Beruflich Dokumente

Kultur Dokumente

Beam To Wall Anchorage Design Based On TMS 402-16/13 Input Data & Design Summary

Hochgeladen von

Eduardo Martinez CaleroOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Beam To Wall Anchorage Design Based On TMS 402-16/13 Input Data & Design Summary

Hochgeladen von

Eduardo Martinez CaleroCopyright:

Verfügbare Formate

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

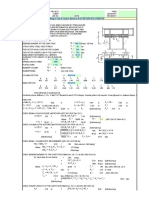

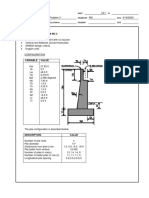

Beam to Wall Anchorage Design Based on TMS 402-16/13

INPUT DATA & DESIGN SUMMARY

MASONRY STRENGTH

fm' = 1.5 ksi

FASTENER YIELD STRESS

fy = 60 ksi

SERVICE VERTICAL LOAD

P = 3.2 kips

VERTICAL LOAD TO FACE DIMENSION

e = 6 in

SERVICE HORIZONTAL TENSION LOAD

T = 1.12 kips

WALL THICKNESS

b = 8 in

FASTENER DIAMETER f = 3/4 in

EFFECTIVE EMBEDMENT Lb = 5 in [THE BEAM ANCHORAGE DESIGN IS ADEQUATE.]

DISTANCE TO WALL TOP Lbe = 16 in

NO. ANCHORS (4,6,or 8) n = 4 MIN. FACE PLATE SIZE - 11 in x 14 in

SPACING Sh = 8 in, o.c.

VERTICAL SPACING Sv = 11 in, o.c.

ALLOWABLE INCREASING ? (IBC/CBC 1605.3.2) Yes

ANALYSIS

ANCHOR LOCATION & FORCE

MAX TENSION STRESS, ASD Anchor X (in) Y (in) XCG2 YCG2 Na Va

ba = 1.2 kips / fastener 1 -4.00 -5.50 16.00 30.25 1.2 0.8

MAX SHEAR STRESS, VERTICAL 2 4.00 -5.50 16.00 30.25 1.2 0.8

bv = 0.8 kips / fastener 3 -4.00 5.50 16.00 30.25 -0.6 0.8

GOVERNING SPACING 4 4.00 5.50 16.00 30.25 -0.6 0.8

S = 8 in, o.c.

CHECK MIN. EMBEDMENT (TMS 402-16/13 6.3.6/6.2.6)

Lb,min = MIN[ 4f , 2] = 2.00 in < Lb [SATISFACTORY]

CHECK TENSION CAPACITY FOR A FASTENER (TMS 402 8.1.3.3.1)

Ba = MIN[ 1.25Apt(fm')0.5 , 0.6Abfy] = 3.41 kips / fastener

> k ba = 0.86 kips / fastener [SATISFACTORY]

Where L = MIN[ Lb , Lbe] = 5.00 in, conservative value

q = COS-1(0.5Sh / L) = 0.64 rad

Aseg = L2 [ q - 0.5 SIN(2q)] = 4.09 in2

Apt = p L2 - 2Aseg = 70.36 in (TMS 402-16/13 6.3.2/6.2.2)

2

Ab = p f 2 / 4 = 0.44 in2

k= 3/4

CHECK SHEAR CAPACITY (TMS 402 8.1.3.3.2)

Bv = MIN[1.25Apv(fm')0.5 , 350(Abfm')1/4 , 2.5Apt(fm')0.5 , 0.36Abfy] = 1.78 kips / fastener

> bv = 0.80 kips / fastener , Gravity only [SATISFACTORY]

Where q = COS-1(0.5S / Lbe) = 1.32 rad

Aseg = Lbe2 [ q - 0.5 SIN(2q)] = 275.47 in2

Apv = 0.5(p Lbe - 2Aseg) =

2

126.65 in2 (TMS 402-16/13 6.3.3/6.2.3)

CHECK COMBINED SHEAR AND TENSION CAPACITY (TMS 402 8.1.3.3.3)

(ba / Ba)(5/3) + (bv / Bv )(5/3) = 0.43 < 1.3333 [SATISFACTORY]

