Beruflich Dokumente

Kultur Dokumente

Lecture14 PDF

Hochgeladen von

Lokesh KumarOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lecture14 PDF

Hochgeladen von

Lokesh KumarCopyright:

Verfügbare Formate

Objectives_template

Module 3: Influence of Engine Design and Operating Parameters on Emissions

Lecture 14:Effect of SI Engine Design and Operating Variables on Emissions

Effect of SI Engine Design and Operating Variables on Emissions

The Lecture Contains:

SI Engine Variables and Emissions

Compression Ratio

Ignition Timing

Air –Fuel Ratio

Residual Gas and EGR

Engine Speed

Cold Start and Warm-up Phase

Coolant Temperature

Summary

file:///C|/...%20and%20Settings/iitkrana1/My%20Documents/Google%20Talk%20Received%20Files/engine_combustion/lecture14/14_1.htm[6/15/2012 3:01:19 PM]

Objectives_template

Module 3:Influence of Engine Design and Operating Parameters on Emissions

Lecture 14:Effect of SI Engine Design and Operating Variables on Emissions

SI Engine Variables and Emissions

Any engine variable that affects oxygen availability during combustion would influence CO emissions.

The factors which influence flame quenching, quench layer thickness and post flame oxidation control

engine out HC emissions. The burned gas temperature-time history and oxygen concentration control

NO formation and emission. Hence the engine variables that influence burned gas temperature and

oxygen concentration would affect the NO emissions.

Principal design and operating variables affecting engine emissions are:

Design Variables :

Compression Ratio

Combustion chamber surface to volume ratio

Ignition timing

Valve timings and valve overlap

Air motion, swirl tumble etc

Charge stratification

Operating Variables :

Air-fuel Ratio

Charge dilution and exhaust gas recirculation (EGR)

Speed

Load

Coolant temperature

Transient engine operation: acceleration, deceleration etc.

The effect of some variables discussed below is typical in nature and variations in the trends with

specific engine design change are observed.

file:///C|/...%20and%20Settings/iitkrana1/My%20Documents/Google%20Talk%20Received%20Files/engine_combustion/lecture14/14_2.htm[6/15/2012 3:01:19 PM]

Objectives_template

Module 3:Influence of Engine Design and Operating Parameters on Emissions

Lecture 14:Effect of SI Engine Design and Operating Variables on Emissions

Compression Ratio

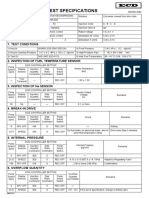

The effect of compression ratio on engine emissions is shown on Fig. 3.1. The typical effect observed

when the engine CR was reduced from 10:1 (CR used on high performance engines during pre-

emission control period) to 8.5 and 7.0:1 are given on this figure.

Use of high CR results in

(i) Higher burned gas temperature

(ii) Lower residual gas content

These lead to higher NO emissions on volume basis. However, as engine efficiency increases with

increase in compression ratio, brake specific NO emissions decrease. High CR combustion chambers

result in

(i) High surface to volume ratio and

(ii) A proportionately higher crevice volume.

(iii) Lower exhaust gas temperatures

Thus the volume of flame quenching regions increases resulting in higher HC emissions. The problem

is further enhanced as due to lower exhaust gas temperatures oxidation of the unburned HC is

reduced during exhaust process. These factors result in an increase in HC emissions with increase in

engine CR. At lower CR% fuel efficiency is also reduced thus increasing specific CO emissions.

