Beruflich Dokumente

Kultur Dokumente

Data Sheet Flanged End Globe Valve

Hochgeladen von

Ibad Alam100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

213 Ansichten1 SeiteGate Valve Datasheet

Originaltitel

GV 3-8 inch

Copyright

© © All Rights Reserved

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenGate Valve Datasheet

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

213 Ansichten1 SeiteData Sheet Flanged End Globe Valve

Hochgeladen von

Ibad AlamGate Valve Datasheet

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

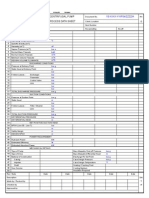

DATA SHEET

Flanged End Globe Valve

Size 3”.- 8”

Bakarabad Siddhirganj Pipeline Project Page 1 of 1 Rev: 0

DATA SHEET FLANGED END GLOBE VALVE

1051-220-VDS-05 SIZE 3"– 8” ( 600# RF)

04 LINE NUMBER REFER LATEST REVISION OF P&ID 05 AREA CODE

06 MANUFACTURER 07 BUILT YEAR 08 CERTIFIED BY

09 TYPE / MODEL 10 REF. DRAWING NO:

11 DESIGN, OPERATING DATA AND SERVICE

12 TAG NUMBERS NOTE : 3

13 FLOW MEDIUM NATURAL GAS 22 OPERATION FLOW RATE Nm³/hr

14 GAS COMPOSITION SEE DESIGN CRITERIA 23 DESIGN FLOW RATE (AT MAX. Dp) Nm³/hr

15 ENVIRONMENTAL DATA 5 – 55°C, MONSOON COND. 24 OPERATION PRESSURE RANGE

16 ACTUATOR SPECIFICATION N. A. 25 DESIGN PRESSURE 78.5 barg / 1135 psig

17 PIPING SPECIFICATION AS PER TECHNICAL SPEC. 26 OPERATING TEMPERATURE 0°C TO 55°C / 32°F TO

131°F

18 VALVE FACE TO FACE DIMENS. ANSI B16.10 27 DESIGN TEMPERATURE -20°C TO +60°C / -4°F TO

140 °F

19 VALVE DESIGN CODE API 600 28 DIFFERENTIAL PRESSURE max 78.5 barg / 1135 psig

20 FLOW COEFFICIENT KG 29 PRESSURE RATING ANSI 600 #

30 VALVE DATA

31 VALVE TYPE GLOBE 44 STEM DIAMETER

32 PORT TYPE-SIZE 45 STEM TRAVEL INDICATION RISING

33 BODY TYPE BOLTED BONNET / OS&Y 46 OPERATION MANUAL/ GOV

OPERATED

34 VALVE ENDS TYPE FLANGED ENDS 47 OPERATOR TYPE GEAR / HAND WHEEL

35 FLANGE RATING/FACING 600 # / ANSI B16.5 RF 48 FAIL SAFE POSITION N.A.

36 DOWNSTREAM LINE SIZE NOTE : 3 49 OPERATOR MANUFACTURER N.A.

37 UPSTREAM LINE SIZE. NOTE : 3 50 FLOW DIRECTION UNI - DIRECTIONAL

38 SEAT CONSTRUCTION SS 52 MAXIMUM NOISE LEVEL AT 1m DIST 85 dbA

39 TRIM TYPE API 600 53 LEAK RATE FCI 70.2 class IV

40 SECOND. SEALING SYSTEM N.A. 54 ANTISTATIC CONSTRUCTION N.A.

41 PUP ENDS / MAT’L N.A. 55 S.S. NAME PLATE YES (WITH TAG NO.)

42 STEM TRAVEL N.A. 56 LOCKING DEVICE NO

43 57 DOUBLE BLOCK&BLEED N.A.

