Beruflich Dokumente

Kultur Dokumente

Mechanical Design Engineer: Engine Design - (Gasoline & Diesel

Hochgeladen von

Vinay SharmaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Mechanical Design Engineer: Engine Design - (Gasoline & Diesel

Hochgeladen von

Vinay SharmaCopyright:

Verfügbare Formate

MECHANICAL DESIGN ENGINEER

ENGINE DESIGN - (GASOLINE & DIESEL

JANKOTI TARUN ACHARYA

Mail Id/ Skype Id: jtarunacharya@gmail.com

Mobile-9049232749, 8208096895

PROFESSIONAL SUMMARY

Mechanical Design Engineer currently working with an OEM-automotive industry, having an industrial experience of 8.5 years in

product design and development (Engine gasoline & diesel).

TECHNICAL SKILLS

Worked on engine sub components (CRANKCASE,BLOCK,COVERS,PISTON,VALVES)

Worked on engine peripheral parts (Air intake system & Exhaust system)

Design of Exhaust system components like exhaust manifold (SCR, & Silencer) Close couple CATCON & Under body Catcon.

Proficiency in PTC Creo-2, Pro-E, Autodesk Inventor, knowledge of Catia-V5 & UG NX-8.5

Worked on production or field issues.

Worked on PLM software-Wind-chill & Team center.

Worked on engine packaging in vehicle & engine integration.

Manufacturing & processes knowledge of Casting (GDC & LPDC), Surfacing, sheet metal.

Process knowledge of plastic and sheet metal component.

Presentation creation for new proposals to carried out in design.

Knowledge of GD&T, DFMEA & DFFS.

RESPONSIBILITIES:

8.5 yrs. of Experience in new product Design & Development, in Automotive & non-automotive domain (Gasoline & Diesel

engine).

5 yrs. of work experience with power-train department (Engine department) with an OEM company.

Working on Diesel Engine (BS_4 & BS-VI) & along with sub peripheral components (Intake, exhaust, Valve train & cooling

system).

Working on BSVI exhaust System, along with Packaging in DMU level.

Worked on single cylinder Quadra cycle engine.

Concept design and packaging study, basic calculations.

Cad preparation of manufacturing Parts and assembly models, Surfacing, Sheet metal, Drawings, layouts and documentation

for release.

Experience in handing of team for project coordination with client.

Worked on concept development for new products(Dipstick, crankcase,conrod,valves & crankcase cover)

Experience in Design & Development of Casting Products according to manufacturing.

Worked in Advance Piping Module, Skeleton modeling, Solid modeling, Surface modeling & Sheet metal.

Experience in G D & T, Stack-up (Stator & Rotor), DFMEA (Intake System) & DFSS.

Tata Motors/Tata Technologies: -

Assistant engineer design: (CVBU-Engine Design & development) Dec 2013 – Feb-2018

June-2018- Till date

Awarded with champion quarter for the year 2017-2018

WORK EXPERIENCE

Discussing with customer/supplier to understand their requirements.

Reviewing concept before sending to customer.

Ensure the Manufacturability of Plastic, Casting components & sheet metal.

Responsible for QC of all the Drawings and component

PLM (Team center) related work for component life cycle.

Preparation of subsequent manufacturing drawings as per requirement.

Documentation of all design freeze report.

Interaction with supplier for proto components.

PROMINENT PROJECTS UNDERTAKEN

QUADRICYCLE CATEGORY-SINGLE CYLINDER GASOLINE ENGINE, SINGLE CYLINDER DIESEL ENGINE

&1.5L 3-CYLINDER DIESEL ENGINE.

Project involved Exposure to Design and Development of Engine, which include design of Engine sub component like. Engine

Mounting, Crankcase, Valve train components, Dipstick, cylinder head cover, crankcase cover, DFMEA sheet creation and

Engineering Change Management (ECN/ECR)

DMU - Engine packaging on a vehicle using creo-2.

Design of Exhaust system components like exhaust manifold (SCR, & Silencer) Close couple CATCON & under body catcon.

Exhaust system support brackets, Hoses routing (cooling system).

DFMEA & DFSS for new component as well for old component.

