Beruflich Dokumente

Kultur Dokumente

A85780-20 Attachment 18 To Ir No. 5.1 - l3r-Wpds-18 Rev. 0 - A5t7s2

Hochgeladen von

BoulHich BoulHichOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

A85780-20 Attachment 18 To Ir No. 5.1 - l3r-Wpds-18 Rev. 0 - A5t7s2

Hochgeladen von

BoulHich BoulHichCopyright:

Verfügbare Formate

Enbridge Pipelines Inc. Enbridge Response to NEB IR No.

5 - Condition 21

Line 3 Replacement Program Attachment 18 to IR No. 5.1

Filed August 31, 2017

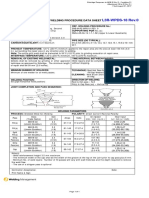

REPAIR WELDING PROCEDURE DATA SHEET L3R-WPDS-18 Rev.0

PROJECT: LINE 3 REPLACEMENT REF. WELDING PROCEDURE No.:

APPLICATION: Weld Repair Welding, Second ENB-M-R2-WPS-01 REV. 0

Repair (partial through-wall repair only) SUPPORTING PQR No.(s):

SERVICE TEMPERATURE : -5°C RMS-L3R-36-19.1-7-1-R2 (Upper & Lower Quadrants)

CODE : CSA Z662-15

SPECIFICATION : Enbridge PCS002-Version 3.0

MATERIAL GRADE: ≤483 MPa (SMYS) PIPE SIZE (OD TYPICAL):

CARBON EQUIVALENT: 0.31 Maximum 914.4 mm (36.0 in.) X 11.8, 12.4, 12.7, 12.8, 15.1, 15.9 & 19.1 mm

W.T.

PREHEAT TEMPERATURE: 120°C (250°F) minimum applied to the repair area and the area at least 150 mm (6.0

in.) surrounding the repair area in any direction prior to welding.

Note: The entire girth weld shall be preheated to 50°C (122°F) prior to grinding excavation of repair area.

INTERPASS TEMPERATURE: 120°C (250°F) minimum, 191°C (376°F) maximum.

REMOVAL OF EXISTING WELD METAL: TIME INTERVAL BETWEEN PASSES:

Defects shall be removed by grinding or other approved Weld repairs shall be completed in a full operation

technique as approved by Enbridge. The minimum length without stopping.

of repair shall be 50 mm (2.0 inches).

MINIMUM NUMBER OF WELDERS: TECHNIQUE: Root/Hot Pass-N/A

Minimum of one welder for all weld passes. Fill/Cap-Weave/Stringer

CLEANING: Wire brush and/or grind as required, remove

all slag.

WELDING POSITION: DIRECTION OF WELDING:

5G (pipe horizontal fixed position) Root & Hot pass – N/A

Fill(s) & Cap Pass (es) – Vertical Up

JOINT COMPLETION AND PASS SEQUENCE:

WELDING PARAMETERS

PROCESS: Shielded Metal Arc Welding POLARITY: Direct Current Reverse Polarity

Class Size Arc Speed Heat Input

Pass Amps Volts

(Trade Name) mm (in.) mm / min. (i.p.m.) kJ / mm (J / inch)

E8018-C3 2.4 48-183 0.59–2.26

Fill(s) 67-113 17.2-27.0

(Lincoln Excalibur) (3/32) (1.9-7.2) (14,986-57,404)

E8018-C3 3.2 46-102 1.38-3.47

Fill(s) 81-148 17-27.4

(Lincoln Excalibur) (1/8) (1.8-4.0) (35,052-88,138)

Split E8018-C3 3.2 56-135 1.14-2.56

91-143 17.4-26.8

Fill(s) (Lincoln Excalibur) (1/8) (2.2-5.3) (28,956-65,024)

Strip E8018-C3 2.4 107-163 0.68-1.02

67-100 18.3-27.4

Pass(es) (Lincoln Excalibur) (3/32) (4.2-6.4) (17,272-25,908)

Strip E8018-C3 3.2 71-112 1.35-2.10

94-140 17.8-27.4

Pass(es) (Lincoln Excalibur) (1/8) (2.8-4.4) (34,290-53,340)

E8018-C3 3.2 64-122 1.25-2.14

Cap 88-142 17-27.4

(Lincoln Excalibur) (1/8) (2.5-4.8) (31,570-54,356)

Note(s)

- Weld reinforcement height 3.5 mm maximum.

- The minimum width of the cap shall be the width of the groove at the top of the joint prior to cap pass plus 6 mm.

- Minimum No. of weld layers: Number of fill passes will vary with wall thickness and the depth required to remove

the weld flaw.

