Beruflich Dokumente

Kultur Dokumente

Design and Fabrication of Human Powered Swing For Electricity Generation

Hochgeladen von

OmkarOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design and Fabrication of Human Powered Swing For Electricity Generation

Hochgeladen von

OmkarCopyright:

Verfügbare Formate

Recent Innovations in Science and Engineering - RISE 2016

30th April 2016

Design and Fabrication of Human Powered Swing

for Electricity Generation

Gokul S P1, Cyril John Tellis2, Joash Anchan3, Nikilesh Reddy Kalluri4

1

Student, Department of Mechanical Engineering, PES Institute of Technology-Bangalore South Campus,

Electronic City, Hosur Road, Bangalore-560100, India

2

Student, Department of Mechanical Engineering, PES Institute of Technology-Bangalore South Campus,

Electronic City, Hosur Road, Bangalore-560100, India

3

Student, Department of Mechanical Engineering, PES Institute of Technology-Bangalore South Campus,

Electronic City, Hosur Road, Bangalore-560100, India

4

Student, Department of Mechanical Engineering, PES Institute of Technology-Bangalore South Campus,

Electronic City, Hosur Road, Bangalore-560100, India

Abstract: Electricity need of today’s modern world is growing day by day because of continues increase in consumption due to

growing population. Many concepts are being carried out to generate electricity on local basis and utilize the same for said to locality.

This paper is about a swing, which is used by children for playing that produces electricity while being used. In it simple construction,

the swinging action of swing makes the horizontal beam member turn through some angle. This horizontal shaft is connected to a wheel

which turns along with it. Now this motion is transferred onto another ring of small diameter which rotates proportional to the angle of

swing of the big wheel, in this was angular movement is converted to complete rotations. This is done by using a flexible leather belt

connecting both the wheels externally. The smaller ring is connected to a step up transforming which in this case is used as a motor to

generate electricity. This is done by rotation of the ring cutting flux lines inside the motor. This electricity generation takes place in both

to and fro motion of the swing which makes the electricity generated in AC form. This is converted to DC current and amplified by

using a special circuit of a bridge rectifier. The electricity thus produced is free of cost and is ecologically friendlier and can be used for

local use by storing it in a battery during the time of operation. This way of generation of electricity if implemented at various parks,

play houses, schools etc. can certainly lower down the load on main grid thus helping saving electricity.

Keywords: human powered swing, electricity generation, mechanical energy, eco-friendly

1.Introduction in construction. The lower efficiency of the resulting system

is compensated by the simplicity, safety, low-cost of

Energy is the driving force of modern societies, and operation and low maintenance cost.

generation and utilization of energy are essential for

socioeconomic development. Per-capita energy consumption The swing can be used in any atmospheric conditions, no

levels are often considered a good measure of economic heavy equipment are used and no harmful effects for the child

development. In recent years, energy scarcity has become a using it. The electricity can be stored in batteries, and used to

serious problem due to depletion of non-renewable energy power dc-operated lights and appliances.

sources, increasing population, globalization of energy

intensive economic development, environmental pollution, In this paper we have proposed a methodology in which we

and global warming. generate electricity during both forward and backward motion

of the swing, without adding any resistance to the person

In recent years, there have been many interesting swinging. This is done by using a wheel and belt mechanism

developments in the field of human power conversion. In the and converting the AC output generated to DC using a

present project, a method of harnessing the power of suitable mechanism makes the construction simple.

children's play in playgrounds and public places, on device

such as swing is proposed. 2.Objective

When large number of children plays in a school playground, The objective of the paper is to provide a method to convert

part of the power of their play can usefully be harnessed obtained mechanical energy during the movement of seating

resulting in significant energy storage. This stored energy can of swing set into electrical energy along with no added effort

then be converted to electricity for powering basic, low power and also storing the electricity thus generated into a battery,

appliances in the school such as lights, fans, communications which can be utilized whenever needed.

equipment, and so on. The method provides a low-cost, low-

resource means of generation of auxiliary electric power, 3.Methodology

especially for use in developing countries.

3.1 Working Principle

In the proposed method, a simple belt and wheel mechanism

is used along with a motor to generation and storage of During the forward and backward stroke of swing some

electricity. Use of this method is very economical and simple torque is induced in shaft. This torque produces motion in the

PES Institute of Technology, Bangalore South Campus, Bangalore, India

www.pes.edu

Recent Innovations in Science and Engineering - RISE 2016

30th April 2016

wheel attached to the shaft which produces motion in the

smaller wheel connected, which is in turn connected to the

motor by which electricity is generated.

