Beruflich Dokumente

Kultur Dokumente

Aluminium Alloy en Ab-47100: Chemical Designation: en Ab-Alsi12Cu1 (Fe) Swedish Standard: Type - , (1)

Hochgeladen von

Roberto Mendoza Villamil0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

155 Ansichten1 SeiteThis document summarizes the properties and applications of the aluminium alloy EN AB-47100. It is an eutectic alloy with excellent castability, fluidity, and resistance to hot tearing. It is suitable for complicated thin-wall, pressure-tight castings subjected to fatigue loading. The alloy has good machinability and satisfactory mechanical properties but poor weldability and resistance to corrosion.

Originalbeschreibung:

ficha tecnica AL

Originaltitel

AlSi12cu

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document summarizes the properties and applications of the aluminium alloy EN AB-47100. It is an eutectic alloy with excellent castability, fluidity, and resistance to hot tearing. It is suitable for complicated thin-wall, pressure-tight castings subjected to fatigue loading. The alloy has good machinability and satisfactory mechanical properties but poor weldability and resistance to corrosion.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

155 Ansichten1 SeiteAluminium Alloy en Ab-47100: Chemical Designation: en Ab-Alsi12Cu1 (Fe) Swedish Standard: Type - , (1)

Hochgeladen von

Roberto Mendoza VillamilThis document summarizes the properties and applications of the aluminium alloy EN AB-47100. It is an eutectic alloy with excellent castability, fluidity, and resistance to hot tearing. It is suitable for complicated thin-wall, pressure-tight castings subjected to fatigue loading. The alloy has good machinability and satisfactory mechanical properties but poor weldability and resistance to corrosion.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

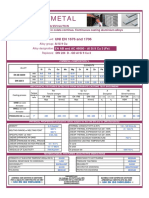

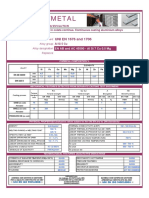

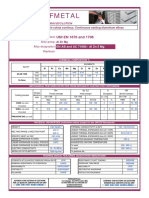

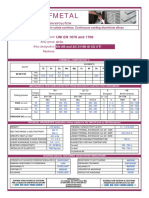

Aluminium alloy EN AB-47100

Chemical designation: EN AB-AlSi12Cu1(Fe)

Swedish standard: Type -, [1], [2]

Chemical composition1:

Min % Max %

General description of properties:

Si 10,5 13,5 Eutectic alloy with excellent castability

properties, excellent fluidity and high

Fe 0,6 1,1

resistance to hot tearing. Good machinability.

Cu 0,7 1,2

Suitable applications:

Mn - 0,55

For complicated thin-wall, pressure-tight

Mg - 0,35 casting that are subjected to fatigue loading.

Cr - 0,10

Heat treatment:

Ni - 0,30 Not usually age hardened

Zn - 0,55

Pb - 0,20

Sn - 0,10

Ti - 0,15

Others each max 0,05%

and total max 0,25%

Casting characteristics2:

Solidification Casting Fluidity Resistance to hot Shrinkage Pressure

range, ºC, about temperature ºC, tearing %, about tightness

about

580-530 650-700 Excellent Excellent 0,5-0,8 Excellent

Mechanical properties of separately untreated cast test bars2:

Tensile strength, Proof stress Elongation Brinell hardness

Rm, MPa, min. Rp0,2, MPa, min. A50, %, min. HBS, min.

240 140 1 70

Mechanical and physical properties2:

Density Strength Machinability Weldability Resistance to

kg/dm³ corrosion

2,65 Good Satisfact. Poor Satisfact.

Decorative Ability to be Linear thermal Electrical conductivity Thermal conductivity

anodizing polished expansion MS/m W/mºK

293-373ºK, ºK¯¹

Not recom. Satisfact. 20 x 10¯6 15 – 20 120 - 150

[1]: SS-EN 1676:2010

[2]: SS-EN 1706:2010

Das könnte Ihnen auch gefallen

- Raffmetal: UNI EN 1676 and 1706Dokument2 SeitenRaffmetal: UNI EN 1676 and 1706Raj RajeshNoch keine Bewertungen

- CuZn10-PNA 222 - ENDokument2 SeitenCuZn10-PNA 222 - ENjurreijndersNoch keine Bewertungen

- Cu ZN 15 TombacDokument2 SeitenCu ZN 15 TombacPetrus UngureanuNoch keine Bewertungen

- eng-EN AB-46100Dokument1 Seiteeng-EN AB-46100Akram Ben KhemisNoch keine Bewertungen

