Beruflich Dokumente

Kultur Dokumente

425e C01 BioSealer - Quality Inspection Vers. 3.0

Hochgeladen von

RamboOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

425e C01 BioSealer - Quality Inspection Vers. 3.0

Hochgeladen von

RamboCopyright:

Verfügbare Formate

Quality

Inspection

425e | C01 Page 1 of 5

Prepared: DH | 11.10.2006

Tested: RM | 17.08.2010

Version 3.0

Quality Inspection | Version 3.0 1|5

General information

Client:

BioSealer® type:

Serial no:

Production date:

Client order no:

SSS AG project no.:

Sartorius Stedim Switzerland AG | Reed Electronics

Manufacturer:

Technician

Name:

Signature:

Date:

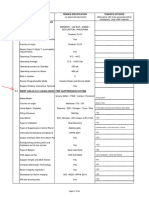

Quality Inspection | Version 3.0 2|5

1. Installation Qualification

1.1 Criteria for acceptance

– Unit must be in operational condition with all parts and manuals.

– Unit is operated with 230 VAC/50 Hz.

Pos Description Fill in

Pos. 1 Part number: Internal product order no

Sartorius Stedim Switzerland AG | REED

Pos. 2 Manufacturer: N /A

Electronics

Pos. 3 Supplier: N /A Sartorius Stedim Switzerland AG

Pos. 4 Description: N /A BioSealer® sterile tube sealer

Pos. 5 Hardware version: Printed on bottom

Pos. 6 Serial number: See manufacturer plate (behind)

Pos. 7 Firmware Version BioSealer®: Only for manufacturer use

Pos. 8 BioSealer® type: See data plate at front

Quality Inspection | Version 3.0 3|5

1.2 Equipment list

Pos Item Version Confirm with

yes or no

Pos. 9 2 Ceramic heater plates type 0 1 Enclosed Yes No

Pos. 10 Manual Enclosed Yes No

Pos. 11 Certificate of Compliance 425.S12 Enclosed Yes No

Pos. 12 Reed temperature control certificate Enclosed Yes No

Specification sheet 425.F04, only necessary by custom sealing

Pos. 13 Enclosed Yes No

parameter

Pos. 14 Torx key for ceramic heating elements N /A Enclosed Yes No

Pos. 15 Power cable 90VAC-250VAC according to country export Enclosed Yes No

Pos. 16 Manufacturer and data plate N /A Installed Yes No

Pos. 17 Danger notice sticker N /A Installed Yes No

Pos. 18 One tube of ordered type and wall-thickness are available. Tube Type and Size: Yes No

(this tube is used for the OQ too).

Correct tubing distance plate installed according to

Pos. 19 Colour: Yes No

Order no.: or 3.2 mm = green

2.4 mm = black

BioSealer® Specification Sheet 425.F04. 1.6 mm = black

Correct sealing parameters uploaded according to Parameter (standard): P

Pos. 20

Order no.: or If custom parameters:

BioSealer® Specification Sheet 425.F04. Pre-sealing temperature [°C]

Pre-sealing time [s]

Sealing temperature [°C]

Sealing time [s]

Temperature encrease [°C/s]

Unlock temperature [°C]

Comment

Inspection of this device was done by:

Date: Name: Signature:

Quality Inspection | Version 3.0 4|5

2. Operational Qualification

2.1 Criteria for acceptance

– Unit must operate automatically without the need for operator intervention.

– Three test seals of one ordered hose type and size type must be visually acceptable with no holes, bubbles or tears.

Tube type (brand) and inner|outer diameter as per Pos. 19 (page 4).

– Counter function is working. (See the counter status before and after the OQ).