The shaft is mounted between two bearings. At one end of the

shaft a large wheel is attached rigidly, this wheel pivots over

shaft axis when the shaft is displaced. The larger wheel is

attached to a smaller wheel using belt. The smaller wheel is

mounted on a motor shaft, on which generator is mounted

with help of screws.

When the seating of the swing set moves in both forward and

backward directions, some torque is induced in the shaft by Figure 2: Part drawing of Side Angle

the holding bars of swing set. This torque displaces the larger

wheel which is pivoted over axis of shaft causing the angular

displacement. This angular movement is converted to

rotational motion of smaller wheel by belt attachment. The

wheel runs the generator, thus producing the electricity. This

electricity is converted by a bridge rectifier and voltage

amplifier. The electricity thus produced is stored in a battery

by using electric circuits.

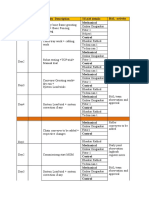

3.2 Design of the Model

Figure 3: Part drawing of Top Link Angle

Figure 1: Model Design

3.3 Design Specifications Figure 4: Part drawing of Bottom Link Angle

3.3.1 L-angles

Steel Angle or L - Angle, is a hot rolled, mild steel angle

shape with inside radius corners that is ideal for all structural

applications, general fabrication and repairs.

Table 1: Specifications of L-angles

(h*h) A Wt./m I

Type T (mm)

mm (cm2) (kg) (cm3)

ISA

30*30 2.26 1.8 4 0.8

3030

Below are shown the required dimensions of the L-angle

used,

Figure 5: Part drawing of Side angle R.H

PES Institute of Technology, Bangalore South Campus, Bangalore, India

www.pes.edu

Recent Innovations in Science and Engineering - RISE 2016

30th April 2016

various members such as pulleys, gears etc, are installed on it.

Material used is C45 Steel

This member causes the shaft to bending. In other words we

may say that a shaft is used for the transmission of torque and

bending. The various members are mounted on the shaft by

means of keys.

Shafts are to be designed on the basis of rigidity considering

the following two types of rigidity.

Figure 6: Part drawing of Side angle L.H

1. Lateral rigidity

3.3.2 Hand Bar and Seat 2. Torsional rigidity

The hand bar connects the shaft and the seat of the swing 1. Lateral Rigidity

through the pad. The main objective of the hand bar is to

provide stability to the motion of the swing and also help It is important in case of transmission, shortening and running

carry the load on the seat. at high speed where small lateral rigidity is also important for

maintaining proper bearing and clearances an for correct gear

The Wooden seat is attached to the MS holding bar rigidly teeth alignment if the shaft is of uniform cross-section then

using fasteners. Here we are using Plywood as material for the lateral deflection of a shaft may be obtained by using the

seat. The seat is attached to the shaft by means of hand bar deflection formulae as in strength of materials.

through pad.

i.e., M/I=σ/y=E/R

Material used: Mild Steel (Hand bar) & Plywood (Wooden

Plate) σ = stress induced in MPa (allowable stress for C45 from

DDHB-2 is 360MPa)

Figures shows the required dimensions of hand bar and E = young’s modulus = 200MPa

wooden seat used, R = radius in mm

M = Bending moment in N-mm

I = Moment of inertia in mm4

Y = Perpendicular to the neutral axis in mm

Equation of bending moment is given by,

Figure 7: Part drawing of Hand bar

= 7855 mm4

y = 10

This is less than the allowable stress of C-45, hence design is

safe.

2. Torsional Rigidity

Figure 8: Part drawing of wooden seat

The torsional rigidity is important in the case of transmission

3.3.3 Shaft shafts deflection 2.5° to 3°/m. Length may be used as limiting

value, the widely used deflection for the shaft is limited to 1

A shaft is a rotating element, which is used to transmit power degree in length equal to 20 times the diameter of the shaft.

from one place to another. The power is delivered to the shaft

by some tangential force and the resultant torque or tensional The torsional deflection may be obtained by using the

moment set up within the shaft permits the power to be

transferred to various machines linked up to the shaft, in

order to transfer the power from one shaft to another the

PES Institute of Technology, Bangalore South Campus, Bangalore, India

www.pes.edu

Recent Innovations in Science and Engineering - RISE 2016

30th April 2016

Ө = Torsional deflection or angle of twist in radians

(angle*/180)

T = twisting moment or torque on the shaft

J = polar moment of inertia of the cross sectional area about

the Axis of rotation.

