Beruflich Dokumente

Kultur Dokumente

Rate Analysis For 1CUM Concrete

Hochgeladen von

Hitesh JaniOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Rate Analysis For 1CUM Concrete

Hochgeladen von

Hitesh JaniCopyright:

Verfügbare Formate

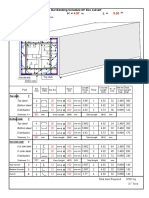

QUANTITIES OF MATERIALS

PER CUBIC METRE OF

CONCRETE

Quantity of materials such as cement, sand, coarse aggregates and water

required per cubic meter of concrete and mortar varies with the mix design of

the concrete and mortar respectively. Following table gives the estimated

quantity of materials required per cubic meter of mortar and concrete for

various nominal mixes.

NOMINAL MIX WATE WATE CEMENT SAN CRUSH

R R PER D ED

CEME 50KG (CU STONE

NT BAG M) S

CEME F.A. C.A. RATIO OF BY BY (CUM)

NT CEME WEIG NUMB

NT HT ER OF

(KG) BAGS

1 1 – 0.25 12.5 1015 20.3 0.7 –

10

1 1.5 0.28 14 815 16.3 0.8 –

55

1 2 – 0.3 15 687 13.74 0.9 –

63

1 2.5 – 0.35 17.5 585 11.7 1.0

23

1 3 – 0.4 20 505 10.1 1.0 –

6

1 4 – 0.53 26.5 395 7.9 1.1 –

06

1 6 – 0.7 35 285 5.7 1.1 –

97

1 8 – 0.9 45 220 4.4 1.2 –

32

1 1 2 0.3 15 560 11.2 0.3 0.784

92

1 2 2 0.42 21 430 8.6 0.6 0.602

02

1 1.5 3 0.42 21 395 7.9 0.4 0.828

14

1 1.6 3.3 0.48 24 363 7.26 0.4 0.838

6 3 19

1 2 3 0.5 25 385 7.7 0.5 0.808

39

1 2 3.5 0.53 26.5 330 6.6 0.4 0.808

62

1 2 4 0.55 27.5 310 6.2 0.4 0.868

34

1 2.5 3.5 0.57 28.5 305 6.1 0.5 0.748

34

1 2.5 4 0.6 30 285 5.7 0.4 0.798

99

1 3 4 0.65 32.5 265 5.3 0.5 0.742

56

1 2.5 5 0.65 32.5 255 5.1 0.4 0.892

46

1 3 5 0.69 34.5 240 4.8 0.5 0.84

04

1 3 6 0.75 37.5 215 4.3 0.4 0.904

52

1 4 8 0.95 47.5 165 3.3 0.4 0.924

62

Notes:

1. F.A.= Fine Aggregates, C.A.= Coarse Aggregates

2. The table is based on assumption that the voids in sand and crushed stone

are 40 and 45 percent respectively.

3. Air content of 1 percent has been assumed.

4. For gravel aggregates decrease cement by 5 percent, increase sand by 2

percent and coarse aggregate in proportion to fine aggregate in mix.

4. No allowance has been made in the table for bulking of sand and wastage./>

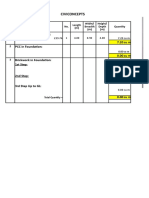

rate analysis for 1m3 of reinforced concrete.

Data required for RCC Rate Analysis:

1. Estimation of materials:

Material estimation include sand, cement, coarse aggregate and steel for a

particular mix design. Let us consider a mix design of 1:1.5:3 for our estimation

practice. The dry volume of total materials required is considered as 1.54 times

the wet volume of concrete, due to voids present in sand and aggregates in dry

stage. Therefore, for our calculation, we will consider the total volume of

materials required as 1.54 m3 for 1 m3 of wet concrete.

a) Bags of cement required:

Volume of cement required for 1m3 of Concrete =

=0.28 m3

Then number of bags of cement (volume of one bag of cement = 0.0347 m 3)

= = 8.07 bags of cement.

b) Volume of Sand required:

Volume of sand required = = 0.42 m3 of sand.

c) Volume of Coarse Aggregate Required

Volume of Coarse Aggregate = = 0.84 m3 of coarse aggregates.

d) Estimation of Reinforced Steel:

Quantity of steel required depends on components of structure, i.e. slabs,

beams, columns, foundations, roads etc. To estimate the steel required, there

are two methods.

