Beruflich Dokumente

Kultur Dokumente

Assignment 1

Hochgeladen von

miza adlinOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Assignment 1

Hochgeladen von

miza adlinCopyright:

Verfügbare Formate

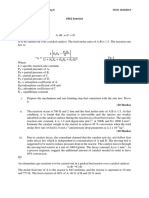

UNIVERSITI MALAYSIA PAHANG

BKF 2453-Chemical Reaction Engineering 1

Assignment 1 (Chapter 1, 2, 3 & 4)

1. The gas-phase reaction and its rate law are as follows,

2 A 3B

k or k '

2C 4 D rC kC C ACB0.5 or rC kC C ACB0.5

is carried out in two isothermal reactors: plug flow reactor (PFR – no catalyst) and packed bed

reactor (PBR) to achieve 95% conversion. The reactants A and B are mixed in a feed at the molar

ratio of 1:2 without inert gas. The feed enters PFR at 3 L s-1 and enters PBR at 3 atm. The reaction

temperature is 300 oC. Design and evaluate the reactors. Additional information:

Superficial mass velocity, G = 2 kg m-2s-1

Reactant density at inlet condition, ρ0 = 2.5 kg m-3

Solid catalyst density, ρc = 2000 kg m-3

Internal diameter of the PBR, D = 0.07 m

Diameter of the catalyst particle, Dp = 0.006 m

The void fraction in the bed, φ = 0.5

Specific rate constant for non-catalytic reaction, kC = 10-2 L0.5 mol-0.5 s-1

Specific rate constant for catalytic reaction, k’C = 0.16 m3 kgcat-1 s-1

Viscosity, = 2 10-5 kg m-2 s-1

Assume the reacting gas is ideal

(20 marks)

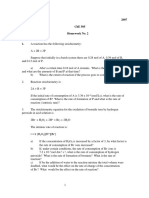

2. By using Polymath try to estimate the time to achieve 99% of steady state concentration of A in a

a 10-L semi batch reactor that runs the elementary liquid phase reaction as follows

A B

k

2C

where NA0 = I0 mol readily loaded to the tank and B is continuously feed to the reactor at CB0 = 0.1

mol L-1 and B0 = 1 L min-1. The specific rate constant is 0.1 L mol-1 min-1.

(10 marks)

Das könnte Ihnen auch gefallen

- Cherekn Problem Set 2Dokument5 SeitenCherekn Problem Set 2Ken ColNoch keine Bewertungen

- CHBE 355 Final Examination W23Dokument7 SeitenCHBE 355 Final Examination W23Awesome GeneralNoch keine Bewertungen

- Tutorial3 - C3 - CHE 244Dokument3 SeitenTutorial3 - C3 - CHE 244Sheikh AdibNoch keine Bewertungen

- Chemical Reaction Engineering Exercise One 2022Dokument4 SeitenChemical Reaction Engineering Exercise One 2022Matone MafologelaNoch keine Bewertungen

- CHE 304 (Spring 2007) Quiz #4 ReviewDokument14 SeitenCHE 304 (Spring 2007) Quiz #4 ReviewDeneshVijayNoch keine Bewertungen

- Using The Differential Method of Analysis.: A0 A0 Cat ADokument2 SeitenUsing The Differential Method of Analysis.: A0 A0 Cat AGauravKinngNoch keine Bewertungen

- NR-320802 Chemical Reaction Engineering-IDokument8 SeitenNR-320802 Chemical Reaction Engineering-ISrinivasa Rao G100% (1)

- CL324 - 2023 - Tutorial 02Dokument2 SeitenCL324 - 2023 - Tutorial 02Prince KumarNoch keine Bewertungen

- Cre IiDokument2 SeitenCre IiPMNoch keine Bewertungen

- Tutorial 1Dokument3 SeitenTutorial 1Aakash R RajwaniNoch keine Bewertungen

- Quizzes 07solDokument15 SeitenQuizzes 07solBeto MelgarejoNoch keine Bewertungen

