Beruflich Dokumente

Kultur Dokumente

Pressure Hose Dn10-400 2.5m Straight

Hochgeladen von

afie pio pioOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pressure Hose Dn10-400 2.5m Straight

Hochgeladen von

afie pio pioCopyright:

Verfügbare Formate

Category: Control Inert Page: 1 of 3

Engineering data sheet

Sheet No: Ci-hoses

Ci Discharge Hoses

Item numbers covered by this datasheet

303102 Pressure Hose DN10-400 0.5m 0+90°

303104 Pressure Hose DN10-400 1.0m 0+90°

303106 Pressure Hose DN10-400 1.5m 0+90°

303108 Pressure Hose DN10-400 2.0m 0+90°

303109 Pressure Hose DN10-400 2.5m 0+90°

303111 Pressure Hose DN10-400 3.0m 0+90°

303113 Pressure Hose DN10-400 4.0m 0+90°

303302 Pressure Hose Dn10-400 0.5m straight

303304 Pressure Hose Dn10-400 1.0m straight

303306 Pressure Hose Dn10-400 1.5m straight

303308 Pressure Hose Dn10-400 2.0m straight

303309 Pressure Hose Dn10-400 2.5m straight

303311 Pressure Hose Dn10-400 3.0m straight L

303313 Pressure Hose Dn10-400 4.0m straight

General

The DN10 pressure hose is used for connection between the

discharge valve and the manifold, and qualifies as a type 1

connector in accordance with EN12094-8.

The hose is used in the Control Inert system, SV systems and older

INERGEN systems.

Specifications

Fittings:

Type: Straight union type with 60° face

Elbow 90° union with 60° face

Thread: ISO228 3/8" BSP

Flow diameter: Ø7.8mm

Materials: Zinc plated steel

Hose:

Outside diameter: 17.6mm

Inside diameter: 10mm (78mm2)

Construction: Two-ply steel wire

Temperature: -40°C to +100°C

Bending radius: > 130mm

Work pressure: 0 – 400 bar (EN12094-8, Wp<1/3xBp)

Burst pressure: > 1400 bar

Materials: Oil and weather resistant synthetic rubber, two-ply steel

Length: as specified in part number above

Markings

Hose: = FIRE EATER = INERGEN =

Fittings: ID – ww – yy (ID = place of pressing, ww = week number, yy = year)

Document: Ci Discharge Hoses for IV8.doc Text

1

2

Product: Id: MK 3

Inergen® Rev: 18.08.10 4

5

6

Vølundsvej 17 7

DK- 3400 Hillerød

Tel +45 7022 2769 8

Fax +45 7023 2769 9

Category: Control Inert Page: 2 of 3

Engineering data sheet

Sheet No: Ci-hoses

Installation

The hose is to be tightened in both ends. As there is no positive stop due to the tapered face, and the

friction of the thread may vary, no specific tightening torque is given, it is important that good workmanship

is applied. When there is surface contact – the hose cannot rotate in union – tighten further by 1/8 to 1/4

turn.

Maintenance

At least once per year all hoses must be inspected.

If there are cracks in the outer skin or visible corrosion the hose must be replaced.

Routine testing

Hoses must be replaced every 10 years from date stamped in collar.

No other requirements.

Document: Ci Discharge Hoses for IV8.doc Text

1

2

Product: Id: MK 3

Inergen® Rev: 18.08.10 4

5

6

Vølundsvej 17 7

DK- 3400 Hillerød

Tel +45 7022 2769 8

Fax +45 7023 2769 9

Category: Control Inert Page: 3 of 3

Engineering data sheet

Sheet No: Ci-hoses

Declaration of conformity & EC certificate (CPD)

1116 10

Manufacturer:

Fire Eater A/S

Vølundsvej 14

DK-3400 Hillerød

Denmark

EN12094-8

Connectors

Ci Discharge hose

Type 1

For inert gas (INERGEN)

Work pressure 400 bar

Free flow diameter 7.8mm

Based upon attached Certificate of conformity, we declare

that the Container valve assembly designated above meets

the provision of Annex ZA of the EN12094-8 standard.

