Beruflich Dokumente

Kultur Dokumente

Tds Renolit Cxi 2 en

Hochgeladen von

Aldair MezaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tds Renolit Cxi 2 en

Hochgeladen von

Aldair MezaCopyright:

Verfügbare Formate

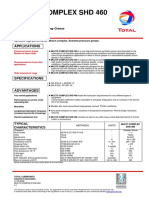

RENOLIT CXI 2

Description Advantages

RENOLIT CXI 2 is an optimized calcium sulphonate • Extremely good EP properties

complex grease based on selected mineral oils. • Good corrosion protection, even in the presence

RENOLIT CXI 2 features excellent working stability, of salt water

EP loadability and wear protection and shows good • Water resistant

corrosion protection behaviour even in the presence

of salt water. • Resistant to aging

RENOLIT CXI 2 has low oil separation, it is water • Smooth structure

and aging resistant and can be used in a wide • High working stability

temperature range. • Good anti-wear properties

Specifications/Approvals

Application

• Ford ESA-M1C 172-A

RENOLIT CXI 2 should be used for all lubrication

points requiring a high performance concerning

water resistance, working stability, EP and AW

properties.

RENOLIT CXI 2 is easily pumpable even in long

tubes, fed by centralized lubrication systems.

RENOLIT CXI 2 was developed to work under

severe conditions in plain and roller bearings in steel

mills, paper industry, mining, concrete industry,

quarries and construction equipment.

Shelf Life

The minimum shelf life is 36 months if the product is

properly stored between 0°C and 40°C in its

unopened original container in a dry place. The

indication of a minimum shelf life does not include

any guarantee of durability.

PI 5-3510e, Page 1/3, PM 5, 08/13

FUCHS SCHMIERSTOFFE GMBH Phone +49 621 3701-0 ISO/TS 16949:2009

DIN EN ISO 14001:2004

Friesenheimer Straße 19 Fax +49 621 3701-570

BS OHSAS 18001:2007

68169 Mannheim/Germany zentrale@fuchs-schmierstoffe.de REG.NR. 2476

RENOLIT CXI 2

Characteristics

Properties Unit Data Test method

Colour - Light brown -

Calcium

Thickener - sulphonate -

complex soap

Dropping point °C ≥ 270 IP 396

Worked penetration (Pw 60) 0,1 mm 265 - 295 DIN ISO 2137

Worked stability ∆P w(100.000-60) 0,1mm ≤ 20 DIN ISO 2137

Shell Roller test 72h/100°C ∆Pw60 0,1mm ≤ 20 ASTM D 1831

NLGI grade - 2 DIN 51 818

Corrosion protection properties

degree of corr. 0 - 0 DIN 51 802

with 3% NaCl (SKF Emcor test)

Copper corrosion degree of corr. 1 - 100 DIN 51 811

Water resistance eval.-stage 0 - 90 DIN 51807-1

Four ball method, welding load N 5500 DIN 51 350

Timken test Ibs 55 ASTM D 2509

Flow pressure at -20°C hPa ≤ 1400 DIN 51 805

Oil separation at 18h / 40°C ≤ 0,1

% DIN 51 817

at 7d / 40°C ≤1

Base oil viscosity at 40°C 350

mm²/s DIN 51 562-1

at 100°C 32,5

Temperature range °C -20 up to +160 -

PI 5-3510e, Page 2/3, PM 5, 08/13

FUCHS SCHMIERSTOFFE GMBH Phone +49 621 3701-0 ISO/TS 16949:2009

DIN EN ISO 14001:2004

Friesenheimer Straße 19 Fax +49 621 3701-570

BS OHSAS 18001:2007

68169 Mannheim/Germany zentrale@fuchs-schmierstoffe.de REG.NR. 2476

RENOLIT CXI 2

The information contained in this product information is based on the experience and know-how of FUCHS

SCHMIERSTOFFE GMBH in the development and manufacturing of lubricants and represents the current state-

of-the-art. The performance of our products can be influenced by a series of factors, especially the specific use,

the method of application, the operational environment, component pre-treatment, possible external

contamination, etc. For this reason, universally-valid statements about the function of our products are not

possible. The information given in this product information represents general, non-binding guidelines. No

warranty expressed or implied is given concerning the properties of the product or its suitability for any given

application.

We therefore recommend that you consult a FUCHS SCHMIERSTOFFE GMBH application engineer to discuss

application conditions and the performance criteria of the products before the product is used. It is the

responsibility of the user to test the functional suitability of the product and to use it with the corresponding care.

