Beruflich Dokumente

Kultur Dokumente

Notes:: Saudi Arabian Oil Company

Hochgeladen von

kdpmansiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Notes:: Saudi Arabian Oil Company

Hochgeladen von

kdpmansiCopyright:

Verfügbare Formate

SAUDIARAMCO.

NOTES:

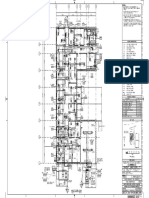

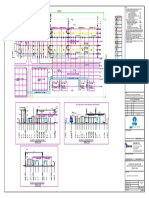

1 2 3 3' 4 4' 5 1. ALL DIMENSIONS ARE IN MILLIMETERS AND

ELEVATIONS ARE IN METERS UNLESS OTHERWISE

NOTED.

22000 2.CONDENSATE DRAIN PIPE SIZE SHALL BE AS

VENDOR RECOMMENDATIONS.

7000 4500 5250 5250 3.TEST POINT FOR THE SMOKE DETECTOR SHALL BE

PROVIDED IN THE HVAC DUCT TO ENABLE TESTING

OF

AIR OF THE DUCT SMOKE DETECTORS.

LOCK-4

CONSENT

026 4.TYPE-I KITCHEN HOOD SHALL BE PROVIDED AND

LOCKER WORKSTATION CONNECTED TO THE EXHAUST FAN IN THE KITCHEN.

ROOM OFFICE 2 JAN

EF-3 027 025 024 023

BDD

TTEN

A

250x200

ECD-2

SCD-21

(TYP-4)

WRI

200x200

SCD-22 200x200 EF-2

250x250

4500

THE

150x150

ECD-3

SCD-19

150x150 BDD TOILET

FSD-34 SCD-20

EDH-6

(TYP-4) 022

THOUT

250x250

300x300

250x200

200x200

D/G

RCD-15

RCD-16

FSD-29 VAV-6

SCD-23

WI

FSD-30

B AIR

FSD-31

NG

200x200 LOCK-3

SCD-24 400x300 400x250

2500

DRAWI

FSD-28 021

(TYP-2) 200x200

RCD-19 200x200

SCD-26 FSD-33 SCD-18

700x300 BELL

MOUTH FSD-32 LEGEND/ABBREVIATIONS

FSD-27

S

250x200

C

THI

200x200 CORRIDOR-3

SITTING AREA/ ACCU AIR COOLED CONDENSING UNIT

700x300

030

COMPUTER LAB

FSD-26

BDD BACK DRAFT DAMPER

KITCHEN

FROM

028 DDC DIRECT DIGITAL CONTROL

020

300x200 DG DOOR GRILLE

4500

RCD-17

300x250

(TYP-2) 300x250 SCD-17 150x150 DUCT

(TYP-2) CONNECTED TO DSD DUCT SMOKE DETECTOR

VAV-5 FSD-25 250x200

NED

KITCHEN HOOD

ECD EXHAUST CEILING DIFFUSER

CORRIDOR-2 FSD-24 BDD

OBTAI

200x200 RCD-14 SCD-16 EDH ELECTRICAL DUCT HEATER

EDH-5

029 (TYP-3)

400x250 ECD-1 EF-1 EF EXHAUST FAN

250x200 FGL FINISH GRADE LEVEL

D

BE

FSD FIRE SMOKE DAMPER

250x250 VAV-4 RCD-13

EDH-4 (TYP-3) MD MOTORIZED DAMPER

PRAYER

PART,SHALL

SHIFT RCD-12 PACU PACKAGED AIR CONDITIONING UNIT

ROOM

SUPERVISOR SCD-14 CONFERENCE PSU PRECISION SPLIT TYPE UNIT

RCD-18 FSD-23 SCD-15 019

4500

017 ROOM

BELL (TYP-3)

500x250 RAG RETURN AIR GRILLE

MOUTH 018

FSD-22

700x400

RCD RETURN CEILING DIFFUSER

700x400

200x200

LOBBY/WAITING

SAG SUPPLY AIR GRILLE

014

SCD SUPPLY CEILING DIFFUSER

DSO OFFICE RCD-11

N

I

200x200

SJD SUPPLY JET DIFFUSER

SCD-13

016

E

FULL,OR

150x150

SCD-11 STL SAND TRAP LOUVER

(TYP-2) VAV VARIABLE AIR VOLUME

VOLUME DAMPER

700x450 250x250

36500

MOTORIZED DAMPER

4500

4500

SCD-10

N

300x250 AIR FIRE SMOKE DAMPER

I

FSD-21

LOCK-2

250x200

OPS RCD-9 SCD-12 ACCESS DOOR

ON

FOREMAN 300x300 RCD-10 015

REPRODUCTI

013 (TYP-2) 150x200

REFERENCE DRAWINGS

VAV-3

300x300 DESCRIPTIONS DRAWING NO.

