Beruflich Dokumente

Kultur Dokumente

24acb7 1w PDF

Hochgeladen von

elekossOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

24acb7 1w PDF

Hochgeladen von

elekossCopyright:

Verfügbare Formate

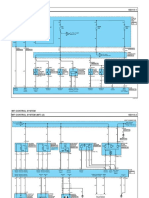

24ACB7

Comfortt17 2---Stage Air Conditioner

with Puronr Refrigerant

1---1/2 to 5 Tons

Wiring Diagram

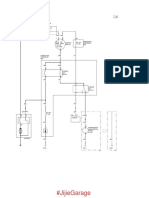

CONNECTION DIAGRAM SCHEMATIC DIAGRAM (LADDER FORM)

L1 *CHS L2

BLU *CH

COMP

*SR

*SC CAP R

C

BRN YEL

2 1 H

S

(NOTE #8) CONT *SR CAP

5 C BLU H

11 21

BLK F 5 2 *SC CONT

COMP EQUIP C

GND 1 23 23

S

*CHS C OFM F

*CH BLK

BLK R

or BLK BLK YEL

RED

(NOTE #9) YEL

RED or BLK

CONT

11 21 BRN CS

L1 OFM

208/230 1Ø 23 23 C

POWER L2

BLK * CTD

SUPPLY

*LPS *HPS

EQUIP GND T2

YEL Y2 CONT

LOGIC

BLK T1 T3 *LLS

*CTD

VIO Y1

T2

RED LOGIC IFR

T3 T1 G

CS

R C

*LPS *HPS R

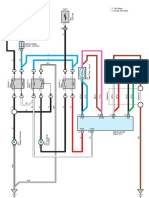

INDOOR THERMOSTAT EXTERNAL POWER SUPPLY 24 V

YEL/ PNK YEL/ PNK BLU/PNK BLU/PNK

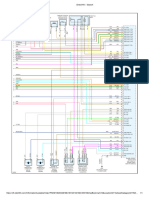

CONDENSING UNIT CHARGING INSTRUCTIONS

For use with units using R-410A refrigerant

BRN/YEL

*LLS REQUIRED LIQUID LINE TEMPERATURE COOLING ONLY

BLU EXTERNAL CHARGING PROCEDURE

BLK BLK POWER Liquid

C SUPPLY Required Subcooling 1. Only use subcooling charging method

R 24 V

Pressure when OD ambient is greater than 70ºF

(NOTE #3) at Service Temperature (ºF)

Valve (psig) 6 8 10 12 14 16 and less than 100ºF, indoor temp is

greater than 70ºF and less than 80ºF,

251 78 76 74 72 70 68 and line set is less than 80 ft.

259 80 78 76 74 72 70 2. Operate unit a minimum of 15 minutes

Y2 Y1 C G R 266 82 80 78 76 74 72 before checking the charge.

INDOOR THERMOSTAT (NOTE #6) 274 84 82 80 78 76 74 3. Measure liquid service valve pressure

INDOOR BLOWER MOTOR by attaching an accurate gauge to the

283 86 84 82 80 78 76

LEGEND 291 88 86 84 82 80 78 service port.

299 90 88 86 84 82 80 4. Measure the liquid line temperature by

FACTORY POWER WIRING *CHS CRANKCASE HEATER SWITCH

308 92 90 88 86 84 82 attaching an accurate thermistor type

COMP COMPRESSOR or electronic thermometer to the

FACTORY CONTROL WIRING 317 94 92 90 88 86 84

CONT CONTACTOR liquid line near the outdoor coil.

FIELD CONTROL WIRING

326 96 94 92 90 88 86

CS COMPRESSOR SOLENOID 335 98 96 94 92 90 88 5. Refer to unit rating plate for required

FIELD POWER WIRING *CTD COMPRESSOR TIME DELAY 345 100 98 96 94 92 90 subcooling temperature.

*HPS HIGH PRESSURE SWITCH 6. Find the point where the required

CONDUCTOR ON CIRCUIT BOARD 354 102 100 98 96 94 92 subcooling temperature intersects the

IFR INDOOR FAN RELAY 364 104 102 100 98 96 94

COMPONENT CONNECTION measured liquid service valve pressure.

*LLS LIQUID LINE SOLENOID VALVE 374 106 104 102 100 98 96 7. To obtain the required subcooling

FIELD SPLICE *LPS LOW PRESSURE SWITCH 384 108 106 104 102 100 98

temperature at specific liquid line

JUNCTION OFM OUTDOOR FAN MOTOR 395 110 108 106 104 102 100 pressure, add refrigerant if liquid line

*SC START CAPICATOR 406 112 110 108 106 104 102 temperature is higher than indicated.