- Raffmetal: UNI EN 1676 and 1706Dokument2 SeitenRaffmetal: UNI EN 1676 and 1706Martin DuarteNoch keine Bewertungen

- 570 950mpa High Tensile Strength SteelDokument32 Seiten570 950mpa High Tensile Strength SteelAde Aidil SyuhadaNoch keine Bewertungen

- Raffmetal: UNI EN 1676 and 1706Dokument2 SeitenRaffmetal: UNI EN 1676 and 1706satheeskumar VikramasingarajNoch keine Bewertungen

- Copper Cu-Dhp / Sf-Cu: Page 1/2Dokument2 SeitenCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNoch keine Bewertungen

- Alloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)Dokument1 SeiteAlloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)rahul vermaNoch keine Bewertungen

- Raffmetal: UNI EN 1676 and 1706Dokument2 SeitenRaffmetal: UNI EN 1676 and 1706Sachin JawaleNoch keine Bewertungen

- Aluminium AlMgSiDokument1 SeiteAluminium AlMgSiAsmir OmeragicNoch keine Bewertungen

- Aluminium Alloy 5251 H22 JWD TDSDokument1 SeiteAluminium Alloy 5251 H22 JWD TDSTALHA AHMADNoch keine Bewertungen

- Aluminium Alloy 5754 Data SheetDokument1 SeiteAluminium Alloy 5754 Data Sheetprasanth cpNoch keine Bewertungen

- Cu Etp c11000 Pna - 211 sm0008 - enDokument2 SeitenCu Etp c11000 Pna - 211 sm0008 - enNitin KumarNoch keine Bewertungen

- EN71000 From ReinferdenDokument2 SeitenEN71000 From ReinferdenJason WuNoch keine Bewertungen

- eng-EN AB-46000Dokument1 Seiteeng-EN AB-46000Dragan PilipovićNoch keine Bewertungen

- Alloy Data Sheet En-Aw 6101B (Ealmgsib) : Type: High Conductivity Alloy)Dokument1 SeiteAlloy Data Sheet En-Aw 6101B (Ealmgsib) : Type: High Conductivity Alloy)Bouchra SonsuzaNoch keine Bewertungen

- eng-EN AB-44300Dokument1 Seiteeng-EN AB-44300Akram Ben KhemisNoch keine Bewertungen

- Cu ZN 15Dokument2 SeitenCu ZN 15wjjt6chgtmNoch keine Bewertungen

- Aluminium Alloy 6082 - T6 T651 PlateDokument2 SeitenAluminium Alloy 6082 - T6 T651 Plateyokartik100% (1)

- Raffmetal: UNI EN 1676 and 1706Dokument2 SeitenRaffmetal: UNI EN 1676 and 1706Amandeep SinghNoch keine Bewertungen

- Steel PropertiesDokument22 SeitenSteel PropertiesMOHD SALMANNoch keine Bewertungen

- Eural-6082-EN RohsDokument1 SeiteEural-6082-EN RohsRoger ColomaNoch keine Bewertungen

- Cu ZN 20Dokument2 SeitenCu ZN 20wjjt6chgtmNoch keine Bewertungen

- EN47100Dokument2 SeitenEN47100tsonjayaNoch keine Bewertungen

- CuZn10-PNA 222 - ENDokument2 SeitenCuZn10-PNA 222 - ENYulwido AdiNoch keine Bewertungen

- Cu ZN 10Dokument2 SeitenCu ZN 10wjjt6chgtmNoch keine Bewertungen

- Material Datasheet Cu-OFDokument2 SeitenMaterial Datasheet Cu-OFmohsen_267Noch keine Bewertungen

- Nom de L'alliage UtiliséDokument1 SeiteNom de L'alliage UtiliséAkram Ben KhemisNoch keine Bewertungen

- Raffmetal: UNI EN 1676 and 1706Dokument1 SeiteRaffmetal: UNI EN 1676 and 1706swaroop NalamNoch keine Bewertungen

- Data Sheet CuZn20Al2AsDokument1 SeiteData Sheet CuZn20Al2AsJean Carlos Reyna PascualNoch keine Bewertungen

- Datasheet For Steel Grades Specialsteel X6Crnimob17-12-2Dokument3 SeitenDatasheet For Steel Grades Specialsteel X6Crnimob17-12-2axis inspection solutionsNoch keine Bewertungen

- Cu ZN 05Dokument2 SeitenCu ZN 05wjjt6chgtmNoch keine Bewertungen

- Raffmetal: UNI EN 1676 and 1706Dokument2 SeitenRaffmetal: UNI EN 1676 and 1706Hareth MRAIDINoch keine Bewertungen