EDH-3

FSD-20

DRAWING CONTROL FOR EWO-16S061A-001 BD-244992

F

200x200

150x200

CONSTRUCTION SCOPE OF WORK BE-244993

SCD-9

OPS HVAC EQUIPMENT SCHEDULE BA-005853-001

CLERK RCD-7

STORE HVAC EQUIPMENT SCHEDULE BA-005854-001

RCD-8

SAUDIARAMCO.NO

012 011 HVAC AIR FLOW DIAGRAM BA-005855-001

400x250 SCD-8

4500

4500

HVAC CONTROL DIAGRAM BA-005856-001

FSD-19

HVAC SEQUENCE OF OPERATION BA-005903-001

SCD-25

MAINTENANCE BELL SCD-7

800x450

(TYP-2) HVAC SECTIONS BA-005904-001

OFFICE MOUTH

150x200

HTC HVAC DETAILS BA-005905-001

009 010 HVAC DETAILS BA-005906-001

200x150

SCD-6 RCD-6 KEY PLAN

G

700x500

200x200

TYP-2)

NORTH

RCD-5

OF

ROLL-UP

(

350x200 200x150 DOOR

PLANNER & RAMP UP ST

4500

PROPERTY

MATERIAL MAN 350x200 VAV-2 FSD-18 250x200 N LP

007

200x150

ADMINISTRATION

FSD-17

BUILDING

900x450

VAV-1

EXISTING COMMUNICATION

SITTING & FH

LP

LP

BUILDING AREA

700x600

EDH-2 SB

MHT

329.220

WP

EDH-1 COMPUTER ROOM

RCD-3 BELL RCD-4 EXISTING CONCRETE

WELDING SHELTER PAD

MOUTH 008 (TYP-2)

SCD-4

U/G

300x250 300x250

SCD-5 THIS

NG

329.756

PI

WP

400x250

NE

ON LI

TY PI

(TYP-2)

SSI

SOLE

LI

N G TRA N SM I

SITE

U TI

FSD-14 FSD-15

H

STI

EXI

FSD-13

400x350

FSD-16

U/G

200x200 329.737

FSD-12 400x250 WP

CORRIDOR-1

2500

MAINTENANCE

BELL

THE

NG

OFFICE

SCD-2

PI

WORKSHOP COMPLEX

TY PI

MOUTH 005

SCD-3

LI

AIR

UTI

FSD-9 200x200

LOCK-1 RCD-2 300x200 001

PAVED ACCESS RO AD

FSD-11 400x250

ARE

006

FSD-7

FSD-5

850x600

900x550

200x150 EXISTING MAINTENANCE

BUILDING AREA

FSD-10 250x200 300x250 U.E.R. WELL

N

NEW

VALVE

HEREI

300x250

BOX

FSD-8

FSD-6

SP-02

300x200 SP-01

DRAWING LIMIT

4"- U W - 185

2"- DW - 185

6"- FW - 180

SAG-2 SAG-1 300x250 SJD-1

RCD-1 300x250

550x400

RAG-3 RAG-2 (TYP-4)

300x250 0 1.0 2.0 3.0 4.0 5.0 6.0 7.0

4500

LIBRARY

PSU-1

COMM.