= Π/32d4 for solid shaft.

G = Modulus of rigidity for the shaft material

L = Length of shaft

(Allowable shear stress for C45 is 186.36MPa)from DDHB,

= 10*79.4*103*0.034/850

τ = 31.76N/mm2

Hence design is safe and feasible.

Figure 10: Part drawing of Bearing

3.3.5 Pad

Figure 9: Part drawing of Shaft Pad is used for attaching the seat and hand bar to the shaft.

Material used: C45 Steel

3.3.4 Bearing

Figure shows the required dimensions of the Pad used,

A standard pedestal bearing housing for 20 mm axle size is

used. Such two number of pedestal bearings are used in this

project which are clamped on the angles at the top portion.

Specifications:

• Material - Cast iron

• Inside Diameter - 20mm

• Centre Height - 33.3mm

• Overall Height - 65mm

• Length - 127mm

• Depth - 32mm

Figure shows the required dimensions of the bearing used,

Figure 11: Part drawing of Pad

By using pad the hand bar can be fixed rigidly to the shaft.

Above fig. shows the brief design that we are going to use. It

is made of MS, machined and drilled to proper dimensions.

3.3.6 Belt and Wheel

A wheel that is used is a normally used cycle wheel which has

groove on the outer surface for meshing with the belt used.

The wheel rim used is of 13 inch radius.

Material used for the wheel – Aluminium

Material used for the Belt - Leather

The angle of contact between both the pulleys and the belt are

as shown below:

Diameter of the larger pulley (D) = 0.325m

PES Institute of Technology, Bangalore South Campus, Bangalore, India

www.pes.edu

Recent Innovations in Science and Engineering - RISE 2016

30th April 2016

Diameter of the smaller pulley (d)= 0.01m 3.4.3 Pad

Centre distance (C) = 0.7m This is used to attach the holding bar to the shaft. Facing,

Hence, the angle of contact of the smaller pulley(ϑ s ) Turning and Drilling operations are performed to get the

required dimension.

Ɵ s = 2.69c or 154°

The angle of contact of the larger pulley (Ɵ l )

Ɵ l = 3.59c or 205° Figure 13: Fabricated pad

The length of the belt used is given as follows: 3.4.4 Hand bar

A 16mm*1300mm shaft is fabricated by reducing the raw

material from Turning and Facing operations.

Holes are drilled and internally threaded in order to be able

to fix them to the seat and the upper shaft.

L = 1.95m

3.3.7 Step up motor and battery

A step up motor is connected to a rectifier circuit and an

amplifier circuit which is then connected to a lead acid

battery to store the energy developed.

3.4 Fabrication

Figure 14: Fabricated Hand bars

Raw materials are fabricated according to the requirement as

explained in the following,

3.5 Assembly

3.4.1 L – Angles

Following are the main steps involved in assembly operation,

L – Angles of required dimensions are cut as per the

• Building the frame

requirements. Later holes are drilled at required positions

• Attaching the Shaft and Holding bars to top of frame.

based on design for introducing fasteners during the

• Attaching the wheel and belt pulley mechanism and

assembly.

Generator to side of frame to form the working mechanism

These L – Angles form the frame of the structure.

The final assembly of the model looks as follows:

3.4.2 Shaft

A 20mm*850mm shaft is fabricated by reducing the raw

material from Turning and Facing operations.

A 34mm*40mm sprocket shaft is fabricated by reducing the

raw material from Turning, Facing and Tapping operation is

also performed to get the holes of required dimension

Figure 15: Side view of the assembled model

Figure 12: Fabricated Shaft

PES Institute of Technology, Bangalore South Campus, Bangalore, India

www.pes.edu

Recent Innovations in Science and Engineering - RISE 2016

30th April 2016

with load

30

Power output (watts)

25 24.5

20

15 16.2

10 9.8

5

3.2

0

20-30 30-60 60-90 90-120

Angle of swing (degrees)

Figure 16: A front view of the assembled model Figure 18: Variation of output voltage with respect to angle

of swing with load

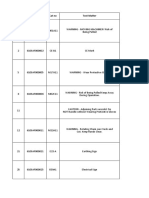

4.Results and Discussions

Hence, the output depends on the angle of swing and time of

Tests were carried down with respect to the angle of swing movement of seating of swing set. We can also observe that

and duration of usage to measure the voltage generated in as the duration of usage increases, slipping starts to take place

both conditions of with load and without load. which reduces the voltage output.