The discharge hose is to be used in combination of Fire Eater

Discharge valves and manifolds with the Ci designation

Certification body for this product is

CNPP, B.P. 2265, F-27950 Saint_Marcel, www.cnpp.com

CNPP certificate: 1116-CPD-046

Signature: _____________

Michael Kroneder, Technical manager

Date: 2010-03-02

Document: Ci Discharge Hoses for IV8.doc Text

1

2

Product: Id: MK 3

Inergen® Rev: 18.08.10 4

5

6

Vølundsvej 17 7

DK- 3400 Hillerød

Tel +45 7022 2769 8

Fax +45 7023 2769 9

Das könnte Ihnen auch gefallen

- Fire Hose Rubber - Firefighting EquipmentDokument1 SeiteFire Hose Rubber - Firefighting Equipmentafie pio pioNoch keine Bewertungen

- Progard H3Dokument15 SeitenProgard H3afie pio pioNoch keine Bewertungen

- Citifire Fire ExtinguisherDokument4 SeitenCitifire Fire Extinguisherafie pio pioNoch keine Bewertungen

- Citifire PRVDokument1 SeiteCitifire PRVafie pio pioNoch keine Bewertungen

- FM Approval Sprinkler VikingDokument10 SeitenFM Approval Sprinkler Vikingafie pio pioNoch keine Bewertungen

- M85001 0297 Input ModulesDokument4 SeitenM85001 0297 Input Modulesafie pio pioNoch keine Bewertungen

- Catalog Citifire Golden Bright PDFDokument2 SeitenCatalog Citifire Golden Bright PDFafie pio pioNoch keine Bewertungen

- M85001-0535 - Riser Monitor Modules PDFDokument4 SeitenM85001-0535 - Riser Monitor Modules PDFafie pio pioNoch keine Bewertungen

- Brochure Siamesse ConnectionDokument1 SeiteBrochure Siamesse Connectionafie pio pioNoch keine Bewertungen

- GSA-CC1 - M85001-0237 - Signal Modules PDFDokument6 SeitenGSA-CC1 - M85001-0237 - Signal Modules PDFafie pio pioNoch keine Bewertungen

- Quickfire IHB InsideDokument1 SeiteQuickfire IHB Insideafie pio pioNoch keine Bewertungen

- M85001-0365 - Universal Input-Output Module MotherboardsDokument4 SeitenM85001-0365 - Universal Input-Output Module Motherboardsafie pio pioNoch keine Bewertungen

- M85006-0069 - Site Monitor SoftwareDokument4 SeitenM85006-0069 - Site Monitor Softwareafie pio pioNoch keine Bewertungen

- Gsa UmDokument6 SeitenGsa Umafie pio pioNoch keine Bewertungen

- Gsa RelDokument8 SeitenGsa Relafie pio pioNoch keine Bewertungen

- RLCD C - M85005 0128 R Series Remote AnnunciatorsDokument4 SeitenRLCD C - M85005 0128 R Series Remote Annunciatorsafie pio pioNoch keine Bewertungen

- M85001 0271 Isolator ModuleDokument4 SeitenM85001 0271 Isolator ModuleDiegoNoch keine Bewertungen

- GSA-CR - M85001-0623 - Sounder Base For CO and Fire DetectorsDokument4 SeitenGSA-CR - M85001-0623 - Sounder Base For CO and Fire Detectorsafie pio pioNoch keine Bewertungen

- GSA-M270 - M85001-0279 - Intelligent Manual Pull Stations PDFDokument4 SeitenGSA-M270 - M85001-0279 - Intelligent Manual Pull Stations PDFafie pio pioNoch keine Bewertungen

- V-PS - M85001-0592 - Intelligent Detectors and Bases PDFDokument6 SeitenV-PS - M85001-0592 - Intelligent Detectors and Bases PDFafie pio pioNoch keine Bewertungen

- RLCD C - M85005 0128 R Series Remote AnnunciatorsDokument4 SeitenRLCD C - M85005 0128 R Series Remote Annunciatorsafie pio pioNoch keine Bewertungen

- Afco - YS01 Series - Y StrainerDokument5 SeitenAfco - YS01 Series - Y Strainerafie pio pioNoch keine Bewertungen

- K85001-0646 - Intelligent Smoke DetectorDokument4 SeitenK85001-0646 - Intelligent Smoke Detectorafie pio pioNoch keine Bewertungen

- 13 Afco - BV01 SeriesDokument5 Seiten13 Afco - BV01 Seriesafie pio pioNoch keine Bewertungen

- Afco - CV01 Series - Swing Check ValveDokument4 SeitenAfco - CV01 Series - Swing Check Valveafie pio pioNoch keine Bewertungen

- Engineering Data Sheet: Pressure Relief CoverDokument1 SeiteEngineering Data Sheet: Pressure Relief Coverafie pio pioNoch keine Bewertungen

- 2102xx In-15 NPT NozzleDokument2 Seiten2102xx In-15 NPT Nozzleafie pio pioNoch keine Bewertungen

- Engineering Data Sheet: Manifold For Connecting 3/8" Hoses With Pressure SwitchDokument2 SeitenEngineering Data Sheet: Manifold For Connecting 3/8" Hoses With Pressure Switchafie pio pioNoch keine Bewertungen