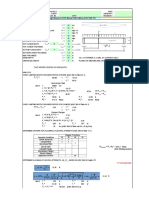

AXIAL LOAD AT WORK POINT P= -1.12 kips, uplift

LOAD AT WORK POINT V= 3.2 kips

MOMENT AT WORK POINT M= 1.6 ft-kips

ANCHOR LOCATION TO WORK POINT

ANCHOR DIAMETER d= 3/4 in Anchor X (in) Y (in)

BASE PLATE THICKNESS t= 0.5 in 1 -5.5 -4

2 -5.5 4

3 5.5 -4

4 5.5 4

BASE PLATE SIZE - 14 in x 11 in x 0.5 in (thk.)

Corner X (in) Y (in)

1 -7 -5.5 Edge = 1.5 in

2 -7 5.5 (AISC 360-05, Tab J3.4 & J3.5)

3 7 5.5

4 7 -5.5

-7 -5.5

Anchor X (in) Y (in) XCG2 YCG2 Na Va

1 -5.5 -4 30.25 16 1.15 0.80

2 -5.5 4 30.25 16 1.15 0.80 XCG = 0 in

3 5.5 -4 30.25 16 -0.59 0.80 YCG = 0 in

4 5.5 4 30.25 16 -0.59 0.80

P,CG = -1.1 kips

V,CG = 3.2 kips

M,CG, X = 1.6 ft-kips

M,CG, Y = 0.0 ft-kips

S 121 64 1.12 3.2

ON TO WORK POINT

2 2

ft-kips

ft-kips

Das könnte Ihnen auch gefallen

- Design For Bending Post at Top of Wall, Based On TMS 402-16/13 Input Data & Design SummaryDokument1 SeiteDesign For Bending Post at Top of Wall, Based On TMS 402-16/13 Input Data & Design Summaryridho ziskaNoch keine Bewertungen

- Suspended AnchorageDokument1 SeiteSuspended Anchoragejorge01Noch keine Bewertungen

- MomentConnection 1aDokument1 SeiteMomentConnection 1aKrishnaNoch keine Bewertungen

- 8-Bolted Moment Connection DesignDokument18 Seiten8-Bolted Moment Connection DesignAlpha50% (2)

- 8-Bolted Stiffened End Plate DesignDokument6 Seiten8-Bolted Stiffened End Plate DesignlucianduNoch keine Bewertungen

- Input Data & Design Summary: Project: Client: Design By: Job No.: Date: Review byDokument1 SeiteInput Data & Design Summary: Project: Client: Design By: Job No.: Date: Review byjklo12Noch keine Bewertungen

- Seismic Design Summary for IMRFDokument3 SeitenSeismic Design Summary for IMRFxuankhoi doanvanNoch keine Bewertungen

- SMRF IbcDokument3 SeitenSMRF Ibcrahul pathakNoch keine Bewertungen

- Masonry Wall Design SummaryDokument8 SeitenMasonry Wall Design Summaryjklo12Noch keine Bewertungen

- Seismic Design For Ordinary Concentrically Braced Frames Based On CBC 07 & AISC 341-05Dokument5 SeitenSeismic Design For Ordinary Concentrically Braced Frames Based On CBC 07 & AISC 341-05xuankhoi doanvanNoch keine Bewertungen

- Composite Girder Design Based On AISC 360-10/16 & 2019 CBC / 2018 IBCDokument2 SeitenComposite Girder Design Based On AISC 360-10/16 & 2019 CBC / 2018 IBCridho ziskaNoch keine Bewertungen

- Composite Floor GirderDokument3 SeitenComposite Floor GirderlucianduNoch keine Bewertungen

- Seismic Design For Ordinary Concentrically Braced Frames Based On IBC 06 & AISC 341-05Dokument5 SeitenSeismic Design For Ordinary Concentrically Braced Frames Based On IBC 06 & AISC 341-05xuankhoi doanvanNoch keine Bewertungen

- Bolted Moment ConnectionDokument9 SeitenBolted Moment ConnectionAmey Gudigar100% (1)

- Connection Design For Column Above Beam, Based On AISC Manual & AISC 360-05Dokument1 SeiteConnection Design For Column Above Beam, Based On AISC Manual & AISC 360-05RayodcNoch keine Bewertungen