Results are shown below for various cases. 5.Conclusion

1. Variation of output voltage with respect to angle of swing A new method for human power conversion based on

without load children’s play on playground swing has been proposed. The

power harnessed can be used as an auxiliary or back-up

Table 2: Variation of output voltage with respect to angle of source for electricity, especially in developing countries. A

swing without load swing has been designed and developed and experimental

Angle of swing(˚) Average Output voltage(V) results are obtained which illustrate the practical effectiveness

20-30 9 of the proposed method of electricity generation.

30-60 13

60-90 17

90-120 22

Acknowledgements

We are grateful to our guide and mentor, Dr. Subrahmanya

S. Katte, HOD of Dept. of Mechanical Engineering, PESIT-

BSC for his constant technical and moral support that has

been of immense help in realizing this work. We would like

to thank Dr. S.V. Satish, Associate Professor, Dept. of

Mechanical Engineering, PESIT-BSC along with all the other

faculty members for helping us as and when required.

References

[1] A Human Power Conversion System Based on

Children’s Play by Shanmugham R. Pandian, Tulane

University IEEE 2010.

[2] J.B.K Das and P.L Srinivas Murthy “Design of machine

Figure 17: Variation of output voltage with respect to angle element I & II” Sapna publications 6th revised edition

of swing without load 2011

[3] A.J. Jansen and A.L.N. Stevels, 1999, “Human power, A

2. Variation of output voltage with respect to angle of swing sustainable option for electronics”, Proc. IEEE Int.

with load Symp. on Electronics and the Environment, Danvers,

MA, 1999, pp.215-218.

Table 3: Variation of output voltage with respect to angle of [4] Intermediate Technology Development Group (ITDG),

swing with load 2000, Sustainable Energy for Poverty Reduction: An

Angle of swing(˚) Average Output voltage(V) action plan, Rugby, UK

20-30 4

30-60 7

60-90 10

90-120 14

PES Institute of Technology, Bangalore South Campus, Bangalore, India

www.pes.edu

Das könnte Ihnen auch gefallen

- Integration of Distributed Energy Resources in Power Systems: Implementation, Operation and ControlVon EverandIntegration of Distributed Energy Resources in Power Systems: Implementation, Operation and ControlToshihisa FunabashiBewertung: 4.5 von 5 Sternen4.5/5 (3)

- IJCRT2106439Dokument6 SeitenIJCRT2106439SrikanthNoch keine Bewertungen

- Power Electronics and Motor Drives: Advances and TrendsVon EverandPower Electronics and Motor Drives: Advances and TrendsNoch keine Bewertungen

- Every Speed Breaker Is A Source of Power: N. N. Ghuge, Arati Sathe, Varsha Patil, Anagha WarankarDokument5 SeitenEvery Speed Breaker Is A Source of Power: N. N. Ghuge, Arati Sathe, Varsha Patil, Anagha WarankarMayurMahajanNoch keine Bewertungen

- Modification and Implementation of Foot Step Power Generation System in Weighting Scale of The GymDokument4 SeitenModification and Implementation of Foot Step Power Generation System in Weighting Scale of The GymCrispNoch keine Bewertungen

- Generation of Electricity With The Help of Speed Breakers Analysis and ApplicationsDokument6 SeitenGeneration of Electricity With The Help of Speed Breakers Analysis and ApplicationsYaser Ali TariqNoch keine Bewertungen

- Power Generation by Shock AbsorberDokument8 SeitenPower Generation by Shock AbsorberIJRASETPublicationsNoch keine Bewertungen

- Design and Fabrication of Shaft Driven Electric BicycleDokument5 SeitenDesign and Fabrication of Shaft Driven Electric BicycleInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Generation of Electricity Through Speed Breaker MechanismDokument7 SeitenGeneration of Electricity Through Speed Breaker MechanismDK3002Noch keine Bewertungen

- Design and Fabrication of A Magnetic Prime Mover For Electric Power GenerationDokument4 SeitenDesign and Fabrication of A Magnetic Prime Mover For Electric Power GenerationJerome GalleonNoch keine Bewertungen

- Power Generation Using Forearm Gym EquipmentDokument7 SeitenPower Generation Using Forearm Gym EquipmentIJRASETPublicationsNoch keine Bewertungen