First method is, when we have the drawing available, we can calculate the total

weight of steel required divided by total volume of concrete for different

components. This will give us the weight of reinforcement steel per cubic meter

of concrete.

Second method is assuming the percentage of reinforcement for different

components. Following are the percentage of reinforcement steel generally

required per different components. Its values can vary from structure to

structure, and can be assumed from past experiences of similar structure.

For slabs = 1.0 % of concrete volume.

For Beam = 2 % concrete volume.

For column = 2.5 % of concrete volume.

For RCC Roads, 0.6% concrete volume.

Lets take example of RCC Column, where reinforcement required is 2.5% of

concrete volume, weight of steel required will be:

=196.25 kg.

2. Labour Requirement for 1m3 of RCC:

Labours required are presented in terms of days required by particular labour to

complete its work for the given quantity of concrete. Following are the various

labours required:

a) Mason: As per Standard Schedule of Rates and Analysis of Rates, One mason

is required for 0.37 days.

b) Labours: One Unskilled labours required for 3.5 days.

c) Water carrier: One water carrier required for 1.39 days.

d) Bar Bender: Bar bender requirement depends on weight of reinforcement.

Lets consider one bar bender required for 100 kg of steel as for 1 day.

e) Mixer Operator: One mixer operator required for 0.0714 days.

f) Vibrator Operator: One vibrator operator required for 0.0714 days.

3. Equipments and sundries:

Equipment and other charges, such as water charges, miscellaneous items,

tools and tackles etc can be assumed as some percentage of total cost of

materials and labours. Lets say it as 7.5%.

4. Contractor’s Profit:

Contractor’s profit depends on place to place, organization to organization and

work to work. It varies from 10 – 20%. For our case lets assume it as 15% of

total cost of materials, labours and equipments.

We have calculated the quantity of every item in above 1 – 3 steps. For rate

analysis of RCC, we need to multiply each quantity with their rates to get the

amount for every item of work. Rates vary from place to place and time to time.

It is advisable to assume local rates or standard rates of the place.

The sum total of all the four items above will give the rate or cost for 1m 3 of

concrete.

Das könnte Ihnen auch gefallen

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Estimate-7420 (Sor 29-08-2017)Dokument37 SeitenEstimate-7420 (Sor 29-08-2017)ankit hardahaNoch keine Bewertungen

- Rate AnalysisDokument32 SeitenRate Analysishemasundar7675Noch keine Bewertungen

- Boddabada Cause Way ESTIMATEDokument18 SeitenBoddabada Cause Way ESTIMATED.V.Srinivasa RaoNoch keine Bewertungen

- Ionic Bonding Worksheet - Type 1 PracticeDokument2 SeitenIonic Bonding Worksheet - Type 1 Practicerichwenekylejc o Evaristo100% (6)

- Complete Rate AnalysisDokument2.302 SeitenComplete Rate AnalysisDeenNoch keine Bewertungen

- NauseaDokument12 SeitenNauseakazakom100% (2)

- RFP Khamgaon EPC Mode SchedulesDokument75 SeitenRFP Khamgaon EPC Mode Schedulesm_vamshikrishna22Noch keine Bewertungen

- Bar Bending Schedule OF Box CulvertDokument1 SeiteBar Bending Schedule OF Box CulvertMaladi MustamilNoch keine Bewertungen

- Abdominal Migraine and HomoeopathyDokument17 SeitenAbdominal Migraine and HomoeopathyDr. Rajneesh Kumar Sharma MD HomNoch keine Bewertungen

- MS Pipe DataDokument11 SeitenMS Pipe DataMaheshNoch keine Bewertungen

- Summary of Balance Quantity R17 27-10-18Dokument75 SeitenSummary of Balance Quantity R17 27-10-18Priyank DUbeyNoch keine Bewertungen

- Passage Planning: Dr. Arwa HusseinDokument15 SeitenPassage Planning: Dr. Arwa HusseinArwa Hussein100% (3)

- R2 Structure Quantities of Beawar Pali NH-14 12 April 2010.zipDokument150 SeitenR2 Structure Quantities of Beawar Pali NH-14 12 April 2010.zipUmesh MishraNoch keine Bewertungen