58 DIMENSIONS

59 VALVE F. TO F. LENGTH ASME B 16.10 mm 62 HIGHT INCL. STEM mm

60 VALVE & ACT. TOTAL WEIGHT kg 63 ANCILLERY EQUIPMENT IF REQUIRED

61 PUP ENDS LENGTH N. A. 64 EXT. STEM LENGTH

65 MATERIALS,TESTS AND DOCUMENTS

66 VALVE BODY MATERIAL A 352 LCB, or equiv. 77 SPRING MATERIAL N. A.

67 VALVE ENDS MATERIAL N.A 78 SEAT LEAK TEST (barg) FCI 70.2

68 BONNET MATERIAL 79 HYDRO TEST (barg) ACC. TO API 6D

69 BOLTING MATERIAL A320 L7 / A194 Gr. L7, 80 MAT’L CERTIFICATION CLASS As per applicable code / std

70 PLUG MATERIAL SST, hard-faced 81 ACTUATOR TEST AND CERTIFICATE N.A.

71 STEM MATERIAL SST 82 FIRE SAFE CONSTRUCTION API 6 FA

72 TRUNNION MATERIAL N.A. 83 FUNCTION TEST YES

73 PLUG SEATS MATERIAL SST 84 FINAL ACCEPTANCE TEST YES

74 STEM SEALS MATERIAL PTFE 85 ACCEPTANCE TEST CERTIFICATE As per applicable code / std

75 BODY SEALS MATERIAL 86 OTHER TESTING N.A

76 87 OTHER

88 REMARKS

89 91

90 PAINTING ACC. TO SPEC. 92

93

94

95 Prepared by Checked by Approved by

96 Rev Date DESCRIPTION ORIGINATOR COMPANY

Notes: 1.The above furnished all details are indicative only. It is to be read in conjunction with relevant Bid specification/drawings. Contractor should follow good

engineering practices and should take prior approval of Employer/Owner’s Engineer before procurement.

2. Unless and otherwise noted, all tests will be witnessed

3. To be provided from latest revision of P&ID.

– Bidder to specify at the time of bidding / – Bidder to specify at the time of commencement of work

Das könnte Ihnen auch gefallen

- Electrical Distribution in Papermills: Monographs on Paper and Board MakingVon EverandElectrical Distribution in Papermills: Monographs on Paper and Board MakingBewertung: 2 von 5 Sternen2/5 (1)

- Oil Cooler - Pre Design Data SheetDokument3 SeitenOil Cooler - Pre Design Data SheetSakthi VelNoch keine Bewertungen

- AGIP STD - Valves Specification SheetDokument1 SeiteAGIP STD - Valves Specification Sheethalim_ka100% (1)

- Penawaran Pekerjaan DED 4 Unit Tanki Rev.0Dokument3 SeitenPenawaran Pekerjaan DED 4 Unit Tanki Rev.0m khaeronNoch keine Bewertungen

- ABO Ball ValveDokument6 SeitenABO Ball ValveSunil BajpaiNoch keine Bewertungen

- Saudi Arabian Oil Company: Instrument Specification Sheet Differential Type Level InstrumentsDokument1 SeiteSaudi Arabian Oil Company: Instrument Specification Sheet Differential Type Level Instrumentsgayu87Noch keine Bewertungen

- Drain Philosophy Rev BDokument26 SeitenDrain Philosophy Rev BAnonymous nxWj29Noch keine Bewertungen

- SBC (Safety Break-Away Couplings) v140630Dokument16 SeitenSBC (Safety Break-Away Couplings) v140630Robert Villavicencio0% (1)

- Safety Valve Technical DetailsDokument5 SeitenSafety Valve Technical DetailsvineethvskkdNoch keine Bewertungen

- Calculation Tank - 1500 KL SolarDokument2 SeitenCalculation Tank - 1500 KL SolarAnonymous 6S9tcbhNoch keine Bewertungen

- Bill of Material For Mechnical & Structure For Hot Water Skid Rev.0 - 3Dokument5 SeitenBill of Material For Mechnical & Structure For Hot Water Skid Rev.0 - 3Vu TranNoch keine Bewertungen