- Sarat IAEMEDokument5 SeitenSarat IAEMECALVARY NIBANDHANANoch keine Bewertungen

- Sarat IAEMEDokument5 SeitenSarat IAEMEDushyant HarneNoch keine Bewertungen

- Power Generation Using Speed Breaker With Auto Street Light: ISO 9001:2008 CertifiedDokument4 SeitenPower Generation Using Speed Breaker With Auto Street Light: ISO 9001:2008 CertifiedChetan Sanikoppa AkkisNoch keine Bewertungen

- Paper 16Dokument5 SeitenPaper 16Mark Nicko Yabut ZablanNoch keine Bewertungen

- Power Generation by Using Railway Track: ISSN: 2455-2631 © March 2020 IJSDR - Volume 5, Issue 3Dokument4 SeitenPower Generation by Using Railway Track: ISSN: 2455-2631 © March 2020 IJSDR - Volume 5, Issue 3ChanduNoch keine Bewertungen

- PR20211003 - Prathmesh KakdeDokument5 SeitenPR20211003 - Prathmesh KakdePrathmesh KakadeNoch keine Bewertungen

- Speed Breaker 1Dokument6 SeitenSpeed Breaker 1AbhishekNoch keine Bewertungen

- Power Generation Fromwasted Energy of Moving Vehicle Using Speed BreakerDokument4 SeitenPower Generation Fromwasted Energy of Moving Vehicle Using Speed Breakerhasan bishNoch keine Bewertungen

- Design and Fabrication of Gravity Power GenerationDokument5 SeitenDesign and Fabrication of Gravity Power GenerationGhafar HassanNoch keine Bewertungen

- De 5th Sem FinalDokument30 SeitenDe 5th Sem FinalAnkit SinghNoch keine Bewertungen

- Generation of Electricity Through Rack and Pinion: Laxmi Gupta Ankita BhartiDokument3 SeitenGeneration of Electricity Through Rack and Pinion: Laxmi Gupta Ankita BhartisandyyansikuNoch keine Bewertungen

- A Project Report SSP 1Dokument22 SeitenA Project Report SSP 120-301 AKSHAYNoch keine Bewertungen

- Design and Analysis of Ultrasmall Power GeneratorDokument5 SeitenDesign and Analysis of Ultrasmall Power GeneratorInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- VIDYUT Generation Via Walking AnalysisDokument3 SeitenVIDYUT Generation Via Walking AnalysisMIRACLE JAMESNoch keine Bewertungen

- Bi Directional Power Generation Using Swing-JournalDokument10 SeitenBi Directional Power Generation Using Swing-JournalDevasish ReddyNoch keine Bewertungen

- Forearms Power GenerationDokument25 SeitenForearms Power GenerationM.t.s.k.tejeshNoch keine Bewertungen

- Foot Step Power GenerationDokument8 SeitenFoot Step Power Generationraja maneNoch keine Bewertungen

- Review - 1 B.Tech - IV PPT Varanaidu (Project)Dokument14 SeitenReview - 1 B.Tech - IV PPT Varanaidu (Project)Krishna MurthyNoch keine Bewertungen

- Design of Composite Material FlywheelDokument7 SeitenDesign of Composite Material FlywheelIJSTE100% (1)

- Ijesrt: VIDYUT Generation Via W VIDYUT Generation Via Walking: AnalysisDokument3 SeitenIjesrt: VIDYUT Generation Via W VIDYUT Generation Via Walking: AnalysisShashi ShekharNoch keine Bewertungen

- Sudhar 1234 - MergedDokument31 SeitenSudhar 1234 - MergedSujanNoch keine Bewertungen

- Power Generation Using Vehicle Suspension: July 2018Dokument4 SeitenPower Generation Using Vehicle Suspension: July 2018Kiran PatilNoch keine Bewertungen

- Project Report 2.0Dokument22 SeitenProject Report 2.0Yassar YelurkarNoch keine Bewertungen

- Power GenerationDokument5 SeitenPower GenerationGhanvir SinghNoch keine Bewertungen

- Power Generation by Vertical Axis Wind Turbine and Solar EnergyDokument10 SeitenPower Generation by Vertical Axis Wind Turbine and Solar EnergyIJRASETPublicationsNoch keine Bewertungen

- Power Generation Through Speed BreakersDokument22 SeitenPower Generation Through Speed BreakersSaikumar MysaNoch keine Bewertungen

- Prototype of Wheel Chair Attachable E Hand BikeDokument7 SeitenPrototype of Wheel Chair Attachable E Hand BikePAVIN ENGG0% (1)