- Isothermal Reactor Design Mole Balances and ConversionDokument10 SeitenIsothermal Reactor Design Mole Balances and ConversionIqbal Al FuadyNoch keine Bewertungen

- Homework 5 QuestionsDokument1 SeiteHomework 5 QuestionsTouqeer iqbalNoch keine Bewertungen

- CHNG 3004 - 2019-2020 AssignmentsDokument26 SeitenCHNG 3004 - 2019-2020 AssignmentsXheikhKaleem100% (1)

- 1. Set A Final Exam QuestionDokument8 Seiten1. Set A Final Exam QuestionDhayalan RamachandranNoch keine Bewertungen

- Problem Set ODokument19 SeitenProblem Set OnimboNoch keine Bewertungen

- Assignment 2Dokument4 SeitenAssignment 2Yi Hong LowNoch keine Bewertungen

- R09 Set No. 2Dokument8 SeitenR09 Set No. 2Shakoor MalikNoch keine Bewertungen

- Final Exam: Chemical Reaction Engineering IDokument4 SeitenFinal Exam: Chemical Reaction Engineering INurul IzzatiNoch keine Bewertungen

- HW 2 2007Dokument4 SeitenHW 2 2007Singh AnujNoch keine Bewertungen

- Che 471 Exam 1 (Closed Book & Notes, 1 Crib Sheet Allowed) : C O O C O C O O O CDokument2 SeitenChe 471 Exam 1 (Closed Book & Notes, 1 Crib Sheet Allowed) : C O O C O C O O O CHungDoNoch keine Bewertungen

- Reaactor 3 SheetDokument5 SeitenReaactor 3 SheetmohamedNoch keine Bewertungen

- Exercise Chapter 5Dokument8 SeitenExercise Chapter 5Arics ChiengNoch keine Bewertungen

- Assignment 2 3Dokument3 SeitenAssignment 2 3Sandeep Challa0% (1)

- CPMS Endsem W20Dokument2 SeitenCPMS Endsem W20Rutuja PathakNoch keine Bewertungen

- CRE I Assignment - 250919Dokument11 SeitenCRE I Assignment - 250919UpanyaaNoch keine Bewertungen

- CHE 430 Fa21 - HW#3 (10-September-2021)Dokument2 SeitenCHE 430 Fa21 - HW#3 (10-September-2021)Charity QuinnNoch keine Bewertungen

- Kinetics and Reactors EngineeringDokument32 SeitenKinetics and Reactors EngineeringJerome JavierNoch keine Bewertungen

- Press ReleaseDokument3 SeitenPress ReleaseJuanita López SánchezNoch keine Bewertungen

- Tutorial For Chapter 1Dokument3 SeitenTutorial For Chapter 1Thurgah VshinyNoch keine Bewertungen

- ECH 146 Homework 1 Due Friday, 17/1/2014Dokument1 SeiteECH 146 Homework 1 Due Friday, 17/1/2014Tiệp MatícNoch keine Bewertungen

- Compulsory Question: Question (1) : 10 Marks: A B C DDokument4 SeitenCompulsory Question: Question (1) : 10 Marks: A B C Dsushant mouleNoch keine Bewertungen

- Tutorial 5drtuhDokument2 SeitenTutorial 5drtuhFikrie MuhdNoch keine Bewertungen

- CRE IdocxDokument8 SeitenCRE IdocxParth DesaiNoch keine Bewertungen

- JAB-TALLER 3er PARCIAL IRQ-2020-1Dokument5 SeitenJAB-TALLER 3er PARCIAL IRQ-2020-1JESSICA PAOLA TORO VASCONoch keine Bewertungen

- Chemical Reaction Engineering AssignmentDokument2 SeitenChemical Reaction Engineering Assignmentvrutu tapirNoch keine Bewertungen

- Cre P.SDokument4 SeitenCre P.SJanine ImeeNoch keine Bewertungen

- 3 - Prob PFR 11-12 23-35 English-1Dokument4 Seiten3 - Prob PFR 11-12 23-35 English-1Biniyam haileNoch keine Bewertungen