Our products undergo continuous improvement. We therefore retain the right to change our product program,

the products, and their manufacturing processes as well as all details of our product information sheets at any

time and without warning, unless otherwise provided in customer-specific agreements. With the publication of

this product information, all previous editions cease to be valid.

Any form of reproduction requires express prior written permission from FUCHS SCHMIERSTOFFE GMBH.

© FUCHS SCHMIERSTOFFE GMBH. All rights reserved.

PI 5-3510e, Page 3/3, PM 5, 08/13

FUCHS SCHMIERSTOFFE GMBH Phone +49 621 3701-0 ISO/TS 16949:2009

DIN EN ISO 14001:2004

Friesenheimer Straße 19 Fax +49 621 3701-570

BS OHSAS 18001:2007

68169 Mannheim/Germany zentrale@fuchs-schmierstoffe.de REG.NR. 2476

Das könnte Ihnen auch gefallen

- Renolit FLM 2: Description AdvantagesDokument3 SeitenRenolit FLM 2: Description AdvantagesЕвгений ИвановNoch keine Bewertungen

- Renolit So-Gfb: Description AdvantagesDokument3 SeitenRenolit So-Gfb: Description AdvantagesAhmed El TayebNoch keine Bewertungen

- Tds Renolin CLP enDokument7 SeitenTds Renolin CLP enrytNoch keine Bewertungen

- Aceite MR520Dokument4 SeitenAceite MR520capc.asesoriasNoch keine Bewertungen

- High-Performance Grease for Ball JointsDokument2 SeitenHigh-Performance Grease for Ball JointsMichael KimNoch keine Bewertungen

- Описания RENOLIT DURAPLEX EP 2Dokument3 SeitenОписания RENOLIT DURAPLEX EP 2ahmed.kab.ak01011954Noch keine Bewertungen

- STABYL TA High-Performance Grease for Telescoping BoomsDokument2 SeitenSTABYL TA High-Performance Grease for Telescoping BoomsCriVe OffeNoch keine Bewertungen

- STEDESA Fisa Tehnica RENOLIT LX-PEP-2 (TDS) (GB) PDFDokument3 SeitenSTEDESA Fisa Tehnica RENOLIT LX-PEP-2 (TDS) (GB) PDFCorina StanculescuNoch keine Bewertungen

- Renolin Eterna (Governor Oil)Dokument2 SeitenRenolin Eterna (Governor Oil)JohanNoch keine Bewertungen

- Tds Renolin 500 Series enDokument3 SeitenTds Renolin 500 Series enNadia SalemNoch keine Bewertungen

- BECHEM_High_Lub_LFB_2000_TDS_enDokument1 SeiteBECHEM_High_Lub_LFB_2000_TDS_enluisvictorbariteNoch keine Bewertungen

- Pi Oks 476 113678 enDokument2 SeitenPi Oks 476 113678 enSophia RoseNoch keine Bewertungen

- Fiche Technique Lub High-Temp-Mp enDokument1 SeiteFiche Technique Lub High-Temp-Mp envladatanNoch keine Bewertungen

- Product Information: High-Temperature Grease For Food Processing TechnologyDokument2 SeitenProduct Information: High-Temperature Grease For Food Processing TechnologyFelipe OsorioNoch keine Bewertungen

- Product Information: Multi-Silicone GreaseDokument3 SeitenProduct Information: Multi-Silicone Greasekamalkraj4002Noch keine Bewertungen

- Product Information: High-Temperature Oil, Light-Coloured, SyntheticDokument2 SeitenProduct Information: High-Temperature Oil, Light-Coloured, SyntheticIván ChávezNoch keine Bewertungen

- Highly Viscous Gear GreaseDokument3 SeitenHighly Viscous Gear GreaseJeremias Utrera100% (1)

- Product Information: High Temperature Oil, Light-Coloured, SyntheticDokument2 SeitenProduct Information: High Temperature Oil, Light-Coloured, SyntheticKevin Daniel Casta?O CorreaNoch keine Bewertungen

- TD - Rhenus LKZ 2Dokument1 SeiteTD - Rhenus LKZ 2Teknik LasallefoodNoch keine Bewertungen

- Graisse N 31315Dokument1 SeiteGraisse N 31315kirandhivya1821Noch keine Bewertungen

- Xtech 20grease 20300 GBDokument1 SeiteXtech 20grease 20300 GBVelibor KaranovicNoch keine Bewertungen