- Experimental Investigation of Pedal Driven Hacksaw: Sreejith K., Aravind K., Danie Davis, Farish K.A., George JohnsonDokument5 SeitenExperimental Investigation of Pedal Driven Hacksaw: Sreejith K., Aravind K., Danie Davis, Farish K.A., George JohnsonChandanSuriyaNoch keine Bewertungen

- Design and Fabrication of Foot Step Power GentrationDokument6 SeitenDesign and Fabrication of Foot Step Power GentrationRocky DeoreNoch keine Bewertungen

- A Review On Solar Operated Agri-CutterDokument5 SeitenA Review On Solar Operated Agri-CutterIJIRSTNoch keine Bewertungen

- Modelling and Analysis of Power Generating Jump BoxDokument8 SeitenModelling and Analysis of Power Generating Jump Boxshivam rathorNoch keine Bewertungen

- Design and Analysis of Power Generating Speed BreakerDokument23 SeitenDesign and Analysis of Power Generating Speed BreakerIJRASETPublicationsNoch keine Bewertungen

- TOMM ReportDokument10 SeitenTOMM ReportMadhur WaghNoch keine Bewertungen

- Gym Power Station Turning Workout Into EDokument3 SeitenGym Power Station Turning Workout Into EEternal TuneNoch keine Bewertungen

- Generation of Electricity With The Use of Speed Breakers: ArticleDokument8 SeitenGeneration of Electricity With The Use of Speed Breakers: ArticleClassic LipuNoch keine Bewertungen

- 36I20-IJAET0520963 v7 Iss2 589-595 PDFDokument8 Seiten36I20-IJAET0520963 v7 Iss2 589-595 PDFShubham JhaNoch keine Bewertungen

- Design and Fabrication of Power Generation System Using Speed BreakerDokument7 SeitenDesign and Fabrication of Power Generation System Using Speed BreakerArmenion Mark AllenNoch keine Bewertungen

- Fabrication of Solar Powered Tricycle For Handicapped PersonDokument5 SeitenFabrication of Solar Powered Tricycle For Handicapped PersonGauravNoch keine Bewertungen

- The International Journal of Engineering and Science (The IJES)Dokument3 SeitenThe International Journal of Engineering and Science (The IJES)theijes100% (1)

- Car GenDokument4 SeitenCar GenharshaNoch keine Bewertungen

- Bi-Directional Power Generation Using Swing MotionDokument10 SeitenBi-Directional Power Generation Using Swing MotionMarlon EvangelistaNoch keine Bewertungen

- 1700100Dokument9 Seiten1700100Logesh DonNoch keine Bewertungen

- Ijser: Power Generation From Train TrackDokument8 SeitenIjser: Power Generation From Train TrackChanduNoch keine Bewertungen

- Departmeant of Mechanical Engineering: Power Generation by Speed BreakerDokument20 SeitenDepartmeant of Mechanical Engineering: Power Generation by Speed BreakerPreshit KshirsagarNoch keine Bewertungen

- Pedal Powedered Cutting PDFDokument10 SeitenPedal Powedered Cutting PDFvasanthavananNoch keine Bewertungen

- 25Dokument10 Seiten25md junuNoch keine Bewertungen

- Hybrid Solar MillDokument6 SeitenHybrid Solar MillInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- IJCRT22A6397Dokument5 SeitenIJCRT22A6397Mobeen AyyazNoch keine Bewertungen

- journalsresaim,+IJRESM V3 I8 53Dokument4 Seitenjournalsresaim,+IJRESM V3 I8 53Akshay bypNoch keine Bewertungen

- SOP Contract Labour Validation and Issuing Gate Passes FormatDokument16 SeitenSOP Contract Labour Validation and Issuing Gate Passes FormatOmkarNoch keine Bewertungen

- Indent Track ReportDokument9 SeitenIndent Track ReportOmkarNoch keine Bewertungen

- Overall Status Report 0rap0158Dokument8 SeitenOverall Status Report 0rap0158OmkarNoch keine Bewertungen

- Indent Track ReportDokument10 SeitenIndent Track ReportOmkarNoch keine Bewertungen

- AutoShop ProcessStatus - Export - 1652855503109Dokument4 SeitenAutoShop ProcessStatus - Export - 1652855503109OmkarNoch keine Bewertungen

- Explosion ReportDokument36 SeitenExplosion ReportOmkarNoch keine Bewertungen

- Explosion ReportDokument66 SeitenExplosion ReportOmkarNoch keine Bewertungen

- Planned: 0RAE034:CKD Robotic Cell RelocationDokument11 SeitenPlanned: 0RAE034:CKD Robotic Cell RelocationOmkarNoch keine Bewertungen

