Beruflich Dokumente

Kultur Dokumente

H07127 Three Phase Horz Test Separator HLB

Hochgeladen von

syazwan0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

215 Ansichten2 SeitenThe document discusses a three-phase horizontal test separator used for well testing. The separator safely separates oil, gas, and water during production testing of reservoirs. It is a self-contained modular unit that regulates pressure and fluid levels during testing. Safety features include relief valves and rupture disks. The separator can be used for various testing applications both offshore and on land, and comes in different sizes to handle high pressures and temperatures.

Originalbeschreibung:

Separator Well

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe document discusses a three-phase horizontal test separator used for well testing. The separator safely separates oil, gas, and water during production testing of reservoirs. It is a self-contained modular unit that regulates pressure and fluid levels during testing. Safety features include relief valves and rupture disks. The separator can be used for various testing applications both offshore and on land, and comes in different sizes to handle high pressures and temperatures.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

215 Ansichten2 SeitenH07127 Three Phase Horz Test Separator HLB

Hochgeladen von

syazwanThe document discusses a three-phase horizontal test separator used for well testing. The separator safely separates oil, gas, and water during production testing of reservoirs. It is a self-contained modular unit that regulates pressure and fluid levels during testing. Safety features include relief valves and rupture disks. The separator can be used for various testing applications both offshore and on land, and comes in different sizes to handle high pressures and temperatures.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

TESTING AND SUBSEA

Surface Well Testing

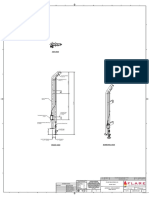

Three-Phase Horizontal Test Separator

The Surface Well Testing Three-Phase Test Separator helps

provide safe and efficient separation for the measurement of

oil, gas, and water phases being produced from the reservoir.

The separator can be used in well-testing applications as well as

cleanup operations for newly completed or stimulated wells.

The test separator is a self-contained modular unit containing

the valves and pneumatic controllers needed to regulate vessel

pressure and fluid levels during a well test.

The redundant safety design incorporates preset safety relief

valves and a rupture disk assembly. The unit can be deployed

both offshore and on land, either as a standalone item or part

of a package. For land operations, it can be retro-fitted to

purpose-designed trailers.

Features

• Exploration and appraisal well testing

• Cleanup and flowback

• Production, in-line testing (including multi-phase

flow metering)

• Extended well testing

Features and Benefits

• Separates produced well fluids, enabling accurate gas, oil, and

water measurement (Sentry™ Data Acquisition system) and

facilitates any requirements for PVT sampling (T-FAS® Total

Fluid Acquisition Services)

• Saves time and cost by using standardized equipment to • Composite design aids client preference measurement devices:

facilitate ease of transportation, maintenance, and operations –– Water cut analyzer

• Engineered Internals: –– Coriolis meters

–– Multi-vane inlet distributor • Designed and operated in accordance with industry standards

–– Mist eliminators and best practices to preserve equipment integrity and client

–– Vortex breakers test objectives

–– Coalescing plates –– Relief system sizing designed to API RP 520 (Design

of Service)

• Accuracy of Measurement Devices:

–– Safety systems methodology to API RP 14C = primary and

–– Liquids: ±.5% of reading (industrial-grade turbine

secondary levels of protection to prevent or minimize the

flow meters)

effects of an equipment failure within the SWT process

–– Gas: ±0.5% (when beta ratio is between 0.20 and 0.70) (Design of Service)

TESTING AND SUBSEA

Equipment Specification Data

(Detailed Equipment Specification Data can be obtained within CWI Database)

Working Pressure Part Number Vessel Data Design Temperature Dimensions

(L × W × H)

800 psi (55 bar) 102007077 34 in. × 8 ft -20 to 250ºF Supplied upon request

(Heli-Lift) (Horizontal) (-29 to 121ºC)

1,440 psi (99 bar) 101856365 42 in. × 10 ft 1,440 psi at -20 to 122ºF / 1,332 psi at 250ºF 20 ft × 8 ft × 8.5 ft

(Horizontal) (99 bar at -29 to 50ºC / 92 bar at 121ºC) (6.1 m × 2.5 m × 2.6 m)