Figure Effect of reduction in compression ratio from 10:1 to 8.5:1 and

3.1 7.0:1 on SI engine emissions

file:///C|/...20and%20Settings/iitkrana1/My%20Documents/Google%20Talk%20Received%20Files/engine_combustion/lecture14/14_2_1.htm[6/15/2012 3:01:19 PM]

Objectives_template

file:///C|/...20and%20Settings/iitkrana1/My%20Documents/Google%20Talk%20Received%20Files/engine_combustion/lecture14/14_2_1.htm[6/15/2012 3:01:19 PM]

Objectives_template

Module 3:Influence of Engine Design and Operating Parameters on Emissions

Lecture 14:Effect of SI Engine Design and Operating Variables on Emissions

Ignition Timing

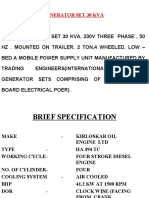

The effect of ignition timing on NO and HC emissions is shown on Fig 3.2 When ignition occurs earlier

in the cycle more heat is released before and around the top dead center. Thus, with advanced ignition

timings higher peak cylinder pressures and temperatures result. As has been discussed lecture 5 with

increase in combution temperatures NO formation increases. Hence , higher NO emissions are obtained

as the ignition timing is advanced.

As the ignition timing is retarded more burning takes place during expansion stroke resulting in lower

peak combustion pressures and a lower of mass of charge is pushed into crevice volume. Also, at the

retarded ignition timings exhaust gas temperature increases as the engine thermal efficiency is

reduced. In the hotter exhaust gas with the retarded ignition timing higher oxidation rates of the HC

and CO in the exhaust system are obtained.. Due to these reasons, lower HC emissions are obtained

with retarded ignition timings. The disadvantage of the retarded ignition timing is lower engine

efficiency, lower power and a poorer fuel economy.

When the emission control legislation was introduced for the first time around 1970 in the USA and

Europe, ignition timing versus speed and manifold vacuum curves were among the first engine

parameters that were modified for control of NO x emissions due to ease of their adjustment.

file:///C|/...20and%20Settings/iitkrana1/My%20Documents/Google%20Talk%20Received%20Files/engine_combustion/lecture14/14_2_2.htm[6/15/2012 3:01:20 PM]

Objectives_template

Module 3:Influence of Engine Design and Operating Parameters on Emissions

Lecture 14:Effect of SI Engine Design and Operating Variables on Emissions

Contd...

Fig

Effect of spark timing on NOx emissions.

3.2(a)

Fig Effect of ignition timing on HC

file:///C|/...%20and%20Settings/iitkrana1/My%20Documents/Google%20Talk%20Received%20Files/engine_combustion/lecture14/14_3.htm[6/15/2012 3:01:20 PM]

Objectives_template

3.2(b) emissions.

file:///C|/...%20and%20Settings/iitkrana1/My%20Documents/Google%20Talk%20Received%20Files/engine_combustion/lecture14/14_3.htm[6/15/2012 3:01:20 PM]

Objectives_template

Module 3:Influence of Engine Design and Operating Parameters on Emissions

Lecture 14:Effect of SI Engine Design and Operating Variables on Emissions

Air –Fuel Ratio

The effect of air-fuel ratio on engine emissions has already been discussed in Lectures 3 , 5 and 7.

Carbon monoxide results due to deficiency of oxygen during combustion and is reduced as the

mixture is leaned. CO emissions are reduced to very low values as the mixture is leaned to =

0.90 – 0.95 i.e. air-fuel ratio is increased above the stoichiometric value by 5 to 10%. Further

leaning of mixture shows very little additional reduction in the CO emissions.

With increase in air fuel ratio, the initial concentration of hydrocarbons in the mixture is reduced

and more oxygen is available for oxidation. Hydrocarbon emissions therefore, decrease with

increase in air-fuel ratio until mixture becomes too lean when partial or complete engine misfire

results which cause a sharp increase in HC emissions For < 0.8 engine may misfire more

frequently thereby increasing HC emissions sharply.

The highest burned gas temperatures are obtained for mixtures that are slightly (5 to 10 percent)

richer than stoichiometric. On the other hand, there is little excess oxygen available under rich

mixture conditions. As the mixture becomes lean, concentration of free oxygen increases but

combustion temperature start decreasing. The interaction between these two parameters results

in peak NO being obtained at about = 0.9 –0.95.