- Centrifugal Fans With Backward-Curved and Forward-Curved BladesDokument8 SeitenCentrifugal Fans With Backward-Curved and Forward-Curved BladesOmkarNoch keine Bewertungen

- Alfa Laval QuestionnaireDokument2 SeitenAlfa Laval QuestionnaireOmkarNoch keine Bewertungen

- Day Date Activity Description TEAM Details BAL Activity MechanicalDokument2 SeitenDay Date Activity Description TEAM Details BAL Activity MechanicalOmkarNoch keine Bewertungen

- Safety Stickers - QAP128Dokument9 SeitenSafety Stickers - QAP128OmkarNoch keine Bewertungen

- SOP Contract Labour Validation and Issuing Gate Passes FormatDokument34 SeitenSOP Contract Labour Validation and Issuing Gate Passes FormatOmkar100% (1)

- Planning Sheet-0rae034Dokument25 SeitenPlanning Sheet-0rae034OmkarNoch keine Bewertungen

- Bom Qap136Dokument54 SeitenBom Qap136OmkarNoch keine Bewertungen

- CAPEX PURCHASE POs 214Dokument14 SeitenCAPEX PURCHASE POs 214OmkarNoch keine Bewertungen

- Technical Details: Quotation No: 30093334Dokument3 SeitenTechnical Details: Quotation No: 30093334OmkarNoch keine Bewertungen

- Leadership Nursing and Patient SafetyDokument172 SeitenLeadership Nursing and Patient SafetyRolena Johnette B. PiñeroNoch keine Bewertungen

- Shot Blasting Machine ApplicationsDokument7 SeitenShot Blasting Machine ApplicationsBhavin DesaiNoch keine Bewertungen

- FDP VLSI Design at Deep Submicron Node PDFDokument2 SeitenFDP VLSI Design at Deep Submicron Node PDFpraneethshubNoch keine Bewertungen

- Hospital Furniture: Project Profile-UpdatedDokument7 SeitenHospital Furniture: Project Profile-UpdatedGaurav GuptaNoch keine Bewertungen

- Normal Consistency of Hydraulic CementDokument15 SeitenNormal Consistency of Hydraulic CementApril Lyn SantosNoch keine Bewertungen

- Nicole Rapp Resume 3Dokument2 SeitenNicole Rapp Resume 3api-341337144Noch keine Bewertungen

- ModelsimDokument47 SeitenModelsimKishor KumarNoch keine Bewertungen

- SQL TestDokument10 SeitenSQL TestGautam KatlaNoch keine Bewertungen

- ESA Mars Research Abstracts Part 2Dokument85 SeitenESA Mars Research Abstracts Part 2daver2tarletonNoch keine Bewertungen

- GT-3000 PrintDokument3 SeitenGT-3000 Printmanual imbNoch keine Bewertungen

- Exam TimetableDokument16 SeitenExam Timetablenyarko_eNoch keine Bewertungen

- Feb-May SBI StatementDokument2 SeitenFeb-May SBI StatementAshutosh PandeyNoch keine Bewertungen

- Denial of LOI & LOP For Ayurveda Colleges Under 13A For AY-2021-22 As On 18.02.2022Dokument1 SeiteDenial of LOI & LOP For Ayurveda Colleges Under 13A For AY-2021-22 As On 18.02.2022Gbp GbpNoch keine Bewertungen

- Master Thesis On Smart GridDokument6 SeitenMaster Thesis On Smart Gridsandraandersondesmoines100% (2)

- Consequences of Self-Handicapping: Effects On Coping, Academic Performance, and AdjustmentDokument11 SeitenConsequences of Self-Handicapping: Effects On Coping, Academic Performance, and AdjustmentAlliah Kate SalvadorNoch keine Bewertungen

- (Database Management Systems) : Biag, Marvin, B. BSIT - 202 September 6 2019Dokument7 Seiten(Database Management Systems) : Biag, Marvin, B. BSIT - 202 September 6 2019Marcos JeremyNoch keine Bewertungen

- Re BuyerDokument20 SeitenRe BuyerElias OjuokNoch keine Bewertungen

- Pre K Kindergarten Alphabet Letter TracingDokument28 SeitenPre K Kindergarten Alphabet Letter TracingNeha RawatNoch keine Bewertungen

- List of Institutions With Ladderized Program Under Eo 358 JULY 2006 - DECEMBER 31, 2007Dokument216 SeitenList of Institutions With Ladderized Program Under Eo 358 JULY 2006 - DECEMBER 31, 2007Jen CalaquiNoch keine Bewertungen

