Beruflich Dokumente

Kultur Dokumente

Garlock 700

Hochgeladen von

Jairo ArroyoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Garlock 700

Hochgeladen von

Jairo ArroyoCopyright:

Verfügbare Formate

Garlock 700

*

MATERIAL PROPERTIES

Color: Green

Composition: Aramid and inorganic fibers with a nitrile binder

1

Fluid Services : Water, aliphatic hydrocarbons, oils and gasoline

2

Temperature , °F (°C)

Minimum: -100 (-73)

Continuous Max: +400 (+205)

Maximum: +700 (+370)

Pressure2, Maximum, psig (bar): 1000 (70)

P x T (max.)2, psig x °F (bar x °C)

1/32 and 1/16": 350,000 (12,000)

1/8": 250,000 (8,600)

PHYSICAL PROPERTIES*

ASTM F36 Compressibility, range, %: 7-17

ASTM F36 Recovery, %: 50

ASTM F38 Creep Relaxation, %: 25

ASTM F152 Tensile, Across Grain, psi (N/mm2): 1500 (10.3)

ASTM F1315 Density, lbs./ft.3 (grams/cm3): 120 (1.9)

ASTM F433 Thermal Conductivity (K), W/m°K (Btu.·in./hr.·ft.2·°F): 0.29-0.38 (2.00-2.65)

ASTM D149 Dielectric Properties, range, volts/mil.

Sample conditioning 1/32" 1/8"

3 hours at 250°F: 597 290

96 hours at 100% Relative Humidity: <2 <2

ASTM F586 Design Factors 1/16" 1/8"

"m" factor: 4.0(4) 4(5)

"y" factor, psi (N/mm2):

(4)

2500 (17.2) 2500 (17.2)(5)

(3)

ASTM F104 Line Call Out: F712100A9B4E22K5L501M5

*

SEALING CHARACTERISTICS

ASTM F37B ASTM F37B

Fuel A Nitrogen

Gasket Load, psi (N/mm2): 500 (3.5) 3000 (20.7)

Internal Pressure, psig (bar): 9.8 (0.7) 30 (2)

Leakage 1.0 ml/hr. 2.0 ml/hr.

IMMERSION PROPERTIES*- ASTM F146 Fluid Resistance after Five Hours

ASTM #1 Oil ASTM IRM #903 ASTM Fuel A ASTM Fuel B

300°F (150°C) 300°F (150°C) 70-85°F (20-30°C) 70-85°F (20-30°C)

Thickness Increase, (%) 0-5 0-15 0-5 0-10

Weight Increase, (%) <15 <35 <10 <15

Notes:

This is a general guide and should not be the sole means of selecting or rejecting this material. ASTM test results in accordance with ASTM F-104;

properties based on 1/32" (0.8mm) sheet thickness unless otherwise mentioned.

* Values do not constitute specification Limits

1

See Garlock chemical resistance guide.

2

Based on ANSI RF flanges at our preferred torque. When approaching maximum pressure, continuous operating temperature, minimum temperature

or 50% of maximum PxT, consult Garlock Applications Engineering. Minimum temperature rating is conservative.

3

A9: Leakage in Fuel A (Isooctane), Gasket Load = 500psi (3.5N/mm2), Pressure = 9.8psig (0.7bar): Typical = 0.4ml/hr, Max = 1.5ml/hr. A9: Leakage

in Nitrogen, Gasket Load = 3,000psi (20.7N/mm2), Pressure = 30psig (2bar): Typical = 1.5ml/hr, Max = 2.5ml/hr.

4

Actual tests showed 3.7 and 1200psi. These are considered too low for effective flange design.

5

Actual tests showed 3.6 and 1150psi. These are considered too low for effective flange design.