Pos. 1 Counter status before the OQ: , and after OQ:

Seal no: Successfully passed - visual check Counter functions work correctly

Pos. 2 1 Yes No Yes No

Pos. 3 2 Yes No Yes No

Pos. 4 3 Yes No Yes No

Confirm with

yes or no

Pos. 5 Unit operates automatically without operator intervention Yes No

2.2 Release Check

Confirm with

yes or no

Pos. 6 Visual check on external damage (buckles, scratches, clefts) Yes No

Pos. 7 Check for loose items Yes No

Pos. 8 All parts are repacked Yes No

Pos. 9 QC conformity sticker is mounted in front of device (initials from Technical Engineer and date). Yes No

Comment

Inspection of this device was done by:

Date: Name: Signature:

This document is reviewed and released by QA:

Date: Name: Signature:

Quality Inspection | Version 3.0 5|5

Das könnte Ihnen auch gefallen

- Design Guidelines for Surface Mount TechnologyVon EverandDesign Guidelines for Surface Mount TechnologyBewertung: 5 von 5 Sternen5/5 (1)

- Inspection Checklist For: Pipework InsulationDokument2 SeitenInspection Checklist For: Pipework InsulationMuquequ@100% (1)

- Technical Data Ig ArgoniteDokument2 SeitenTechnical Data Ig ArgoniteTun JebatNoch keine Bewertungen

- 1PDSforPlantAirReceiver 220505 235117Dokument4 Seiten1PDSforPlantAirReceiver 220505 235117abhishek bawgeNoch keine Bewertungen

- Instrument Datasheet WIKADokument36 SeitenInstrument Datasheet WIKAMahmud RezaNoch keine Bewertungen

- Data Sheet: SAK Series SAK 2.5/35 BLDokument4 SeitenData Sheet: SAK Series SAK 2.5/35 BLdeniglei ribeiroNoch keine Bewertungen

- 1710F01 - Side Stream Filter - PDSDokument4 Seiten1710F01 - Side Stream Filter - PDSAkram VhoraNoch keine Bewertungen

- ScopeDokument7 SeitenScopeSiva ShankarNoch keine Bewertungen

- Data Sheet: SAK Series SAK 2.5/35Dokument4 SeitenData Sheet: SAK Series SAK 2.5/35deniglei ribeiroNoch keine Bewertungen

- Zdu 2.5 4anDokument5 SeitenZdu 2.5 4anAllen BradleyNoch keine Bewertungen

- Data Sheet: Product ImageDokument5 SeitenData Sheet: Product ImageMuhammad YousufNoch keine Bewertungen

- ITR-CNI (Instrument)Dokument21 SeitenITR-CNI (Instrument)mahmoudNoch keine Bewertungen

- DS 26-103-ISO 13706 Air-Cooled Heat Exchangers (API 661)Dokument7 SeitenDS 26-103-ISO 13706 Air-Cooled Heat Exchangers (API 661)andhucaosNoch keine Bewertungen

- Temperature Transmitter Specification Sheet: Client Project Unit LocationDokument2 SeitenTemperature Transmitter Specification Sheet: Client Project Unit LocationFranklin J Talero BNoch keine Bewertungen

- Pressure Test ReportDokument9 SeitenPressure Test Reportjaysonquitelgonzales06Noch keine Bewertungen

- 4.pour Card For RCC WorkDokument1 Seite4.pour Card For RCC WorkMuthu Kumar palaniNoch keine Bewertungen

- AKZ 1.5 inDokument4 SeitenAKZ 1.5 inhesaNoch keine Bewertungen

- DasaDokument2 SeitenDasaAbarajithan RajendranNoch keine Bewertungen

- Weil Qe&i CL 005 JB InstalltionDokument1 SeiteWeil Qe&i CL 005 JB InstalltionSayed AhammadNoch keine Bewertungen

- Welder Monitoring SheetDokument1 SeiteWelder Monitoring SheetQC apollohx100% (1)

- GTP'sDokument1 SeiteGTP'sSuMit MisHraNoch keine Bewertungen

- OGC-FIC-002-I-Control Valve Calibration Stroke Test Report-Field Installation ChecklistDokument2 SeitenOGC-FIC-002-I-Control Valve Calibration Stroke Test Report-Field Installation ChecklistTaylor100% (1)

- Pre-Commissioning Inspection / Calibration (Pressure Relief Valve) DN-M007-BDokument5 SeitenPre-Commissioning Inspection / Calibration (Pressure Relief Valve) DN-M007-BRozh SammedNoch keine Bewertungen