Residual Gas and EGR

Burned residual gases left from the previous cycle or part of the exhaust gas recirculated back to engine

act as charge diluents. The charge dilution by recirculation of part of the exhaust gas back to the engine

is called exhaust gas recirculation (EGR). The combustion temperatures decrease due to charge

dilution caused by the residual burned gases or EGR , the decrease in combution temperatures is

nearly proportional to the heat capacity of the diluents as discusses earlier. The lower combustion

temperatures resulting from the residual gas dilution/EGR reduces NO formation and emissions as

shown on Fig 3.3.

file:///C|/...%20and%20Settings/iitkrana1/My%20Documents/Google%20Talk%20Received%20Files/engine_combustion/lecture14/14_4.htm[6/15/2012 3:01:20 PM]

Objectives_template

Figure Effect of EGR on NO and HC emissions in normal burn and fast

3.3 burn SI engines.

As the EGR is increased the combustion rates become more and more slow, and combustion becomes

unstable. With increase in EGR cycle-to-cycle combustion variations increase and, more and more

engine cycles having only partial combustion are observed . The frequency of partial burn cycles

increases and these turn into misfired cycles at EGR rates of about more than 20%. . In the partial burn

and misfire cycles, combustion remains incomplete and results in high HC emissions. Moreover with

EGR the burned gas temperatures are reduced and post-flame oxidation also reduces. Increase in HC

becomes sharp as EGR increases beyond about 20 percent for a normal combustion engine. With EGR

rates of 20 percent or higher Fast burn engines due to higher flame speeds have higher burned gas

temperatures and tolerate higher EGR rates before the combustion

becomes very unstable and loss in fuel efficiency becomes unacceptably high. Fast burn rates are

usually obtained by use of high air swirl and increasing turbulence in the charge through use of suitable

designs of intake valve port and the combustion chamber.

The amount of charge dilution or EGR is usually limited to below 15% due to its adverse impact on

engine performance causing power loss, high specific fuel consumption and high unburned fuel

emissions.

file:///C|/...%20and%20Settings/iitkrana1/My%20Documents/Google%20Talk%20Received%20Files/engine_combustion/lecture14/14_4.htm[6/15/2012 3:01:20 PM]

Objectives_template

Module 3:Influence of Engine Design and Operating Parameters on Emissions

Lecture 14:Effect of SI Engine Design and Operating Variables on Emissions

Engine Speed

Volumetric efficiency of the engine changes with speed, it being highest in the mid-speed range. At high

engine speeds the volumetric efficiency generally decreases resulting in high residual gas dilution.

Although heat transfer rates increase with increase in engine speed as a result of higher turbulence, but

total amount of heat transfer is lower due to shorter cycle time. This gives higher gas temperatures at

higher speeds. However, at high speeds a shorter time is available for NO formation kinetics. The net

result is a moderate effect of speed on NO although this is specific to the engine design and operating

conditions. Increase in exhaust gas temperatures at higher speeds enhances post flame oxidation of

unburned hydrocarbons. A reduction of 20 to 50 percent in HC emissions has been observed with

increase in speed from 1000 to 2000 rpm.

Cold Start and Warm-up Phase

Engine cold start and warm-up phase contribute significantly to unburned hydrocarbons. One of the

main sources of HC emissions during cold start and engine warm-up period is very rich fuel-air ratio

needed for ignition and combustion for several seconds after engine start. During cold start, the engine

has to be over-fuelled 5 to10 times the stoichiometric amount of gasoline. To obtain robust ignition on

the first cycle on cold start, a fuel vapour- air equivalence ratio above lean threshold limit (f = 0.7-0.9) is

required. This threshold is independent of the engine coolant temperature. The fuel-air equivalence ratio

supplied to the engine during cold start is in the range, f = 4 to 7.