Das könnte Ihnen auch gefallen

- MQ11-02-TE-0000-GA0001 - R1 PinturaDokument49 SeitenMQ11-02-TE-0000-GA0001 - R1 PinturaAlvaro Cesar Iparraguirre NavarroNoch keine Bewertungen

- FRP Pipe Specification GuideDokument24 SeitenFRP Pipe Specification GuideJUAN PABLO LUCERONoch keine Bewertungen

- As Built T-181Dokument14 SeitenAs Built T-181Angel100% (1)

- 610 Series Product BulletinDokument2 Seiten610 Series Product BulletinEran LopezNoch keine Bewertungen

- Solvent Removable Dye Penetrant AnalysisDokument1 SeiteSolvent Removable Dye Penetrant AnalysisAries MarteNoch keine Bewertungen

- Design Standard for FRP StructuresDokument27 SeitenDesign Standard for FRP Structuresjdiaz87Noch keine Bewertungen

- Not For Production Use (For Reference Only) : ASTM A778-01Dokument1 SeiteNot For Production Use (For Reference Only) : ASTM A778-01Abu Bakr AsharefNoch keine Bewertungen

- Anexo I - Típicos de Soportes Metálicos PDFDokument174 SeitenAnexo I - Típicos de Soportes Metálicos PDFAngely CanalesNoch keine Bewertungen

- DOSIFicaciones Concreto-1Dokument6 SeitenDOSIFicaciones Concreto-1Ángel manuelNoch keine Bewertungen

- 5.1 Sumatane HSDokument4 Seiten5.1 Sumatane HSjnu6mnju6njNoch keine Bewertungen

- Lorbrand Idler&Pulley PresentationDokument31 SeitenLorbrand Idler&Pulley PresentationhendrobamaNoch keine Bewertungen

- Content of Standard 4S-10.02: FRP Pressure Pipe, Fittings and FlangesDokument24 SeitenContent of Standard 4S-10.02: FRP Pressure Pipe, Fittings and FlangesJuan Ayala ValdebenitoNoch keine Bewertungen

- Bolt Torque Chart: ASTM A307Dokument5 SeitenBolt Torque Chart: ASTM A307Leonardo Díaz Cerna100% (1)

- Anexo T - API 650Dokument4 SeitenAnexo T - API 650ChristiaanNoch keine Bewertungen

- Technology Guide 15: SSPC: The Society For Protective CoatingsDokument16 SeitenTechnology Guide 15: SSPC: The Society For Protective CoatingsIris Carmen100% (1)

- From ASME B31.3 para 304.5.3: T D SQRT (3P/ (16SE) ) +C: Variable Description Variable Value UnitDokument10 SeitenFrom ASME B31.3 para 304.5.3: T D SQRT (3P/ (16SE) ) +C: Variable Description Variable Value UnitSong TaoNoch keine Bewertungen

- Denso Protal 7200Dokument2 SeitenDenso Protal 7200min_one447065Noch keine Bewertungen

- HDPE الوسايلDokument151 SeitenHDPE الوسايلMohamed ElarabiNoch keine Bewertungen

- FLIR P65 Manual PDFDokument246 SeitenFLIR P65 Manual PDFTomas PeñateNoch keine Bewertungen

- ASTM A36 Steel plate propertiesDokument1 SeiteASTM A36 Steel plate propertiesStan HonNoch keine Bewertungen

- Gri GT 12Dokument14 SeitenGri GT 12gadNoch keine Bewertungen

- QT 16Cr PDFDokument1 SeiteQT 16Cr PDFYaroslav RuizNoch keine Bewertungen

- DIN EN 10268 Steel Pipe and Fittings SpecificationsDokument4 SeitenDIN EN 10268 Steel Pipe and Fittings SpecificationsAlex LacerdaNoch keine Bewertungen

- PPR VerdeDokument96 SeitenPPR VerdeIonut SomneaNoch keine Bewertungen

- Table 11 of API 5LDokument1 SeiteTable 11 of API 5LBilly Kurniawan100% (1)

- Biocleaner - Manual de Operacion y MantenimientoDokument9 SeitenBiocleaner - Manual de Operacion y MantenimientoFabian Ignacio Marquez OsorioNoch keine Bewertungen