102083075 42 in. × 10 ft 1,440 psi at -20 to 122ºF / 1,332 psi at 250ºF 20 ft × 8 ft × 8.5 ft

(Horizontal) (99 bar at -29 to 50ºC / 92 bar at 121ºC) (6.1 m × 2.5 m × 2.6 m)

101915426 42 in. × 15 ft 1,440 psi at -20 to 122ºF / 1,332 psi at 250ºF 20 ft × 8 ft × 9.5 ft

(Horizontal) (99 bar at -29 to 50ºC / 92 bar at 121ºC) (6.1 m × 2.5 m × 2.9 m)

101999794 42 in. × 15 ft 1,440 psi at -20 to 122ºF / 1,308 psi at 300ºF 20 ft × 8 ft × 9.5 ft

(Horizontal) (99 bar at -29 to 50ºC / 90 bar at 149ºC) (6.1 m × 2.5 m × 2.9 m)

102067089 42 in. × 15 ft 1,440 psi at -20 to 100ºF / 1,350 psi at 200ºF 20 ft × 8 ft × 9.5 ft

(Horizontal) (99 bar at -29 to 38ºC / 93 bar at 93ºC) (6.1 m × 2.5 m × 2.9 m)

102225872 42 in. × 15 ft 1,440 psi at -20 to 100ºF / 1,350 psi at 200ºF 20 ft × 8 ft × 9.5 ft

(Horizontal) (99 bar at -29 to 38ºC / 93 bar at 93ºC) (6.1 m × 2.5 m × 2.9 m)

102361837 48 in. × 12 ft 1,440 psi at -20 to 122ºF / 1,332 psi at 250ºF 20 ft × 8 ft × 9.5 ft

(Horizontal) (99 bar at -29 to 50ºC / 92 bar at 121ºC) (6.1 m × 2.5 m × 2.9 m)

2,160 psi (149 bar) 101999735 42 in. × 15 ft 2,160 psi at -20ºF to 122ºF / 1,998 psi at 250ºF 20 ft × 8 ft × 9.6 ft

(Horizontal) (99 bar at -29ºC to 50ºC / 138 bar at 121ºC) (6.1 m × 2.5 m × 2.9 m)

102120361 24 in. × 10 ft 2,160 psi at -20 to 100ºF / 2,000 psi at 200ºF 20 ft × 8 ft × 9.5 ft

(Vertical) (99 bar at -29 to 38ºC / 138 bar at 93ºC) (6.1 m × 2.5 m × 2.9 m)

Notes:

1. Refer to the equipment databook for individual equipment specifications.

2. Equipment is designed/certified to ASME VIII, Div-1, NACE MR-01-75, DNV 2.7-1, 2.7-3, CE / PED, NORSOK standards as applicableand documented on the individual

Equipment Specification Data Sheets (ESDS).

3. Separator Flowrates are to be calculated via the Design of Service software package taking into consideration all variables and flowing conditions:

(i.e. Vessel sizing, Internals, Safety Systems, Measurement Devices, Pipe/Component Sizing, Retention, Foaming, Emulsion, etc.)

4. These ratings are guidelines only. Contact your local Halliburton SWT representative for more information.

For more information contact your local Halliburton representative

or email us at welltesting@halliburton.com.

© 2014 Halliburton. All rights reserved. Sales of Halliburton products and services will be in accord solely with the terms and conditions contained in the

contract between Halliburton and the customer that is applicable to the sale. H07127 9/14

www.halliburton.com

Das könnte Ihnen auch gefallen

- Aquastore Vitrium SS - Web VersionDokument2 SeitenAquastore Vitrium SS - Web VersionhusnulhuluqiNoch keine Bewertungen

- Circulation and Well ControlDokument17 SeitenCirculation and Well ControlAndrés LópezNoch keine Bewertungen

- Work Permit SystemDokument42 SeitenWork Permit SystemDamien Gracious K.D100% (2)

- Well Control MethodsDokument90 SeitenWell Control MethodsMike Ross100% (2)