- Chemical Reactors - Problems of Reactor Association 47-60: (Exam Jan'09)Dokument6 SeitenChemical Reactors - Problems of Reactor Association 47-60: (Exam Jan'09)Alfredo ZuñigaNoch keine Bewertungen

- Tut1 2016 QDokument5 SeitenTut1 2016 QAbhishek SardaNoch keine Bewertungen

- CHFEN 3553 Final ExamDokument7 SeitenCHFEN 3553 Final ExamRam chandraNoch keine Bewertungen

- DQE January 2001: Additional InformationDokument12 SeitenDQE January 2001: Additional InformationryezhuNoch keine Bewertungen

- Exam I: Chemical Reactor Design (CHEG 322)Dokument6 SeitenExam I: Chemical Reactor Design (CHEG 322)Faisal MumtazNoch keine Bewertungen

- Taller 3 - 2016Dokument2 SeitenTaller 3 - 2016LifeswolfsNoch keine Bewertungen

- AsdfghjklDokument4 SeitenAsdfghjklJV CustodioNoch keine Bewertungen

- CHCE 3004 CHEG 333 Chemical Reaction Engineering I QP 2020 SUPPLIMENTRY - AM PDFDokument2 SeitenCHCE 3004 CHEG 333 Chemical Reaction Engineering I QP 2020 SUPPLIMENTRY - AM PDFLGK KlanNoch keine Bewertungen

- CHE3044F Reactor Design Tutorial 1Dokument2 SeitenCHE3044F Reactor Design Tutorial 1nmhatityeNoch keine Bewertungen

- Worksheet On Chapter 6Dokument4 SeitenWorksheet On Chapter 6fikadubiruk87Noch keine Bewertungen

- 2018l19 Final Exam With SolutionDokument13 Seiten2018l19 Final Exam With SolutionGAMERS OF KUWAITNoch keine Bewertungen

- R (DC /DT) 0.2 Mol L C: ASSIGNMENT #2 - Reaction Kinetics 2Dokument2 SeitenR (DC /DT) 0.2 Mol L C: ASSIGNMENT #2 - Reaction Kinetics 2AndreNoch keine Bewertungen

- CHE 430 FA21 - HW#4 Due Sept 24Dokument3 SeitenCHE 430 FA21 - HW#4 Due Sept 24Charity QuinnNoch keine Bewertungen

- Chosen Problems of Chapter 3-QuestionsDokument6 SeitenChosen Problems of Chapter 3-QuestionsBilal AhmedNoch keine Bewertungen

- Tutorial 3 QuestionDokument3 SeitenTutorial 3 Questionnur hidayatiNoch keine Bewertungen

- REACTION ENGINEERING HOMEWORK PROBLEMS SOLVEDDokument4 SeitenREACTION ENGINEERING HOMEWORK PROBLEMS SOLVEDGanesh Chandra BaroNoch keine Bewertungen

- BITSP-HYDERABAD MIDSEM TEST KINETICS AND REACTOR DESIGNDokument2 SeitenBITSP-HYDERABAD MIDSEM TEST KINETICS AND REACTOR DESIGNHarshal MahajanNoch keine Bewertungen

- Cre-II EndtermDokument2 SeitenCre-II Endtermbt21cme061Noch keine Bewertungen

- A R K K: Chbe 6300: Kinetics and Reactor Design Homework 1Dokument2 SeitenA R K K: Chbe 6300: Kinetics and Reactor Design Homework 1AnnNoch keine Bewertungen

- CHBE 355 Midterm Examination 2024Dokument5 SeitenCHBE 355 Midterm Examination 2024Awesome GeneralNoch keine Bewertungen

- CDB2043 - Reaction EngineeringDokument6 SeitenCDB2043 - Reaction EngineeringXin-YiWoonNoch keine Bewertungen

- Chapter 3Dokument4 SeitenChapter 3miza adlinNoch keine Bewertungen

- M-101 P-101 P-102 C-101 E-101 R-101 VLV-101 process flowDokument1 SeiteM-101 P-101 P-102 C-101 E-101 R-101 VLV-101 process flowmiza adlinNoch keine Bewertungen

