Beruflich Dokumente

Kultur Dokumente

Model Based Development of Future Small Electric Vehicle by Modelica

Hochgeladen von

shubhamformeOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Model Based Development of Future Small Electric Vehicle by Modelica

Hochgeladen von

shubhamformeCopyright:

Verfügbare Formate

Model Based Development of Future Small Electric Vehicle by

Modelica

Yutaka Hirano 1 Shintaro Inoue 1 Junya Ota 1

1

Toyota Motor Corporation, Japan, {yutaka_hirano, shintaro_inoue_aa,

junya_ota}@mail.toyota.co.jp

Abstract This feature of Modelica is very powerful for model-

For future low carbon mobility society, new-type small based system development because it enables to

electric vehicles (EVs) are developed actively in recent modify the whole vehicle model very easily by using

period. To reduce the energy consumption in various the results of experiments and physical investigations

actual driving conditions, considering overall running of each component. It is just necessary to replace the

resistance from tire characteristics, mechanical losses existing equations of the component model to the

and electrical losses is necessary. In this paper, model- modified ones and replace the component model to the

based development of system performance of a new revised one by object-oriented way.

EV is described. Full vehicle model considering both In the previous paper (Hirano, 2014), authors

vehicle dynamics and energy consumption was showed the capability of new construction of the new

developed using Modelica. Research for both structure EV using new type tire based on ‘Large and Narrow

and specification of components of the vehicle and also concept’ and torque vectoring differential gear. For the

of the control were performed to find the solution to model based development of the new EV, various kind

satisfy both energy consumption and vehicle dynamics of running resistance, vehicle dynamic performance

by using the full vehicle model. Finally trade-off and proper design of electric regeneration system were

between vehicle stability and energy consumption and studied.

also between driver workload and energy consumption In this paper, a multi-physics full vehicle model of

by using direct yaw moment control was indicated. the new EV is expanded to consider the detailed loss of

motors and inverters. Also front and rear suspension

Keywords: Model Based System Development, Vehicle model which has same 3D mechanical design as the

Dynamics, Energy Consumption, Electric Vehicle real experimental vehicle was made and verified. By

technical investigations using this full vehicle model,

1 Introduction structure, specifications and control of the new EV

To satisfy needs for future low-carbon mobility society, system were researched about vehicle dynamics and

development of many new small electric vehicles energy consumption.

(EVs) is increasingly active in recent years. Those

vehicles are often smaller and lighter than conventional 2 Characteristics of Target EV

vehicles and are often equipped with low RRC (Rolling

Table 1. Specifications of new experimental EV

Resistance Coefficients) tires for less energy

consumption. On the other hand, low RRC tires tend to Conventional

New EV

have less cornering performance than conventional car

tires in general. Because of light weight and low RRC Vehicle Weight 750 kg 1240 kg

tires, those vehicles become to have reduced dynamic Yaw Moment Inertia 869 kgm2 2104 kgm2

stability against external disturbances such as side Wheelbase 2.6 m 2.6 m

wind. To analyze and cope with all the problems about Front : Rear Weight

0.48 : 0.52 0.62 : 0.38

energy consumption and vehicle stability, a holistic Distribution

approach of vehicle system design considering multi- Height of CG 0.38 m 0.55 m

Aerodynamic Drag

physics of mechanics, electrics, aerodynamics, control 0.392 m 2

0.644 m2

and so on is necessary. ×Frontal Area

For this purpose, authors made an integrated model Tire RRC 5×10-3 8.8×10-3

of the total vehicle system using acausal multi-domain Tire Normalized CP 16.1 20.4

physical modeling language Modelica (Hirano, 2014).

By using Modelica, it is only necessary to define The proposed experimental EV has specifications as

physical relationship written as equations in each shown in Table 1. Compared with a conventional

component model and connect those component small-class passenger car, the new EV has

models as same as assembling the components to make characteristics of lighter vehicle weight, smaller yaw

the model of the whole system by hierarchical way. moment of inertia, lower height of the center of gravity

DOI Proceedings of the 11th International Modelica Conference 143

10.3384/ecp15118143 September 21-23, 2015, Versailles, France

Model Based Development of Future Small Electric Vehicle by Modelica

(CG) and lower RRC value of tires. Because of these 3.2 Mechanical Power by Driving Resistances

characteristics, this new EV is expected to have better Power consumption of each system was calculated

handling and lower energy consumption than simultaneously to investigate the good balance of

conventional vehicles. On the other hand, because of energy consumption and vehicle performances. At first,

lighter weight and lower value of tire normalized CP total mechanical power of driving resistances acting on

(Cornering Power), this new EV seems more sensitive the vehicle was calculated by following equations

against external disturbances such as crosswind and (Kobayashi et al., 2013).

road irregularity than the conventional cars. To cope

with this problem, direct yaw moment control (DYC) Total driving resistance power:

was applied by using a new integrated transaxle unit

for rear axle which has a main electric motor and also Pv Prr Par Psy Psx (1)

torque-vectoring differential (TVD) gear unit with a Rolling resistance power:

control motor. Prr r Mg V (2)

Aerodynamic resistance power:

3 Full Vehicle Model

Par ACDV 2 / 2 V (3)

3.1 Structure of the Full-Vehicle Model

Cornering drag resistance power:

To consider total balance of energy consumption,

handling, stability, ride comfort and NVH (noise, d f d

Psy r MAy2 / g V (4)

vibration, harshness) of the vehicle, a full vehicle

C pf C pr

model including mechanics, electronics, vehicle

dynamics and control was developed based on Longitudinal resistance power:

commercially available Vehicle Dynamics Library Psx (MAx Mg sin ) V (5)