350x150

NED

004 METERS

ROOM SCALE:

CONTAI

003 1 :75M

DDC PANEL STL-2 SAND TRAP

UP UP

650

RAG-1 LOUVER 350x250 REVISION VALIDATION

FLOOR FSD-4

SCD-1 @ 2.4M HIGH FROM

DRAIN FSD-3 200x200

FGL THIS REVISION NO. 00 IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

J REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

FSD-1

900x600

300 800

ON

FSD-2 DSD-4 16S061A-001

MD-2

NFORMATI

900x600 DSD-2 RAD

2000

2150

DESIGN CERTIFICATION REVIEW FOR KEY DRAWINGS OTHER

MD-1 550x400

325

STL-1 SAND TRAP ELECT. (DESIGN AGENCY) x REQUIRED (SAUDI ARAMCO)

LOUVER 1000x600 ACCU-1

ENGG./DATE CERTIFIED BY/DATE CONST. AGENCY/DATE OPERATIONS/DATE BY/DATE

@ 2.4M HIGH FROM DSD-1 002 ATB ELS ABA

01/09/18 01/09/18 01/22/18

FGL

DSD-3 REV.NO. DATE REVISION DESCRIPTION

RETURN PLENUM

I

400x1500x700 00 01/09/18 ISSUED FOR CONSTRUCTION

2200

3390

THE

500x350 SAD JOB ORDER/EWO NO.

THIS REVISION IS NOT TO BE USED FOR

550x400

16S061A CONSTRUCTION UNTIL CERTIFIED AND DATED

RETURN PLENUM BOX PACU-1 SEEPAGE

SAUDI ARABIAN OIL COMPANY

AND

1000x700x2000 PIT

CONDENSATE CONDENSATE DRAWING TYPE

DRAIN PIPE DRAIN PIPE HVAC FLOOR PLAN HVA

NG

SEEPAGE

B SUPPLY PLENUM

700x1000x600 CENTRAL-OPERATION SUPPORT BUILDING

DRAWI

PIT BA-005904 PACU-2

1535 4437

SH 001

1650 4050 HARADH WATER INJECTION FACILITIES

A HARADH SAUDI ARABIA

BA-005904

S

HVAC FLOOR PLAN PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

THI

SH 001

SCALE 1:75 M H14 K BA-005852 001 00

Saudi Aramco 2615 ENG. (05/05)

CONFIDENTIAL VECTOR CADD-01

SAUDIARAMCO.

NOTES:

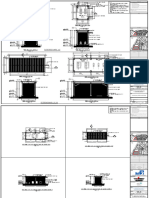

PACKAGE AIR CONDITIONING UNIT SCHEDULE 1.ALL DIMENSIONS ARE IN MILLIMETERS UNLESS

OTHERWISE NOTED.

COOLING COIL

OUT SUPPLY FAN FILTER SECTION CONDENSER COMPRESSOR POWER SUPPLY

AIR MANUFACTURER

AMBIENT SIDE TOTAL

EQPT. TOTAL SEN. MAKE/MODEL OR

SERVING TEMP. AIR EER/IEER REMARKS

NO. COIL FACE RLA LRA INPUT MCA MOCP

CAP. E.S.P. PD PD CAP. CAP. E.A.T. E.A.T. L.A.T. L.A.T. FAN APPROVED EQUAL

°F (CFM) PRE-FILTER FINAL VELOCITY QTY. KW QTY (EACH) (EACH) KW V PH HZ

OF

KW DRIVE TYPE DB °F WB °F DB °F WB °F TYPE TYPE

(CFM) (In of Wg) (IN W.G.) FILTER (IN W.G.) MBH MBH AMPS AMPS

(m/s)

2" THICK

CONSENT

PROPELLER HERMETIC

OFFICE WASHABLE

PACU-1 125 1836 7333 2.0 7.5 BELT FC 0.5 BAG 1.0 255.57 184.08 2.5 80.82 66.95 55.00 54.18 WITH DIRECT 2 2.68 2 30.1 225 36.97 87.6 120 480 3 60 9.8/9.9 ZAMIL/PAX030

AREA ALUMINUM

SCROLL

MOTOR

2" THICK PROPELLER

MAINTENANCE HERMETIC

PACU-2 125 181 2512 2.0 2.2 BELT FC WASHABLE 0.5 BAG 1.0 62.00 59.88 2.5 77.38 63.08 55.00 54.60 WITH DIRECT 2 0.53 2 10 75 12.7 28 40 480 3 60 11.0/11.2 ZAMIL/PAX008