PLUG RECEPTACLE START RELAY

416 114 112 110 108 106 104 When adding refrigerant, charge in

*SR 427 116 114 112 110 108 106

CAP CAPACITOR liquid form using a flow restricting

*CH CRANKCASE HEATER * MAY BE FACTORY INSTALLED 439 118 116 114 112 110 108 device into suction service port.

450 120 118 116 114 112 110 Recover refrigerant if temperature is

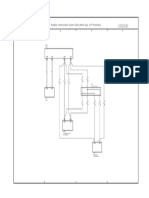

NOTES: 462 122 120 118 116 114 112 lower. Allow a tolerance of +/- 3ºF.

1. Symbols are electrical representation only. 474 124 122 120 118 116 114

2. Compressor and fan motor furnished with inherent thermal protection. CAUTION

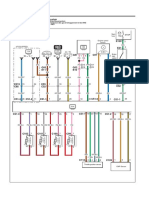

3. To be wired in accordance with National Electric N.E.C. and local codes. 1. Compressor damage may occur if system is over charged.

4. N.E.C. class 2, 24 V circuit, min. 40 VA required, 60 VA on units installed with LLS. 2. This unit is factory charged with R-410A in accordance with the amount shown

5. Use copper conductors only. Use conductors suitable for at least 75ºC (167ºF). on the rating plate. The charge is adequate for most systems using matched

6. Connection for typical cooling only thermostat. For other arrangements see Installation coils and tubing not over 15 feet long. Check refrigerant charge for maximum

Instructions. efficiency. See Product Data Literature for required Indoor air Flow Rates and

7. If indoor section has a transformer with a grounded secondary, connect the grounded for use of line lengths over 15 feet.

side to the BRN/YEL lead. 3. Relieve pressure and recover all refrigerant before system repair or final

8. When start relay and start capacitor are installed, start thermistor is not used. disposal. Use all service ports and open all flow-control devices, including

9. CH not used on all units. solenoid valves.

10. If any of the original wire, as supplied, must be replaced, use the same or equivalent wire. 4. Never vent refrigerant to atmosphere. Use approved recovery equipment.

11. Check all electrical connections inside control box for tightness.

12. Do not attempt to operate unit until service valves have been opened.

13. Do not rapid cycle compressor. Compressor must be off 3 minutes to allow pressures to

equalize between high and low side before starting. 3 3 6 3 2 3 -1 0 1 R E V . B

Fig. 1 – Wiring Diagram — Model sizes 2 -- 5 tons, 208/230--1

Copyright 2011 Carrier Corp. S 7310 W. Morris St. S Indianapolis, IN 46231 Printed in U.S.A. Edition Date: 04/11 Catalog No: 24ACB7---1W

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations. Replaces: New

Das könnte Ihnen auch gefallen

- Wiring Diagram of AcDokument2 SeitenWiring Diagram of AcNawab AnsariNoch keine Bewertungen

- Wiring Diagrams: PA16NADokument2 SeitenWiring Diagrams: PA16NAMarlou RabinaNoch keine Bewertungen

- Wiring Diagrams - CarrierDokument2 SeitenWiring Diagrams - CarrierMinh nhut LưuNoch keine Bewertungen

- Starting System Circuit Diagram Except '18-21 L12B4, M/TDokument2 SeitenStarting System Circuit Diagram Except '18-21 L12B4, M/TTomyNoch keine Bewertungen

- DLC3 Yaris 2016Dokument3 SeitenDLC3 Yaris 2016kurnia wanNoch keine Bewertungen

- Ecm 3-1Dokument3 SeitenEcm 3-1Mario S.M.Noch keine Bewertungen

- Charging HighlanderDokument4 SeitenCharging HighlanderSideth ChivNoch keine Bewertungen

- Hiace 2018 (Caja de Velocidades)Dokument10 SeitenHiace 2018 (Caja de Velocidades)jamespituco3Noch keine Bewertungen

- DA1 Model DecodificationDokument1 SeiteDA1 Model DecodificationAmarnath YadavNoch keine Bewertungen

- sơ đồ hộp số ECT và ATDokument11 Seitensơ đồ hộp số ECT và ATnamnguyen.2808199Noch keine Bewertungen