(Modelon, 2014). The vehicle dynamics model was Here

built as a full 3-dimentional (3D) multi-body-dynamics

model of all of vehicle body, suspension, tires and r : tire rolling resistance coefficient (RRC) ,

power train. Aerodynamics was also considered in the g: acceleration of gravity [m/s2],,

vehicle dynamics model. Component models of control M: vehicle mass [kg],

systems such as TVD gearbox, electric motor and V: vehicle speed [m/s],

inverter were newly developed and connected with the : air density [kg/m3],

full vehicle model. The control logic for DYC was also A: vehicle frontal area [m2],

implemented as a controller block model. Additionally,

driving environment such as road shape, side wind and

C D : aerodynamic resistance coefficient,

air parameters (density, temperature, etc.) can be d f : front weight distribution ratio,

defined as the environment model. Figure 1 shows the

top level of model hierarchy of the full vehicle model.

d r : rear weight distribution ratio,

C pf : front normalized cornering power [1/rad],

C pr : rear normalized cornering power [1/rad],

C p : average normalized cornering power [1/rad],

Ay : lateral acceleration [m/s2],

Ax : longitudinal acceleration [m/s2],

: road inclination [rad].

Total mechanical power of driving resistances can

be calculated by equation (1) to equation (5) by using

state variables of vehicle motion.

3.3 TVD Gear Train Model

For the TVD gear train, a driveline structure

referencing the MUTE project of the Technische

Universität München (TUM) (Höhn et al., 2013) was

selected and the TVD model was constructed using

Figure 1. Top level structure of full vehicle mode commercially available Power Train Library (DLR,

2013) .

144 Proceedings of the 11th International Modelica Conference DOI

September 21-23, 2015, Versailles, France 10.3384/ecp15118143

Session 2D: Automotive Applications 1

1 0.97 τ A ωAB 0, τ A 0

1 1 / 0.97 τ ωAB 0, τ A 0

Δτ A

(6)

1 0 .97 τ A ωAB 0, τ A 0

1 1 / 0.97 τ A

ωAB 0, τ A 0

where, τA is the sun gear torque and ωAB is the difference

in the speed of the sun gear and the carrier of the

planetary gear.

Figure 4 shows a simulation result to investigate the

torque distribution ability of the TVD. It became clear

that this TVD unit has capability of distributing the

driving torque between right and left wheels according

Figure 2. Torque vectoring differential (TVD) driveline

to the input torque of the control motor and the torque

distribution ratio can be bigger than ordinary LSD

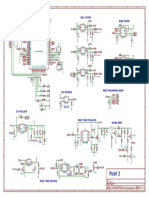

Figure 2 shows the configuration of the gear trains.

(limited slip differential) gear set if the mechanical

This gear trains have a complex configuration

strength is enough to cope with the maximum torque.

constructed from several planetary gear sets. Torque

The torque distribution ability is thus only limited by

from the main motor is distributed equally to the left

mechanical strength of the gear sets and the ability of

and right wheel through the differential gear. Sun gear

the control motor.

3 is connected to carrier 2 in the control gear portion,

Figure 5 shows an example of calculation result of

and this configuration generates differences in torque

each gear speed of the TVD. It was confirmed that this

between the left and right wheel by increasing or

result coincide with the actual motion.

decreasing the torque distributed to the wheel on one

side by torque input of the control motor.

Specifications of the motors are shown in Table 2.

Table 2. Motor specification

Main Motor Control Motor

Max Torque 65 Nm 40 Nm

Max Speed 10,000 rpm 1,050 rpm

Max Power 15 kW 2 kW

Rdif

Rdif_rpm

right w

P4

w add1

C34

+1

controlMotor

mountB6 w

C34_rpm

+

-1add2

P4_rpm

Figure 4. Torque distribution ability of TVD

P3

+1

P3_rpm

Torque Vectoring Gear Box w -1

+

support by PowerTrain Library S4

S4_rpm

w

S3

S3_rpm

S4_LeftTyre

mountA C4_RightTyre w

R2

R2_rpm

differential Part2 Part1

w

C2

C2_rpm

w

S2

S2_rpm

mountB3 w

R1

Brake R1_rpm

w

C1

C1_rpm

w

S1

S1_rpm

left w

Figure 3. Modelica model of TVD gear train

Figure 3 shows a diagram of Modelica model of the

torque vectoring gear train. The model is provided with

elements that define the relational expression between

the torque and speed of each gear engagement portion.

Furthermore, these elements are capable of factoring in

the overall gear torque loss by defining the torque loss Figure 5. Example of TVD gear speed calculation

for each element by following equations[7].

DOI Proceedings of the 11th International Modelica Conference 145

10.3384/ecp15118143 September 21-23, 2015, Versailles, France

Model Based Development of Future Small Electric Vehicle by Modelica

3.4 Electrical Model of Motor and Inverter vod 0 e Lq iod 0

v (11)

oq e Ld 0 ioq

e a

where, vd and vq are the voltage of the d and q axis,

respectively, id and iq are the current of the d and q axis,

respectively, ωe is the electric angular velocity, Ra is

the winding unbalance voltage attenuation, Rc is the

Figure 6. Equivalent circuits of each motor equivalent iron loss resistance, Ld and Lq are the

inductance of the d and q axis, respectively, and a is

the inter-linkage magnetic flux. Also the motor

characteristics of efficiency according to motor torque

and rotational speed are considered as shown in Figure

8.