- Datasheet For Gate Valves: ProjectDokument3 SeitenDatasheet For Gate Valves: ProjectbecpavanNoch keine Bewertungen

- ENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)Dokument4 SeitenENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)m khaeronNoch keine Bewertungen

- SPBG PLBG - Kalkulasi Tebal Pipa-ASME B31.3 - High PressureDokument1 SeiteSPBG PLBG - Kalkulasi Tebal Pipa-ASME B31.3 - High PressureAris KancilNoch keine Bewertungen

- Mechanical Tender CNG PDFDokument161 SeitenMechanical Tender CNG PDFAWANI SRIVASTAVANoch keine Bewertungen

- Pig Receiver Data Sheet 91303 - 8 InchDokument4 SeitenPig Receiver Data Sheet 91303 - 8 InchSinaNoch keine Bewertungen

- Controlled Volume Pump (Api 675-2Nd) Data Sheet U.S. Customary UnitsDokument3 SeitenControlled Volume Pump (Api 675-2Nd) Data Sheet U.S. Customary UnitshamedNoch keine Bewertungen

- Limpet With Jacket Nozzle OrientationDokument1 SeiteLimpet With Jacket Nozzle OrientationArunkumar MyakalaNoch keine Bewertungen

- PC-01 - Process Column Design Calculations Using CademPVD SoftwareDokument127 SeitenPC-01 - Process Column Design Calculations Using CademPVD SoftwareCADEM SoftwaresNoch keine Bewertungen

- 0 WD990 EM440 00101 Equipment List RevFDokument20 Seiten0 WD990 EM440 00101 Equipment List RevFManuel Jesus Perez MelgarNoch keine Bewertungen

- Material Requisition For Expansion Joint - Rev1Dokument4 SeitenMaterial Requisition For Expansion Joint - Rev1altipatlarNoch keine Bewertungen

- Blowdown RepDokument3 SeitenBlowdown RepNurcahyo Djati WNoch keine Bewertungen

- LPG Blending Facilities - List of Documents For TenderDokument235 SeitenLPG Blending Facilities - List of Documents For TenderManish MehtaNoch keine Bewertungen

- Pump CalcDokument5 SeitenPump CalcpavanNoch keine Bewertungen

- A 1 KDokument5 SeitenA 1 KSumantrra ChattopadhyayNoch keine Bewertungen

- Pig Launcher Data Sheet 91303 - 8 InchDokument4 SeitenPig Launcher Data Sheet 91303 - 8 InchSinaNoch keine Bewertungen

- 10P87-D0003-046-R0-WHRU by TEPLDokument23 Seiten10P87-D0003-046-R0-WHRU by TEPLjigarNoch keine Bewertungen

- Specification Sheet For Pressure TransmitterDokument5 SeitenSpecification Sheet For Pressure TransmitterManodipPatilNoch keine Bewertungen

- Data Sheet For Silencer PDFDokument3 SeitenData Sheet For Silencer PDFAlvin Smith0% (1)

- Att 15 - Equipment Nozzle LoadsDokument11 SeitenAtt 15 - Equipment Nozzle LoadsahmedalishNoch keine Bewertungen

- WRC 107 WRC 297 Co MP PDFDokument11 SeitenWRC 107 WRC 297 Co MP PDFIqbal Muhammad100% (1)

- Technical Data: 150x125 CNHA 5 18.5Dokument5 SeitenTechnical Data: 150x125 CNHA 5 18.5سمير البسيونىNoch keine Bewertungen

- Pms Eil BPCLDokument79 SeitenPms Eil BPCLManjunatha VNoch keine Bewertungen

- Mto Valve: CHKD Appd Appd Date DEC DSP/PPN REV Date Description BYDokument4 SeitenMto Valve: CHKD Appd Appd Date DEC DSP/PPN REV Date Description BYAnonymous 6S9tcbhNoch keine Bewertungen