- MB (Miza)Dokument24 SeitenMB (Miza)miza adlinNoch keine Bewertungen

- Chemical Engineering & Processing: Process Intensi Fication: ArticleinfoDokument9 SeitenChemical Engineering & Processing: Process Intensi Fication: Articleinfomiza adlinNoch keine Bewertungen

- BKC URP2 Technical Paper - KA17295Dokument10 SeitenBKC URP2 Technical Paper - KA17295miza adlinNoch keine Bewertungen

- BKC4543 - Environmental Engineering 21516 PDFDokument16 SeitenBKC4543 - Environmental Engineering 21516 PDFmiza adlinNoch keine Bewertungen

- BKC Urp2 Thesis - Ka17295Dokument65 SeitenBKC Urp2 Thesis - Ka17295miza adlinNoch keine Bewertungen

- Chapter 2Dokument15 SeitenChapter 2miza adlinNoch keine Bewertungen

- BKC Urp2 Slide Presentation - Ka17295Dokument20 SeitenBKC Urp2 Slide Presentation - Ka17295miza adlinNoch keine Bewertungen

- Process SynthesisDokument30 SeitenProcess Synthesismiza adlin100% (1)

- (Updated) Internal Model ControlDokument5 Seiten(Updated) Internal Model Controlmiza adlinNoch keine Bewertungen

- Quiz#03 PEE 1920 II Grp-K01+K02Dokument3 SeitenQuiz#03 PEE 1920 II Grp-K01+K02miza adlinNoch keine Bewertungen

- Process Engineering Economics Quiz 02 Book ValuesDokument1 SeiteProcess Engineering Economics Quiz 02 Book Valuesmiza adlinNoch keine Bewertungen

- A MIEZADokument1 SeiteA MIEZAmiza adlinNoch keine Bewertungen

- Text TKKDokument1 SeiteText TKKmiza adlinNoch keine Bewertungen

- 23 Jan 2020 - Student - SV - Title - URP1 SEM 2 2019.2020Dokument15 Seiten23 Jan 2020 - Student - SV - Title - URP1 SEM 2 2019.2020miza adlinNoch keine Bewertungen

- Exam 1 SolDokument4 SeitenExam 1 Solrebelde96Noch keine Bewertungen

- Science MaterialDokument26 SeitenScience Materialmiza adlinNoch keine Bewertungen

- Acrylic AcidDokument7 SeitenAcrylic AcidElok Faiqotul Umma0% (1)

- Pengajian IslamDokument93 SeitenPengajian Islammiza adlinNoch keine Bewertungen

- Conventional Disaster ManagementDokument12 SeitenConventional Disaster Managementmiza adlinNoch keine Bewertungen

- Richardson 2008Dokument25 SeitenRichardson 2008miza adlinNoch keine Bewertungen

- Portable BlenderDokument1 SeitePortable Blendermiza adlinNoch keine Bewertungen

- Adabi Consumer Interview QuestionsDokument1 SeiteAdabi Consumer Interview Questionsmiza adlinNoch keine Bewertungen

- Assignment 1Dokument4 SeitenAssignment 1miza adlinNoch keine Bewertungen

- Group Members: Abdullah Aiman Bin Sharuddin 1171785 Muhammad Firdaus Bin Faisal 1171780 Noor Hamizan Mohd Noor 1171774Dokument12 SeitenGroup Members: Abdullah Aiman Bin Sharuddin 1171785 Muhammad Firdaus Bin Faisal 1171780 Noor Hamizan Mohd Noor 1171774miza adlinNoch keine Bewertungen

- Assignment 1 PDFDokument1 SeiteAssignment 1 PDFmiza adlinNoch keine Bewertungen

- Chapter 2Dokument2 SeitenChapter 2miza adlinNoch keine Bewertungen

- Producing Cumene from Benzene and PropyleneDokument4 SeitenProducing Cumene from Benzene and Propylenemiza adlinNoch keine Bewertungen