The inverter can be handled simply as a component

that generates loss Linv proportionally to the current

vectors of the motors as follows.

LInv I a (12)

3.5 Mechanical Model of Suspension and Body

3D multi-body dynamic system (MBS) models of

suspension, steering and body were installed to

Figure 7. Electrical motor model by Modelica

calculate vehicle dynamics characteristics. Suspension

model was constructed as an assembled model of each

suspension linkage, joints and force elements such as

spring, damper and bushing. Non-linear tire model

based on ‘Magic Formula’ model (Pacejka02) was

used to calculate combined lateral force and

longitudinal force of each tire. Steering model

considered the characteristics of viscous friction of

steering gear box and steering shaft as well as steering

shaft stiffness. By these detailed models, it became

possible to analyze the effects of steering angle change

and camber angle change caused by vehicle roll, side

Figure 8. Motor characteristics force and tire aligning torque.

Figure 9 shows a comparison of simulation results

Both the main and control motors installed in the target and experimental test results about camber angle

EV are permanent magnet synchronous motors. The change by wheel bump displacement and steering

equivalent circuits of these motors can be expressed as angle change by tire aligning moment. It was

shown in Figure 6 as d-axis and q-axis direct current confirmed that the simulation results matched with the

(DC) circuits (Park, 1933). It is not necessary to experimental results with good consistency.

describe the explicit equations here since modeling can Figure 10 shows an analysis result about the effect

be performed simply by laying out each device as of suspension characteristics to cornering compliance

shown in Figure 7 using freely available electric circuit coefficient normalized by the effect of tire slip angle

library of Modelica Standard Libraries (MSL). change for one example of a front double wish-born

Concurrently copper loss LCu and iron loss LFe of each suspension. It became clear that the effect of the tire

motor are calculated using following equations (Inoue aligning torque to tire toeing angle is relatively large

et al., 2014). than other design indexes.

LCu Ra I a 2 Ra id 2 iq 2 (7)

Also 6 degree-of-freedom motion of the vehicle

body was calculated by considering all the reaction

e 2 Ld iod a Lq ioq forces and torques acting at suspension upper support

2 2

vod 2 voq 2

LFe (8) and all of the connection portions of the linkages.

Rc Rc Additionally 3D MBS model of TVD gear unit mounts

id iod icd , iq ioq icq (9) was applied in the vehicle dynamics model. And

vd iod Ra vod Ld 0 iod rotational stiffness of the drive shafts was also

v Ra i 1 v p

Lq ioq

(10) considered. This feature enabled calculation of the

q oq Rc oq 0 body motion (mainly pitching motion) caused by the

146 Proceedings of the 11th International Modelica Conference DOI

September 21-23, 2015, Versailles, France 10.3384/ecp15118143

Session 2D: Automotive Applications 1

reaction of driving torque and oscillation caused by Figure 11. Slip angle feedback controller shown in

resonance of tire rotational stiffness, drive shaft Figure 12 aims to let the vehicle slip angle to zero to

stiffness and differential gear mount stiffness. stabilize the vehicle attitude while cornering and lane

change.

Figure 11. Yaw rate feedback controller of DYC

Figure 12. Slip angle feedback controller of DYC

In both controllers, the main motor performs

feedback control by proportional and integral (PI)

control of the vehicle speed because the vehicle speed

is dominant for the total driving torque supplied by the

main motor. The control motor performs feedback

control by PI control of the yaw rate and vehicle slip

angle respectively. As shown in Figure 4, control

motor changes the distribution of left wheel torque TRL

Figure 9. Example of suspension characteristics and right wheel torque TRR. Therefore the vehicle

motion can be changed by yaw moment generated by

the torque difference between left wheel and right

wheel. In general, the vehicle motion can be estimated

by single track model of vehicle dynamics described by

equation (13) and (14).

c f cr a f c f ar cr

1

d MV

MV 2

dt a f c f a r cr a f c f a r cr

2 2

Iz I zV

(13)

cf cr

0

aMV MV f 1 N

ac

f cf r r r I z

I z I z

Figure 10. Effect of suspension characteristics to N = w(TRL – TRR) / rt (14)

cornering compliance coefficient. (Normalized by the Here,

effect of tire slip angle.) : Vehicle slip angle [rad]

: Yaw rate [rad/s]

M : Vehicle mass [kg]

3.6 Model of DYC Controller

V : Vehicle speed [m/s]

The control element generates the torque command Iz : Vehicle yaw moment of inertia [kgm2]

values of the main motor and control motor. These af : Length between front axle and CG [m]

command values are then input into the motor models. ar : Length between rear axle and CG [m]

Two kinds of DYC controller were researched. Yaw l : Wheel base炷= af +ar炸[m]

rate feedback control to let the vehicle yaw rate follow cf : Front tire cornering power [N/rad]

the desired yaw rate for stabilizing crosswind cr : Rear tire cornering power [N/rad]

disturbances comprises the control laws shown in f : Front tire steering angle [rad]

DOI Proceedings of the 11th International Modelica Conference 147

10.3384/ecp15118143 September 21-23, 2015, Versailles, France

Model Based Development of Future Small Electric Vehicle by Modelica

r : Rear tire steering angle [rad] relationship between the vehicle slip angle and energy

: Direct yaw moment [Nm] consumption in the β=0 control. Figure 15 shows the

rt : Tire radius [m] same relationship for the yaw rate feedback control.

w : Tread [m] Here, the target yaw rate was calculated by following

equation.