- B.3.2.2 Pipe List - 0NE2 - MEW - 0007Dokument3 SeitenB.3.2.2 Pipe List - 0NE2 - MEW - 0007Jaroslav KurucNoch keine Bewertungen

- Special Pipe SupportsDokument293 SeitenSpecial Pipe Supportsbkm dizaynNoch keine Bewertungen

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Dokument5 Seiten18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaNoch keine Bewertungen

- PMS Rev 0Dokument36 SeitenPMS Rev 0rami ghorbelNoch keine Bewertungen

- One Direction Guide For Vertical Cryogenic Pipes 2" - 24" NpsDokument3 SeitenOne Direction Guide For Vertical Cryogenic Pipes 2" - 24" NpsMainuddin AliNoch keine Bewertungen

- Calculation BS 31.3Dokument1 SeiteCalculation BS 31.3prabhjot123Noch keine Bewertungen

- Trun CalcDokument215 SeitenTrun CalcmohamedeliasNoch keine Bewertungen

- 150# Cs Ball Valve Datasheet: GeneralDokument3 Seiten150# Cs Ball Valve Datasheet: GeneralVijay GaikwadNoch keine Bewertungen

- Detail Wall Thickness Calc. CorrosionDokument69 SeitenDetail Wall Thickness Calc. Corrosionbagus handokoNoch keine Bewertungen

- Petroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputDokument5 SeitenPetroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputAbhijeetNoch keine Bewertungen

- API 650 Baseplate DesignDokument3 SeitenAPI 650 Baseplate DesignmjlazoNoch keine Bewertungen

- DGS 0000 002 Rev 2Dokument71 SeitenDGS 0000 002 Rev 2Anoop NairNoch keine Bewertungen

- PSV Sizing (Steam)Dokument2 SeitenPSV Sizing (Steam)Saeid Rahimi Mofrad100% (1)

- FlangeDokument13 SeitenFlangehuangjlNoch keine Bewertungen

- A869-6-44-0005 PMS For RevampDokument950 SeitenA869-6-44-0005 PMS For RevampMastram HatheshNoch keine Bewertungen

- Data Sheet Air Foam ChamberDokument1 SeiteData Sheet Air Foam ChamberPinjala AnoopNoch keine Bewertungen

- Superheated Steam SeparatorDokument4 SeitenSuperheated Steam SeparatorGanesh BhardwajNoch keine Bewertungen

- PR1978 Workbook July-24-2017Dokument1.085 SeitenPR1978 Workbook July-24-2017rewqNoch keine Bewertungen

- Fuel Oil Unloading, Storage and Transfer System Storage Volume Calculation of Dyke AreaDokument2 SeitenFuel Oil Unloading, Storage and Transfer System Storage Volume Calculation of Dyke Areaananyo_senguptaNoch keine Bewertungen

- CN5191 - L2 - A1-Centrifugal Pump Process Data SheetDokument1 SeiteCN5191 - L2 - A1-Centrifugal Pump Process Data SheetMochi CumilinaNoch keine Bewertungen

- Mechanical Data Sheet - Air Filter (031-GN-002AB)Dokument5 SeitenMechanical Data Sheet - Air Filter (031-GN-002AB)Gaurav PandeyNoch keine Bewertungen

- 6-Pressure Safety ValveDokument1 Seite6-Pressure Safety ValveFari NazariNoch keine Bewertungen

- File 5Dokument1 SeiteFile 5VENKATACHALAM SUBBARAJNoch keine Bewertungen

- Line Information: Instrument Specification RotameterDokument3 SeitenLine Information: Instrument Specification Rotametermilton1987Noch keine Bewertungen

- Data Sheet For Globe ValveDokument4 SeitenData Sheet For Globe ValveShaaban Noaman100% (1)

- Bakhrabad Siddhirganj Pipeline Project Piping / Equipment Piping Design CriteriaDokument16 SeitenBakhrabad Siddhirganj Pipeline Project Piping / Equipment Piping Design CriteriaIbad AlamNoch keine Bewertungen