- The Design Is Adequate.: W F F X X X y XDokument3 SeitenThe Design Is Adequate.: W F F X X X y Xxuankhoi doanvanNoch keine Bewertungen

- Daniel Tian Li: Design CriteriaDokument32 SeitenDaniel Tian Li: Design Criteriacurlyjockey100% (1)

- Composite Beam Design SummaryDokument7 SeitenComposite Beam Design Summaryஅம்ரு சாந்திவேலுNoch keine Bewertungen

- Moment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16Dokument4 SeitenMoment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16gyanwapiNoch keine Bewertungen

- HSS WF CapacityDokument7 SeitenHSS WF CapacityMoe Oo HtunNoch keine Bewertungen

- The Design Is Adequate.: Ksi, (345 Mpa) Kips, (120.1 KN) FT, (10.06 M) FT, (2.74 M)Dokument3 SeitenThe Design Is Adequate.: Ksi, (345 Mpa) Kips, (120.1 KN) FT, (10.06 M) FT, (2.74 M)Ridho ZiskaNoch keine Bewertungen

- The Design Is Adequate.: F y U UDokument6 SeitenThe Design Is Adequate.: F y U UIndustry Standard Structural DesignNoch keine Bewertungen

- Masonry Shear Wall DesignDokument8 SeitenMasonry Shear Wall Designjklo12Noch keine Bewertungen

- Beam ConnectionDokument3 SeitenBeam ConnectionLeonardo PimentelNoch keine Bewertungen

- 8Dokument6 Seiten8Mohan BhalmeNoch keine Bewertungen

- THE BEAM DESIGN IS ADEQUATEDokument2 SeitenTHE BEAM DESIGN IS ADEQUATEjklo12Noch keine Bewertungen

- Ebf IbcDokument7 SeitenEbf IbcBang SutresNoch keine Bewertungen

- BraceconnectionDokument10 SeitenBraceconnectionLeonardo PimentelNoch keine Bewertungen

- Composite Beam Design With Verco Floor Deck Based On AISC Manual 9thDokument6 SeitenComposite Beam Design With Verco Floor Deck Based On AISC Manual 9thnugroho87Noch keine Bewertungen

- Beam With TorsionDokument11 SeitenBeam With TorsionR ASTUSNoch keine Bewertungen

- Beam Connection of Conventional Configuration Based On AISC Manual 13th Edition (AISC 360-05)Dokument64 SeitenBeam Connection of Conventional Configuration Based On AISC Manual 13th Edition (AISC 360-05)christian abogadoNoch keine Bewertungen

- Bridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-14Dokument3 SeitenBridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-14Mukhlish AkhatarNoch keine Bewertungen

- DoubleAngleCapacityDokument2 SeitenDoubleAngleCapacityIsprotec IngenieriaNoch keine Bewertungen

- Double Angle CapacityDokument2 SeitenDouble Angle CapacityAmey GudigarNoch keine Bewertungen

- AISC 360-05 Rectangular Section DesignDokument1 SeiteAISC 360-05 Rectangular Section DesignMatiur Rahman BasumNoch keine Bewertungen

- Cantilever Column & Footing DesignDokument8 SeitenCantilever Column & Footing DesignRayodc100% (1)

- Abutment Type 3 DesignDokument29 SeitenAbutment Type 3 DesignBun KunNoch keine Bewertungen

- HSS WF CapacityDokument7 SeitenHSS WF CapacitylucianduNoch keine Bewertungen

- Steel ColumnDokument41 SeitenSteel Columnchristian abogadoNoch keine Bewertungen

- Bridge PortionDokument16 SeitenBridge PortionNagara SelvarajNoch keine Bewertungen

- Beam connection design summaryDokument1 SeiteBeam connection design summaryKaren Esther Acuña VelasquezNoch keine Bewertungen

- Concrete pool design analysisDokument6 SeitenConcrete pool design analysisadmin cabuildersNoch keine Bewertungen

- Angle Section Design AnalysisDokument46 SeitenAngle Section Design Analysisgenergia100% (1)

- SEO SLAB DESIGNDokument11 SeitenSEO SLAB DESIGNHanafiahHamzahNoch keine Bewertungen