V

3.7 Model of Energy Consumption by Electric * K yaw _ gain (19)

R

Drives In the case of both controls, the turning resistance

Energy consumption in mechanical part (= gear train), became lower as the slip angle and steering angle

electrical part (= motor, inverter) are calculated by decreased. As a result, the power of the main motor

using following equations. decreased (point “i” in Figure 14 and Figure 15). In

2 contrast, application of TVD generated mechanical loss,

Pe Pm Lmj Lej (15) which resulted in an overall increase in energy

j 1

consumption due to the energy consumption of the

Pm Pv I z Prr Par Psy Psx I z (16) control motor (point “ii” in Figure 14 and Figure 15).

Lmj 0.95 (TM TC ) (17) Furthermore, the TVD mechanical loss was lower than

the electrical loss. This result indicates that, in this

Lej LCuj LFej LInvj (18) configuration, a reduction in motor/inverter electrical

Here, Pe is the sum of the energy consumption, Pm loss is extremely important for reducing energy

is the total mechanical work using driving resistance consumption. Finally, further examination of the β=0

power defined by equation (1), Lmj is the TVD control in Figure 14 shows that a very slight vehicle

mechanical loss, and Lej is the electrical loss of motor slip angle remains when the control is applied (point

and inverter. LCuj is copper loss, LFej is iron loss and “iii” in Figure 14). Focusing on the TVD control motor

LInvj is switching loss of inverter respectively. Here, torque shows that, in an ideal condition without TVD

j=1 refers to the main motor and j=2 refers to the or motor/inverter loss (Figure 16), the vehicle slip

control motor. Since it is difficult to accurately angle is zero because the power of the control motor

calculate the TVD mechanical loss including all kinds does not exceed the maximum possible output torque

of friction, the calculation assumes a constant overall of 40 Nm. However, after factoring in each type of loss,

efficiency of 95% of main motor torque TM and control the control motor power becomes saturated (point “iv”

motor torque Tc. in Figure 16). In this way, integrating different

Figure 13 shows the calculation results using the full- physical models into a single model enables

vehicle model in steady-state cornering with a turning quantitative studies of the effects of each type of loss

radius of 60 m and a vehicle speed of 40 km/h. The on vehicle dynamics and control.

calculated results using the full-vehicle model closely

matched the theoretical results calculated based on

Equations (15) and (16), thereby confirming the validity

of this model. It is shown that electrical loss increases

much when large DYC torque is applied.

Figure 13. Comparison of energy consumption

Figure 14. Energy consumption with β=0 control

4 Simulation Results

4.1 Steady State Cornering

The simulation of steady state cornering assumed

running condition of a turning radius R of 135 m and a

vehicle speed V of 60 km/h. Figure 14 shows the

148 Proceedings of the 11th International Modelica Conference DOI

September 21-23, 2015, Versailles, France 10.3384/ecp15118143

Session 2D: Automotive Applications 1

Figure 18 shows the time-series data for the total

energy consumption and steering wheel angle with a

yaw gain ratio of 1.5. (Abbreviation of ‘W/O Control’

means ‘Without Control’.) Although yaw gain control

causes an increase in total energy consumption, the

steering wheel angle decreases. These prediction

results facilitate the identification of the optimum

control gain with respect to a set system configuration,

assuming real-world driving conditions.

Figure 15. Energy consumption with yaw rate feedback

Control

Figure 17. Time-series data for lateral acceleration

Energy Consumption [kW] 10

W/O Control Total 0.077 kWh/km

9

With Control Total 0.080 kWh/km

8

7

6

5

4

3

3 0 100 200 300 400 500

W/O Control Average 0.33 rad/s

Steering Wheel Angle [rad]

2

With Control Average 0.22 rad/s

Figure 16. Relationship between vehicle slip angle and 1

control motor torque with β=0 control 0

-1

-2

4.2 Winding Road Driving

-3

Actual driving conditions generally feature many turns 0 100 200 300 400 500

and the proposed EV is also likely to be driven while Time [s]

utilizing controls to actively enhance dynamic

Figure 18. Time-series data (upper: energy consumption,

performance. Therefore, to simply evaluate lower: steering wheel angle)

performance under real-world driving conditions, a

study was performed on winding roads to simulate

actual continuous steady-state cornering. The study

5 Conclusions

simulated an actual 8.1 km winding road course, which

combines straight sections and gradients. This paper described the development of a full-vehicle

First, the course was constructed using the model to quantitatively evaluate the relationship

commercially available CarMaker software. Driving between vehicle dynamics with DYC input and energy

behavior was predicted using a driver model of consumption for a small EV. The following

CarMaker assuming a constant speed of 60 km/h. conclusions were obtained.

Developed Modelica model of TVD was connected (i) TVD drivelines with several planetary gear

with CarMaker using FMI (Functional Mockup sets and motor/inverters with multiple

Interface). Only vehicle speed was set in the driver electrical elements can be constructed simply

model and lateral acceleration was calculated during in one model using Modelica.

the simulation. By using CarMaker as a virtual driving (ii) The model was able to quantitatively identify

test platform, it became possible to combine the good the breakdown of energy consumption

realistic driver model of CarMaker and the detailed increases and decreases for achieving the

drive train model made by using Modelica. target vehicle dynamics. In addition, it was

Finally, the energy consumption and steering wheel found that reducing motor loss makes a larger

angle by the driver model were predicted using the

time-series data for lateral acceleration in Figure 17.