Engine testing support (Mounting bracket t& adapter plate for dyno)

Design & develop small dipstick (cost reduction initiative)

TATA ACE - CNG

DMU - Engine packaging on a vehicle using Pro-E.

Design of Exhaust system components like exhaust manifold, close couple CATCON and exhaust system support brackets.

Envelop creation for packaging of engine in vehicle DMU.

ICR (Cost reduction) – Idea generation, cost saving sheet preparation, Idea implementation plan preparation Support

Provided for Field issues.

Onward technologies- Feb-2018 to May 2018

PROMINENT WORK UNDERTAKEN

Taking Interview for new joiners.

Cad trainings provided to new joiners

PACCAR (Kpit Client):

Design engineer: Paccar India May 2012 –Dec 2012

WORK EXPERIENCE

MOM with foreign customer to understand their requirements.

Resolving Technical issues or Providing Technical support to team member.

Responsible for QC of all the Drawings & cad data.

Presentation submission before new proposals to carried out for design.

PROMINENT PROJECTS UNDERTAKEN

Design of cost effective proposal for material handling equipment’s(Like trolley)

Co-ordinate activities with customer for final approval.

Routing of hydraulic pipe in truck assembly.

To determine and implement design approaches and parameters and conduct feasibility studies on new designs.

Making mold for rubber gaskets in filters.

Atlas cast alloy Pvt. ltd: - (Tool Design of Casting in GDC &LPDC) Jul 2010 – April 2012

Engineer : Gravity die-casting & Low pressure die-casting

Onsite:-Atlas Copco

WORK EXPERIENCE

Preparation of subsequent component for manufacturing with BOM table.

Sand core prepared from the casting model.

Cast part making with draft and machining allowances as per customer Input drawing.

Preparation of subsequent manufacturing drawings as per customer requirement.

Discussion with clients to understand the requirement and standards

Worked on Genset- Engine Application (crankcase & pipe routing)

Educational and training details:

Diploma course in cad (pro-e. wf.3)

Diploma in Mechanical Eng. M.S.B.T.E (PUNE) 2006-2009.

I.T.I (ELECTRICAL) N.CV.T.E (DELHI) 2003-2005.

S.S C. -C.B.S.E (ORISSA) 2003.

Personnel Profile: J TARUN ACHARYA

Date of Birth: 21 JANUARY 1986.

Passport No. J 8060146 valid till 2022

Nationality: Indian

Languages known: English, Hindi, Telgu, Marathi.

Das könnte Ihnen auch gefallen

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successVon EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Darshan Shanbhag: Professional SummaryDokument5 SeitenDarshan Shanbhag: Professional SummaryPrajwal JambheNoch keine Bewertungen

- Exploring Bentley STAAD.Pro CONNECT Edition, 3rd EditionVon EverandExploring Bentley STAAD.Pro CONNECT Edition, 3rd EditionBewertung: 5 von 5 Sternen5/5 (3)

- Gurpreet Banhal1Dokument5 SeitenGurpreet Banhal1aditya_pandey_77Noch keine Bewertungen

- Abhay Pratap Singh Sengar: Phone: - +91-9329883200Dokument4 SeitenAbhay Pratap Singh Sengar: Phone: - +91-9329883200fiemsabyasachiNoch keine Bewertungen

- Sample Resume LTDokument3 SeitenSample Resume LTGladwin JesNoch keine Bewertungen

- To Excel in The Field of Engine Design & DevelopmentDokument4 SeitenTo Excel in The Field of Engine Design & Developmentpooja gulatiNoch keine Bewertungen

- Vikas Prakash Todkar: ObjectiveDokument4 SeitenVikas Prakash Todkar: ObjectiveChetan HinganeNoch keine Bewertungen

- Gomathi Nayagam - CV 2023Dokument5 SeitenGomathi Nayagam - CV 2023mathinayakNoch keine Bewertungen

- SD ResumeDokument2 SeitenSD ResumeShashanka DuttaNoch keine Bewertungen

- CV Nataraj M 19Dokument4 SeitenCV Nataraj M 19Nataraj ShettyNoch keine Bewertungen