- Dimensions of Sockolets Pressure Class 3000 and 6000 Lbs - MSS-SP97Dokument3 SeitenDimensions of Sockolets Pressure Class 3000 and 6000 Lbs - MSS-SP97konazoi100% (1)

- Cab3 Cab4 Series Cabinets Product (15330)Dokument5 SeitenCab3 Cab4 Series Cabinets Product (15330)Evita Elizabeth Ramos CuevasNoch keine Bewertungen

- S235JR PDFDokument3 SeitenS235JR PDFRv Vaghasia100% (1)

- IPC2022 87194 Enhancing MFL A Ultra UtilizingFEM JSpille FinalDokument5 SeitenIPC2022 87194 Enhancing MFL A Ultra UtilizingFEM JSpille FinalOswaldo MontenegroNoch keine Bewertungen

- Hydro TestDokument14 SeitenHydro TestUNIISCRIBDNoch keine Bewertungen

- ISO 3302-1:1996(E) M-Class TolerancesDokument1 SeiteISO 3302-1:1996(E) M-Class Tolerancespiturro88Noch keine Bewertungen

- ASME B16.5 - 3 InchDokument1 SeiteASME B16.5 - 3 InchRanjan KumarNoch keine Bewertungen

- DOC011Dokument4 SeitenDOC011InggitNoch keine Bewertungen

- Technical Data: 702G Internal Pipe Coating SystemDokument4 SeitenTechnical Data: 702G Internal Pipe Coating Systemcesar_p80-1Noch keine Bewertungen

- Cámara de Espuma - Certificado UL PDFDokument3 SeitenCámara de Espuma - Certificado UL PDFvivicastedoNoch keine Bewertungen

- Banco de Preguntas GestionDokument135 SeitenBanco de Preguntas GestionItzel GaragayNoch keine Bewertungen

- PCR PCRH Full lit-SP PDFDokument18 SeitenPCR PCRH Full lit-SP PDFjuanfco1965100% (1)

- Manual Weldoffice PDFDokument51 SeitenManual Weldoffice PDFAnonymous wKvJXBJ2iNoch keine Bewertungen

- B - 670 Pump PerformanceDokument1 SeiteB - 670 Pump PerformanceHery Mardiono HeryNoch keine Bewertungen

- Pressure safety valve sizing for gas serviceDokument66 SeitenPressure safety valve sizing for gas servicePROCESOS PROCESOSNoch keine Bewertungen

- Polyken Pipe Coating CalculatorDokument4 SeitenPolyken Pipe Coating CalculatorGustavo CarrilloNoch keine Bewertungen

- Perú Corp. S.A.: Piping Class Fire Fighting SystemDokument16 SeitenPerú Corp. S.A.: Piping Class Fire Fighting SystemRonny Estremadoiro ArteagaNoch keine Bewertungen

- Acsr SPLN 41-7 PDFDokument2 SeitenAcsr SPLN 41-7 PDFDharta Wira100% (1)

- Stub EndDokument4 SeitenStub EndFranciscoplazaNoch keine Bewertungen

- ASME Section V - Art 1 - Subsection A Nondestructive Methods of ExaminationDokument18 SeitenASME Section V - Art 1 - Subsection A Nondestructive Methods of ExaminationFavio Fernández LongNoch keine Bewertungen

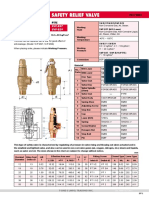

- Bronze Safety Relief Valve: SV-B27 SVP-B27 SV-B29 SVP-B29Dokument1 SeiteBronze Safety Relief Valve: SV-B27 SVP-B27 SV-B29 SVP-B29Shishan Ahmad100% (1)

- Butterfly Valve Spec SheetDokument3 SeitenButterfly Valve Spec SheetJulio Cabrera50% (2)

- Split Tee CatalogoDokument3 SeitenSplit Tee Catalogobotella berNoch keine Bewertungen