- Audio System: 2004 LEXUS LS 430 (EWD577U)Dokument8 SeitenAudio System: 2004 LEXUS LS 430 (EWD577U)bob loblawNoch keine Bewertungen

- Jazz GK5 Starting System Circuit Diagram Build-In Type MICUDokument1 SeiteJazz GK5 Starting System Circuit Diagram Build-In Type MICUTomyNoch keine Bewertungen

- Open B70 1DC Istruzioni IS117 Rev13-En PDFDokument56 SeitenOpen B70 1DC Istruzioni IS117 Rev13-En PDFivoivan99Noch keine Bewertungen

- Vfewdsou 1992 92trucke Systemci CombmeteDokument4 SeitenVfewdsou 1992 92trucke Systemci CombmeteRicardo GonzalezNoch keine Bewertungen

- 2 SUBMERSIBLE PUMPS CONTROLDokument1 Seite2 SUBMERSIBLE PUMPS CONTROLahmed fathyNoch keine Bewertungen

- Doosan Solar 340 LCDokument1 SeiteDoosan Solar 340 LCRaja SekarNoch keine Bewertungen

- Destroyer SoundTech S375WR & PSM1200 IC8 M65831 PDFDokument2 SeitenDestroyer SoundTech S375WR & PSM1200 IC8 M65831 PDFSandro José100% (1)

- Arduino Uno Project for Measuring AC VoltageDokument1 SeiteArduino Uno Project for Measuring AC VoltageRonald MamaniNoch keine Bewertungen

- A45 (A), A46 (B) : 40A Rdi Fan 10A Ecu-Ig No. 1 30A Cds FanDokument1 SeiteA45 (A), A46 (B) : 40A Rdi Fan 10A Ecu-Ig No. 1 30A Cds FanvarenziaNoch keine Bewertungen

- Electrical Wiring Diagram for 2008 PZ464 VehicleDokument1 SeiteElectrical Wiring Diagram for 2008 PZ464 VehicleDragan StanicNoch keine Bewertungen

- Hydraulic circuit diagram for Volvo EC210B-16 option hydraulic systemDokument28 SeitenHydraulic circuit diagram for Volvo EC210B-16 option hydraulic systemZawminhtunNoch keine Bewertungen

- Avanza CAN Communication SystemDokument1 SeiteAvanza CAN Communication Systemaritw541214Noch keine Bewertungen

- 2003 Chevy Truck K Tahoe 4WD V8-5.3L VIN TDokument5 Seiten2003 Chevy Truck K Tahoe 4WD V8-5.3L VIN Tluis leonNoch keine Bewertungen

- Engine Controls Hybrid System Circuit D2Dokument1 SeiteEngine Controls Hybrid System Circuit D2FranciscoNoch keine Bewertungen

- Manual de Circuito Hyunday H940CDokument71 SeitenManual de Circuito Hyunday H940CJonathan Giraldo100% (1)

- Coaster - Ecs NewDokument7 SeitenCoaster - Ecs NewArfa ArsalNoch keine Bewertungen

- AD ELEV 1886 Canberra, Act (Yscb) Aerodrome Chart - Page 1: AirservicesDokument40 SeitenAD ELEV 1886 Canberra, Act (Yscb) Aerodrome Chart - Page 1: AirservicesBen HermannNoch keine Bewertungen

- ANN & BZ 결선Dokument1 SeiteANN & BZ 결선박건호 (잼디아)Noch keine Bewertungen

- Suzuki Gran Vitara RH 2001 Gestion MotorDokument5 SeitenSuzuki Gran Vitara RH 2001 Gestion MotorBer HonzaNoch keine Bewertungen

- Schematic - Zigbee Stick 4.0 CH340CDokument1 SeiteSchematic - Zigbee Stick 4.0 CH340CSergey SuloevNoch keine Bewertungen

- MFI control system overviewDokument6 SeitenMFI control system overviewJeni67% (3)

- Accent 2010 1.$L y 1.6LDokument12 SeitenAccent 2010 1.$L y 1.6Lgian marco llamojaNoch keine Bewertungen

- Cruise Control, Engine ControlDokument20 SeitenCruise Control, Engine Controlwalter ortizNoch keine Bewertungen

- Air ConditionerDokument16 SeitenAir ConditionerRachmatulloh RamdaniNoch keine Bewertungen

- Ecu Chevrolet S10 1998 2.2Dokument4 SeitenEcu Chevrolet S10 1998 2.2AUTOMOTRIZ TIPO SPCA100% (2)