- Mechanical Design Professional: Ashok KumarDokument3 SeitenMechanical Design Professional: Ashok KumarPrabhat SharmaNoch keine Bewertungen

- Annexure 1Dokument2 SeitenAnnexure 1Pandi RajNoch keine Bewertungen

- Senthil Kumar.R: Career ProfileDokument5 SeitenSenthil Kumar.R: Career ProfileGurmeet SinghNoch keine Bewertungen

- Resume - Abhishek - 23 (1) (1) 1Dokument4 SeitenResume - Abhishek - 23 (1) (1) 1shruthiNoch keine Bewertungen

- Automotive Plastic Product DesignDokument3 SeitenAutomotive Plastic Product Designravanlegend22Noch keine Bewertungen

- Praful ResumeDokument3 SeitenPraful Resumeapi-27051669Noch keine Bewertungen

- Resume (Before Muk)Dokument4 SeitenResume (Before Muk)Anonymous xrBCp9EjNoch keine Bewertungen

- Mechanical Engineer-Syed Zain AliDokument5 SeitenMechanical Engineer-Syed Zain AliSyedZainAliNoch keine Bewertungen

- Early Career Notable Projects - ARNOLD LABARESDokument5 SeitenEarly Career Notable Projects - ARNOLD LABARESArnold LabaresNoch keine Bewertungen

- Key Expertise:: Educational Qualification & CertificationsDokument4 SeitenKey Expertise:: Educational Qualification & Certificationsyups97Noch keine Bewertungen

- YuFeng CV 2023 Rev3Dokument4 SeitenYuFeng CV 2023 Rev3杨鹏Noch keine Bewertungen

- Ernani D. Ubalde: ObjectiveDokument4 SeitenErnani D. Ubalde: Objectiveernani ubaldeNoch keine Bewertungen

- Akash ResumeDokument3 SeitenAkash ResumeAkashNoch keine Bewertungen

- Naukri AbhishekGowda (10y 0m)Dokument2 SeitenNaukri AbhishekGowda (10y 0m)vinitha mohanrajNoch keine Bewertungen

- NafeesShaikh (7 0)Dokument4 SeitenNafeesShaikh (7 0)ajuuNoch keine Bewertungen

- Rahul Kohinkar Old OnwardDokument6 SeitenRahul Kohinkar Old OnwardRahul KohinkarNoch keine Bewertungen

- K UpenderDokument6 SeitenK UpenderSuresh YadavNoch keine Bewertungen

- Mourya ResumeDokument3 SeitenMourya Resumesweta prakash sahooNoch keine Bewertungen

- Venkatesh Rajagopal: Career ObjectiveDokument4 SeitenVenkatesh Rajagopal: Career ObjectiveSuresh MadhevanNoch keine Bewertungen

- 2.resume - Santhosh Kumar TDokument2 Seiten2.resume - Santhosh Kumar TAbhishek MNNoch keine Bewertungen

- Vivek Jain Jan2014Dokument5 SeitenVivek Jain Jan2014Vivek JainNoch keine Bewertungen

- Ernani D. Ubalde: Objective: Qualiffications and BackgroundDokument4 SeitenErnani D. Ubalde: Objective: Qualiffications and Backgroundernani ubaldeNoch keine Bewertungen

- Piping CVDokument4 SeitenPiping CVNicole DavisNoch keine Bewertungen

- Akshay Pawar CV2Dokument3 SeitenAkshay Pawar CV2Akshay pawarNoch keine Bewertungen

- CV-Modeler 3Dokument8 SeitenCV-Modeler 3adarsh tNoch keine Bewertungen

- Raj ResumeDokument4 SeitenRaj ResumeRaj TiwariNoch keine Bewertungen

- Curriculum Vitae: Roni A ThomasDokument4 SeitenCurriculum Vitae: Roni A ThomasAshish SinghNoch keine Bewertungen

- Piping Engineer: Resume CV: Sponsored LinksDokument7 SeitenPiping Engineer: Resume CV: Sponsored Linksravi gurungNoch keine Bewertungen