- 70 EPDM 291-En - 1Dokument4 Seiten70 EPDM 291-En - 1ashfaq shaikhNoch keine Bewertungen

- 3.5 Network CabinetDokument1 Seite3.5 Network CabinetBoualem AisNoch keine Bewertungen

- Itr-Pgr (GRP Piping)Dokument10 SeitenItr-Pgr (GRP Piping)mahmoudNoch keine Bewertungen

- Enclosure Ex. Protection Type Gas Group Temp. Class IP Rating Certifying Authority Certificate NoDokument2 SeitenEnclosure Ex. Protection Type Gas Group Temp. Class IP Rating Certifying Authority Certificate Nowinandra 97Noch keine Bewertungen

- CERTIFICADO PLASSON PORTABRIDA 90 MMDokument1 SeiteCERTIFICADO PLASSON PORTABRIDA 90 MMangel rojasNoch keine Bewertungen

- Commissioning Service Department Commissioning Standard Test Formats Description: Functional Test - Bus EarthingDokument6 SeitenCommissioning Service Department Commissioning Standard Test Formats Description: Functional Test - Bus EarthingDinesh PitchaivelNoch keine Bewertungen

- NR Test Items Acceptance Remark/Results: MEP-G-005 Unit: 03015-0Dokument1 SeiteNR Test Items Acceptance Remark/Results: MEP-G-005 Unit: 03015-0pepenapao1217Noch keine Bewertungen

- Monolithic Isolating Joint DatasheetDokument3 SeitenMonolithic Isolating Joint DatasheetEpwe100% (1)

- 7S10LEN00839 - Single Round 5 Adapter 25 I - TypeDokument4 Seiten7S10LEN00839 - Single Round 5 Adapter 25 I - TypeDen TseNoch keine Bewertungen

- Commissioning Checklist Condensing UnitDokument3 SeitenCommissioning Checklist Condensing UnitJohnNoch keine Bewertungen

- SDV, BDV, Esdv ChecklistDokument2 SeitenSDV, BDV, Esdv ChecklistMusab Shabbir67% (3)

- As Per The Schematic Drawings The Contents in This Test Format Can Be ModifiedDokument12 SeitenAs Per The Schematic Drawings The Contents in This Test Format Can Be ModifiedAlexNoch keine Bewertungen

- 2.5 QK-CL-08-00002-2-Installation of Ductile Iron Pipes For Water Tank Main Pump Room PipingDokument1 Seite2.5 QK-CL-08-00002-2-Installation of Ductile Iron Pipes For Water Tank Main Pump Room PipingMoh'd SameerNoch keine Bewertungen

- OGC-FIC-003-I-Control Valve Inspection Record-Field Installation ChecklistDokument2 SeitenOGC-FIC-003-I-Control Valve Inspection Record-Field Installation ChecklistTaylorNoch keine Bewertungen

- Installation and Operation For Climate IncubatorDokument29 SeitenInstallation and Operation For Climate IncubatorFilipa ChinêsNoch keine Bewertungen

- SWGR Feeder - Functional TestDokument13 SeitenSWGR Feeder - Functional TestChheng KimhokNoch keine Bewertungen

- Cal Cert FormatDokument6 SeitenCal Cert FormatINSTRUCAL CALIBRATION SERVICESNoch keine Bewertungen

- Genset Startup and Commissioning Checklist C 175Dokument3 SeitenGenset Startup and Commissioning Checklist C 175Dwi Mulyanti Dwimulyantishop100% (1)

- Commissioning Service Department Commissioning Standard Test Formats Description: Functional Test - FeederDokument8 SeitenCommissioning Service Department Commissioning Standard Test Formats Description: Functional Test - FeedererstendrainNoch keine Bewertungen

- Work Sheet: Page 1 of 2Dokument11 SeitenWork Sheet: Page 1 of 2kevin joseyNoch keine Bewertungen