- Renolin CLP - PIDokument6 SeitenRenolin CLP - PIDương LêNoch keine Bewertungen

- Cassida Grease Eps 2 - Pi - (Gb-En)Dokument3 SeitenCassida Grease Eps 2 - Pi - (Gb-En)CriVe OffeNoch keine Bewertungen

- Lithium Grease Technical DataDokument2 SeitenLithium Grease Technical DatamcnpopaNoch keine Bewertungen

- Pds Renolin Anti Stick SlipDokument2 SeitenPds Renolin Anti Stick SliptribolasNoch keine Bewertungen

- Pi Oks 252 113701 enDokument2 SeitenPi Oks 252 113701 enGokulNoch keine Bewertungen

- Titan Cargo 10W-40Dokument3 SeitenTitan Cargo 10W-40Mohamed LabibNoch keine Bewertungen

- Molykote G-2003Dokument2 SeitenMolykote G-2003Luz Angela GuerreroNoch keine Bewertungen

- Turmotemp II 400 Rs 00 Ti enDokument1 SeiteTurmotemp II 400 Rs 00 Ti enKoushar MechanictcNoch keine Bewertungen

- Agip Arnica S: Characteristics (Typical Figures)Dokument2 SeitenAgip Arnica S: Characteristics (Typical Figures)AMAZING AGNoch keine Bewertungen

- Gear Oil CLP 220-11-En - GBDokument1 SeiteGear Oil CLP 220-11-En - GBputel_ajaNoch keine Bewertungen

- Reniso SP Series - Ficha TecnicaDokument5 SeitenReniso SP Series - Ficha TecnicaJavier ChangNoch keine Bewertungen

- Interflon Food Grease EP TDSDokument2 SeitenInterflon Food Grease EP TDSKamila AriasNoch keine Bewertungen

- Poly Gear PG en PDFDokument2 SeitenPoly Gear PG en PDFAlfredo CarlosNoch keine Bewertungen

- Industrial Gear Oils ComparisonDokument2 SeitenIndustrial Gear Oils ComparisondanililloNoch keine Bewertungen

- Total Altis SH 2 Grease TDSDokument1 SeiteTotal Altis SH 2 Grease TDSANoch keine Bewertungen

- Addinol Gear Oil 100 F, 150 F, 220 F, 320 F, 460 F, 680 F: Industrial Special Gear OilsDokument2 SeitenAddinol Gear Oil 100 F, 150 F, 220 F, 320 F, 460 F, 680 F: Industrial Special Gear OilsMateo RincónNoch keine Bewertungen

- Altis em 2Dokument1 SeiteAltis em 2Pedro DuqueNoch keine Bewertungen

- High Performance Lubricants Molykote: G-2001 High Speed Bearing GreaseDokument2 SeitenHigh Performance Lubricants Molykote: G-2001 High Speed Bearing GreaseRildo CarvalhoNoch keine Bewertungen

- High-Temp Dry Lubricant PasteDokument2 SeitenHigh-Temp Dry Lubricant PasteJORGE VELAZQUEZNoch keine Bewertungen

- TDS - Reniso Triton Se, Sez - enDokument6 SeitenTDS - Reniso Triton Se, Sez - enshahiffudinNoch keine Bewertungen

- Perma Multipurpose Grease SF01 TDS enDokument2 SeitenPerma Multipurpose Grease SF01 TDS enDwi April YantoNoch keine Bewertungen

- Biodegradable Grease for Construction and Agricultural MachinesDokument1 SeiteBiodegradable Grease for Construction and Agricultural MachinesStrange AhadNoch keine Bewertungen

- P004916 Commercial Vehicle Multi Purpose Grease K2K 20 15 en - GBDokument1 SeiteP004916 Commercial Vehicle Multi Purpose Grease K2K 20 15 en - GBSaeed QahremaniNoch keine Bewertungen

- Pi - Titan Supersyn Longlife 0w-40Dokument3 SeitenPi - Titan Supersyn Longlife 0w-40PT. GrokindoNoch keine Bewertungen

- RAVENOL Oldtimer 50-Er SAE 20W-50 API SCDokument3 SeitenRAVENOL Oldtimer 50-Er SAE 20W-50 API SCddNoch keine Bewertungen

- OKS 252 - Product Information: White High Temperature Paste For The Food IndustryDokument2 SeitenOKS 252 - Product Information: White High Temperature Paste For The Food IndustryIván ChávezNoch keine Bewertungen

