morlina S1 B PDFDokument4 SeitenMorlina S1 B PDFerfan kurniawanNoch keine Bewertungen

- Ramesh Kumar Guduru CV and Research ProfileDokument8 SeitenRamesh Kumar Guduru CV and Research ProfileAnonymous v9cXHdjNoch keine Bewertungen