- 12 MEPL P 1019 0 (Pipeline Calculation Book)Dokument40 Seiten12 MEPL P 1019 0 (Pipeline Calculation Book)Ibad Alam100% (4)

- Bakhrabad Siddhirganj Pipeline Project Piping / Equipment Specifications For Launcher and ReceiverDokument8 SeitenBakhrabad Siddhirganj Pipeline Project Piping / Equipment Specifications For Launcher and ReceiverIbad AlamNoch keine Bewertungen

- Cable Sizing: in Circuit Breaker Size Ib Amperage LoadDokument29 SeitenCable Sizing: in Circuit Breaker Size Ib Amperage LoadIbad AlamNoch keine Bewertungen

- Chapter 18 Hazard and RiskDokument18 SeitenChapter 18 Hazard and RiskIbad AlamNoch keine Bewertungen

- Krohne Oil & Gas: Customer Review CodeDokument8 SeitenKrohne Oil & Gas: Customer Review CodeIbad Alam100% (1)

- Applying Buncefield Recommendations and IEC61508 and IEC 61511 Standards To Fuel Storage SitesDokument12 SeitenApplying Buncefield Recommendations and IEC61508 and IEC 61511 Standards To Fuel Storage SitesIbad AlamNoch keine Bewertungen

- Earthing Calculations MachikeDokument5 SeitenEarthing Calculations MachikeIbad AlamNoch keine Bewertungen

- Cal 00 e 0001Dokument8 SeitenCal 00 e 0001Ibad AlamNoch keine Bewertungen

- SIL Verification ReportDokument206 SeitenSIL Verification ReportIbad Alam100% (2)

- ISO 15589 1 Cathodic Protection of Pipeline Transportation of Systems On Land PipelinesDokument48 SeitenISO 15589 1 Cathodic Protection of Pipeline Transportation of Systems On Land PipelinesIbad Alam100% (4)

- Control Valve With Electronic PositionerDokument2 SeitenControl Valve With Electronic PositionerIbad AlamNoch keine Bewertungen

- Ei 1541Dokument17 SeitenEi 1541milecsa100% (1)

- Pump Commissioning ProcedureDokument11 SeitenPump Commissioning ProcedureIbad Alam100% (4)

- Power Cable Connection BoxDokument1 SeitePower Cable Connection BoxIbad AlamNoch keine Bewertungen

- Bakhrabad Siddhirganj Pipeline Project Inspection / Test Requirements - CivilDokument5 SeitenBakhrabad Siddhirganj Pipeline Project Inspection / Test Requirements - CivilIbad AlamNoch keine Bewertungen

- Cal 00 e 0002Dokument7 SeitenCal 00 e 0002Ibad AlamNoch keine Bewertungen

- STD 00 S 0008Dokument1 SeiteSTD 00 S 0008Ibad AlamNoch keine Bewertungen

- Selecting A Pipeline Leak Detection SystemDokument7 SeitenSelecting A Pipeline Leak Detection SystemGalo AyalaNoch keine Bewertungen

- EagleBurgmann Heat Exchanger Gasket Standard CodeDokument1 SeiteEagleBurgmann Heat Exchanger Gasket Standard CodeIbad AlamNoch keine Bewertungen

- Pallet RacksDokument5 SeitenPallet RacksIbad AlamNoch keine Bewertungen

- Pipe Color CodeDokument1 SeitePipe Color CodePatricia de los SantosNoch keine Bewertungen

- Poloyagan Integrated School Monitoring Tool On Aip ImplementationDokument3 SeitenPoloyagan Integrated School Monitoring Tool On Aip ImplementationLALAINE BONILLANoch keine Bewertungen

- OHT Estimates 50000 LtrsDokument59 SeitenOHT Estimates 50000 LtrsSandgrouse RajNoch keine Bewertungen