- Senior Design Engineer For Static Equipment With 13 Years of ExperienceDokument7 SeitenSenior Design Engineer For Static Equipment With 13 Years of ExperienceTushar MangratiNoch keine Bewertungen

- Protected UploadDokument6 SeitenProtected UploadRebecca SchroederNoch keine Bewertungen

- CV-Modeler 2Dokument8 SeitenCV-Modeler 2adarsh tNoch keine Bewertungen

- Kumaravel Resume 14+ Lead Mechanical Designer - TLDokument3 SeitenKumaravel Resume 14+ Lead Mechanical Designer - TLKumarNoch keine Bewertungen

- Venkadachalapathy Thangavel: LinkedinDokument4 SeitenVenkadachalapathy Thangavel: Linkedinvenkatachalapathy.thNoch keine Bewertungen

- Jaiganesh Resume CAEDokument2 SeitenJaiganesh Resume CAEjaiguNoch keine Bewertungen

- Resume ModelDokument2 SeitenResume ModelDeepak KaruppusamyNoch keine Bewertungen

- Dilip Kumar 14th June 2014Dokument3 SeitenDilip Kumar 14th June 2014Dilip Kumar JothiNoch keine Bewertungen

- CV Nirav Patel (BE Mechanical) - 4Dokument5 SeitenCV Nirav Patel (BE Mechanical) - 4Nirav PatelNoch keine Bewertungen

- Dabba ResumeDokument5 SeitenDabba ResumeAnkur SaxenaNoch keine Bewertungen

- Rishabh Engineering ServicesDokument19 SeitenRishabh Engineering ServicesmayankjainrfNoch keine Bewertungen

- JAVED LATIF (US Citizen)Dokument5 SeitenJAVED LATIF (US Citizen)kiran2710Noch keine Bewertungen

- Praven Kumar. K: Work ExperienceDokument5 SeitenPraven Kumar. K: Work ExperienceVignesh Kannan KuppuswamyNoch keine Bewertungen

- Resume-Rahul Sah2Dokument5 SeitenResume-Rahul Sah2Rahul SahNoch keine Bewertungen

- Key Expertise:: Educational Qualification & CertificationsDokument3 SeitenKey Expertise:: Educational Qualification & CertificationsYoussef EL IdrissiiNoch keine Bewertungen

- Navas Onthath CV 11.12.2018Dokument8 SeitenNavas Onthath CV 11.12.2018NavasOT100% (1)

- Curriculum Vitae: Maruthupandian.P Maruthu - Sri@yahoo - Co.inDokument5 SeitenCurriculum Vitae: Maruthupandian.P Maruthu - Sri@yahoo - Co.inPraveen KumarNoch keine Bewertungen

- Resume - Interior TrimDokument4 SeitenResume - Interior TrimRohit NevaseNoch keine Bewertungen

- Tension Structures EngineerDokument3 SeitenTension Structures EngineerChezben ShopNoch keine Bewertungen

- Professional Profile: Project ManagementDokument2 SeitenProfessional Profile: Project ManagementSumit TembhareNoch keine Bewertungen

- Design Through Engineering Integration of Connecting ROD: AbstractDokument4 SeitenDesign Through Engineering Integration of Connecting ROD: Abstractketthegr8Noch keine Bewertungen

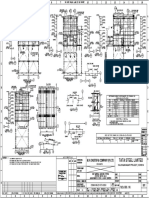

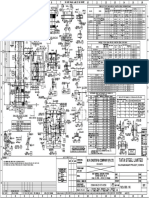

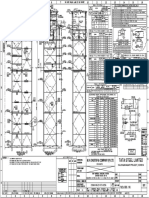

- View Looking North On Gridline CDokument1 SeiteView Looking North On Gridline CVinay SharmaNoch keine Bewertungen

- 08 Z2 STD 1204Dokument1 Seite08 Z2 STD 1204Vinay SharmaNoch keine Bewertungen

- Tata Steel Limited M. N. Dastur & Company (P) LTD.: Kalinganagar Project, OdishaDokument1 SeiteTata Steel Limited M. N. Dastur & Company (P) LTD.: Kalinganagar Project, OdishaVinay SharmaNoch keine Bewertungen