- Analysis of Rates For Estimate of DPRDokument34 SeitenAnalysis of Rates For Estimate of DPRAnamika SinghNoch keine Bewertungen

- Analysis of RateDokument45 SeitenAnalysis of RateDigvijay SinghNoch keine Bewertungen

- Fyp 070 FinalDokument190 SeitenFyp 070 FinalSunil Kharbuja100% (1)

- Data Rates-Dam Works-Part 4Dokument21 SeitenData Rates-Dam Works-Part 4vpmohammedNoch keine Bewertungen

- Detailed Estimation of RoadDokument476 SeitenDetailed Estimation of RoadJharana KcNoch keine Bewertungen

- Data Rates-Canal Works Part 1Dokument20 SeitenData Rates-Canal Works Part 1vpmohammedNoch keine Bewertungen

- NBC - Fire SafetyDokument200 SeitenNBC - Fire Safetyvenkin84507486% (7)

- Unilever PakistanDokument26 SeitenUnilever PakistanElie Mints100% (3)

- Iso Iec 25030 2007 eDokument44 SeitenIso Iec 25030 2007 eAngélica100% (1)

- Quantity Estimate and Work ProgressDokument4 SeitenQuantity Estimate and Work ProgressrayguntanNoch keine Bewertungen

- Question Calculate Rate Analysis For Size Stone Masonry (SSM) in CM 1:6 in Foundation SolDokument1 SeiteQuestion Calculate Rate Analysis For Size Stone Masonry (SSM) in CM 1:6 in Foundation SolAnusha ChikmathNoch keine Bewertungen

- PM 2017 LNT RefDokument30 SeitenPM 2017 LNT Refjigyesh sharmaNoch keine Bewertungen

- Barbending ScheduleDokument11 SeitenBarbending ScheduleCivil Engineering CalculationsNoch keine Bewertungen

- Project Estmate (Final)Dokument65 SeitenProject Estmate (Final)Bilal Ahmed BarbhuiyaNoch keine Bewertungen

- KM-HM Stones EstimateDokument50 SeitenKM-HM Stones EstimateHappy HourNoch keine Bewertungen

- Whats New in AutoPlotter 9Dokument14 SeitenWhats New in AutoPlotter 9BLG InfyconsNoch keine Bewertungen

- Schedule HDokument10 SeitenSchedule HABPL INFONoch keine Bewertungen

- Brief Rate AnalysisDokument15 SeitenBrief Rate AnalysisSaroj AcharyaNoch keine Bewertungen

- Rate Analysis (2016) - Cpwd-Part1Dokument4.174 SeitenRate Analysis (2016) - Cpwd-Part1dreamspacearchitects100% (1)

- Civil Work - CONCRETE GRADE - M5 1 - 4 - 8 M10 1 - 3 - 6 M15 1 - 2 - 4 M20 PDFDokument6 SeitenCivil Work - CONCRETE GRADE - M5 1 - 4 - 8 M10 1 - 3 - 6 M15 1 - 2 - 4 M20 PDFArjun S SanakanNoch keine Bewertungen

- CC Road Model Estimate With SSR 2012-13 ExcelDokument18 SeitenCC Road Model Estimate With SSR 2012-13 Excelsankar_rao333Noch keine Bewertungen

- 09 Construction Material Lead ChartDokument1 Seite09 Construction Material Lead ChartManish KapadneNoch keine Bewertungen

- Design of 15m Span Superstructure Re - 2Dokument1 SeiteDesign of 15m Span Superstructure Re - 2vivek100% (1)

- Community Hall Estimation ReportDokument11 SeitenCommunity Hall Estimation ReportBibhash SutradharNoch keine Bewertungen

- Rate Analysis BrickworkDokument10 SeitenRate Analysis BrickworkRaj Kumar SharmaNoch keine Bewertungen

- RCC SLAB 11-12 Rate AnalysisDokument2 SeitenRCC SLAB 11-12 Rate AnalysisRiazahemad B Jagadal0% (1)

- Toilet EstimateDokument74 SeitenToilet Estimatedee balkondaNoch keine Bewertungen

- Dense Graded Bituminous Macadam v-30 & 40Dokument28 SeitenDense Graded Bituminous Macadam v-30 & 40a k pantNoch keine Bewertungen