WORKSHOP SCROLL

ALUMINUM MOTOR LEGEND

TTEN

NOTE 1 : PACU SHALL HAVE COPPER FINS ON COPPER COILS FOR EVAPORATOR. ACCU - AIR COOLED CONDENSING UNIT

CAP - CAPACITY

WRI

CFM - CUBIC FEET PER MINUTE

EXHAUST FAN SCHEDULE VAV SCHEDULE

DB - DRY BULB

THE

POWER SUPPLY AIR QUANTITY

CAPACITY ESP MOTOR FAN RPM MANUFACTURER MAKE/ MAXIMUM

SERVING DESIGNATION TYPE DRIVE REMARKS TAG NO LOCATION SERVING (CFM) REMARKS EAT - ENTERING AIR TEMPERATURE

(CFM) (IN W.G.) (HP) (MAX) PRESSURE

V/PH/HZ MODEL OR APPROVED EQUAL ROOM NO MAX. MIN. DROP (IN W.G.)

ECD - EXHAUST CEILING DIFFUSER

THOUT

KITCHEN EF-1 WALL MOUNTED 355 0.25 DIRECT 0.2 1550 230/1/60 GREENHECK/CW-080 SEE NOTES BELOW

PLANNER & MATERIAL PLANNER & MATERIAL MAN UNIT COMPLETE EDH - ELECTRIC DUCT HEATER

VAV-1 376 300 50

TOILET EF-2 WALL MOUNTED 308 0.25 DIRECT 0.2 1550 230/1/60 GREENHECK/CW-080 SEE NOTES BELOW MAN & MAINTENANCE OFFICE W/THERMOSTAT

EER - ENERGY EFFICIENCY RATIO

WI

LOCKER ROOM EF-3 WALL MOUNTED 243 0.25 DIRECT 0.2 1550 230/1/60 GREENHECK/CW-080 SEE NOTES BELOW

SITTING & COMPUTER SITTING & COMPUTER UNIT COMPLETE EF - EXHAUST FAN

VAV-2 413 330 50

ROOM ROOM, HTC W/THERMOSTAT

NG

EQPT - EQUIPMENT

DRAWI

NOTE 1 : EXHAUST FAN COMPLETE WITH ACCESSORIES SWITCH NEMA-1 ALUMINUM, BACK DRAFT DAMPERS, BIRD SCREEN DISCONNECT SWITCH AND AMCA RATED.

CLERK, OPS FOREMAN, UNIT COMPLETE ESP - EXTERNAL STATIC PRESSURE

VAV-3 OPS FOREMAN 557 445 50

NOTE 2 : ALL FANS SHALL BE PROVIDED WITH STARTERS WITH OPERATED SOLENOID RATED FOR 24 VAC AND THEIR CONTACTS FOR THE AMCA REQUIREMENT OF THE FANS. DSO W/THERMOSTAT

°F - DEGREE FAHRENHEIT

NOTE 3 : ALL EXHAUST FANS SHALL BE DIRECT DRIVE TYPE.

SITTING AREA, SHIFT UNIT COMPLETE FPM - FEET PER MINUTE

VAV-4 SITTING AREA 611 488

S

50

THI

SUPERVISOR W/THERMOSTAT

HP - HORSE POWER

CONFERENCE ROOM UNIT COMPLETE

ELECTRIC DUCT HEATER SCHEDULE VAV-5 CONFERENCE ROOM 1177 942 50 HZ - HERTZ

FROM

PRAYER ROOM W/THERMOSTAT

IEER - INTEGRATED ENERGY EFFICIENCY RATIO

POWER SUPPLY

SERVING MANUFACTURER MAKE/ WORKSTATION UNIT COMPLETE

AIR FLOW WIDTH HEIGHT VAV-6 WORKSTATION 797 638

EQUIP NO. CAPACITY REMARKS 50 KW - KILOWATT

ROOM NO MODEL OR APPROVED EQUAL OFFICE W/THERMOSTAT

(CFM) (MM) (MM)

NED

(KW) VOLTS Hz

PH LAT - LEAVING AIR TEMPERATURE

NOTE: 1. ALL VAV SHALL BE BY-PASS TYPE.

OBTAI

PLANNER & MATERIAL MAN TUTCO INC. / DHB

EDH-1 376 1.2 230 1 60 250 250 SEE BELOW NOTE-1&2 NO - NUMBER

& MAINTENANCE OFFICE

2. POWER SUPPLY FOR VAV SHALL BE SUPPLIED THROUGH DDC PANEL.

SITTING & COMPUTER PACU - PACKAGE AIR CONDITIONING UNIT

EDH-2 413 1.2 230 1 60 250 250 TUTCO INC. / DHB SEE BELOW NOTE-1&2

ROOM HTC 3. COORDINATE WITH DDC VENDOR FOR VAV POWER SUPPLY.