- SAK 10 enDokument4 SeitenSAK 10 enaluhNoch keine Bewertungen

- LCC Bus Section - Functional TestDokument10 SeitenLCC Bus Section - Functional TestAmr ElkadyNoch keine Bewertungen

- P 1717 Quality Certificate Lot 1Dokument6 SeitenP 1717 Quality Certificate Lot 1Adink M AlwiNoch keine Bewertungen

- Documentation Sheet Sterilization EnglishDokument2 SeitenDocumentation Sheet Sterilization EnglishBanita CarmenNoch keine Bewertungen

- WPE 50N enDokument5 SeitenWPE 50N enindra yantomoNoch keine Bewertungen

- TDC For Plates - SA 516 65Dokument3 SeitenTDC For Plates - SA 516 65Renny DevassyNoch keine Bewertungen

- History Card. - Water BathDokument1 SeiteHistory Card. - Water BathRISHI FOOD TESTING LABNoch keine Bewertungen

- AIMultiSpGr 1498878343030Dokument1 SeiteAIMultiSpGr 1498878343030krishna kumarNoch keine Bewertungen

- Thermography Inspection At: Customer Demo Site Inspection Date: TBD Thermographer: EverdroneDokument11 SeitenThermography Inspection At: Customer Demo Site Inspection Date: TBD Thermographer: EverdroneMikeNoch keine Bewertungen

- Temperature Client Transmitter Project Specification Sheet Unit LocationDokument2 SeitenTemperature Client Transmitter Project Specification Sheet Unit LocationFranklin J Talero BNoch keine Bewertungen

- PFT - 0025A: Construction Check Sheet Piping Flushing & TestingDokument1 SeitePFT - 0025A: Construction Check Sheet Piping Flushing & TestinghrimklimNoch keine Bewertungen

- IQ Procedure & Report ALP AutoclaveDokument9 SeitenIQ Procedure & Report ALP AutoclavePhong LeNoch keine Bewertungen

- Checklist For Fire Fighting Works: Metec Design and Construction Engineers India Privite LimitedDokument1 SeiteChecklist For Fire Fighting Works: Metec Design and Construction Engineers India Privite LimitedBalaNoch keine Bewertungen

- DCDB - Function TestDokument5 SeitenDCDB - Function TestAmr ElkadyNoch keine Bewertungen

- Itr-Pug (Ug Piping)Dokument12 SeitenItr-Pug (Ug Piping)mahmoudNoch keine Bewertungen

- Panel Inspection Report FormatDokument5 SeitenPanel Inspection Report Formatp mahesh goud100% (1)

- NS0 Serum Free CultureDokument9 SeitenNS0 Serum Free CultureRamboNoch keine Bewertungen

- Cleaning Validation Studies To CFR Title 21 Part 211.67: M-Scan 26 Years of Analytical Excellence 1979-2005Dokument1 SeiteCleaning Validation Studies To CFR Title 21 Part 211.67: M-Scan 26 Years of Analytical Excellence 1979-2005RamboNoch keine Bewertungen

- Percoll Methodology and ApplicationsDokument84 SeitenPercoll Methodology and Applicationsadamos1945Noch keine Bewertungen

- Guidance For IndustryDokument17 SeitenGuidance For IndustryBabbooNoch keine Bewertungen

- Meth ValDokument37 SeitenMeth ValRamboNoch keine Bewertungen

- Validation of An Enterprise Resourse Planning System (ERP)Dokument17 SeitenValidation of An Enterprise Resourse Planning System (ERP)Fred100% (9)

- GST FusionDokument28 SeitenGST FusionBabbooNoch keine Bewertungen

- Meth ValDokument140 SeitenMeth ValRamboNoch keine Bewertungen

- Percoll Methodology and ApplicationsDokument84 SeitenPercoll Methodology and Applicationsadamos1945Noch keine Bewertungen

- Classification of Clean Rooms 2005Dokument27 SeitenClassification of Clean Rooms 2005RamboNoch keine Bewertungen

- Data SartoJet-Pump SPC2054Dokument4 SeitenData SartoJet-Pump SPC2054RamboNoch keine Bewertungen