DOI Proceedings of the 11th International Modelica Conference 149

10.3384/ecp15118143 September 21-23, 2015, Versailles, France

Model Based Development of Future Small Electric Vehicle by Modelica

contribution to lower energy consumption than

reducing TVD mechanical loss.

(iii) The real-world energy consumption and

driver’s workload (steering wheel angle)

through DYC was predicted on a simulated

course based on actual winding roads.

For future works, it is planned to consider the effect

of drive shaft stiffness for TVD control. Also

controlling tire slip by motor torque as well as

maximizing regeneration by breaking is essential to

expand the capability of electric control of optimal tire

slip control. This work will also be useful to design a

proper system configuration of mechanical break and

electric break and also designing proper torque

blending control.

References

DLR, PowerTrain Library Users Guide (Version 2.1.0), 2013

Y. Hirano, S. Inoue and J. Ota, Model-based Development

of Future Small EVs using Modelica, Proceedings of

Modelica Conference 2014, 2014.

B. Höhn et al., Torque Vectoring Driveline for Electric

Vehicle, Proceedings of the FISITA 2012 World

Automotive Congress, Vol. 191, pp. 585-593, 2013.

S. Inoue, J. Ota, Y. Hirano, T. Kobayashi, A. Kawaguchi and

H. Sugiura, Study on Full-Vehicle Model Integrating

Vehicle Dynamics and Energy Consumption, Proceeding

of 12th International Symposium on Advanced Vehicle

Control (AVEC’14), 20149329, 2014.

T. Kobayashi, E. Katsuyama, G. Sugiura, E. Ono, M.

Yamamoto, A research about driving force distribution

control and energy consumption while cornering,

Proceeding of 2013 JSAE Annual Congress (Spring), 352-

20135393, 2013 (in Japanese).

Modelon, A.B., Vehicle Dynamics library Users Guide

(Version 1.8), 2014.

R.H.Park, Two-reaction Theory of Synchronous Machines:

Part II, AIEE Trans., Vol.52, pp.352-355, 1933.

C. Pelchen et al., Modeling and Simulating the Efficiency of

Gearboxes and of Planetary Gearboxes, Proceedings of

2nd International Modelica Conference, pp. 257-266,

2002.

150 Proceedings of the 11th International Modelica Conference DOI

September 21-23, 2015, Versailles, France 10.3384/ecp15118143

Das könnte Ihnen auch gefallen

- A Dynamic Model For The Performance and Environmental Analysis of An Innovative E-BikeDokument10 SeitenA Dynamic Model For The Performance and Environmental Analysis of An Innovative E-BikeGuna SeelanNoch keine Bewertungen

- BMA4723 Vehicle DynamicsDokument327 SeitenBMA4723 Vehicle DynamicsFu Hong75% (4)

- Dr. Reckeweg Reference Guide - United RemediesDokument4 SeitenDr. Reckeweg Reference Guide - United RemediesshubhamformeNoch keine Bewertungen

- Inverted Delta Wig Effect Aircraft 1Dokument92 SeitenInverted Delta Wig Effect Aircraft 1xxxguysNoch keine Bewertungen

- Modeling, Simulation, and Analysis of Hybrid Electric Vehicle Using MATLAB Simulink2Dokument5 SeitenModeling, Simulation, and Analysis of Hybrid Electric Vehicle Using MATLAB Simulink2SureshNoch keine Bewertungen

- General Loads On Aircraft StructureDokument42 SeitenGeneral Loads On Aircraft StructureSunil Panwar86% (7)

- Effect of Transmission Design On Electric Vehicle (EV) PerformanceDokument6 SeitenEffect of Transmission Design On Electric Vehicle (EV) PerformanceSwati NikamNoch keine Bewertungen

- Power Control Unit, Hydraulic - SizingDokument4 SeitenPower Control Unit, Hydraulic - SizingdodoNiyo100% (1)

- 03 2D-3D GeometryDokument77 Seiten03 2D-3D GeometryTuseeq RazaNoch keine Bewertungen

- LCR-92 - Installation ManualDokument122 SeitenLCR-92 - Installation Manualramiro69100% (2)

- What Are Disadvantages of Wing SweepDokument57 SeitenWhat Are Disadvantages of Wing SweepElton CacefoNoch keine Bewertungen

- Missile GuidanceDokument59 SeitenMissile GuidanceSardendu PramanikNoch keine Bewertungen

- Basics of Electric Vehicle Technology and A DesignDokument6 SeitenBasics of Electric Vehicle Technology and A DesignCarlos HT Tmberto Tranamil BarrosNoch keine Bewertungen

- Basics of Electric Vehicle Technology and A Design StudyDokument5 SeitenBasics of Electric Vehicle Technology and A Design StudyHuynh Thanh AnhNoch keine Bewertungen

- Thermal Management of Electric Vehicle Battery SystemsVon EverandThermal Management of Electric Vehicle Battery SystemsNoch keine Bewertungen

- Flight Stability and Control of Tailless Lambda Unmanned AircraftDokument5 SeitenFlight Stability and Control of Tailless Lambda Unmanned AircraftDr Pascual MarquesNoch keine Bewertungen

- Sample Paper 1Dokument8 SeitenSample Paper 1Kunal Thakran100% (1)

- Flight DynamicsDokument57 SeitenFlight Dynamicsmarker_inNoch keine Bewertungen

- 28 Fuel PDFDokument222 Seiten28 Fuel PDFcarlos manuel restrepo rendonNoch keine Bewertungen