For the first few engine cycles, a large fraction of inducted fuel is stored as liquid film in the intake port

and cylinder as only the most volatile fractions evaporate when the engine is cold. The liquid fuel films

do not participate in combustion and is emitted as unburned fuel emissions.

file:///C|/...%20and%20Settings/iitkrana1/My%20Documents/Google%20Talk%20Received%20Files/engine_combustion/lecture14/14_5.htm[6/15/2012 3:01:20 PM]

Objectives_template

Module 3:Influence of Engine Design and Operating Parameters on Emissions

Lecture 14:Effect of SI Engine Design and Operating Variables on Emissions

Coolant Temperature

As the coolant temperature is increased, the contribution of piston ring zone crevice becomes lower due

to decrease in gas density within this crevice. Secondly, the top piston-land side clearance is also

reduced due to higher thermal expansion of the piston. A thinner oil film and reduced fuel vapour

solubility would result in reduced absorption of fuel vapours in engine oil. Increased postflame oxidation

at high temperatures also contributes to reduction in HC emissions. Increase in coolant temperatures

has been observed to reduce HC emissions by about 0.4 to 1.0 % per K increase in temperature. An

increase in the coolant temperature from 20 to 90º C, roughly results in 25% lower HC emissions and

hence, the need of a rapid engine warm up is obvious.

For reduction of the cold start and warm up HC emissions, an important area of development is to

improve the fuel injection and delivery to the cylinder with minimum wall wetting. Over-fuelling during

cold start and warm-up is to be kept at a minimum, while still forming the combustible charge.

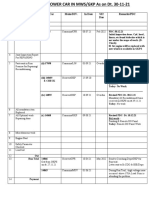

Summary

The effects of some of the important engine design and operating variables on emissions from SI

engines are summarized below Table 3.1.

Table 3.1

Effect of SI Engine Design and Operating Variables on Exhaust

Emissions

(Source: IC Engines - Combustion and Emissions by Pundir, 2010)

Variable Increased HC CO NO X

Fuel-air equivalence ratio

Compression ratio ↑ - ↑

Surface/volume ratio ↑ - ↓

Bore/stroke ratio ↑ - ↓

Ignition timing advance ↑ - ↓

Port fuel injection ↑ ↓ ↓

Engine speed ↑ - ↑↓

Engine load ↑ - ↑

Coolant temperatures ↓ - ↑

Combustion chamber deposits ↓ - ↑

EGR ↓ - ↓

Intake swirl and turbulence ↓ - ↑

↑= increase; ↓ = decrease; ↑↓= uncertain; - = no effect

file:///C|/...%20and%20Settings/iitkrana1/My%20Documents/Google%20Talk%20Received%20Files/engine_combustion/lecture14/14_6.htm[6/15/2012 3:01:20 PM]

Objectives_template

file:///C|/...%20and%20Settings/iitkrana1/My%20Documents/Google%20Talk%20Received%20Files/engine_combustion/lecture14/14_6.htm[6/15/2012 3:01:20 PM]

Das könnte Ihnen auch gefallen

- Emission Control Techniques for Diesel EnginesDokument8 SeitenEmission Control Techniques for Diesel Engineszyzz 10Noch keine Bewertungen

- Lecture15 PDFDokument14 SeitenLecture15 PDFsonu kumarNoch keine Bewertungen

- Engine-Out Characterisation Using Speed-Load Mapping and Reduced Test Cycle For A Light-Duty Diesel Engine Fuelled With Biodiesel BlendsDokument5 SeitenEngine-Out Characterisation Using Speed-Load Mapping and Reduced Test Cycle For A Light-Duty Diesel Engine Fuelled With Biodiesel BlendsLim Wei ChienNoch keine Bewertungen

- ENGINE EMISSIONS & OPERATING PARAMETERSDokument50 SeitenENGINE EMISSIONS & OPERATING PARAMETERSAnkur SachdevaNoch keine Bewertungen

- Mechanisms of CO and HC Formation in SI Engines The Lecture ContainsDokument5 SeitenMechanisms of CO and HC Formation in SI Engines The Lecture ContainsSaju SebastianNoch keine Bewertungen