- Powerchokes: Standard Choke SCB All-Purpose Severe ServiceDokument2 SeitenPowerchokes: Standard Choke SCB All-Purpose Severe ServiceZeeshan KhanNoch keine Bewertungen

- Slickline CalculationsDokument0 SeitenSlickline CalculationsKHALEDFEKAIR100% (2)

- Slickline CalculationsDokument0 SeitenSlickline CalculationsKHALEDFEKAIR100% (2)

- Gate Valve Trim ChartDokument5 SeitenGate Valve Trim ChartWaseem IqbalNoch keine Bewertungen

- 18 Best Practice For Stand Alone Screens Ian WattieDokument30 Seiten18 Best Practice For Stand Alone Screens Ian WattieQaiser HafeezNoch keine Bewertungen

- Burner Manual - 60 FTDokument18 SeitenBurner Manual - 60 FTsambhajiNoch keine Bewertungen

- Burn BodyDokument32 SeitenBurn BodyMahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- QBH Ram Bop'S: 4-1/16" 15,000 Psi WPDokument32 SeitenQBH Ram Bop'S: 4-1/16" 15,000 Psi WPjuan olarte0% (1)

- 01 - ValvesDokument25 Seiten01 - ValvesMahmoud Ahmed Ali Abdelrazik100% (1)

- Strata RCDDokument2 SeitenStrata RCDDavid VilchesNoch keine Bewertungen

- EXP Well Testing Commisioning A4 24p ProofDokument24 SeitenEXP Well Testing Commisioning A4 24p ProofMohan RajaNoch keine Bewertungen

- Completion - Drilling FormulasDokument13 SeitenCompletion - Drilling FormulassyazwanNoch keine Bewertungen

- SWT PreSolidsSeparation H011840 A4Dokument2 SeitenSWT PreSolidsSeparation H011840 A4slbclqrkNoch keine Bewertungen

- Autochoke Drilling Choke Ps PDFDokument3 SeitenAutochoke Drilling Choke Ps PDFCristiTancuNoch keine Bewertungen

- Sand Filter BrochureDokument2 SeitenSand Filter BrochureadrianioantomaNoch keine Bewertungen

- 290-00 - PHPA Polymer Concentration KitDokument5 Seiten290-00 - PHPA Polymer Concentration KitJessica Matos TacuriNoch keine Bewertungen

- Installation & Routine Maintenance Manual: FOR Type: 3" Mud Gate Valve (Model I)Dokument8 SeitenInstallation & Routine Maintenance Manual: FOR Type: 3" Mud Gate Valve (Model I)Sergio Fabian VasicekNoch keine Bewertungen

- @@@@API Technical Data Book Tanques Bombas y Tuberías PDFDokument78 Seiten@@@@API Technical Data Book Tanques Bombas y Tuberías PDFjorge pajonNoch keine Bewertungen

- Super Green BurnerDokument2 SeitenSuper Green BurnerShima Rahmanian100% (1)

- 1 - 5 Well Test Equipment 26.03.2015Dokument49 Seiten1 - 5 Well Test Equipment 26.03.2015Lakshman Kumar JulapalliNoch keine Bewertungen

- Surface Well Testing Reporting Format and Standard GD-GL-HAL-SWT-601Dokument10 SeitenSurface Well Testing Reporting Format and Standard GD-GL-HAL-SWT-601Said100% (1)

- Well Intervention Courses Slide Linkedin PDFDokument185 SeitenWell Intervention Courses Slide Linkedin PDFsyazwan100% (2)

- Well Intervention Courses Slide Linkedin PDFDokument185 SeitenWell Intervention Courses Slide Linkedin PDFsyazwan100% (2)

- UBM 85 FT BoomDokument2 SeitenUBM 85 FT Boomwahid_100Noch keine Bewertungen

- ASME B16.5 FlangesDokument15 SeitenASME B16.5 FlangesCArolina Macias100% (1)

- Onshore Pipeline Design Course BrochureDokument6 SeitenOnshore Pipeline Design Course Brochureilze86Noch keine Bewertungen

- Tc1350 Drilling ChokeDokument26 SeitenTc1350 Drilling ChokeazeazeazeNoch keine Bewertungen