- Raffmetal: UNI EN 1676 and 1706Dokument2 SeitenRaffmetal: UNI EN 1676 and 1706Raj RajeshNoch keine Bewertungen

- Alloy 6082 - Rev2012Dokument2 SeitenAlloy 6082 - Rev2012Ysraels Santisteban DurandNoch keine Bewertungen

- Yellow: LM6 (EN 1706 AC-44100) Aluminium Casting AlloyDokument3 SeitenYellow: LM6 (EN 1706 AC-44100) Aluminium Casting AlloySohail ShaikhNoch keine Bewertungen

- Cu Ofe c10100 Pna 203 - enDokument2 SeitenCu Ofe c10100 Pna 203 - enNitin KumarNoch keine Bewertungen

- Kme STOL76 C19010 enDokument1 SeiteKme STOL76 C19010 enMattia Terri TerrandoNoch keine Bewertungen

- Aluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesDokument3 SeitenAluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesBeni hidayatullahNoch keine Bewertungen

- Callister - Fundamentals of Materials Science and Engineering 5e HQDokument2 SeitenCallister - Fundamentals of Materials Science and Engineering 5e HQsathwikNoch keine Bewertungen

- CuZn30-PNA 226 - ENDokument2 SeitenCuZn30-PNA 226 - ENNHadesNoch keine Bewertungen

- Aluminium-Alloy-6082-T6 or T651Dokument2 SeitenAluminium-Alloy-6082-T6 or T651Marcelo Noé CorsiNoch keine Bewertungen

- CuFe2p - AurubisDokument2 SeitenCuFe2p - AurubisJan NoscilNoch keine Bewertungen

- B - Boehler NiMo 1-IG - de - en - 5Dokument1 SeiteB - Boehler NiMo 1-IG - de - en - 5cristian popescuNoch keine Bewertungen

- Material Datasheet Cuzn30Dokument2 SeitenMaterial Datasheet Cuzn30alex94kgNoch keine Bewertungen

- YAWATA 7018: Classification Applications Characteristics ApprovalsDokument1 SeiteYAWATA 7018: Classification Applications Characteristics ApprovalsDenny AgusNoch keine Bewertungen

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Dokument3 SeitenAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Karan NanwaniNoch keine Bewertungen

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Dokument3 SeitenAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338minhyen88Noch keine Bewertungen

- Cuznpb2 LeadedDokument3 SeitenCuznpb2 Leadedwjjt6chgtmNoch keine Bewertungen

- Al 99.5 AW 10-50 Aluminium A 1050 Technical Data Sheet RLSADokument2 SeitenAl 99.5 AW 10-50 Aluminium A 1050 Technical Data Sheet RLSAAlex GăuruşNoch keine Bewertungen

- Cu-HCP: C10300 Industrial RolledDokument7 SeitenCu-HCP: C10300 Industrial RolledpierocarnelociNoch keine Bewertungen

- Data Sheet: 304/304L Stainless SteelDokument2 SeitenData Sheet: 304/304L Stainless SteelFranco SwanepoelNoch keine Bewertungen

- Cuzn37-Pna 243 enDokument2 SeitenCuzn37-Pna 243 enAbrahan Tinco PariNoch keine Bewertungen

- Nedal Alloy Datasheet EN AW 7108ADokument1 SeiteNedal Alloy Datasheet EN AW 7108ANico VazquezNoch keine Bewertungen

- Low Alloy WiresDokument10 SeitenLow Alloy WiresRyan KimNoch keine Bewertungen

- S-8018 B2Dokument5 SeitenS-8018 B2Abhishek AnandNoch keine Bewertungen

- UTP 6222 MoDokument1 SeiteUTP 6222 ModantegimenezNoch keine Bewertungen

- Thermal Spray Coatings: Ads Ta, E'Dokument6 SeitenThermal Spray Coatings: Ads Ta, E'Darryl007Noch keine Bewertungen

- Science: Quarter 2 - : Carbon Compounds General Classes and Its UsesDokument22 SeitenScience: Quarter 2 - : Carbon Compounds General Classes and Its UsesPsycho Kpop OtakuNoch keine Bewertungen

- Group 10 Data Sheet Alcohols and PhenolsDokument3 SeitenGroup 10 Data Sheet Alcohols and PhenolsJovan Paul DeldaNoch keine Bewertungen