- Kabel 3x075 BrandsikkerDokument2 SeitenKabel 3x075 Brandsikkerafie pio pioNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Pre-Trip Inspection For School BusDokument6 SeitenPre-Trip Inspection For School BusReza HojjatNoch keine Bewertungen

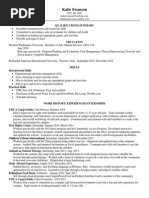

- Katie SwansonDokument1 SeiteKatie Swansonapi-254829665Noch keine Bewertungen

- Thermal Engineering Lesson Plan for Mechanical Engineering StudentsDokument3 SeitenThermal Engineering Lesson Plan for Mechanical Engineering StudentsblessyNoch keine Bewertungen

- NCP For PneumoniaDokument3 SeitenNCP For PneumoniaKahMallari100% (10)

- VVBVBVBBDokument19 SeitenVVBVBVBBnasimakhtarNoch keine Bewertungen

- Who Would Think That Love - LyricDokument1 SeiteWho Would Think That Love - LyricNatália RamosNoch keine Bewertungen

- Historic Costume: (Early 15 Century) 1400-1500 European FashionDokument33 SeitenHistoric Costume: (Early 15 Century) 1400-1500 European FashionRaina varshneyNoch keine Bewertungen

- TDS - J TOWhead D60Dokument1 SeiteTDS - J TOWhead D60TahirNoch keine Bewertungen

- Example of A Chronological CVDokument2 SeitenExample of A Chronological CVThe University of Sussex Careers and Employability CentreNoch keine Bewertungen

- TERHADAP KEPUASAN PELANGGAN PENGGUNA JASA OjJEK ONLINEDokument14 SeitenTERHADAP KEPUASAN PELANGGAN PENGGUNA JASA OjJEK ONLINET Rizal HusnyNoch keine Bewertungen

- Pembangunan Modal Insan Perspektif Pengurusan IslamDokument26 SeitenPembangunan Modal Insan Perspektif Pengurusan IslamMujiburrahmanNoch keine Bewertungen

- ElearningDokument1.488 SeitenElearningsudhansu0% (1)

- DevOps Overview PDFDokument50 SeitenDevOps Overview PDFSubba Rao KedarisettyNoch keine Bewertungen

- Chp2 Taxonomy SW MaintaineanceDokument7 SeitenChp2 Taxonomy SW MaintaineanceTooba AkhterNoch keine Bewertungen

- User Manual CCS-SeriesDokument76 SeitenUser Manual CCS-SeriesYaron David Haro VasseurNoch keine Bewertungen

- Worksheet A: Teacher's Notes: Level 2 (Upper Intermediate - Advanced)Dokument9 SeitenWorksheet A: Teacher's Notes: Level 2 (Upper Intermediate - Advanced)Elena SinisiNoch keine Bewertungen

- Bba Summer InternshipDokument3 SeitenBba Summer InternshipVedanth ChoudharyNoch keine Bewertungen

- PR Notes - III FINALDokument24 SeitenPR Notes - III FINALWeekly Recorder100% (1)

- Introduction To Research MethodologyDokument24 SeitenIntroduction To Research MethodologyRishi Dominic Dave ShaffieNoch keine Bewertungen

- Cinnamomum Cassia - Twig: 1. ScopeDokument3 SeitenCinnamomum Cassia - Twig: 1. ScopeTaufik HidayatullohNoch keine Bewertungen

- Ossy Compression Schemes Based On Transforms A Literature Review On Medical ImagesDokument7 SeitenOssy Compression Schemes Based On Transforms A Literature Review On Medical ImagesijaitjournalNoch keine Bewertungen

- Introduction To Well ServiceDokument16 SeitenIntroduction To Well ServiceDini Nur IslamiNoch keine Bewertungen

- Explosion Proof ClassificationsDokument2 SeitenExplosion Proof Classificationsneurolepsia3790Noch keine Bewertungen

- Speaking Culturally n3Dokument16 SeitenSpeaking Culturally n3Mai FalakyNoch keine Bewertungen

- The Derivatives of Trigonometric FunctionsDokument29 SeitenThe Derivatives of Trigonometric FunctionsM Arifin RasdhakimNoch keine Bewertungen

- Wiring 87T E01Dokument4 SeitenWiring 87T E01Hau NguyenNoch keine Bewertungen

- The Freshwater BiomeDokument3 SeitenThe Freshwater BiomedlpurposNoch keine Bewertungen

- Non-Ferrous Metal SmeltingDokument47 SeitenNon-Ferrous Metal SmeltinggtdomboNoch keine Bewertungen

- English Grammar: The differences between across, over and throughDokument1 SeiteEnglish Grammar: The differences between across, over and throughYuresh NadishanNoch keine Bewertungen

- TerraPower Case PDFDokument7 SeitenTerraPower Case PDFKaustav DeyNoch keine Bewertungen