- Eai 3ZZDokument10 SeitenEai 3ZZFix Gps GarminNoch keine Bewertungen

- Tire Pressure Warning System: 240 CAMRY Hybrid Vehicle (EM02H0U)Dokument3 SeitenTire Pressure Warning System: 240 CAMRY Hybrid Vehicle (EM02H0U)Aran HaydarNoch keine Bewertungen

- Legend:: Ground Floor Power Layout Second Floor Power LayoutDokument1 SeiteLegend:: Ground Floor Power Layout Second Floor Power LayoutAYSON N. DELA CRUZNoch keine Bewertungen

- Abs PDFDokument4 SeitenAbs PDFOliver leal100% (2)

- 5 PDFDokument1 Seite5 PDFANH LÊNoch keine Bewertungen

- Legend (Power)Dokument1 SeiteLegend (Power)rajavelNoch keine Bewertungen

- $RJX76N7Dokument1 Seite$RJX76N7franklinNoch keine Bewertungen

- FRLElementPressureRangeCombinationChartDokument6 SeitenFRLElementPressureRangeCombinationChartDaryl Barrios LamedaNoch keine Bewertungen

- Starting (W/o Smart Entry & Start System)Dokument4 SeitenStarting (W/o Smart Entry & Start System)CLC 18C4Noch keine Bewertungen

- DLC3 CalyaDokument4 SeitenDLC3 Calyakurnia wanNoch keine Bewertungen

- Q-07 Domae: General NotesDokument1 SeiteQ-07 Domae: General NotesrosaNoch keine Bewertungen

- Eai 1ZZDokument10 SeitenEai 1ZZFix Gps GarminNoch keine Bewertungen

- Power WindowDokument6 SeitenPower WindowFix Gps GarminNoch keine Bewertungen

- Eis FDokument3 SeitenEis Fforeman pemudaNoch keine Bewertungen

- Auto document feeder unit wiring diagramDokument1 SeiteAuto document feeder unit wiring diagramSERGE MACIANoch keine Bewertungen

- Lights annunciator light test and dimming Sys 1 board diagramDokument1 SeiteLights annunciator light test and dimming Sys 1 board diagramSami OmranNoch keine Bewertungen

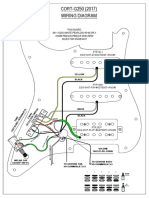

- Cort G250DX WiringDokument1 SeiteCort G250DX WiringMuhammad Irvan FardaniNoch keine Bewertungen

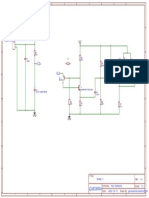

- Schematic - TRANSMISOR DE ONDAS - 2022-10-13Dokument1 SeiteSchematic - TRANSMISOR DE ONDAS - 2022-10-13gerson sanchez pimentelNoch keine Bewertungen

- Location - Routing Engine Compartment Relay Location (RHD) Engine Room R - B and Engine Room J - BDokument4 SeitenLocation - Routing Engine Compartment Relay Location (RHD) Engine Room R - B and Engine Room J - BAnibal Fabian GonzalezNoch keine Bewertungen

- C/L of Dornakal (DKJ) Stn. BUILDING AT KM.461.32: LevelDokument1 SeiteC/L of Dornakal (DKJ) Stn. BUILDING AT KM.461.32: LevelarchitNoch keine Bewertungen

- Light Auto Turn Off 40Dokument2 SeitenLight Auto Turn Off 40Sherman KillerNoch keine Bewertungen

- Eai 3ZRDokument10 SeitenEai 3ZRFix Gps GarminNoch keine Bewertungen

- Engine Control 1ND-TV, TMMF Made From Nov. 2008 ProductionDokument17 SeitenEngine Control 1ND-TV, TMMF Made From Nov. 2008 Productiondavid aliagaNoch keine Bewertungen

- Tag MC LarenDokument34 SeitenTag MC LarenelekossNoch keine Bewertungen

- Valhalla Schematic PDFDokument1 SeiteValhalla Schematic PDFelekoss100% (1)

- Casa System: Installation ManualDokument64 SeitenCasa System: Installation ManualelekossNoch keine Bewertungen

- Reloop CD Player RMP-1 PDFDokument42 SeitenReloop CD Player RMP-1 PDFelekossNoch keine Bewertungen

- Jura Brew Group Refurbishing GuideDokument46 SeitenJura Brew Group Refurbishing GuideelekossNoch keine Bewertungen