- 4 A Comparison of Vehicle Simulation Software and Dynamometer Results For Battery Electric VehiclesDokument6 Seiten4 A Comparison of Vehicle Simulation Software and Dynamometer Results For Battery Electric Vehiclesbirdview champlainNoch keine Bewertungen

- FINALVERSIONDokument12 SeitenFINALVERSIONquang caoNoch keine Bewertungen

- Parallel HEV Hybrid Controller Modeling For Power ManagementDokument7 SeitenParallel HEV Hybrid Controller Modeling For Power ManagementIago HenriqueNoch keine Bewertungen

- Optimal Energy Control Strategy Design For A HybriDokument9 SeitenOptimal Energy Control Strategy Design For A HybribhargavNoch keine Bewertungen

- Torque Vectoring For Electric Vehicles With Individually Controlled Motors: State-of-the-Art and Future DevelopmentsDokument12 SeitenTorque Vectoring For Electric Vehicles With Individually Controlled Motors: State-of-the-Art and Future DevelopmentseldincelebicNoch keine Bewertungen

- PM BLDC RatingsDokument7 SeitenPM BLDC RatingsBHARDA KUNJNoch keine Bewertungen

- Design and Static Analysis of Regenerative Shock Absorber PDFDokument6 SeitenDesign and Static Analysis of Regenerative Shock Absorber PDFKarthek SpNoch keine Bewertungen

- 13 Ijaet Vol III Issue II 2012Dokument6 Seiten13 Ijaet Vol III Issue II 2012Arun GargNoch keine Bewertungen

- Paper 2 PDFDokument6 SeitenPaper 2 PDFSwati NikamNoch keine Bewertungen

- Chapter Electric VehicleDokument51 SeitenChapter Electric VehicleAmit goyalNoch keine Bewertungen

- 1.an Introduction To Regenerative Braking of Electric Vehicles AsDokument5 Seiten1.an Introduction To Regenerative Braking of Electric Vehicles AsEssa SiddiquiNoch keine Bewertungen

- Design of A Hybrid Electric Motorcycle For OptimumDokument9 SeitenDesign of A Hybrid Electric Motorcycle For OptimumAryan AmeenNoch keine Bewertungen

- Design of B-S SystemDokument6 SeitenDesign of B-S SystemRadoy CristyNoch keine Bewertungen

- Novel Operation and Control of An Electr PDFDokument12 SeitenNovel Operation and Control of An Electr PDFRohanNoch keine Bewertungen

- Mechanical Engineering and SciencesDokument11 SeitenMechanical Engineering and ScienceswarnoiseNoch keine Bewertungen

- Draft 2Dokument22 SeitenDraft 2Poornima MNoch keine Bewertungen

- Cost Estimation of Electric Traction Machine and Gearbox For A Hybrid Vehicle ApplicationDokument5 SeitenCost Estimation of Electric Traction Machine and Gearbox For A Hybrid Vehicle ApplicationPrafulla DandgeNoch keine Bewertungen

- ICAC2021 YK NAO VV DI DG Optimized Selfadaptive PID Speed Control For Autonomous VehiclesDokument6 SeitenICAC2021 YK NAO VV DI DG Optimized Selfadaptive PID Speed Control For Autonomous VehiclesLy Hoang HiepNoch keine Bewertungen

- Simulation Analysis of Dynamical Performance and eDokument9 SeitenSimulation Analysis of Dynamical Performance and eFolix AckahNoch keine Bewertungen

- Design Optimization and Analysis of An Outer-Rotor Direct-Drive Permanent-Magnet Motor For Medium-Speed Electric VehicleDokument19 SeitenDesign Optimization and Analysis of An Outer-Rotor Direct-Drive Permanent-Magnet Motor For Medium-Speed Electric VehicleARUN KUMARNoch keine Bewertungen

- Analysis and Design of A Functional Electric Motorcycle PrototypeDokument6 SeitenAnalysis and Design of A Functional Electric Motorcycle PrototypearielguerreroNoch keine Bewertungen

- Xiang 2017Dokument14 SeitenXiang 2017Snowdenn BreddNoch keine Bewertungen

- Btech Final Year Project Report PDFDokument25 SeitenBtech Final Year Project Report PDFShaiz AkhtarNoch keine Bewertungen

- Go Kart REPORTDokument5 SeitenGo Kart REPORTRayleighNoch keine Bewertungen

- Energy Conversion and Management: Chengqun Qiu, Guolin WangDokument10 SeitenEnergy Conversion and Management: Chengqun Qiu, Guolin WangSapana Kudake SKNoch keine Bewertungen

- Modeling Simulation and Energy-Flow Study of A Battery Electric Vehicle in LabviewDokument7 SeitenModeling Simulation and Energy-Flow Study of A Battery Electric Vehicle in LabviewhemaNoch keine Bewertungen

- Crashworthiness Aspects of Electric Vehicle DesignDokument21 SeitenCrashworthiness Aspects of Electric Vehicle DesigngfdczxNoch keine Bewertungen

- Research ArticleDokument13 SeitenResearch ArticleozieNoch keine Bewertungen

- EV Walker ComparationDokument8 SeitenEV Walker Comparationmihai_1957Noch keine Bewertungen

- A1-Article PublishedDokument8 SeitenA1-Article PublishedTHIAGO ROSANoch keine Bewertungen

- Energy Conversion and Management: Khaled Itani, Alexandre de Bernardinis, Zoubir Khatir, Ahmad JammalDokument19 SeitenEnergy Conversion and Management: Khaled Itani, Alexandre de Bernardinis, Zoubir Khatir, Ahmad JammalAhmad Y. Abu GazalNoch keine Bewertungen