- Ravenol Getriebeol CLP 100 1Dokument1 SeiteRavenol Getriebeol CLP 100 1norbertoNoch keine Bewertungen

- PDS - Addinol Gear Oil CLP 10, 68, 100, 150, 220, 320, 460, 680Dokument2 SeitenPDS - Addinol Gear Oil CLP 10, 68, 100, 150, 220, 320, 460, 680LeoNoch keine Bewertungen

- Gear Compound Plus Iso - 68 - enDokument1 SeiteGear Compound Plus Iso - 68 - enSedin MurtićNoch keine Bewertungen

- Gear Compound Plus Iso - 68 - enDokument1 SeiteGear Compound Plus Iso - 68 - enSedin MurtićNoch keine Bewertungen

- Renolit H 443-HD 88Dokument2 SeitenRenolit H 443-HD 88miguelfpintoNoch keine Bewertungen

- Additex SW 22, SW 32, SW 46: Textile Machine OilDokument2 SeitenAdditex SW 22, SW 32, SW 46: Textile Machine OilRonald Mario Kupa AnticonaNoch keine Bewertungen

- Eni BlasiaDokument2 SeitenEni BlasiaranjanguptNoch keine Bewertungen

- Renolin CLP - enDokument7 SeitenRenolin CLP - enDANE80Noch keine Bewertungen

- High-speed roller bearing greaseDokument1 SeiteHigh-speed roller bearing greaseSandeepNoch keine Bewertungen

- Tds Total Multis Complex SHD 460 O8k 201412 enDokument1 SeiteTds Total Multis Complex SHD 460 O8k 201412 enM.TayyabNoch keine Bewertungen

- Tds Total Multis Complex SHD 460 O8k 201412 enDokument1 SeiteTds Total Multis Complex SHD 460 O8k 201412 enM.TayyabNoch keine Bewertungen

- Renolin CLPDokument6 SeitenRenolin CLPjacl88Noch keine Bewertungen

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsVon EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsBewertung: 5 von 5 Sternen5/5 (1)

- Design of a 5-Ton Bridge CraneDokument104 SeitenDesign of a 5-Ton Bridge CraneAndres RestrepoNoch keine Bewertungen

- Long Pitch Conveyor Chain Sprockets SpecificationsDokument16 SeitenLong Pitch Conveyor Chain Sprockets SpecificationsAldair MezaNoch keine Bewertungen

- Nadella Cam Follower PF810EDokument22 SeitenNadella Cam Follower PF810EAldair MezaNoch keine Bewertungen

- Filtro Domat ConvencionalDokument19 SeitenFiltro Domat ConvencionalAldair MezaNoch keine Bewertungen

- Iso Dis 50006 PDFDokument54 SeitenIso Dis 50006 PDFbarouyel1984Noch keine Bewertungen

- Traducción de Borrador Norma ISO 50004Dokument45 SeitenTraducción de Borrador Norma ISO 50004Aldair Meza100% (1)

- Filtro Universal DomatDokument27 SeitenFiltro Universal DomatAldair MezaNoch keine Bewertungen

- Sebp5558 00 00 All PDFDokument1.151 SeitenSebp5558 00 00 All PDFAldair MezaNoch keine Bewertungen

- Sebp5558 00 00 All PDFDokument1.151 SeitenSebp5558 00 00 All PDFAldair MezaNoch keine Bewertungen

- Full Catalog 7 PDFDokument65 SeitenFull Catalog 7 PDFAldair MezaNoch keine Bewertungen

- Y0110039 enDokument34 SeitenY0110039 enAldair MezaNoch keine Bewertungen

- GLXXMobil SHC Gear SeriesDokument8 SeitenGLXXMobil SHC Gear SeriesMarcelo GuarachiNoch keine Bewertungen

- z43 180309152305Dokument46 Seitenz43 180309152305Aldair MezaNoch keine Bewertungen

- z43 180309152305Dokument46 Seitenz43 180309152305Aldair MezaNoch keine Bewertungen

- H40-70FT TG PDFDokument10 SeitenH40-70FT TG PDFAldair MezaNoch keine Bewertungen

- EN Project LogisticsDokument2 SeitenEN Project Logisticsdevie shyntiaNoch keine Bewertungen

- New Haven Harbor Connecticut Navigation Improvement Project Integrated Feasibility Report and Environmental Impact StatementDokument23 SeitenNew Haven Harbor Connecticut Navigation Improvement Project Integrated Feasibility Report and Environmental Impact StatementHelen BennettNoch keine Bewertungen