- Formation of NOx and NO2 in CI EnginesDokument6 SeitenFormation of NOx and NO2 in CI EnginesgopalbarathiNoch keine Bewertungen

- 15.3. Operating Variables That Affect Si Engine Performance, Efficiency, and EmissionsDokument21 Seiten15.3. Operating Variables That Affect Si Engine Performance, Efficiency, and EmissionsDUVAN FELIPE MUNOZ GARCIANoch keine Bewertungen

- Deakin Research Online: This Is The Published VersionDokument11 SeitenDeakin Research Online: This Is The Published VersionZeusKirster VitangcolNoch keine Bewertungen

- Mechanisms of Formation of Soot and PM The Lecture ContainsDokument9 SeitenMechanisms of Formation of Soot and PM The Lecture ContainsKeval ParmarNoch keine Bewertungen

- Advances of The Natural GasDiesel RCCI Concept Application For Light-Duty Engines PDFDokument17 SeitenAdvances of The Natural GasDiesel RCCI Concept Application For Light-Duty Engines PDFUlster classicNoch keine Bewertungen

- Actual CyclesDokument12 SeitenActual Cyclesjehadyam50% (2)

- Automotive Electrical and Electronic Systems VTUDokument18 SeitenAutomotive Electrical and Electronic Systems VTUNandakumar BasavarajNoch keine Bewertungen

- A Review of Design Considerations For Light-Duty Diesel Combustion SystemsDokument15 SeitenA Review of Design Considerations For Light-Duty Diesel Combustion Systemsnpatil_10Noch keine Bewertungen

- Theories of Combustion in SI EngineDokument4 SeitenTheories of Combustion in SI EngineBALAMBAL RNoch keine Bewertungen

- CompltDokument61 SeitenCompltSachin Kumar J KNoch keine Bewertungen

- Control Emissions Variable Geometry Turbocharged DieselDokument12 SeitenControl Emissions Variable Geometry Turbocharged DieselDan PetreNoch keine Bewertungen

- Diesel Will Continue - Why Advanced Technologies Support Lower EmissionsDokument3 SeitenDiesel Will Continue - Why Advanced Technologies Support Lower EmissionsatuladeupesNoch keine Bewertungen

- "Genset Engine Development To Meet Current Emission Norms" (Conversion From CPCB-I To CPCB-II)Dokument4 Seiten"Genset Engine Development To Meet Current Emission Norms" (Conversion From CPCB-I To CPCB-II)inventionjournalsNoch keine Bewertungen

- Motor Vehicle Emission: Submitted By: HarshanDokument27 SeitenMotor Vehicle Emission: Submitted By: HarshanHarshanNoch keine Bewertungen

- Investigations On Reduction of Emissions in Spark Ignition EngineDokument8 SeitenInvestigations On Reduction of Emissions in Spark Ignition EngineTb Arief vebiantoNoch keine Bewertungen

- Fuel Air CyclcesDokument23 SeitenFuel Air Cyclcesuday kiran thagirchiNoch keine Bewertungen

- Combustion and Emission Study of Ethanol Blended Fuels in IC EnginesDokument9 SeitenCombustion and Emission Study of Ethanol Blended Fuels in IC EnginesIJRASETPublicationsNoch keine Bewertungen

- Lecture 38Dokument11 SeitenLecture 38Matthew SmithNoch keine Bewertungen

- Clean and Cool PDFDokument4 SeitenClean and Cool PDFMoaed KanbarNoch keine Bewertungen

- Experimental Analysis of A Diesel Engine With Cooled Egr Using BiodieselDokument8 SeitenExperimental Analysis of A Diesel Engine With Cooled Egr Using Biodieselglobal-marketin8184Noch keine Bewertungen