PH - PHASE

CLERK, OPS FOREMAN,

BE

EDH-3 557 1.5 230 1 60 350 250 TUTCO INC. / DHB SEE BELOW NOTE-1&2

DSO PSU - PRECISION SPLIT TYPE UNIT

SITTING AREA, SHIFT

PART,SHALL

EDH-4 611 1.5 230 1 60 350 200 TUTCO INC. / DHB SEE BELOW NOTE-1&2 -

SUPERVISE ROOM QTY QUANTITY

CONFERENCE ROOM, PRAYER TUTCO INC. / DHB RAG - RETURN AIR GRILLE

EDH-5 1177 2.0 230 1 60 400 300 SEE BELOW NOTE-1&2

ROOM

RCD - RETURN CEILING DIFFUSER

EDH-6 WORKSTATION, OFFICE 798 1.5 230 1 60 350 250 TUTCO INC. / DHB SEE BELOW NOTE-1&2

RH - RELATIVE HUMIDITY

NOTE: 1. DUCT HEATERS SHALL BE UL LISTED AND APPROVED. SAG - SUPPLY AIR GRILLE

N

I

2. CONTROL BOX SHALL BE LOCATED ON HEATER. SCD - SUPPLY CEILING DIFFUSER

FULL,OR

IN W.G. - INCHES OF WATER GAGE

V - VOLTS

FAN COIL UNIT SCHEDULE DESIGN INDOOR=72°F

VAV - VARIABLE AIR VOLUME

FAN CAP COOLING FAN MOTOR MANUFACTURE NAME & WB - WET BULB

TAG NO. QTY TYPE V PH HZ MINIMUM EER REMARKS

MODEL OR APPROVED EQUAL

N

(CFM) CAP. (M.BTU/HR) POWER (KW)

I ON

PSU-1 01 WALL MOUNTED 345 6.8 0.15 LIEBERT/DME 027E 230 1 60 11.5 STAND-BY, PRECISION UNIT

REPRODUCTI

REFERENCE DRAWINGS

DESCRIPTIONS DRAWING NO.

DRAWING CONTROL FOR EWO-16S061A-001 BD-244992

AIR COOLED CONDENSING UNIT SCHEDULE AMBIENT TEMP.= 125°F CONSTRUCTION SCOPE OF WORK BE-244993

HVAC FLOOR PLAN BA-005852-001

COMPRESSOR MANUFACTURE NAME &

TAG NO. QTY TYPE CAPACITY REFRIGERANT MOCP MCA FLA V PH HZ MINIMUM EER REMARKS

TYPE MODEL OR APPROVED EQUAL HVAC EQUIPMENT SCHEDULE BA-005854-001

SAUDIARAMCO.NO

HVAC AIR FLOW DIAGRAM BA-005855-001

SCROLL MATCHING

ACCU-1 01 FLOOR MOUNTED R-407C 30 18.4 15.4 230 1 60 LIEBERT / PFH027A-PH7 11.5 STAND-BY HVAC CONTROL DIAGRAM BA-005856-001

HERMITICALLY SEALED TO PSU-1

HVAC SEQUENCE OF OPERATION BA-005903-001

HVAC SECTIONS BA-005904-001

HVAC DETAILS BA-005905-001

HVAC DETAILS BA-005906-001

DESIGN PARAMETERS

OF

PACU-1 PACU-2 PSU-1 / ACCU-1

PROPERTY

(STAND-BY)

CONDITION-1 CONDITION-2 CONDITION-1 CONDITION-2 CONDITION-1

DESIGN OUTSIDE TEMPERATURE, DB/WB °F (SUMMER) 113/72 97/77 113/72 97/77 113/72

SOLE

DESIGN OUTSIDE TEMPERATURE, DB °F (WINTER) 41 41 41 41 41

DESIGN INDOOR TEMPERATURE, DB °F - RH % (OFFICE, ELECTRICAL ROOM, 75-50% 75-50% - - -

THE

AIR LOCK, LOCKERS, STORAGE ROOMS, KITCHEN & TOILET)