- The use of a stripper pass is optional

Contractor Acceptance: Date:

Print Name & Sign

Page 1 of 1

Das könnte Ihnen auch gefallen

- SB05 02 Rev. 2 October 15 2018Dokument4 SeitenSB05 02 Rev. 2 October 15 2018BoulHich BoulHichNoch keine Bewertungen

- A85780-20 Attachment 18 To Ir No. 5.1 - l3r-Wpds-18 Rev. 0 - A5t7s2Dokument1 SeiteA85780-20 Attachment 18 To Ir No. 5.1 - l3r-Wpds-18 Rev. 0 - A5t7s2BoulHich BoulHichNoch keine Bewertungen

- Hot Tapping Checklist GuideDokument6 SeitenHot Tapping Checklist GuideBoulHich BoulHichNoch keine Bewertungen

- What Is A Hot Tap, Why It Is Made and How To Make A Hot Tap in A Pipe LineDokument9 SeitenWhat Is A Hot Tap, Why It Is Made and How To Make A Hot Tap in A Pipe LineBoulHich BoulHichNoch keine Bewertungen

- A0K5Y4 - Attachment No. 1 - Specification SP 51-32 Rev. 2Dokument32 SeitenA0K5Y4 - Attachment No. 1 - Specification SP 51-32 Rev. 2BoulHich BoulHichNoch keine Bewertungen

- A2D6V0 R2 O MSM 0510 InstallationOfHotTapConnectionsDokument14 SeitenA2D6V0 R2 O MSM 0510 InstallationOfHotTapConnectionsShahrin KamaruzamanNoch keine Bewertungen

- PTC 2017 AchterkampDokument12 SeitenPTC 2017 AchterkampBoulHich BoulHichNoch keine Bewertungen

- NoiseMap - Real-Time Participatory Noise MapsDokument5 SeitenNoiseMap - Real-Time Participatory Noise MapsBoulHich BoulHichNoch keine Bewertungen

- Metal fastener corrosion models predict timber structure service lifeDokument9 SeitenMetal fastener corrosion models predict timber structure service lifeBoulHich BoulHichNoch keine Bewertungen

- Pipe Material Specs (MCP)Dokument106 SeitenPipe Material Specs (MCP)BoulHich BoulHichNoch keine Bewertungen

- Code of ConductDokument1 SeiteCode of Conductangeloflight179Noch keine Bewertungen

- Pipeline External Corrosion Analysis Using A 3D Laser ScannerDokument9 SeitenPipeline External Corrosion Analysis Using A 3D Laser ScannerBoulHich BoulHichNoch keine Bewertungen

- A85780-20 Attachment 18 To Ir No. 5.1 - l3r-Wpds-18 Rev. 0 - A5t7s2Dokument1 SeiteA85780-20 Attachment 18 To Ir No. 5.1 - l3r-Wpds-18 Rev. 0 - A5t7s2BoulHich BoulHichNoch keine Bewertungen

- Oil & Gas Solutions: Trelleborg Fluid Handling SolutionsDokument20 SeitenOil & Gas Solutions: Trelleborg Fluid Handling SolutionssegunoyesNoch keine Bewertungen

- PTC 2017 AchterkampDokument12 SeitenPTC 2017 AchterkampBoulHich BoulHichNoch keine Bewertungen

- SMAW Welding Guidelines for Safety and ProceduresDokument28 SeitenSMAW Welding Guidelines for Safety and ProceduresD S Sagar TripuramalluNoch keine Bewertungen

- 2 JASA2008v123 p1706 StreamingDokument15 Seiten2 JASA2008v123 p1706 StreamingBoulHich BoulHichNoch keine Bewertungen

- Oil & Gas Solutions: Trelleborg Fluid Handling SolutionsDokument20 SeitenOil & Gas Solutions: Trelleborg Fluid Handling SolutionssegunoyesNoch keine Bewertungen

- Sampling Phased Array - A New Technique For Signal Processing and Ultrasonic ImagingDokument12 SeitenSampling Phased Array - A New Technique For Signal Processing and Ultrasonic ImagingBoulHich BoulHichNoch keine Bewertungen

- Met 54 3 539 542 PDFDokument4 SeitenMet 54 3 539 542 PDFBoulHich BoulHichNoch keine Bewertungen

- Sampling Phased Array - A New Technique For Signal Processing and Ultrasonic ImagingDokument12 SeitenSampling Phased Array - A New Technique For Signal Processing and Ultrasonic ImagingBoulHich BoulHichNoch keine Bewertungen

- Research Article: A Theoretical Model For Metal Corrosion DegradationDokument8 SeitenResearch Article: A Theoretical Model For Metal Corrosion DegradationBoulHich BoulHichNoch keine Bewertungen

- Met 54 3 539 542 PDFDokument4 SeitenMet 54 3 539 542 PDFBoulHich BoulHichNoch keine Bewertungen

- Pipeline External Corrosion Analysis Using A 3D Laser ScannerDokument9 SeitenPipeline External Corrosion Analysis Using A 3D Laser ScannerBoulHich BoulHichNoch keine Bewertungen

- PTC 2017 AchterkampDokument12 SeitenPTC 2017 AchterkampBoulHich BoulHichNoch keine Bewertungen

- Dot 22407 DS1Dokument95 SeitenDot 22407 DS1BoulHich BoulHichNoch keine Bewertungen

- Corrosion protection of flanges and valves field trial resultsDokument7 SeitenCorrosion protection of flanges and valves field trial resultsBoulHich BoulHichNoch keine Bewertungen