- UntitledDokument107 SeitenUntitledniko_seppanenNoch keine Bewertungen

- BSM BWMP - D1 and D2Dokument34 SeitenBSM BWMP - D1 and D2Adnan DjamalNoch keine Bewertungen

- CharanDokument25 SeitenCharanCharan KumarNoch keine Bewertungen

- Plastic Coatings: Advanced Polymer Technologies ForDokument13 SeitenPlastic Coatings: Advanced Polymer Technologies ForFazlul HoqueNoch keine Bewertungen

- SEPARATION THEORY - From Basic Separation To ALCAP SystemDokument42 SeitenSEPARATION THEORY - From Basic Separation To ALCAP SystemmgbouneNoch keine Bewertungen

- PCMX Data Eng 01Dokument13 SeitenPCMX Data Eng 01spamNoch keine Bewertungen

- Csprog 2 WorkingnaDokument9 SeitenCsprog 2 WorkingnaAaron CoroniaNoch keine Bewertungen

- AMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Dokument5 SeitenAMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Andre SanarNoch keine Bewertungen

- Chevrolet Captiva Service Manual. MAINTENANCE AND REPAIR.Dokument57 SeitenChevrolet Captiva Service Manual. MAINTENANCE AND REPAIR.krisdiarto@gmail.com96% (23)

- Excel 2010 Cheatsheet PDFDokument2 SeitenExcel 2010 Cheatsheet PDFVinith VimalNoch keine Bewertungen

- Keystone - GR SeriesDokument16 SeitenKeystone - GR SeriesMohd Khairi Mohd NorzianNoch keine Bewertungen

- Chapter5 Memory ManagementDokument78 SeitenChapter5 Memory ManagementJackYuan JinFengNoch keine Bewertungen

- TSM SmokeDokument2 SeitenTSM SmokeSudin AmatyaNoch keine Bewertungen

- SampleDokument2 SeitenSamplesaurabhverma08Noch keine Bewertungen

- Error Codes Samsung SL Fin 501l 502lDokument33 SeitenError Codes Samsung SL Fin 501l 502lcesar salasNoch keine Bewertungen

- Lab 3 SST 4303Dokument5 SeitenLab 3 SST 4303Muazrul MangsorNoch keine Bewertungen

- Freezing Point Depression and Boiling Point Elevation LabDokument4 SeitenFreezing Point Depression and Boiling Point Elevation LabBeatrice Dominique Caragay25% (4)

- Material Handling System and ASRS PDFDokument13 SeitenMaterial Handling System and ASRS PDFHarsh PatelNoch keine Bewertungen

- Bhanu Brose Excursion ReportDokument6 SeitenBhanu Brose Excursion ReportBhanu Pratap SinghNoch keine Bewertungen

- Vol Damper (Smacna)Dokument9 SeitenVol Damper (Smacna)MohamedOmar83Noch keine Bewertungen

- Mooring SystemsDokument6 SeitenMooring SystemsVinicius PessottiNoch keine Bewertungen

- "Part - I - General Central Services Group B'Dokument13 Seiten"Part - I - General Central Services Group B'NarayanaNoch keine Bewertungen

- NEMA Premium CatalogDokument38 SeitenNEMA Premium CatalogPedro SanchezNoch keine Bewertungen

- 13 Ijee2962nsDokument15 Seiten13 Ijee2962nspurvakul10Noch keine Bewertungen

- Investigating The Effect of Liquid Viscosity On Two Phase Gas Liquid FlowDokument252 SeitenInvestigating The Effect of Liquid Viscosity On Two Phase Gas Liquid FlowAnonymous DMh6pdl0aNoch keine Bewertungen

- Ultrasonic Atomizing Nozzle SystemsDokument40 SeitenUltrasonic Atomizing Nozzle SystemsAnonymous H8hysGxA100% (1)

- Thermal Processing - Quality Management Is Vital in Heat-TreatingDokument1 SeiteThermal Processing - Quality Management Is Vital in Heat-TreatingJader PitangueiraNoch keine Bewertungen