- CASA Local Input-TMDokument8 SeitenCASA Local Input-TMelekossNoch keine Bewertungen

- CASA Controller-OM PDFDokument63 SeitenCASA Controller-OM PDFelekossNoch keine Bewertungen

- MECC - A Novel Control Method PDFDokument25 SeitenMECC - A Novel Control Method PDFelekossNoch keine Bewertungen

- Casa Acm 60: P o W e Red Ceiling Mon Itor Product SummaryDokument1 SeiteCasa Acm 60: P o W e Red Ceiling Mon Itor Product SummaryelekossNoch keine Bewertungen

- A Novel Audio Power Amplifier Topology PDFDokument26 SeitenA Novel Audio Power Amplifier Topology PDFelekossNoch keine Bewertungen

- Daewoo MatizDokument41 SeitenDaewoo Matizelekoss0% (1)

- Solid PowerBass TMDokument6 SeitenSolid PowerBass TMelekossNoch keine Bewertungen

- Wash Machine AW122 - Repair Manual PDFDokument18 SeitenWash Machine AW122 - Repair Manual PDFelekossNoch keine Bewertungen

- Control Operation and Troubleshooting InstructionsDokument20 SeitenControl Operation and Troubleshooting InstructionselekossNoch keine Bewertungen

- Jura A9 PDFDokument28 SeitenJura A9 PDFelekoss100% (2)

- 97B0003N12 PDFDokument20 Seiten97B0003N12 PDFelekossNoch keine Bewertungen

- Официальное руководство по ремонту АКПП ZF 4HP20Dokument140 SeitenОфициальное руководство по ремонту АКПП ZF 4HP20icechieff86% (7)

- Control Operation and Troubleshooting InstructionsDokument20 SeitenControl Operation and Troubleshooting InstructionselekossNoch keine Bewertungen

- Technical Service Bulletin 17B0001N01 PDFDokument2 SeitenTechnical Service Bulletin 17B0001N01 PDFelekossNoch keine Bewertungen

- Control Operation and Troubleshooting InstructionsDokument20 SeitenControl Operation and Troubleshooting InstructionselekossNoch keine Bewertungen

- Kenwood Kdc-Mp408u Mp438u x492 Mp5039u Mp5539u W5041ua W5041ug W5141uay W5141ugy W5541u W5641uy Et 169Dokument48 SeitenKenwood Kdc-Mp408u Mp438u x492 Mp5039u Mp5539u W5041ua W5041ug W5141uay W5141ugy W5541u W5641uy Et 169mrdevil83Noch keine Bewertungen

- Control Operation and Troubleshooting InstructionsDokument20 SeitenControl Operation and Troubleshooting InstructionselekossNoch keine Bewertungen

- Repair ManualDokument193 SeitenRepair ManualMárk NémethNoch keine Bewertungen

- Performance 24acb7 Ig PDFDokument10 SeitenPerformance 24acb7 Ig PDFelekossNoch keine Bewertungen

- CFD-S07CP 988982301Dokument42 SeitenCFD-S07CP 988982301Anthony Resse ReynoldsNoch keine Bewertungen

- Manual de Mantenimiento CXM ClimateMasterDokument16 SeitenManual de Mantenimiento CXM ClimateMasterAlejandro ÁlvarezNoch keine Bewertungen

- 565efb4ebe389 PDFDokument34 Seiten565efb4ebe389 PDFelekossNoch keine Bewertungen

- Control Operation and Troubleshooting InstructionsDokument20 SeitenControl Operation and Troubleshooting InstructionselekossNoch keine Bewertungen

- 24ACB7 Product DataDokument42 Seiten24ACB7 Product DataMarianela MasyRubiNoch keine Bewertungen

- Motor Electrico Bojin J4103 - B User ManualDokument6 SeitenMotor Electrico Bojin J4103 - B User ManualJordan BonnettNoch keine Bewertungen

- Accounting Students' Attitude Towads AccountingDokument29 SeitenAccounting Students' Attitude Towads AccountingSham Salonga Pascual50% (2)

- Roxas Avenue, Isabela City, Basilan Province AY: 2018-2019: Claret College of IsabelaDokument2 SeitenRoxas Avenue, Isabela City, Basilan Province AY: 2018-2019: Claret College of IsabelaJennilyn omnosNoch keine Bewertungen