- Plate GirderDokument15 SeitenPlate GirderRayodcNoch keine Bewertungen

- Bsep SMFDokument8 SeitenBsep SMFcurlyjockeyNoch keine Bewertungen

- Free Standing Masonry Wall Design Based On ACI 530-05 & ACI 318-05Dokument9 SeitenFree Standing Masonry Wall Design Based On ACI 530-05 & ACI 318-05SadatcharaMoorthi NNoch keine Bewertungen

- Enhanced Composite Beam Design Project SummaryDokument5 SeitenEnhanced Composite Beam Design Project SummarygalatiansNoch keine Bewertungen

- Slab DesignDokument10 SeitenSlab DesignKeeperNoch keine Bewertungen

- Beam With TorsionDokument11 SeitenBeam With TorsionAmey GudigarNoch keine Bewertungen

- Beam SpliceDokument2 SeitenBeam SplicePaoloEduardoCarusid'EmpaireNoch keine Bewertungen

- Free Standing Retaining WallDokument6 SeitenFree Standing Retaining WallAamirShabbirNoch keine Bewertungen

- Flush Wall Pilaster Design Based On TMS 402-16/13: Input Data & Design SummaryDokument7 SeitenFlush Wall Pilaster Design Based On TMS 402-16/13: Input Data & Design Summaryjklo12Noch keine Bewertungen

- Retaining WallDokument3 SeitenRetaining WallkbnoblezadaNoch keine Bewertungen

- Beam ConnectionDokument3 SeitenBeam ConnectionMalik awanNoch keine Bewertungen

- UntitledDokument4 SeitenUntitledLuis Alfredo Atencia VillarealNoch keine Bewertungen

- Plate Girder Design Summary in 40 CharactersDokument22 SeitenPlate Girder Design Summary in 40 CharactersBang OchimNoch keine Bewertungen

- Solution Manual for an Introduction to Equilibrium ThermodynamicsVon EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNoch keine Bewertungen

- VLF Radio Engineering: International Series of Monographs in Electromagnetic WavesVon EverandVLF Radio Engineering: International Series of Monographs in Electromagnetic WavesNoch keine Bewertungen

- (John - Chrysler, - MIA Reinforced Concrete Masonry ConstructionDokument208 Seiten(John - Chrysler, - MIA Reinforced Concrete Masonry ConstructionEduardo Martinez Calero0% (2)

- Seismic Masonry Guide 2nd Edition Oct 2018 R1 Split 4Dokument71 SeitenSeismic Masonry Guide 2nd Edition Oct 2018 R1 Split 4Eduardo Martinez CaleroNoch keine Bewertungen

- Quitar ContraseñaDokument1 SeiteQuitar ContraseñaEduardo Martinez CaleroNoch keine Bewertungen

- Design of Reinforced Masonry BeamsDokument3 SeitenDesign of Reinforced Masonry BeamsEduardo Martinez CaleroNoch keine Bewertungen

- Quitar ContraseñaDokument1 SeiteQuitar ContraseñaEduardo Martinez CaleroNoch keine Bewertungen

- En 1996-1-1 Reinforced Masonry Design Example 1: (Note: This Uses The Uk National Annex NDP Values)Dokument6 SeitenEn 1996-1-1 Reinforced Masonry Design Example 1: (Note: This Uses The Uk National Annex NDP Values)Eduardo Martinez CaleroNoch keine Bewertungen

- Bpo Segment by Vitthal BhawarDokument59 SeitenBpo Segment by Vitthal Bhawarvbhawar1141100% (1)

- NQC User ManualDokument6 SeitenNQC User ManualgarneliNoch keine Bewertungen

- Minsc and Boo's Journal of VillainyDokument158 SeitenMinsc and Boo's Journal of VillainyAPCommentator100% (1)

- Adult Education and Training in Europe 2020 21Dokument224 SeitenAdult Education and Training in Europe 2020 21Măndița BaiasNoch keine Bewertungen

- Consolidation of AccountsDokument14 SeitenConsolidation of Accountsram_alaways0% (1)

- Successfull Weight Loss: Beginner'S Guide ToDokument12 SeitenSuccessfull Weight Loss: Beginner'S Guide ToDenise V. FongNoch keine Bewertungen