- JD - Hygiene Promotion OfficerDokument2 SeitenJD - Hygiene Promotion OfficerBeauty ChigwazaNoch keine Bewertungen

- Motor Doosan DV11Dokument220 SeitenMotor Doosan DV11David Catari100% (4)

- تحليل البول بالصور والشرحDokument72 Seitenتحليل البول بالصور والشرحDaouai TaaouanouNoch keine Bewertungen

- CX-5 BX-10 No. 1 & 1.5 Fluid Cylinder PartsDokument5 SeitenCX-5 BX-10 No. 1 & 1.5 Fluid Cylinder PartsPierreNoch keine Bewertungen

- SITHCCC018 Assessment 2Dokument9 SeitenSITHCCC018 Assessment 2Taimoor Ahmed0% (1)

- Higuey, Dom Rep Mdpc/Puj: .Eff.23.MayDokument5 SeitenHiguey, Dom Rep Mdpc/Puj: .Eff.23.MayVanessa Yumayusa0% (1)

- EDC MS 6.4 System DescriptionDokument10 SeitenEDC MS 6.4 System Descriptionmarsh2002Noch keine Bewertungen

- On Prem Vs CloudDokument10 SeitenOn Prem Vs CloudJeev AnandNoch keine Bewertungen

- Bangladesh National Building Code 2012 Part 07 - Construction Practices and SafetyDokument83 SeitenBangladesh National Building Code 2012 Part 07 - Construction Practices and SafetyPranoy Barua100% (3)

- Design and Analysis of Cooling Fins: Deepak Gupta, Wankhade S.RDokument4 SeitenDesign and Analysis of Cooling Fins: Deepak Gupta, Wankhade S.RAntonio SilvaNoch keine Bewertungen

- Habit TrackersDokument38 SeitenHabit Trackersjesus100% (1)

- JMPR 2010 ContentsDokument55 SeitenJMPR 2010 ContentsTÙNGNoch keine Bewertungen

- Res Ipsa LoquiturDokument6 SeitenRes Ipsa LoquiturZydalgLadyz NeadNoch keine Bewertungen

- HVAC Report FINALDokument65 SeitenHVAC Report FINALIanNoch keine Bewertungen

- ABO BLOOD GROUP Part 1Dokument104 SeitenABO BLOOD GROUP Part 1Taladua Cayla Grace O.Noch keine Bewertungen

- Full Test 14 (Key) PDFDokument4 SeitenFull Test 14 (Key) PDFhoang lichNoch keine Bewertungen

- Rules of SungazingDokument2 SeitenRules of SungazingaustralexdiNoch keine Bewertungen

- Paper TropicsDokument8 SeitenPaper Tropicsdarobin21Noch keine Bewertungen

- Here's Your Water Bill: LitresDokument4 SeitenHere's Your Water Bill: Litrestvnm2ymmkdNoch keine Bewertungen

- Agemp Two MarksDokument8 SeitenAgemp Two MarksKishore CrazeNoch keine Bewertungen

- Elements (Industrial Plant)Dokument5 SeitenElements (Industrial Plant)Veralyn Mae BondadNoch keine Bewertungen

- Firemac FM Fire Ducts Provide Fire Resistant VentilationDokument12 SeitenFiremac FM Fire Ducts Provide Fire Resistant Ventilationsiva8784Noch keine Bewertungen

- EXERCISE 1.1.2: Daub, Elycka Dela Cruz, Jesson Igne, Cyril Joy Labbao, Trinity RZL110 - A56Dokument7 SeitenEXERCISE 1.1.2: Daub, Elycka Dela Cruz, Jesson Igne, Cyril Joy Labbao, Trinity RZL110 - A56-Noch keine Bewertungen

- 7220 Instrucciones de Intalacion PDFDokument2 Seiten7220 Instrucciones de Intalacion PDFAttackDenied123Noch keine Bewertungen

- Hydrocele: CausesDokument7 SeitenHydrocele: CauseslanaNoch keine Bewertungen

- Product BrochureDokument2 SeitenProduct BrochureNoel RodríguezNoch keine Bewertungen

- AZIZ Ur RehmanDokument3 SeitenAZIZ Ur Rehmantop writerNoch keine Bewertungen

- Exp. 5 Test For Fats and ProteinsDokument6 SeitenExp. 5 Test For Fats and ProteinsEMELIE GRACE E CACHERONoch keine Bewertungen