- Hydrophobic Interaction ChromatographyDokument104 SeitenHydrophobic Interaction ChromatographytyahaaNoch keine Bewertungen

- No.49/A, Sri Chakra Thazhuvar Salai,: R.Bhupathy. SR - Executive - Sterile & Non Sterile Drugs ManufacturingDokument4 SeitenNo.49/A, Sri Chakra Thazhuvar Salai,: R.Bhupathy. SR - Executive - Sterile & Non Sterile Drugs ManufacturingRamboNoch keine Bewertungen

- Meth ValDokument37 SeitenMeth ValRamboNoch keine Bewertungen

- Nbs Fermentation Basics PDFDokument26 SeitenNbs Fermentation Basics PDFsadatrafiaNoch keine Bewertungen

- Derivation, Growth and Application of HESCDokument6 SeitenDerivation, Growth and Application of HESCRamboNoch keine Bewertungen

- ICHQ3C Residual SolventsDokument16 SeitenICHQ3C Residual SolventstaimourjawaidNoch keine Bewertungen

- Guidance For IndustryDokument19 SeitenGuidance For IndustryRamboNoch keine Bewertungen

- Guidance For IndustryDokument14 SeitenGuidance For IndustryRamboNoch keine Bewertungen

- Practical Guide To Autoclave Validation: by Raymond G. Lewis, PEDokument8 SeitenPractical Guide To Autoclave Validation: by Raymond G. Lewis, PEElektroNiNoch keine Bewertungen

- Derivation, Growth and Application of HESCDokument6 SeitenDerivation, Growth and Application of HESCRamboNoch keine Bewertungen

- Standards For Classification of Clean RoomsDokument8 SeitenStandards For Classification of Clean Roomszvieizikovics50% (2)

- V. S. Hno:7-1 - 401 - A - 29, Dno: Behi Ndsrnagarpol I Cest at I On, Srnagar, Hyder Abad, Tel Angana - 500038Dokument2 SeitenV. S. Hno:7-1 - 401 - A - 29, Dno: Behi Ndsrnagarpol I Cest at I On, Srnagar, Hyder Abad, Tel Angana - 500038RamboNoch keine Bewertungen

- Derivation, Growth and Application of hESC PDFDokument9 SeitenDerivation, Growth and Application of hESC PDFRamboNoch keine Bewertungen

- Conductivity Theory and Practice - Radiometer Analytical SASDokument50 SeitenConductivity Theory and Practice - Radiometer Analytical SASjumojumo100% (5)

- Electrodiagnostics Chronaxymetry: Honorata Nawrocka-Bogusz, Marek Tuliszka, Leszek KubiszDokument9 SeitenElectrodiagnostics Chronaxymetry: Honorata Nawrocka-Bogusz, Marek Tuliszka, Leszek KubiszRamboNoch keine Bewertungen

- Guidance For IndustryDokument8 SeitenGuidance For IndustryRamboNoch keine Bewertungen

- Data SartoJet-Pump SPC2054Dokument4 SeitenData SartoJet-Pump SPC2054RamboNoch keine Bewertungen

- Guidance For Industry: Comparability ProtocolsDokument22 SeitenGuidance For Industry: Comparability ProtocolsRamboNoch keine Bewertungen

- Classification of Clean Rooms 2005Dokument27 SeitenClassification of Clean Rooms 2005RamboNoch keine Bewertungen

- O Socrealizmu (Jugoslovenski Spomenici)Dokument5 SeitenO Socrealizmu (Jugoslovenski Spomenici)Re Born100% (2)

- MistServer Manual 2.13Dokument47 SeitenMistServer Manual 2.13t_912Noch keine Bewertungen

- Archaeology and Epigraphy at Tayma (Saudi Arabia)Dokument14 SeitenArchaeology and Epigraphy at Tayma (Saudi Arabia)binsaeed100% (1)

- Pipeline HazardsDokument94 SeitenPipeline HazardsManasa RavelaNoch keine Bewertungen