ARE

DESIGN INDOOR TEMPERATURE, DB °F - RH % (WORKSHOP) - - 75-50% 75-50% -

DESIGN INDOOR TEMPERATURE, DB °F - RH % (COMMUNICATION ROOM) 72-50% 72-50% - - 72-50%

N

HEREI

2

WALL COMPONENTS "U" FACTOR TOTAL, BTU/HR, °F, FT 0.055 0.055 0.055 0.055 0.055

2

ROOF COMPONENTS "U" FACTOR TOTAL, BTU/HR, °F, FT 0.057 0.057 0.063 0.057 0.057

NED

2

GLASS "U" FACTOR TOTAL, BTU/HR, °F, FT 0.1 0.1 0.1 0.1 0.01 SCALE:

CONTAI

AIR QUANTITY, CFM 7333 6742 2512 2165 345

REVISION VALIDATION

OUTSIDE AIR, CFM 1836 1836 181 181 15 THIS REVISION NO. 00 IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

ON

TOTAL SENSIBLE COOLING LOAD, BTU/HR 227893 184076 59879 49412 6815 16S061A-001

NFORMATI

DESIGN CERTIFICATION REVIEW FOR KEY DRAWINGS OTHER

LIGHTING 40379 40379 8558 8558 2094

(DESIGN AGENCY) x REQUIRED (SAUDI ARAMCO)

ENGG./DATE CERTIFIED BY/DATE CONST. AGENCY/DATE OPERATIONS/DATE BY/DATE

INTERNAL SENSIBLE HEAT GAIN, EQUIPMENT 41287 41287 15013 15013 2252 ATB ELS ABA

01/09/18 01/09/18 01/22/18

BTU/HR

REV.NO. DATE REVISION DESCRIPTION

PEOPLE 17875 17875 1815 1815 0

I

00 01/09/18 ISSUED FOR CONSTRUCTION

THE

OTHERS 51068 38550 28132 20749 1893 JOB ORDER/EWO NO.

THIS REVISION IS NOT TO BE USED FOR

16S061A CONSTRUCTION UNTIL CERTIFIED AND DATED

EXTERNAL SENSIBLE HEAT GAIN, BTU/HR 77284 45985 6361 3277 575

SAUDI ARABIAN OIL COMPANY

AND

TOTAL LATENT COOLING LOAD, BTU/HR 3154 71490 2119 8777 -20 DRAWING TYPE

HVAC EQUIPMENT SCHEDULE SCH

NG

EXTERNAL LATENT HEAT GAIN, BTU/HR -11146 57190 -1016 5642 -20

CENTRAL-OPERATION SUPPORT BUILDING

DRAWI

INTERNAL LATENT HEAT GAIN, BTU/HR 14300 14300 3135 3135 0 HARADH WATER INJECTION FACILITIES

HARADH SAUDI ARABIA

GRAND TOTAL COOLING LOAD, BTU/HR 231046 255566 61998 58189 6815

S

PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

THI

H14 K BA-005853 001 00

Saudi Aramco 2615 ENG. (05/05)

RESTRICTED VECTOR CADD-01

SAUDIARAMCO.

NOTES:

1.ALL DIMENSIONS ARE IN MILLIMETERS UNLESS

OTHERWISE NOTED.

SUPPLY AIR DEVICES COMBINATION FIRE/SMOKE DAMPER SCHEDULE (MOTORIZED)

FACE SIZE NECK SIZE AIR VOLUME LOCATION SIZE

ROOM NO. QTY ROOM NAME REFERENCE TYPE THROW REMARKS WIDTH x HEIGHT QTY. REMARKS

(MM) (MM) (CFM) TAG NO.