- Petrotrim Services - Jason BeckDokument3 SeitenPetrotrim Services - Jason BeckPetrotrim ServicesNoch keine Bewertungen

- ABOP ElementsDokument1 SeiteABOP ElementsArdalan FezziNoch keine Bewertungen

- Absorption Chiller GuidelineDokument97 SeitenAbsorption Chiller Guidelineeng_badawy20044942100% (3)

- Well Stimulation VesselsDokument2 SeitenWell Stimulation VesselsOscar RamirezNoch keine Bewertungen

- Well Stimulation VesselDokument8 SeitenWell Stimulation VesselHossein ramezaniNoch keine Bewertungen

- Choke Manifold 5KDokument2 SeitenChoke Manifold 5KFernando Olaveo100% (1)

- Flow HeadDokument2 SeitenFlow HeadAliNoch keine Bewertungen

- Wellhead Plug Catcher (WPC)Dokument2 SeitenWellhead Plug Catcher (WPC)Wade DavisNoch keine Bewertungen

- Piping: Wing Union ConnectionsDokument8 SeitenPiping: Wing Union ConnectionsMahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- HP Mud Gas SeparatorDokument2 SeitenHP Mud Gas SeparatorKapwell LimitedNoch keine Bewertungen

- Model 7875 Rotating Control Device: Marine SeriesDokument4 SeitenModel 7875 Rotating Control Device: Marine Serieslich_tran01Noch keine Bewertungen

- Surge Tank: Pressurized Vessel H S Gas Leaving The Surge Tank Is Burned OffDokument13 SeitenSurge Tank: Pressurized Vessel H S Gas Leaving The Surge Tank Is Burned OffMahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- MANUAL DezumidificatorDokument98 SeitenMANUAL DezumidificatorcivodulNoch keine Bewertungen

- Know Energy - P&P Test 2 With AnswersDokument21 SeitenKnow Energy - P&P Test 2 With AnswerssyazwanNoch keine Bewertungen

- E OilGas Upstream Wellhead Desander Cyclones enDokument2 SeitenE OilGas Upstream Wellhead Desander Cyclones enyamen-691904Noch keine Bewertungen

- Managed Pressure Drilling (SPE MPD Seminar Abstracts)Dokument6 SeitenManaged Pressure Drilling (SPE MPD Seminar Abstracts)Anonymous H9n5g3aaCENoch keine Bewertungen

- Biomass Feasibility StudyDokument51 SeitenBiomass Feasibility StudySalli MarindhaNoch keine Bewertungen

- IWCF Practice 1 (With Answer)Dokument22 SeitenIWCF Practice 1 (With Answer)syazwan80% (5)

- IWCF Practice 1 (With Answer)Dokument22 SeitenIWCF Practice 1 (With Answer)syazwan80% (5)

- Dual-Pot Sand Filter Type A (DSF-A)Dokument2 SeitenDual-Pot Sand Filter Type A (DSF-A)Balaji SelvarajNoch keine Bewertungen

- Cyclo TechDokument27 SeitenCyclo TechAli AliievNoch keine Bewertungen

- Fundamentals and Applications of Bionic Drilling FluidsVon EverandFundamentals and Applications of Bionic Drilling FluidsNoch keine Bewertungen

- NIPPON PYLOX PAINT Technical SpecificationDokument8 SeitenNIPPON PYLOX PAINT Technical SpecificationhudaNoch keine Bewertungen

- IV. Operation Guidelines For Shore To Ship LNG TransferDokument54 SeitenIV. Operation Guidelines For Shore To Ship LNG TransferMuhammad YasinNoch keine Bewertungen

- MPD Dhs 1400 RCDDokument2 SeitenMPD Dhs 1400 RCDali_yy2003Noch keine Bewertungen

- JT Assembly English A4Dokument2 SeitenJT Assembly English A4HectorNoch keine Bewertungen

- Maintenance and Operation Manual Hydraulic Choke and Control ConsoleDokument42 SeitenMaintenance and Operation Manual Hydraulic Choke and Control ConsoleMehdi Hajd KacemNoch keine Bewertungen