- Effect of Air Fuel Mixer Design On Engine Performance and Exhaust Emission of A CNG Fuelled VehiclesDokument5 SeitenEffect of Air Fuel Mixer Design On Engine Performance and Exhaust Emission of A CNG Fuelled VehiclesAshik MahmudNoch keine Bewertungen

- Optimization of EGR Rate On Multi Cylinders 4-Stroke Diesel Engine.Dokument7 SeitenOptimization of EGR Rate On Multi Cylinders 4-Stroke Diesel Engine.Inder MukhopadhyayNoch keine Bewertungen

- Comparison of Diesel and Petrol EnginesVon EverandComparison of Diesel and Petrol EnginesBewertung: 2.5 von 5 Sternen2.5/5 (3)

- Dual Fuel Engine Emissions and PerformanceDokument14 SeitenDual Fuel Engine Emissions and PerformanceRavi AnuNoch keine Bewertungen

- Numerical Investigation On The Effect of Injection Timing On Combustion and Emissions in A Di Diesel Engine at Low Temperature Combustion ConditionsDokument15 SeitenNumerical Investigation On The Effect of Injection Timing On Combustion and Emissions in A Di Diesel Engine at Low Temperature Combustion ConditionsErick DominguezNoch keine Bewertungen

- Lubricants Assignment Final PDFDokument22 SeitenLubricants Assignment Final PDFNitin AugustineNoch keine Bewertungen

- Long Term Continuous Use of Auto-Lpg Causes Thermal Pitting in Automotive S. I. Engine PartsDokument5 SeitenLong Term Continuous Use of Auto-Lpg Causes Thermal Pitting in Automotive S. I. Engine Partsmanit1963Noch keine Bewertungen

- Full Paper No 4 M 2Dokument10 SeitenFull Paper No 4 M 2Anonymous 8qUHG4SlNoch keine Bewertungen

- Spark Ignition Natural Gas Engines-A Review: Haeng Muk Cho, Bang-Quan HeDokument11 SeitenSpark Ignition Natural Gas Engines-A Review: Haeng Muk Cho, Bang-Quan Healejandro_roldán_61Noch keine Bewertungen

- Exhaust Gas RecirculationDokument7 SeitenExhaust Gas RecirculationPrabir Kumar PatiNoch keine Bewertungen

- HSD Term 22-23 EvenDokument38 SeitenHSD Term 22-23 EvenViraj ParmarNoch keine Bewertungen

- YANMAR Technical Review Dual FuelDokument12 SeitenYANMAR Technical Review Dual FuelKarim Sowley DelgadoNoch keine Bewertungen

- Garuda 1421187Dokument10 SeitenGaruda 1421187Imam TrionoNoch keine Bewertungen

- National Conference On Recent Trends and Developments in Sustainable Green Technologies-2015Dokument4 SeitenNational Conference On Recent Trends and Developments in Sustainable Green Technologies-2015h4harishNoch keine Bewertungen

- MTU White Paper Exhaust Gas RecirculationDokument4 SeitenMTU White Paper Exhaust Gas RecirculationSon VtNoch keine Bewertungen

- Level 7 TwoDokument7 SeitenLevel 7 TwoSire MkubwaNoch keine Bewertungen

- Effect of Cold Start Emissions From Gasoline-Fueled Engines of Light Duty Vehicles at Low and High Ambient TemperaturesDokument11 SeitenEffect of Cold Start Emissions From Gasoline-Fueled Engines of Light Duty Vehicles at Low and High Ambient TemperaturesTanuj ChauhanNoch keine Bewertungen

- Pengaruh Masa Pakai Dan Tingkat Transmisi Terhadap Kadar Emisi Gas Buang Sepeda Motor Honda Astrea GrandDokument6 SeitenPengaruh Masa Pakai Dan Tingkat Transmisi Terhadap Kadar Emisi Gas Buang Sepeda Motor Honda Astrea GrandettypasewangNoch keine Bewertungen