- Karan Chawla and Joshua Lee November 21, 2016 MEDS 3020 - Fall 2016 Dr. Rosevear, Dr. Cartwright, Dr. LiebermanDokument2 SeitenKaran Chawla and Joshua Lee November 21, 2016 MEDS 3020 - Fall 2016 Dr. Rosevear, Dr. Cartwright, Dr. LiebermanJeremy DelaneyNoch keine Bewertungen

- MEC332-MA 3rd Sem - Development EconomicsDokument9 SeitenMEC332-MA 3rd Sem - Development EconomicsRITUPARNA KASHYAP 2239239Noch keine Bewertungen

- Introduction To The Philosophy of The Human Person Quarter I - Module 2Dokument26 SeitenIntroduction To The Philosophy of The Human Person Quarter I - Module 2Katrina TulaliNoch keine Bewertungen

- MATH6113 - PPT5 - W5 - R0 - Applications of IntegralsDokument58 SeitenMATH6113 - PPT5 - W5 - R0 - Applications of IntegralsYudho KusumoNoch keine Bewertungen

- Cat IQ TestDokument3 SeitenCat IQ TestBrendan Bowen100% (1)

- 26 05 29 Hangers and Supports For Electrical SystemsDokument8 Seiten26 05 29 Hangers and Supports For Electrical SystemskaichosanNoch keine Bewertungen

- July 4th G11 AssignmentDokument5 SeitenJuly 4th G11 Assignmentmargo.nicole.schwartzNoch keine Bewertungen

- Painter CardDokument1 SeitePainter CardPraveen RANANoch keine Bewertungen

- Anki Very Useful ManualDokument5 SeitenAnki Very Useful ManualSoundaryaNoch keine Bewertungen

- EDUC 5 - QuestionairesDokument7 SeitenEDUC 5 - QuestionairesWilliam RanaraNoch keine Bewertungen

- Resistance and ResisivityDokument2 SeitenResistance and ResisivityDeddy KismanaNoch keine Bewertungen

- 2021.01.28 - Price Variation of Steel Items - SAIL Ex-Works Prices of Steel - RB-CivilDokument2 Seiten2021.01.28 - Price Variation of Steel Items - SAIL Ex-Works Prices of Steel - RB-CivilSaugata HalderNoch keine Bewertungen

- DionWIred Black FridayDokument13 SeitenDionWIred Black FridayAmon SimelaneNoch keine Bewertungen

- Tos IcuDokument1 SeiteTos IcuMary Cris RombaoaNoch keine Bewertungen

- Unit 01 Family Life Lesson 1 Getting Started - 2Dokument39 SeitenUnit 01 Family Life Lesson 1 Getting Started - 2Minh Đức NghiêmNoch keine Bewertungen

- Impact of Endurance Exercise Training in the Fasted State on Muscle Metabolism and Insulin SensitivityDokument14 SeitenImpact of Endurance Exercise Training in the Fasted State on Muscle Metabolism and Insulin SensitivityYo Vivo Fit Pablo y KarlaNoch keine Bewertungen

- Tender Evaluation Template GuideDokument15 SeitenTender Evaluation Template GuideKhalid NaeemNoch keine Bewertungen

- Njhs Application EssayDokument4 SeitenNjhs Application Essaycjawrknbf100% (2)

- LP IV Lab Zdvzmanual Sem II fbsccAY 2019-20z 20-ConvxvzzertedDokument96 SeitenLP IV Lab Zdvzmanual Sem II fbsccAY 2019-20z 20-ConvxvzzertedVikas GuptaNoch keine Bewertungen

- Marikina Development Corporation vs. FiojoDokument8 SeitenMarikina Development Corporation vs. FiojoJoshua CuentoNoch keine Bewertungen

- Pressing and Finishing (Latest)Dokument8 SeitenPressing and Finishing (Latest)Imran TexNoch keine Bewertungen

- 4900 DatasheetDokument2 Seiten4900 DatasheetMakam Raghu100% (1)

- V60 Ventilator Specifications PDFDokument4 SeitenV60 Ventilator Specifications PDFJonathan Issac Dominguez RamirezNoch keine Bewertungen

- IBM Credit Corp BPR ProcessDokument8 SeitenIBM Credit Corp BPR ProcessAnubhav PuriNoch keine Bewertungen

- PExam 2020Dokument126 SeitenPExam 2020Omama MaazNoch keine Bewertungen

- Assessing Khazaria-Serpent PeopleDokument1 SeiteAssessing Khazaria-Serpent PeopleJoao JoseNoch keine Bewertungen

- Book 2 - Test 1Dokument2 SeitenBook 2 - Test 1Đức LongNoch keine Bewertungen