- Ram BOP Manual BookDokument28 SeitenRam BOP Manual BookIgor Ungur100% (2)

- Choke Manifold EXPRODokument2 SeitenChoke Manifold EXPROfurnaNoch keine Bewertungen

- General Arrangement For Mod 245 Pilot, SS316 PDFDokument1 SeiteGeneral Arrangement For Mod 245 Pilot, SS316 PDFJabel Oil Services Technical DPTNoch keine Bewertungen

- M60eh44 Man 001Dokument40 SeitenM60eh44 Man 001Riski KurniawanNoch keine Bewertungen

- Drilling Fluids Additives Catalog 2020 (Updated)Dokument47 SeitenDrilling Fluids Additives Catalog 2020 (Updated)melvinkuriNoch keine Bewertungen

- Technical Agreement: Solid Control Equipments Technical DescriptionDokument9 SeitenTechnical Agreement: Solid Control Equipments Technical DescriptionMihai MateiNoch keine Bewertungen

- Cleancut CCB PDFDokument2 SeitenCleancut CCB PDFbruce lian100% (1)

- Separator Design: Rev Description Date Prepared by Client ApprovalDokument18 SeitenSeparator Design: Rev Description Date Prepared by Client ApprovalUsɱâñ Måâñ100% (1)

- Texas Oil Tools: Packer Inserts & EnergizersDokument12 SeitenTexas Oil Tools: Packer Inserts & Energizersshahrol effendy rodziNoch keine Bewertungen

- Drain Valve - Bussines CatalogDokument2 SeitenDrain Valve - Bussines CatalogAnne SophiaNoch keine Bewertungen

- Sand Handling Experience in Subsea Processing ApplicationsDokument18 SeitenSand Handling Experience in Subsea Processing ApplicationsLiu MengLongNoch keine Bewertungen

- Sand Filtration Units150Dokument3 SeitenSand Filtration Units150Smriti PrasadNoch keine Bewertungen

- Mj-1645-Us Expanding Gate Valve MJDokument16 SeitenMj-1645-Us Expanding Gate Valve MJgm_revankar3942Noch keine Bewertungen

- Uztel OrizontalDokument5 SeitenUztel OrizontalDorin RaduNoch keine Bewertungen

- Expanding Gate 2016 2Dokument56 SeitenExpanding Gate 2016 2ramyzottyNoch keine Bewertungen

- MGS Capacity CalculatorDokument13 SeitenMGS Capacity CalculatorRodolfo MendezNoch keine Bewertungen

- Mud/Gas Separator Sizing and Evaluation: Aipu Solids ControlDokument24 SeitenMud/Gas Separator Sizing and Evaluation: Aipu Solids ControlNicoFocheNoch keine Bewertungen

- LPR-N Tester Valve Funcionamiento 1Dokument33 SeitenLPR-N Tester Valve Funcionamiento 1Александр КинтероNoch keine Bewertungen

- National Oilwell Varco: Distributed by EESDokument2 SeitenNational Oilwell Varco: Distributed by EESG MahendraNoch keine Bewertungen

- Pulsation Damper Specification Form: Accumulator Type Fluids/medium Further InformationDokument1 SeitePulsation Damper Specification Form: Accumulator Type Fluids/medium Further InformationsanthoshkumarplNoch keine Bewertungen

- 500 BBL Mobile Frac Tank Brochure1Dokument2 Seiten500 BBL Mobile Frac Tank Brochure1enggmohanNoch keine Bewertungen

- BJ05 Cen3 Mycjy1: 21032356R21HKVDokument1 SeiteBJ05 Cen3 Mycjy1: 21032356R21HKVsyazwanNoch keine Bewertungen

- What Are Turbines - Types of Turbines & Their Applications - MechStuffDokument7 SeitenWhat Are Turbines - Types of Turbines & Their Applications - MechStuffsyazwanNoch keine Bewertungen

- Overview of The Oil and Gas ExplorationDokument7 SeitenOverview of The Oil and Gas ExplorationArcenio Jimenez MorganNoch keine Bewertungen