- Guía de Evaluación AWS G1.10MDokument45 SeitenGuía de Evaluación AWS G1.10MDaniel Jimenez100% (1)

- WeldBend Catalog PDFDokument186 SeitenWeldBend Catalog PDFDavid MahoneyNoch keine Bewertungen

- Blind Flange 1,2, Hinge, Handlen & Plug PDFDokument1 SeiteBlind Flange 1,2, Hinge, Handlen & Plug PDFArief MaulanaNoch keine Bewertungen

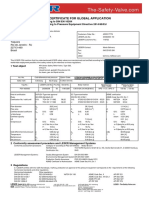

- PSV 430066 PDFDokument41 SeitenPSV 430066 PDFErikikoNoch keine Bewertungen

- Nch203 of 1977Dokument13 SeitenNch203 of 1977Pamela Saavedra Moya100% (1)

- Garlock 9900 Data Sheet PDFDokument1 SeiteGarlock 9900 Data Sheet PDFMartin Andrew TugadeNoch keine Bewertungen

- Garlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsDokument1 SeiteGarlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsChristian SanhuezaNoch keine Bewertungen

- 3504 Blue Gylon Data Sheet PDFDokument1 Seite3504 Blue Gylon Data Sheet PDFYnuzneNoch keine Bewertungen

- Garlock Style 700 Spec Sheet - (NA) 2016-11 enDokument1 SeiteGarlock Style 700 Spec Sheet - (NA) 2016-11 enMarín HernándezNoch keine Bewertungen

- Garlock Style 3000 Spec Sheet - (NA) 2016-11 enDokument1 SeiteGarlock Style 3000 Spec Sheet - (NA) 2016-11 enalan2003_1_29040Noch keine Bewertungen

- Garlock GYLON 3500Dokument1 SeiteGarlock GYLON 3500echavarriNoch keine Bewertungen

- Elcometer 106Dokument14 SeitenElcometer 106eknoboyNoch keine Bewertungen

- Astm E23Dokument25 SeitenAstm E23Jairo ArroyoNoch keine Bewertungen

- Amercoat 450HDokument2 SeitenAmercoat 450HJairo ArroyoNoch keine Bewertungen

- Elcometer 106Dokument14 SeitenElcometer 106eknoboyNoch keine Bewertungen

- Astm G12Dokument2 SeitenAstm G12Jairo Arroyo100% (1)

- Sfa-5 1 PDFDokument44 SeitenSfa-5 1 PDFRyan Man100% (3)

- American Fastener TablesDokument7 SeitenAmerican Fastener TablesAhmed BdairNoch keine Bewertungen

- Answered by Kenneth Erickson & Kip Mankenberg: 36 - Inspection TrendsDokument4 SeitenAnswered by Kenneth Erickson & Kip Mankenberg: 36 - Inspection TrendsJuan Gutier CcNoch keine Bewertungen

- MATH Concepts PDFDokument2 SeitenMATH Concepts PDFs bNoch keine Bewertungen

- Money MBA 1Dokument4 SeitenMoney MBA 1neaman_ahmed0% (1)

- Chapter 1 Critical Thin...Dokument7 SeitenChapter 1 Critical Thin...sameh06Noch keine Bewertungen

- Antenatal AssessmentDokument9 SeitenAntenatal Assessmentjyoti singhNoch keine Bewertungen

- Assignment No.7Dokument2 SeitenAssignment No.7queen estevesNoch keine Bewertungen

- Ra 11223 PDFDokument34 SeitenRa 11223 PDFNica SalazarNoch keine Bewertungen

- Resp Part 4Dokument95 SeitenResp Part 4Kristian CadaNoch keine Bewertungen

- Case Study On Maruti 800Dokument4 SeitenCase Study On Maruti 800Nizar MesaniNoch keine Bewertungen

- Soil Testing Lab Results SummaryDokument2 SeitenSoil Testing Lab Results SummaryMd SohagNoch keine Bewertungen