- Grey Structure Material CostDokument8 SeitenGrey Structure Material CostMuhammad Sarmad SonyalNoch keine Bewertungen

- Building EstimateDokument36 SeitenBuilding EstimatesamNoch keine Bewertungen

- EstimateDokument14 SeitenEstimateAnonymous fQLEF2tQpqNoch keine Bewertungen

- Cost Analysis For Bridge and CulvertsDokument14 SeitenCost Analysis For Bridge and CulvertsjnshreyNoch keine Bewertungen

- Anganwaadi Model Building EstimateDokument860 SeitenAnganwaadi Model Building EstimateRajendra Prasad GubbalaNoch keine Bewertungen

- Model Road Estimate 1Dokument211 SeitenModel Road Estimate 1sankar_rao333Noch keine Bewertungen

- Rate Analysis - Gujarat - Pkg-27 PDFDokument200 SeitenRate Analysis - Gujarat - Pkg-27 PDFAayush AggarwalNoch keine Bewertungen

- Rate Analyses Door and Window FixingDokument1 SeiteRate Analyses Door and Window Fixingsachin_mateNoch keine Bewertungen

- Civil Engg Basic Knowledge PDFDokument3 SeitenCivil Engg Basic Knowledge PDFASHUTOSH GUPTA100% (5)

- Building Material CalculationDokument2 SeitenBuilding Material Calculationbackstreetboy17100% (1)

- Rate Analysis 15-09 Final Road LATESTDokument18 SeitenRate Analysis 15-09 Final Road LATESTKotoju Rajitha SaisindhujaNoch keine Bewertungen

- Data 2019-20Dokument84 SeitenData 2019-20raja sankarNoch keine Bewertungen

- Rate Analysis of Box CulvertDokument3 SeitenRate Analysis of Box CulvertA M100% (1)

- HPC 1000 Single Row 7.5 MDokument2 SeitenHPC 1000 Single Row 7.5 MgagajainNoch keine Bewertungen

- Pradeep Jha June-2019Dokument13 SeitenPradeep Jha June-2019mkpNoch keine Bewertungen

- S.No Item Description Bar Description Bar Dia in MM Cut Length (M) Total Length (M) WT/M (KG) Total WT (KG) Shape No. of BarsDokument6 SeitenS.No Item Description Bar Description Bar Dia in MM Cut Length (M) Total Length (M) WT/M (KG) Total WT (KG) Shape No. of BarsshailendraNoch keine Bewertungen

- DPRDokument166 SeitenDPRRam Narendra NathNoch keine Bewertungen

- KPWD 2019 - Ce 1 PDFDokument35 SeitenKPWD 2019 - Ce 1 PDFmadhuri100% (3)

- Cost Analysis For Brick WorkDokument14 SeitenCost Analysis For Brick WorkVittal Kumar50% (2)

- Nominal Mix Water Cement RatioDokument3 SeitenNominal Mix Water Cement RatioS Muneer HussainNoch keine Bewertungen

- Water Conveyance EstimationDokument26 SeitenWater Conveyance EstimationRajesh SapkotaNoch keine Bewertungen

- Ac Resistance and Reactance 50 HZDokument6 SeitenAc Resistance and Reactance 50 HZJoseph B Delos ReyesNoch keine Bewertungen

- Steel Pipe DimensionsDokument2 SeitenSteel Pipe Dimensionsali osman0% (1)

- 04b. Proracun - Tablica PDFDokument1 Seite04b. Proracun - Tablica PDFANRISNoch keine Bewertungen

- UK PPR DJ PPR STV STV .S PPR DJ PPR STV STV R RU 2-1 2-2 2-3 VL - Ob TR - Ob Uk - Ob Spec. Vl.s Tr.s Uk.s UK Kol Kol PPR PPR 2 C 1Dokument1 SeiteUK PPR DJ PPR STV STV .S PPR DJ PPR STV STV R RU 2-1 2-2 2-3 VL - Ob TR - Ob Uk - Ob Spec. Vl.s Tr.s Uk.s UK Kol Kol PPR PPR 2 C 1ANRISNoch keine Bewertungen

- Government Publications: Key PapersVon EverandGovernment Publications: Key PapersBernard M. FryNoch keine Bewertungen