- Influence of Pilot Injection On Combustion Characteristics and Emissions in A Di Diesel Engine Fueled With Diesel and DmeDokument9 SeitenInfluence of Pilot Injection On Combustion Characteristics and Emissions in A Di Diesel Engine Fueled With Diesel and DmeLia LismeriNoch keine Bewertungen

- Investigating Diesel Engine Performance and Emissions Using CFDDokument10 SeitenInvestigating Diesel Engine Performance and Emissions Using CFDmfmechanics2020Noch keine Bewertungen

- Ctual Cycles and Their AnalysisDokument7 SeitenCtual Cycles and Their AnalysisAndlnatu TDNoch keine Bewertungen

- Lecture 31Dokument8 SeitenLecture 31Matthew SmithNoch keine Bewertungen

- 259-266 J O KONES 2015 NO. 2 Vol. 22 ISSN 1231-4005 TUTAK PDFDokument8 Seiten259-266 J O KONES 2015 NO. 2 Vol. 22 ISSN 1231-4005 TUTAK PDFtsegayNoch keine Bewertungen

- Exhaust Gas Recirculation ReportDokument18 SeitenExhaust Gas Recirculation Reportashoku2Noch keine Bewertungen

- Ultra-Low-Emission Diesel Engine Fuelled With Dimethoxymethane-Diesel Fuel BlendsDokument10 SeitenUltra-Low-Emission Diesel Engine Fuelled With Dimethoxymethane-Diesel Fuel BlendsPratik Ramesh PappaliNoch keine Bewertungen

- Energy Conversion and Management: S. D'ambrosio, A. FerrariDokument12 SeitenEnergy Conversion and Management: S. D'ambrosio, A. FerrariCostin DanielNoch keine Bewertungen

- H2ICEDokument10 SeitenH2ICElucasNoch keine Bewertungen

- A Report On: Gasoline Direct Injection EngineDokument17 SeitenA Report On: Gasoline Direct Injection EngineSrikanth Kabbal MNoch keine Bewertungen

- Project Report NewDokument14 SeitenProject Report NewAbhishek SinghNoch keine Bewertungen

- Ic Engine PaperDokument19 SeitenIc Engine PaperAjitKumarPandeyNoch keine Bewertungen

- Lecture20 PDFDokument8 SeitenLecture20 PDFMusabbab Ahmad NaifNoch keine Bewertungen

- NOx Emission Control Technologies in Stationary and Automotive Internal Combustion Engines: Approaches Toward NOx Free AutomobilesVon EverandNOx Emission Control Technologies in Stationary and Automotive Internal Combustion Engines: Approaches Toward NOx Free AutomobilesB. AshokNoch keine Bewertungen

- Natural Gas Processing from Midstream to DownstreamVon EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNoch keine Bewertungen

- Hydrogen Production TechnologiesVon EverandHydrogen Production TechnologiesMehmet SankirNoch keine Bewertungen

- Hyundai D4FB Diesel Fuel System 2Dokument727 SeitenHyundai D4FB Diesel Fuel System 2Alexey Koshelnik100% (1)

- Hatz Repair ManualDokument174 SeitenHatz Repair ManualGeert Vda92% (12)

- Test Specifications for Mazda R2 Injection PumpDokument3 SeitenTest Specifications for Mazda R2 Injection PumpMiguel RojasNoch keine Bewertungen

- Catalogo Motor Honda GX630Dokument28 SeitenCatalogo Motor Honda GX630Paulo RibeiroNoch keine Bewertungen

- Gen Set 30 KVA HA 494Dokument20 SeitenGen Set 30 KVA HA 494Pankaj TiwariNoch keine Bewertungen

- Reservedelskatalog Lombardini 15 LD400Dokument32 SeitenReservedelskatalog Lombardini 15 LD400Joao SilvaNoch keine Bewertungen

- Motor 2.0 T Tsi InfoDokument56 SeitenMotor 2.0 T Tsi InfoRicardo Rangel Posadas100% (2)