- LESSON 2 - Nguyễn Thu Hồng - 1917710050Dokument2 SeitenLESSON 2 - Nguyễn Thu Hồng - 1917710050Thu Hồng NguyễnNoch keine Bewertungen

- Aldecoa v. Insular GovtDokument1 SeiteAldecoa v. Insular Govtowenalan buenaventuraNoch keine Bewertungen

- Soil Mechanics: Principle of Effective Stress, Capillarity and Permeability On SoilDokument54 SeitenSoil Mechanics: Principle of Effective Stress, Capillarity and Permeability On SoilAwadhiNoch keine Bewertungen

- Unit 2 - Programming of 8085 MicroprocessorDokument32 SeitenUnit 2 - Programming of 8085 MicroprocessorSathiyarajNoch keine Bewertungen

- Mobil Oil v. DiocaresDokument2 SeitenMobil Oil v. DiocaresAntonio Rebosa100% (2)

- Adjusted School Reading Program of Buneg EsDokument7 SeitenAdjusted School Reading Program of Buneg EsGener Taña AntonioNoch keine Bewertungen

- A Chat (GPT) About The Future of Scientific PublishingDokument3 SeitenA Chat (GPT) About The Future of Scientific Publishingraul kesumaNoch keine Bewertungen

- Indian Medicinal PlantsDokument121 SeitenIndian Medicinal PlantsN S Arun KumarNoch keine Bewertungen

- Amazfit Bip 5 Manual enDokument30 SeitenAmazfit Bip 5 Manual enJohn WalesNoch keine Bewertungen

- Iso 1964 1987Dokument11 SeitenIso 1964 1987Dina ANDRIAMAHEFAHERYNoch keine Bewertungen

- 2020052336Dokument4 Seiten2020052336Kapil GurunathNoch keine Bewertungen

- Statement. Cash.: M.B.A. Semester-Ill Exadinatioh Working Capital Management Paper-Mba/3103/FDokument2 SeitenStatement. Cash.: M.B.A. Semester-Ill Exadinatioh Working Capital Management Paper-Mba/3103/FPavan BasundeNoch keine Bewertungen

- Here Late?", She Asked Me.: TrangDokument3 SeitenHere Late?", She Asked Me.: TrangNguyễn Đình TrọngNoch keine Bewertungen

- Oxfordhb 9780199731763 e 13Dokument44 SeitenOxfordhb 9780199731763 e 13florinaNoch keine Bewertungen

- Presentations - Benefits of WalkingDokument1 SeitePresentations - Benefits of WalkingEde Mehta WardhanaNoch keine Bewertungen

- Mitanoor Sultana: Career ObjectiveDokument2 SeitenMitanoor Sultana: Career ObjectiveDebasish DasNoch keine Bewertungen

- Hbo Chapter 6 Theories of MotivationDokument29 SeitenHbo Chapter 6 Theories of MotivationJannelle SalacNoch keine Bewertungen

- Fatwa Backbiting An Aalim Fatwa Razwiya PDFDokument3 SeitenFatwa Backbiting An Aalim Fatwa Razwiya PDFzubairmbbsNoch keine Bewertungen

- Best Safety Practices in The Philippine Construction PDFDokument16 SeitenBest Safety Practices in The Philippine Construction PDFDione Klarisse GuevaraNoch keine Bewertungen

- CA - Indonesia Digital Business Trend Final 2 Agust 2017Dokument38 SeitenCA - Indonesia Digital Business Trend Final 2 Agust 2017silver8700Noch keine Bewertungen

- 10 1108 - Apjie 02 2023 0027Dokument17 Seiten10 1108 - Apjie 02 2023 0027Aubin DiffoNoch keine Bewertungen

- (Section-A / Aip) : Delhi Public School GandhinagarDokument2 Seiten(Section-A / Aip) : Delhi Public School GandhinagarVvs SadanNoch keine Bewertungen

- Test Bank For Understanding Pathophysiology 4th Edition Sue e HuetherDokument36 SeitenTest Bank For Understanding Pathophysiology 4th Edition Sue e Huethercarotin.shallowupearp100% (41)

- Corporate Office Design GuideDokument23 SeitenCorporate Office Design GuideAshfaque SalzNoch keine Bewertungen