- Aggregate Moisture and Physical CharDokument22 SeitenAggregate Moisture and Physical CharHitesh JaniNoch keine Bewertungen

- Progress Monitoring SheetDokument2 SeitenProgress Monitoring SheetHitesh JaniNoch keine Bewertungen

- Guj FontDokument2 SeitenGuj FontHitesh JaniNoch keine Bewertungen

- Nitrate Test:: For ExampleDokument2 SeitenNitrate Test:: For ExampleHitesh JaniNoch keine Bewertungen

- Is 9417 1989Dokument15 SeitenIs 9417 1989Ganesh RajaNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument10 SeitenDisclosure To Promote The Right To InformationRoyal JadhavNoch keine Bewertungen

- 2023 2024 Syllabus PDFDokument23 Seiten2023 2024 Syllabus PDFRika DianaNoch keine Bewertungen

- MATH 304 Linear Algebra Lecture 9 - Subspaces of Vector Spaces (Continued) - Span. Spanning Set PDFDokument20 SeitenMATH 304 Linear Algebra Lecture 9 - Subspaces of Vector Spaces (Continued) - Span. Spanning Set PDFmurugan2284Noch keine Bewertungen

- Department of Education: Republic of The PhilippinesDokument2 SeitenDepartment of Education: Republic of The PhilippinesISMAEL KRIS DELA CRUZNoch keine Bewertungen

- DeadlocksDokument41 SeitenDeadlocksSanjal DesaiNoch keine Bewertungen

- Immobilization of Rhodococcus Rhodochrous BX2 (An AcetonitriledegradingDokument7 SeitenImmobilization of Rhodococcus Rhodochrous BX2 (An AcetonitriledegradingSahar IrankhahNoch keine Bewertungen

- Shoshana Bulka PragmaticaDokument17 SeitenShoshana Bulka PragmaticaJessica JonesNoch keine Bewertungen

- Brochure - OasisDokument24 SeitenBrochure - OasisVivek RNoch keine Bewertungen

- Ec 0301Dokument25 SeitenEc 0301Silvio RomanNoch keine Bewertungen

- Chain: SRB Series (With Insulation Grip)Dokument1 SeiteChain: SRB Series (With Insulation Grip)shankarNoch keine Bewertungen

- Calendar of Activities A.Y. 2015-2016: 12 Independence Day (Regular Holiday)Dokument3 SeitenCalendar of Activities A.Y. 2015-2016: 12 Independence Day (Regular Holiday)Beny TawanNoch keine Bewertungen

- The Handmaid's TaleDokument40 SeitenThe Handmaid's Taleleher shahNoch keine Bewertungen

- Lecture 7 - Friction - NptelDokument18 SeitenLecture 7 - Friction - Nptels_murugan02Noch keine Bewertungen

- Random Questions From Various IIM InterviewsDokument4 SeitenRandom Questions From Various IIM InterviewsPrachi GuptaNoch keine Bewertungen

- CBC DrivingDokument74 SeitenCBC DrivingElonah Jean ConstantinoNoch keine Bewertungen

- Ortho TechnologyDokument196 SeitenOrtho Technologyr3doc3Noch keine Bewertungen

- Task of ProjectDokument14 SeitenTask of ProjectAbdul Wafiy NaqiuddinNoch keine Bewertungen

- On The Wings of EcstasyDokument79 SeitenOn The Wings of Ecstasygaya3mageshNoch keine Bewertungen

- NamalDokument5 SeitenNamalAyusnab KarkiNoch keine Bewertungen

- XXXX96 01 01 2023to28 08 2023Dokument18 SeitenXXXX96 01 01 2023to28 08 2023dabu choudharyNoch keine Bewertungen

- A Method For Prediction of Gas/Gas Ejector PerformanceDokument6 SeitenA Method For Prediction of Gas/Gas Ejector PerformancedhavaleshNoch keine Bewertungen

- Chapter 4 Signal Flow GraphDokument34 SeitenChapter 4 Signal Flow GraphAbhishek PattanaikNoch keine Bewertungen

- Final Lesson PlanDokument3 SeitenFinal Lesson Planapi-510713019Noch keine Bewertungen

- ENSC1001 Unit Outline 2014Dokument12 SeitenENSC1001 Unit Outline 2014TheColonel999Noch keine Bewertungen