- 6869-24178-1-SM - Do Sau An Mon Theo KlinsmithDokument10 Seiten6869-24178-1-SM - Do Sau An Mon Theo KlinsmithLe Anh Thu KhuatNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Fireball Tool Vise Build GuideDokument15 SeitenFireball Tool Vise Build GuideRadu RA100% (2)

- Self Tapping Vs Self Drilling Vs Sheet Metal Screws GuideDokument1 SeiteSelf Tapping Vs Self Drilling Vs Sheet Metal Screws GuideMac-Ross CordovaNoch keine Bewertungen

- Iso 9268 1988Dokument9 SeitenIso 9268 1988Uswatun KhasanahNoch keine Bewertungen

- European Steel and Alloy Grades: 50crmov13-15 (1.2355)Dokument2 SeitenEuropean Steel and Alloy Grades: 50crmov13-15 (1.2355)farshid KarpasandNoch keine Bewertungen

- Experienced CNC Machinist Seeking New OpportunityDokument3 SeitenExperienced CNC Machinist Seeking New OpportunityYhuna JcerNoch keine Bewertungen

- Lec2 Lathe MachineDokument70 SeitenLec2 Lathe MachineFELIX KEUYANoch keine Bewertungen

- Side Milling: Operation On Milling MachineDokument21 SeitenSide Milling: Operation On Milling MachineChris NIrvanaNoch keine Bewertungen

- Armox 370T Class 1: General Product DescriptionDokument2 SeitenArmox 370T Class 1: General Product DescriptionSuneelNoch keine Bewertungen

- Ferrous Metallurgy Non-Ferrous MetallurgyDokument2 SeitenFerrous Metallurgy Non-Ferrous MetallurgySathish KumarNoch keine Bewertungen

- Quality Control PlanDokument1 SeiteQuality Control PlanJoki PenangNoch keine Bewertungen

- Boring BasicsDokument4 SeitenBoring Basicsnandhu1977Noch keine Bewertungen

- CNC Programming PDFDokument63 SeitenCNC Programming PDFVinay ChilukuriNoch keine Bewertungen

- Table A-1 Basic Allowable Stresses in Tension For MetalsDokument28 SeitenTable A-1 Basic Allowable Stresses in Tension For MetalsMohamed ElsayedNoch keine Bewertungen

- Improve Aluminum Casting with Smoother MoldsDokument1 SeiteImprove Aluminum Casting with Smoother MoldsNurulSyafiqah0% (1)

- Material Removal Processes (IM 213) : Arab Academy For Science, Technology, and Maritime TransportDokument22 SeitenMaterial Removal Processes (IM 213) : Arab Academy For Science, Technology, and Maritime TransportNicolas EleftheriouNoch keine Bewertungen

- Surface Hardening of Steels PDFDokument319 SeitenSurface Hardening of Steels PDFHaydee VNoch keine Bewertungen

- Fed STD H28aDokument11 SeitenFed STD H28amurphygtNoch keine Bewertungen

- TA-201 Lab MannualDokument19 SeitenTA-201 Lab MannualAnujNagpalNoch keine Bewertungen

- DIY Disk Sander 2 - WoodArchivistDokument5 SeitenDIY Disk Sander 2 - WoodArchivistEricsNoch keine Bewertungen

- Tools and machinery specificationsDokument4 SeitenTools and machinery specificationsMohd Dinie HafiqNoch keine Bewertungen

- Imperial Thread Chart (Threads Per Inch)Dokument2 SeitenImperial Thread Chart (Threads Per Inch)Otto Waldmann-MoloneyNoch keine Bewertungen

- Making Minature ChainDokument5 SeitenMaking Minature ChainJF LuisNoch keine Bewertungen

- K KL2 0 C0069 BDokument15 SeitenK KL2 0 C0069 BRaduIonNoch keine Bewertungen

- Forming Interview Questions and Answers For Freshers - SanfoundryDokument4 SeitenForming Interview Questions and Answers For Freshers - SanfoundryrahmaNoch keine Bewertungen

- Aluminum Die Casting Process FlowDokument13 SeitenAluminum Die Casting Process FlowPrabish KumarNoch keine Bewertungen

- Kreg Jig Potting Bench InstructionsDokument4 SeitenKreg Jig Potting Bench InstructionsSteven Taylor100% (2)

- Gleason To Demonstrate Advanced Bevel and Cylindrical Gear Production and Inspection Solutions at IMTS 2014Dokument4 SeitenGleason To Demonstrate Advanced Bevel and Cylindrical Gear Production and Inspection Solutions at IMTS 2014Dogaru RazvanNoch keine Bewertungen

- Pickling HandbookDokument32 SeitenPickling HandbookPradeepNoch keine Bewertungen

- Amp ProjectDokument14 SeitenAmp Projectshankar biradarNoch keine Bewertungen

- Follow A Myford Lathe Rebuild - Myford Factory RebuildsDokument13 SeitenFollow A Myford Lathe Rebuild - Myford Factory Rebuildsalexandrubudu100% (2)