- Chapter 19 NHDokument89 SeitenChapter 19 NH蔡易斈Noch keine Bewertungen

- (Review of Analysis 1 and Introduction) : Chemical/ General MethodDokument1 Seite(Review of Analysis 1 and Introduction) : Chemical/ General MethodJean GanubNoch keine Bewertungen

- Steel Equivalent Table: en / BS To SAE - Page 1 of 20Dokument3 SeitenSteel Equivalent Table: en / BS To SAE - Page 1 of 20LASCARZAMFIRESCUNoch keine Bewertungen

- Optimization Raja 2015 PDFDokument46 SeitenOptimization Raja 2015 PDFDiego RodriguezNoch keine Bewertungen

- Chemicals Zetag MSDS Inverse Emulsion Zetag 8848 FS - 0710Dokument6 SeitenChemicals Zetag MSDS Inverse Emulsion Zetag 8848 FS - 0710PromagEnviro.comNoch keine Bewertungen

- CFNS Experiment 54 - Colourful ElectrolysisDokument3 SeitenCFNS Experiment 54 - Colourful ElectrolysisSyed Iftikhar Hussain ShahNoch keine Bewertungen

- Labs A&B - The Two-Step Synthesis of AspirinDokument12 SeitenLabs A&B - The Two-Step Synthesis of AspirinSabrina LiNoch keine Bewertungen

- Binder PDFDokument55 SeitenBinder PDFRaju NiraulaNoch keine Bewertungen

- Production of BioplasticDokument7 SeitenProduction of Bioplasticpritesh tamboliNoch keine Bewertungen

- Chapter 1 & Chapter 2 - Chemistry and LifeDokument25 SeitenChapter 1 & Chapter 2 - Chemistry and Lifeprehealthhelp100% (6)

- Cologne Making 1Dokument5 SeitenCologne Making 1Von Joby RomeroNoch keine Bewertungen

- Organic Nitrogen CompoundsDokument9 SeitenOrganic Nitrogen CompoundsSaranga BuwanekaNoch keine Bewertungen

- (Worksheet 2.1) - (Acids Bases and Salts)Dokument10 Seiten(Worksheet 2.1) - (Acids Bases and Salts)AnilNoch keine Bewertungen

- Program Pecutan Akhir Chemistry SPM 2012 2Dokument14 SeitenProgram Pecutan Akhir Chemistry SPM 2012 2Zuliana ZolkafliNoch keine Bewertungen

- ITW Product Catalog21 PDFDokument1 SeiteITW Product Catalog21 PDFjohnNoch keine Bewertungen

- Organic ConceptsDokument83 SeitenOrganic ConceptsAlisha Roy ChoudharyNoch keine Bewertungen

- Week 4 - Classification of Matter and Separating MixturesDokument25 SeitenWeek 4 - Classification of Matter and Separating MixturesyvetteNoch keine Bewertungen

- Stock 07 Oktober 2022Dokument19 SeitenStock 07 Oktober 2022Dwi AnggrainiNoch keine Bewertungen

- Chapter One 1.0 Introduction To Siwes ProgrameDokument51 SeitenChapter One 1.0 Introduction To Siwes ProgrameUzoma EmekaNoch keine Bewertungen

- Activated Carbon From Corn Cobs and Coconut Shell For Heavy Metal Ions AdsorptionDokument8 SeitenActivated Carbon From Corn Cobs and Coconut Shell For Heavy Metal Ions AdsorptionS Bharadwaj Reddy100% (1)

- Httppostedfile Track Eqp 1feb11 23393Dokument12 SeitenHttppostedfile Track Eqp 1feb11 23393dorao80Noch keine Bewertungen

- Aspirin and SoapDokument4 SeitenAspirin and SoapyeeeyyyNoch keine Bewertungen

- How Is Plastic Made A Simple Step-By-Step ExplanationDokument12 SeitenHow Is Plastic Made A Simple Step-By-Step Explanationsalemg82Noch keine Bewertungen

- Scotch-Weld Epoxy Adhesive DP460, DP460NS-349252Dokument9 SeitenScotch-Weld Epoxy Adhesive DP460, DP460NS-349252sinofreebirdNoch keine Bewertungen

- Nickel Aluminum Bronze GuideDokument9 SeitenNickel Aluminum Bronze GuideAnoir AkkariNoch keine Bewertungen

- Is.1446.2002 Class of Dang GoodsDokument88 SeitenIs.1446.2002 Class of Dang GoodsMD ParthiNoch keine Bewertungen

- CHM243 Final Exam #2 2011Dokument15 SeitenCHM243 Final Exam #2 2011XiaohanJinNoch keine Bewertungen