- Energies 15 07243 v3Dokument26 SeitenEnergies 15 07243 v3Tran DanteNoch keine Bewertungen

- EV Conversion Performance Analysis and Sizing of Traction Motor and BatteryDokument6 SeitenEV Conversion Performance Analysis and Sizing of Traction Motor and BatteryChayathorn DuangtongsukNoch keine Bewertungen

- 2020 Ditrolio ''A Hybrid Power-Unit Based On A Passive Fuel Cellbattery System For Light Weight Vehicles''Dokument11 Seiten2020 Ditrolio ''A Hybrid Power-Unit Based On A Passive Fuel Cellbattery System For Light Weight Vehicles''Abdul RehmanNoch keine Bewertungen

- Acceleration Speed Optimization of Intelligent EVs in Consideration of Battery AgingDokument10 SeitenAcceleration Speed Optimization of Intelligent EVs in Consideration of Battery Agingu2005044Noch keine Bewertungen

- Power Generating Shock Absorber: A Seminar Report Submitted in Partial Fulfilment For The Award of The Degree ofDokument20 SeitenPower Generating Shock Absorber: A Seminar Report Submitted in Partial Fulfilment For The Award of The Degree ofsaikiranNoch keine Bewertungen

- The Value of A Clutch Mechanism in Electric Vehicles: EVS27 Barcelona, Spain, November 17-20, 2013Dokument11 SeitenThe Value of A Clutch Mechanism in Electric Vehicles: EVS27 Barcelona, Spain, November 17-20, 2013Shubham YadavNoch keine Bewertungen

- 3 Sneha SeminarDokument21 Seiten3 Sneha SeminarNamrta DeokateNoch keine Bewertungen

- Regenerative Braking System: Group GuideDokument14 SeitenRegenerative Braking System: Group GuidePooja BanNoch keine Bewertungen

- Electric Vehicles - Latest EditionsDokument5 SeitenElectric Vehicles - Latest EditionsSaeedAhmedKhan100% (1)

- Final Project Report 1Dokument99 SeitenFinal Project Report 1Sikander GirgoukarNoch keine Bewertungen

- Torque Vectoring Control: July 2018Dokument8 SeitenTorque Vectoring Control: July 2018Santhoshbharathi MECHNoch keine Bewertungen

- Design of An Outer-Rotor-Type Permanent Magnet Motor For Electric Scooter Propulsion SystemsDokument7 SeitenDesign of An Outer-Rotor-Type Permanent Magnet Motor For Electric Scooter Propulsion SystemsVinay KashyapNoch keine Bewertungen

- Design and Implementation of Hybrid Energy Storage System ......Dokument8 SeitenDesign and Implementation of Hybrid Energy Storage System ......GALLEGO LUPIANEZNoch keine Bewertungen

- Comparison of Power Consumption Efficiency of CVT and Multi-Speed Transmissions For Electric VehicleDokument8 SeitenComparison of Power Consumption Efficiency of CVT and Multi-Speed Transmissions For Electric VehicleNguyen Ke DucNoch keine Bewertungen

- ES140304 - Omkar Tade 103-108Dokument6 SeitenES140304 - Omkar Tade 103-108namanbhatia505Noch keine Bewertungen

- Analysis of The Regenerative Braking Efficiency of A Latest Electric VehicleDokument6 SeitenAnalysis of The Regenerative Braking Efficiency of A Latest Electric VehicleJustinNoch keine Bewertungen

- ElectricscooterDokument4 SeitenElectricscooterSurya AnjuNoch keine Bewertungen

- Efficiency Evaluation of E-Commerce WebsitesDokument8 SeitenEfficiency Evaluation of E-Commerce WebsitesAvisheik Barua 1721158Noch keine Bewertungen

- IJEART03703Dokument4 SeitenIJEART03703anil kasotNoch keine Bewertungen

- Adaptive Multiresolution Energy Consumption Prediction For Electric VehiclesDokument11 SeitenAdaptive Multiresolution Energy Consumption Prediction For Electric VehiclesMuhammed AlhanoutiNoch keine Bewertungen

- Nonlinear Model Predictive Extended Eco-Cruise Control For Battery Electric VehiclesDokument6 SeitenNonlinear Model Predictive Extended Eco-Cruise Control For Battery Electric VehiclesasadjadiNoch keine Bewertungen

- Designing Energy Efficient Traction Machines For Electric and Hybrid VehiclesDokument9 SeitenDesigning Energy Efficient Traction Machines For Electric and Hybrid VehicleskodeegNoch keine Bewertungen

- Mathematical Modeling of The Three Phase Induction Motor Couple To DC Motor in Hybrid Electric VehicleDokument5 SeitenMathematical Modeling of The Three Phase Induction Motor Couple To DC Motor in Hybrid Electric Vehiclenico dishanthNoch keine Bewertungen

- ADAS ASSIGNMENT FinalDokument14 SeitenADAS ASSIGNMENT FinalshubhamformeNoch keine Bewertungen

- National Train Enquiry System: 12612 Nzm-Mas Garib Rath Exp Garib Rath 12434 Nzm-Mas Rajdhani Exp RajdhaniDokument1 SeiteNational Train Enquiry System: 12612 Nzm-Mas Garib Rath Exp Garib Rath 12434 Nzm-Mas Rajdhani Exp RajdhanishubhamformeNoch keine Bewertungen

- ADAS Assignment ReportDokument11 SeitenADAS Assignment ReportshubhamformeNoch keine Bewertungen