- Overview of The Oil and Gas ExplorationDokument7 SeitenOverview of The Oil and Gas ExplorationArcenio Jimenez MorganNoch keine Bewertungen

- Offshore PlatformDokument30 SeitenOffshore PlatformAnonymous pH3jHscX9100% (2)

- Intro Series 2 Completion Concepts PDFDokument6 SeitenIntro Series 2 Completion Concepts PDFjayhawkmbNoch keine Bewertungen

- Mdd00001en Lowres-4Dokument20 SeitenMdd00001en Lowres-4Viajero Del MundoNoch keine Bewertungen

- Renewable Energy Supply To Ships at PortDokument4 SeitenRenewable Energy Supply To Ships at PortAli SalahNoch keine Bewertungen

- Carbon Steel Pipe Standards & SpecificationsDokument9 SeitenCarbon Steel Pipe Standards & SpecificationsTunji AminuNoch keine Bewertungen

- List of Approved CNG Cylinders Testing StationsDokument25 SeitenList of Approved CNG Cylinders Testing StationsGaurav HarjaiNoch keine Bewertungen

- Javier IpdDokument57 SeitenJavier IpdChristian Banzuela PadillaNoch keine Bewertungen

- Punj Lloyd Project On "Working Capital Management and Cash Flow Analysis"Dokument81 SeitenPunj Lloyd Project On "Working Capital Management and Cash Flow Analysis"Arindam MitraNoch keine Bewertungen

- V5 RatioMatic RM0200 Datasheet 110-3 A4 PDFDokument4 SeitenV5 RatioMatic RM0200 Datasheet 110-3 A4 PDFcarlosloucaoNoch keine Bewertungen

- PNGRB Retail OutletDokument84 SeitenPNGRB Retail OutletwahamanwahNoch keine Bewertungen

- Decommissioning Obsolete Power Plants Why Do It NowDokument5 SeitenDecommissioning Obsolete Power Plants Why Do It Nowjohnny SalazarNoch keine Bewertungen

- OSHA Citations Against O&G and Ducci ElectricDokument107 SeitenOSHA Citations Against O&G and Ducci ElectricRepublican-AmericanNoch keine Bewertungen

- Gabriel Valentin ComanescuDokument6 SeitenGabriel Valentin ComanescuGabriel ComanescuNoch keine Bewertungen

- Ocean Energy Conversions: Dr. M. SubramanianDokument27 SeitenOcean Energy Conversions: Dr. M. SubramanianNkugwa Mark WilliamNoch keine Bewertungen

- Mercer Valves PDFDokument16 SeitenMercer Valves PDFJamesTorresPalmaNoch keine Bewertungen

- 10 Driller - Vijaykumar A. PatelDokument3 Seiten10 Driller - Vijaykumar A. PateljoystonNoch keine Bewertungen

- Visit To Water BankDokument26 SeitenVisit To Water BankMandar Vaman SatheNoch keine Bewertungen

- Alternative Fuels1Dokument25 SeitenAlternative Fuels1Sumedh HiwaleNoch keine Bewertungen

- P663 - 16B - Phase Behavior - T. A. Blasingame (Texas A & M)Dokument58 SeitenP663 - 16B - Phase Behavior - T. A. Blasingame (Texas A & M)mexx4u2nvNoch keine Bewertungen

- TSS PNGRB Refineries RegulationsDokument123 SeitenTSS PNGRB Refineries RegulationsMobin CheriyanNoch keine Bewertungen

- Workpapers - Activity Statement AnswerDokument24 SeitenWorkpapers - Activity Statement AnswerElvie BangcoyoNoch keine Bewertungen

- CNG JournalDokument11 SeitenCNG JournalVaibhavNoch keine Bewertungen

- Coal Combustion Theory - Electrical4uDokument11 SeitenCoal Combustion Theory - Electrical4uAarthi JayakumarNoch keine Bewertungen

- CRE AssignmentDokument5 SeitenCRE AssignmentKuldeepChoudharyNoch keine Bewertungen

- Summaryof StandardsDokument2 SeitenSummaryof Standardsroman_maximoNoch keine Bewertungen