- 08 Z2 STD 1201Dokument1 Seite08 Z2 STD 1201Vinay SharmaNoch keine Bewertungen

- 08 Z2 STD 0263Dokument1 Seite08 Z2 STD 0263Vinay SharmaNoch keine Bewertungen

- Licensing GettingStartedDokument10 SeitenLicensing GettingStartedVinay SharmaNoch keine Bewertungen

- Vinay Sharma - FTC Employment AgreementSignedDokument11 SeitenVinay Sharma - FTC Employment AgreementSignedVinay Sharma100% (1)

- Tata Steel Limited: M. N. Dastur & Company (P) LTDDokument1 SeiteTata Steel Limited: M. N. Dastur & Company (P) LTDVinay SharmaNoch keine Bewertungen

- Tata Steel Limited: M. N. Dastur & Company (P) LTDDokument1 SeiteTata Steel Limited: M. N. Dastur & Company (P) LTDVinay SharmaNoch keine Bewertungen

- Tata Steel Limited: M. N. Dastur & Company (P) LTDDokument1 SeiteTata Steel Limited: M. N. Dastur & Company (P) LTDVinay SharmaNoch keine Bewertungen

- Tata Steel Limited: M. N. Dastur & Company (P) LTDDokument1 SeiteTata Steel Limited: M. N. Dastur & Company (P) LTDVinay SharmaNoch keine Bewertungen

- Tata Steel Limited M. N. Dastur & Company (P) LTD.: Kalinganagar Project, OdishaDokument1 SeiteTata Steel Limited M. N. Dastur & Company (P) LTD.: Kalinganagar Project, OdishaVinay SharmaNoch keine Bewertungen

- Tata Steel Limited: M. N. Dastur & Company (P) LTDDokument1 SeiteTata Steel Limited: M. N. Dastur & Company (P) LTDVinay SharmaNoch keine Bewertungen

- Tata Steel Limited: M. N. Dastur & Company (P) LTDDokument1 SeiteTata Steel Limited: M. N. Dastur & Company (P) LTDVinay SharmaNoch keine Bewertungen

- Administrator Command Reference ManualDokument201 SeitenAdministrator Command Reference ManualĐình NamNoch keine Bewertungen

- Tata Steel Limited: M. N. Dastur & Company (P) LTDDokument1 SeiteTata Steel Limited: M. N. Dastur & Company (P) LTDVinay SharmaNoch keine Bewertungen

- Introduction To Gate Valves and Gate Valve TypesDokument16 SeitenIntroduction To Gate Valves and Gate Valve TypesVinay Sharma100% (1)

- Pipe Thickness Calculation (Internal Pressure Design Thickness) As Per ASME B31.3Dokument10 SeitenPipe Thickness Calculation (Internal Pressure Design Thickness) As Per ASME B31.3Vinay SharmaNoch keine Bewertungen

- Vinay Sharma-PipingDokument5 SeitenVinay Sharma-PipingVinay SharmaNoch keine Bewertungen

- Butterfly Valves: Uses, Types, Working, Advantages, Symbols: Skip To ContentDokument9 SeitenButterfly Valves: Uses, Types, Working, Advantages, Symbols: Skip To ContentVinay SharmaNoch keine Bewertungen

- Butterfly Valves: Uses, Types, Working, Advantages, Symbols: Skip To ContentDokument9 SeitenButterfly Valves: Uses, Types, Working, Advantages, Symbols: Skip To ContentVinay SharmaNoch keine Bewertungen

- Syllabus of p3dDokument3 SeitenSyllabus of p3dVinay SharmaNoch keine Bewertungen

- Syllabus of p3dDokument3 SeitenSyllabus of p3dVinay SharmaNoch keine Bewertungen

- Talk Like A Boss:: How To Communicate Assertively in The Job SearchDokument37 SeitenTalk Like A Boss:: How To Communicate Assertively in The Job SearchVinay SharmaNoch keine Bewertungen

- E3d-Module Equipment in Aveva E3d PDFDokument12 SeitenE3d-Module Equipment in Aveva E3d PDFRobles Dresch71% (7)