- Electrical Works and CodesDokument35 SeitenElectrical Works and CodesĢI ĢINoch keine Bewertungen

- Nor Zarifah BT Mohd ZakiDokument36 SeitenNor Zarifah BT Mohd ZakiNor Zarifah ZakiNoch keine Bewertungen

- Energy System1Dokument20 SeitenEnergy System1atharvasaxena93Noch keine Bewertungen

- Jsa ExcavationDokument33 SeitenJsa Excavationlal5012002390782% (17)

- MEP Planning ManualDokument197 SeitenMEP Planning Manualsmshaidr50% (2)

- BRKNMS 3134 PDFDokument155 SeitenBRKNMS 3134 PDFpaulo_an7381Noch keine Bewertungen

- AppletDokument20 SeitenAppletloveleeshNoch keine Bewertungen

- $MP 026 18Dokument12 Seiten$MP 026 18Safura BegumNoch keine Bewertungen

- Samsung Magician Manual.v.4.1 (En)Dokument30 SeitenSamsung Magician Manual.v.4.1 (En)bugyourselfNoch keine Bewertungen

- Automation and Troubleshooting of Citrix Group Policy For XenApp & XenDesktop 7.x - ArchitectureDokument57 SeitenAutomation and Troubleshooting of Citrix Group Policy For XenApp & XenDesktop 7.x - ArchitectureGowtam DharmarajNoch keine Bewertungen

- SAILOR 6194 TCU - InstUserManual PDFDokument102 SeitenSAILOR 6194 TCU - InstUserManual PDFVictor Vello LobatoNoch keine Bewertungen

- Structural Risk Assessment & Method Statement: Planning ApplicationDokument19 SeitenStructural Risk Assessment & Method Statement: Planning ApplicationNaresh DharmaNoch keine Bewertungen

- Security in Sprin-WsDokument20 SeitenSecurity in Sprin-Wsmanu1212Noch keine Bewertungen

- Civil PPM Checklist 01Dokument48 SeitenCivil PPM Checklist 01dinie90100% (1)

- Topic 6 Electrical Services To BuildingsDokument14 SeitenTopic 6 Electrical Services To Buildingsullhan84100% (1)

- Fontana Dam Spillway and Crack Investigation: Mamorrison0@tva - Gov Jarossillon@tva - GovDokument20 SeitenFontana Dam Spillway and Crack Investigation: Mamorrison0@tva - Gov Jarossillon@tva - GovMarcelo ProtzNoch keine Bewertungen

- MCQ - TrussDokument4 SeitenMCQ - TrussViren PatelNoch keine Bewertungen

- Material SpecificationDokument3 SeitenMaterial SpecificationRobert M. Longo, AIANoch keine Bewertungen

- Pgcet-Civil Enginnering: SyllabusDokument2 SeitenPgcet-Civil Enginnering: SyllabusMohammed AliNoch keine Bewertungen

- 10 de Thi Tieng Anh Lop 7 HK 2 Co Dap AnDokument33 Seiten10 de Thi Tieng Anh Lop 7 HK 2 Co Dap AnVinh Dao CongNoch keine Bewertungen

- Basic Weights Calc - ACHEDokument6 SeitenBasic Weights Calc - ACHESiva ShankarNoch keine Bewertungen

- Top 10 IKEA ChairsDokument21 SeitenTop 10 IKEA ChairsErin CunninghamNoch keine Bewertungen

- FM Fire Pump Inspection Checklist and FormDokument4 SeitenFM Fire Pump Inspection Checklist and Formkrunalb@inNoch keine Bewertungen

- Manual Tehnic ADI-CD - 2013Dokument79 SeitenManual Tehnic ADI-CD - 2013Vlad BalanNoch keine Bewertungen

- TIPC: Communication For Linux Clusters: Jon P. MaloyDokument44 SeitenTIPC: Communication For Linux Clusters: Jon P. MaloyfoobidolphNoch keine Bewertungen

- Intro Wes7 v1.7Dokument9 SeitenIntro Wes7 v1.7Yu-Diann LuNoch keine Bewertungen