- TOYOTA & IMPORT VEHICLE HARNESS GUIDEDokument6 SeitenTOYOTA & IMPORT VEHICLE HARNESS GUIDEcarropracapracaNoch keine Bewertungen

- S. No Stages of Power Car During D-Check Power Car Make/DIV. in Date SS2 Due Remarks/PDCDokument12 SeitenS. No Stages of Power Car During D-Check Power Car Make/DIV. in Date SS2 Due Remarks/PDCshakeel alamNoch keine Bewertungen

- Workshop Manual Royal EnfieldDokument41 SeitenWorkshop Manual Royal EnfieldThierry Roman100% (1)

- T 580rtsa55626 1 Pmrev0 161212215238Dokument141 SeitenT 580rtsa55626 1 Pmrev0 161212215238Irwin Gonzalez100% (1)

- Lubrication System GuideDokument10 SeitenLubrication System Guidelaura MtNoch keine Bewertungen

- Motorcycle Mechanics General Manual PDFDokument270 SeitenMotorcycle Mechanics General Manual PDFkillfreely83% (47)

- 2000 2.4L (LD9) J-car Engine Diagnostic ParametersDokument10 Seiten2000 2.4L (LD9) J-car Engine Diagnostic ParametersFelipe ValdebenitoNoch keine Bewertungen

- Codigos Motor 1kdDokument5 SeitenCodigos Motor 1kdJenny Mora LeonNoch keine Bewertungen

- Dat Pu126ti PDFDokument2 SeitenDat Pu126ti PDFناجى ابوعورةNoch keine Bewertungen

- M20 Displacement PDFDokument3 SeitenM20 Displacement PDFgowrielNoch keine Bewertungen

- Varad Bichu Varun Shreedhar Chitnis Vinayaka B S Vishnuraj Mankude Under The Able Guidance Of: PROF. V. V. KulkarniDokument25 SeitenVarad Bichu Varun Shreedhar Chitnis Vinayaka B S Vishnuraj Mankude Under The Able Guidance Of: PROF. V. V. KulkarniVarun Shreedhar ChitnisNoch keine Bewertungen

- PMB 668Dokument3 SeitenPMB 668Sergio Ramos RiveraNoch keine Bewertungen

- Glamour Fi PDFDokument100 SeitenGlamour Fi PDFMohammed RayeezNoch keine Bewertungen

- Toyota Trouble CodesDokument12 SeitenToyota Trouble Codesnekotamo123100% (1)

- dr8h Ufaa92 UsaDokument8 Seitendr8h Ufaa92 UsaAnandNoch keine Bewertungen

- Catalogo New Holland7630-8030 4-CILIN - BRADokument506 SeitenCatalogo New Holland7630-8030 4-CILIN - BRAmarcio50% (2)

- XG25-XG30: 44208060100 REV.003 03/2008 This Catalogue Is Valid For Trucks As From Serial NumbersDokument153 SeitenXG25-XG30: 44208060100 REV.003 03/2008 This Catalogue Is Valid For Trucks As From Serial Numbersalexandre donizetiNoch keine Bewertungen

- TM 9-6115-670-14P Mep 903 Part 2 (Of2)Dokument315 SeitenTM 9-6115-670-14P Mep 903 Part 2 (Of2)AdvocateNoch keine Bewertungen

- Chevrolet Pinout Diagrama SPARK 2001 MatizDokument3 SeitenChevrolet Pinout Diagrama SPARK 2001 MatizJarlinson Oyuela100% (1)

- Illustrated Parts Catalogue for UL350i and UL350iS EnginesDokument40 SeitenIllustrated Parts Catalogue for UL350i and UL350iS EnginesDarren-Edward O'NeillNoch keine Bewertungen

- Timing Chain InstallationDokument5 SeitenTiming Chain InstallationToriTo LevyNoch keine Bewertungen

- @perkins: 1000 SeriesDokument2 Seiten@perkins: 1000 SeriesAnas BasarahNoch keine Bewertungen