- Jio Apn SettingsDokument1 SeiteJio Apn SettingsshubhamformeNoch keine Bewertungen

- Msa 0386 Lns For ArmyDokument4 SeitenMsa 0386 Lns For ArmyshubhamformeNoch keine Bewertungen

- Mplab Snap In-Circuit Debugger Mplab Snap In-Circuit Debugger Information SheetDokument12 SeitenMplab Snap In-Circuit Debugger Mplab Snap In-Circuit Debugger Information SheetshubhamformeNoch keine Bewertungen

- Quick Start Guide: Mplab Pickit 4 In-Circuit DebuggerDokument2 SeitenQuick Start Guide: Mplab Pickit 4 In-Circuit DebuggershubhamformeNoch keine Bewertungen

- PickitDokument1 SeitePickitshubhamformeNoch keine Bewertungen

- Improving Noise Immunity For Serial InterfaceDokument7 SeitenImproving Noise Immunity For Serial InterfaceshubhamformeNoch keine Bewertungen

- ARDUINO RF Power & SWR Meter: How To Calibrate The Power Indication ?Dokument11 SeitenARDUINO RF Power & SWR Meter: How To Calibrate The Power Indication ?shubhamformeNoch keine Bewertungen

- Micro908 Schematic B1 0427Dokument2 SeitenMicro908 Schematic B1 0427shubhamformeNoch keine Bewertungen

- Homebrewing HFI 2016 SWR Meter: SP BhatnagarDokument22 SeitenHomebrewing HFI 2016 SWR Meter: SP BhatnagarshubhamformeNoch keine Bewertungen

- Ibm Thinkpad R51/R40 Notebooks: Mainstream Performance and FeaturesDokument4 SeitenIbm Thinkpad R51/R40 Notebooks: Mainstream Performance and FeaturesshubhamformeNoch keine Bewertungen

- Smallest Petrol Generator in The WorldDokument24 SeitenSmallest Petrol Generator in The WorldshubhamformeNoch keine Bewertungen

- 2m BP Filter-Yu1lmDokument5 Seiten2m BP Filter-Yu1lmshubhamformeNoch keine Bewertungen

- EasyDigi Schematic PDFDokument1 SeiteEasyDigi Schematic PDFshubhamformeNoch keine Bewertungen

- Excellent SWR MeterDokument3 SeitenExcellent SWR Metershubhamforme100% (1)

- Orig Mech Report Tail SizingDokument18 SeitenOrig Mech Report Tail SizingAlg PRasadNoch keine Bewertungen

- Kites 101Dokument6 SeitenKites 101Paulo JavierNoch keine Bewertungen

- Chapter 1 Introduction 2013 Flight Dynamics PrinciplesDokument11 SeitenChapter 1 Introduction 2013 Flight Dynamics PrinciplesMinseung KuNoch keine Bewertungen

- Aerodynamic Design, Characterization and Flight Performance of RLV-TDDokument16 SeitenAerodynamic Design, Characterization and Flight Performance of RLV-TDbalasubramanian.sNoch keine Bewertungen

- Helicopter Aerodynamics From M8Dokument18 SeitenHelicopter Aerodynamics From M8REZA TAJBAKHSHNoch keine Bewertungen

- Mathematical Model To Simulate The Trajectory Elements of An Artillery Projectile Proof ShotDokument10 SeitenMathematical Model To Simulate The Trajectory Elements of An Artillery Projectile Proof ShotperryNoch keine Bewertungen

- A Review of Flight Dynamic Simulation Model of MissilesDokument5 SeitenA Review of Flight Dynamic Simulation Model of Missilessiva perumanNoch keine Bewertungen

- Athena Vortex Lattice (AVL) User GuideDokument40 SeitenAthena Vortex Lattice (AVL) User Guide12654789100% (1)

- Idiada Sim4u Workshop Motorsport 2010Dokument108 SeitenIdiada Sim4u Workshop Motorsport 2010Cristi AntonNoch keine Bewertungen

- Aircraft Control Devices and Systems: Review QuestionsDokument34 SeitenAircraft Control Devices and Systems: Review QuestionsHafidy RizkyNoch keine Bewertungen

- Lecture 7: Flight Equations of Motion: or The Differential Equations For A 6 DOF ModelDokument24 SeitenLecture 7: Flight Equations of Motion: or The Differential Equations For A 6 DOF ModelNeetu SharmaNoch keine Bewertungen

- Multi Variable Sliding Mode Control For AUV Steering and DivingDokument13 SeitenMulti Variable Sliding Mode Control For AUV Steering and DivinglauralallyNoch keine Bewertungen

- 2011 Goupil, P. AIRBUS State of The Art and Practices On FDI and FTC in FCSDokument10 Seiten2011 Goupil, P. AIRBUS State of The Art and Practices On FDI and FTC in FCScmpmarinhoNoch keine Bewertungen

- Aircraft ConstructionDokument126 SeitenAircraft ConstructionnathanNoch keine Bewertungen

- Aerodynamics SeminoleDokument9 SeitenAerodynamics SeminolesuperaxiNoch keine Bewertungen

- Mackay Standard Submarine 2003 PDFDokument114 SeitenMackay Standard Submarine 2003 PDFMichael PobleteNoch keine Bewertungen

- Nptel: Flight Dynamics I - Airplane Performance - Web CourseDokument3 SeitenNptel: Flight Dynamics I - Airplane Performance - Web CourseCrimson WestNoch keine Bewertungen