- RepaymentDokument5 SeitenRepaymentVinay SharmaNoch keine Bewertungen

- AVEVA Plant 12.1.SP4.29 Partial Fix Release 52447 Windows XP or Windows 7Dokument143 SeitenAVEVA Plant 12.1.SP4.29 Partial Fix Release 52447 Windows XP or Windows 7Vinay SharmaNoch keine Bewertungen

- W 52751Dokument1 SeiteW 52751venkatagopiNoch keine Bewertungen

- E3d-Module Equipment in Aveva E3d PDFDokument12 SeitenE3d-Module Equipment in Aveva E3d PDFRobles Dresch71% (7)

- Brochure AVEVA E3D For Marine 11-18Dokument11 SeitenBrochure AVEVA E3D For Marine 11-18Vinay SharmaNoch keine Bewertungen

- June 2017 (IAL) MS - Unit 1 Edexcel Physics A-LevelDokument16 SeitenJune 2017 (IAL) MS - Unit 1 Edexcel Physics A-LevelNyraStardollNoch keine Bewertungen

- Natural Cataclysms and Global ProblemsDokument622 SeitenNatural Cataclysms and Global ProblemsphphdNoch keine Bewertungen

- Stucor Qp-Ec8095Dokument16 SeitenStucor Qp-Ec8095JohnsondassNoch keine Bewertungen

- Action ResearchDokument2 SeitenAction ResearchGeli BaringNoch keine Bewertungen

- Consent Form: Republic of The Philippines Province of - Municipality ofDokument1 SeiteConsent Form: Republic of The Philippines Province of - Municipality ofLucette Legaspi EstrellaNoch keine Bewertungen

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Dokument1 SeiteS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaNoch keine Bewertungen

- Directorate of Technical Education, Admission Committee For Professional Courses (ACPC), GujaratDokument2 SeitenDirectorate of Technical Education, Admission Committee For Professional Courses (ACPC), GujaratgamailkabaaaapNoch keine Bewertungen

- Pedagogy MCQS 03Dokument54 SeitenPedagogy MCQS 03Nawab Ali MalikNoch keine Bewertungen

- Calculus For The Life Sciences 2nd Edition Greenwell Solutions ManualDokument26 SeitenCalculus For The Life Sciences 2nd Edition Greenwell Solutions ManualSharonPerezozqy100% (56)

- LEMBAR JAWABAN CH.10 (Capital Budgeting Techniques)Dokument4 SeitenLEMBAR JAWABAN CH.10 (Capital Budgeting Techniques)Cindy PNoch keine Bewertungen

- Green Dot ExtractDokument25 SeitenGreen Dot ExtractAllen & UnwinNoch keine Bewertungen

- The Body Shop Case Analysis. The Challenges of Managing Business As Holistic ConfigurationDokument28 SeitenThe Body Shop Case Analysis. The Challenges of Managing Business As Holistic ConfigurationHanna AbejoNoch keine Bewertungen

- LPS 1131-Issue 1.2-Requirements and Testing Methods For Pumps For Automatic Sprinkler Installation Pump Sets PDFDokument19 SeitenLPS 1131-Issue 1.2-Requirements and Testing Methods For Pumps For Automatic Sprinkler Installation Pump Sets PDFHazem HabibNoch keine Bewertungen

- Galman V PamaranDokument7 SeitenGalman V PamaranChow Momville EstimoNoch keine Bewertungen

- Boarding House Preferences by Middle Up Class Students in SurabayaDokument8 SeitenBoarding House Preferences by Middle Up Class Students in Surabayaeditor ijeratNoch keine Bewertungen

- Data Network Unit 6 - UCDokument15 SeitenData Network Unit 6 - UCANISHA DONDENoch keine Bewertungen

- Internship Format HRMI620Dokument4 SeitenInternship Format HRMI620nimra tariqNoch keine Bewertungen

- UFO Yukon Spring 2010Dokument8 SeitenUFO Yukon Spring 2010Joy SimsNoch keine Bewertungen

- 1.co - Deb4113 - Industrial ManagementDokument10 Seiten1.co - Deb4113 - Industrial ManagementrohaizadNoch keine Bewertungen