- Volvo HU 803Dokument8 SeitenVolvo HU 803GiegloNoch keine Bewertungen

- Diffrent Types of MapDokument3 SeitenDiffrent Types of MapIan GamitNoch keine Bewertungen

- Advocating For Appropriate Educational ServicesDokument32 SeitenAdvocating For Appropriate Educational ServicesTransverse Myelitis AssociationNoch keine Bewertungen

- EceDokument75 SeitenEcevignesh16vlsiNoch keine Bewertungen

- Chapter 3: Verbal Communication SkillsDokument14 SeitenChapter 3: Verbal Communication SkillsFares EL DeenNoch keine Bewertungen

- Pin Joint en PDFDokument1 SeitePin Joint en PDFCicNoch keine Bewertungen

- 27 Points of Difference Between Personnel Management & HRDDokument2 Seiten27 Points of Difference Between Personnel Management & HRDMurtaza Ejaz33% (3)

- A History of The Ecological Sciences, Part 1 - Early Greek OriginsDokument6 SeitenA History of The Ecological Sciences, Part 1 - Early Greek OriginskatzbandNoch keine Bewertungen

- Do I Need A 1PPS Box For My Mulitbeam SystemDokument3 SeitenDo I Need A 1PPS Box For My Mulitbeam SystemutkuNoch keine Bewertungen

- Agriculture Vision 2020Dokument10 SeitenAgriculture Vision 20202113713 PRIYANKANoch keine Bewertungen

- Acdc - DC Motor - Lecture Notes 5Dokument30 SeitenAcdc - DC Motor - Lecture Notes 5Cllyan ReyesNoch keine Bewertungen

- Advanced Modelling Techniques in Structural DesignVon EverandAdvanced Modelling Techniques in Structural DesignBewertung: 5 von 5 Sternen5/5 (3)

- Piping Engineering Leadership for Process Plant ProjectsVon EverandPiping Engineering Leadership for Process Plant ProjectsBewertung: 5 von 5 Sternen5/5 (1)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresVon EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresBewertung: 1 von 5 Sternen1/5 (2)

- To Engineer Is Human: The Role of Failure in Successful DesignVon EverandTo Engineer Is Human: The Role of Failure in Successful DesignBewertung: 4 von 5 Sternen4/5 (138)

- Structural Cross Sections: Analysis and DesignVon EverandStructural Cross Sections: Analysis and DesignBewertung: 4.5 von 5 Sternen4.5/5 (19)

- Onshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesVon EverandOnshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesBewertung: 4.5 von 5 Sternen4.5/5 (13)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNoch keine Bewertungen

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsVon EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsBewertung: 4 von 5 Sternen4/5 (16)

- Mechanics of Flow-Induced Sound and Vibration, Volume 2: Complex Flow-Structure InteractionsVon EverandMechanics of Flow-Induced Sound and Vibration, Volume 2: Complex Flow-Structure InteractionsNoch keine Bewertungen

- Marine Structural Design CalculationsVon EverandMarine Structural Design CalculationsBewertung: 4.5 von 5 Sternen4.5/5 (13)

- Non-destructive Testing and Evaluation of Civil Engineering StructuresVon EverandNon-destructive Testing and Evaluation of Civil Engineering StructuresJean-Paul BalayssacNoch keine Bewertungen

- Net Zero Energy Buildings (NZEB): Concepts, Frameworks and Roadmap for Project Analysis and ImplementationVon EverandNet Zero Energy Buildings (NZEB): Concepts, Frameworks and Roadmap for Project Analysis and ImplementationBewertung: 5 von 5 Sternen5/5 (1)

- Wind Effects on Structures: Modern Structural Design for WindVon EverandWind Effects on Structures: Modern Structural Design for WindNoch keine Bewertungen

- Earthquake-Resistant Structures: Design, Build, and RetrofitVon EverandEarthquake-Resistant Structures: Design, Build, and RetrofitBewertung: 4.5 von 5 Sternen4.5/5 (8)

- Working Guide to Pump and Pumping Stations: Calculations and SimulationsVon EverandWorking Guide to Pump and Pumping Stations: Calculations and SimulationsBewertung: 5 von 5 Sternen5/5 (3)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsVon EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNoch keine Bewertungen

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesVon EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraBewertung: 4.5 von 5 Sternen4.5/5 (4)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsVon EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNoch keine Bewertungen