- Human Resource Management (MGT 4320) : Kulliyyah of Economics and Management SciencesDokument9 SeitenHuman Resource Management (MGT 4320) : Kulliyyah of Economics and Management SciencesAbuzafar AbdullahNoch keine Bewertungen

- Book 2 - Test 1Dokument2 SeitenBook 2 - Test 1Đức LongNoch keine Bewertungen

- BRKSPG-2904-2904 - Cisco Live Session - v2-CL PDFDokument182 SeitenBRKSPG-2904-2904 - Cisco Live Session - v2-CL PDFMohamed SamirNoch keine Bewertungen

- Argenti, P. Corporate Communication. Cap. 8-9Dokument28 SeitenArgenti, P. Corporate Communication. Cap. 8-9juan100% (1)

- CPS Layoffs BreakdownDokument21 SeitenCPS Layoffs BreakdownjroneillNoch keine Bewertungen

- ES1 Work Panel DatasheetDokument3 SeitenES1 Work Panel DatasheetGerardo Alberto Navarro LopezNoch keine Bewertungen

- Penilaian Risiko Kerja Menggunakan Metode Hirarc Di Pt. Sinar Laut Indah Natar Lampung SelatanDokument7 SeitenPenilaian Risiko Kerja Menggunakan Metode Hirarc Di Pt. Sinar Laut Indah Natar Lampung SelatanIndun InsiyahNoch keine Bewertungen

- Project Cost ForecastDokument11 SeitenProject Cost ForecastJames MendesNoch keine Bewertungen

- Literature Revisited: Understanding Key Concepts and Applying Analytical SkillsDokument31 SeitenLiterature Revisited: Understanding Key Concepts and Applying Analytical SkillsMuhammad Furqan Aslam Awan100% (2)

- 1 Starter WBDokument88 Seiten1 Starter WBHYONoch keine Bewertungen

- Digital Burner Controller: Tbc2800 SeriesDokument4 SeitenDigital Burner Controller: Tbc2800 SeriesSUDIP MONDALNoch keine Bewertungen

- 60Hz Axial-Fan Centrifugal-Fan AC EN (2009) PDFDokument136 Seiten60Hz Axial-Fan Centrifugal-Fan AC EN (2009) PDFRodrigo GonçalvesNoch keine Bewertungen

- JKR Specs L-S1 Addendum No 1 LED Luminaires - May 2011Dokument3 SeitenJKR Specs L-S1 Addendum No 1 LED Luminaires - May 2011Leong KmNoch keine Bewertungen

- CELTA Pre-Interview Grammar, Vocabulary and Pronunciation ExercisesDokument4 SeitenCELTA Pre-Interview Grammar, Vocabulary and Pronunciation ExercisesMichelJorge100% (2)

- Pankaj Screener 10 Oct 2014Dokument127 SeitenPankaj Screener 10 Oct 2014Sadul Singh Naruka100% (1)

- List of SQAC DQAC SISC DISC 2019 20Dokument39 SeitenList of SQAC DQAC SISC DISC 2019 20Shweta jainNoch keine Bewertungen

- Mathematics Specimen Papers and Mark Schemes UG013054Dokument102 SeitenMathematics Specimen Papers and Mark Schemes UG013054minnie murphy86% (7)

- Financial Reporting Statement Analysis Project Report: Name of The Company: Tata SteelDokument35 SeitenFinancial Reporting Statement Analysis Project Report: Name of The Company: Tata SteelRagava KarthiNoch keine Bewertungen

- SLU Missalette 2016 Capping (Not-Final)Dokument18 SeitenSLU Missalette 2016 Capping (Not-Final)Teanu Jose Gabrillo TamayoNoch keine Bewertungen

- IntegrityDokument5 SeitenIntegrityPritam Kumar100% (1)

- 2021.01.28 - Price Variation of Steel Items - SAIL Ex-Works Prices of Steel - RB-CivilDokument2 Seiten2021.01.28 - Price Variation of Steel Items - SAIL Ex-Works Prices of Steel - RB-CivilSaugata HalderNoch keine Bewertungen