- Openvpn ReadmeDokument7 SeitenOpenvpn Readmefzfzfz2014Noch keine Bewertungen

- Existentialism in LiteratureDokument2 SeitenExistentialism in LiteratureGirlhappy Romy100% (1)

- Roles and Responsibilities of An InstructorDokument4 SeitenRoles and Responsibilities of An InstructorMohanlal SainiNoch keine Bewertungen

- Rotating Equipment & ServiceDokument12 SeitenRotating Equipment & Servicenurkasih119Noch keine Bewertungen

- An Eastern Orthodox Understanding of The Dangers of Modernity and TechnologyDokument10 SeitenAn Eastern Orthodox Understanding of The Dangers of Modernity and TechnologyTimothy ZelinskiNoch keine Bewertungen

- Microwave EngineeringDokument2 SeitenMicrowave Engineeringசுந்தர் சின்னையா0% (9)

- Rishika Reddy Art Integrated ActivityDokument11 SeitenRishika Reddy Art Integrated ActivityRishika ReddyNoch keine Bewertungen

- Animal Health ChecklistDokument4 SeitenAnimal Health ChecklistcapsfastNoch keine Bewertungen

- Introduction To HDLDokument28 SeitenIntroduction To HDLBack UpNoch keine Bewertungen

- Multimedia System DesignDokument95 SeitenMultimedia System DesignRishi Aeri100% (1)

- William Hallett - BiographyDokument2 SeitenWilliam Hallett - Biographyapi-215611511Noch keine Bewertungen

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesVon EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesBewertung: 4.5 von 5 Sternen4.5/5 (21)

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionBewertung: 5 von 5 Sternen5/5 (1)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsVon EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNoch keine Bewertungen

- Workbook to Accompany Maintenance & Reliability Best PracticesVon EverandWorkbook to Accompany Maintenance & Reliability Best PracticesBewertung: 3.5 von 5 Sternen3.5/5 (3)

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!Von EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!Noch keine Bewertungen

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterVon EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNoch keine Bewertungen

- Shorting the Grid: The Hidden Fragility of Our Electric GridVon EverandShorting the Grid: The Hidden Fragility of Our Electric GridBewertung: 4.5 von 5 Sternen4.5/5 (2)

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceVon EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceNoch keine Bewertungen

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsVon EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressVon EverandNuclear Energy in the 21st Century: World Nuclear University PressBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Practical Power Distribution for IndustryVon EverandPractical Power Distribution for IndustryBewertung: 2.5 von 5 Sternen2.5/5 (2)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successVon EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successBewertung: 4.5 von 5 Sternen4.5/5 (3)

- A Pathway to Decarbonise the Shipping Sector by 2050Von EverandA Pathway to Decarbonise the Shipping Sector by 2050Noch keine Bewertungen

- Renewable Energy: A Very Short IntroductionVon EverandRenewable Energy: A Very Short IntroductionBewertung: 4.5 von 5 Sternen4.5/5 (12)

- A Complete Guide to Safety Officer Interview Questions and AnswersVon EverandA Complete Guide to Safety Officer Interview Questions and AnswersBewertung: 4 von 5 Sternen4/5 (1)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsVon EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNoch keine Bewertungen

- Heat Transfer Engineering: Fundamentals and TechniquesVon EverandHeat Transfer Engineering: Fundamentals and TechniquesBewertung: 4 von 5 Sternen4/5 (1)

- Global Landscape of Renewable Energy FinanceVon EverandGlobal Landscape of Renewable Energy FinanceNoch keine Bewertungen

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerVon EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerNoch keine Bewertungen

- Guidelines for Auditing Process Safety Management SystemsVon EverandGuidelines for Auditing Process Safety Management SystemsNoch keine Bewertungen

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsVon EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsNoch keine Bewertungen

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsVon EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsBewertung: 4 von 5 Sternen4/5 (11)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentVon EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentBewertung: 4.5 von 5 Sternen4.5/5 (21)

- Practical Reservoir Engineering and CharacterizationVon EverandPractical Reservoir Engineering and CharacterizationBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Von EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Noch keine Bewertungen

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionNoch keine Bewertungen