ROOM NAME (MM)

001 4 MAINTENANCE WORKSHOP SJD-1 600x600 300{ 628 4-WAY

FSD-1 LIBRARY 900x600 1 SEE NOTES-1, 2, 3

OF

002 1 ELECTRICAL ROOM SAG-1 - 300x200 394 HORIZONTAL 1 SEE NOTES-1, 2, 3

FSD-2 LIBRARY 900x600

CONSENT

003 1 COMMUNICATION ROOM SAG-2 - 300x250 345 HORIZONTAL FSD-3 MAINTENANCE WORKSHOP 550x400 1 SEE NOTES-1, 2, 3

004 1 LIBRARY SCD-1 600x600 300{ 293 4-WAY FSD-4 MAINTENANCE WORKSHOP 550x400 1 SEE NOTES-1, 2, 3

005 1 CORRIDOR-1 SCD-2 600x600 200{ 104 4-WAY FSD-5 COMMUNICATION ROOM 300x250 1 SEE NOTES-1, 2, 3

FSD-6 COMMUNICATION ROOM 300x250 1 SEE NOTES-1, 2, 3

006 1 AIRLOCK-1 SCD-3 600x600 150{ 95 4-WAY

TTEN

FSD-7 ELECTRICAL ROOM 300x200 1 SEE NOTES-1, 2, 3

007 1 PLANNER & MATERIAL MAN SCD-4 600x600 200{ 184 4-WAY

FSD-8 ELECTRICAL ROOM 300x200 1 SEE NOTES-1, 2, 3

008 2 SITTING & COMPUTER RM. SCD-5 600x600 200{ 132 4-WAY

WRI

FSD-9 CORRIDOR 900x550 1 SEE NOTES-1, 2, 3

009 1 MAINTENANCE OFFICE SCD-6 600x600 200{ 192 4-WAY

FSD-10 AIR LOCK-1 850x600 1 SEE NOTES-1, 2, 3

010 1 HTC SCD-7 600x600 150{ 148 4-WAY

THE

FSD-11 AIR LOCK-1 200x150 1 SEE NOTES-1, 2, 3

011 1 OPS STORE SCD-8 600x600 150{ 147 4-WAY FSD-12 CORRIDOR 400x250 1 SEE NOTES-1, 2, 3

THOUT

012 1 CLERK SCD-9 600x600 200{ 181 4-WAY FSD-13 CORRIDOR 900x450 1 SEE NOTES-1, 2, 3

013 1 OPS FOREMAN SCD-10 600x600 200{ 192 4-WAY FSD-14 PLANNER & MATERIAL MAN 700x600 1 SEE NOTES-1, 2, 3

FSD-15 CORRIDOR 400x250 1 SEE NOTES-1, 2, 3

WI

014 2 LOBBY/WAITING SCD-11 600x600 150{ 144 4-WAY

FSD-16 CORRIDOR 400x250 1 SEE NOTES-1, 2, 3

015 1 AIRLOCK-2 SCD-12 600x600 250{ 260 4-WAY

NG

FSD-17 CORRIDOR 350x200 1 SEE NOTES-1, 2, 3

016 1 DSO OFFICE SCD-13 600x600 200{ 184 4-WAY

DRAWI

FSD-18 CORRIDOR 350x200 1 SEE NOTES-1, 2, 3

017 1 SHIFT SUPERVISOR SCD-14 600x600 200{ 184 4-WAY

FSD-19 CORRIDOR 200x150 1 SEE NOTES-1, 2, 3

018 3 CONFERENCE ROOM SCD-15 600x600 200{ 239 4-WAY

FSD-20 CORRIDOR 150x200 1 SEE NOTES-1, 2, 3

S

019 1 PRAYER ROOM SCD-16 600x600 250{ 459 4-WAY

THI

FSD-21 CORRIDOR 300x250 1 SEE NOTES-1, 2, 3

020 1 KITCHEN SCD-17 600x600 250{ 355 4-WAY FSD-22 CORRIDOR 500x250 1 SEE NOTES-1, 2, 3

FSD-23 CORRIDOR 500x250 1 SEE NOTES-1, 2, 3

FROM

021 1 AIRLOCK-3 SCD-18 600x600 200{ 129 4-WAY

022 1 TOILET SCD-19 600x600 200{ 269 4-WAY FSD-24 CORRIDOR 300x250 1 SEE NOTES-1, 2, 3

FSD-25 CORRIDOR 300x250 1 SEE NOTES-1, 2, 3

024 1 WORKSTATION-2 SCD-20 600x600 250{ 528 4-WAY

NED

FSD-26 CORRIDOR 200x200 1 SEE NOTES-1, 2, 3

025 1 OFFICE SCD-21 600x600 200{ 269 4-WAY

OBTAI

FSD-27 CORRIDOR 700x300 1 SEE NOTES-1, 2, 3

026 1 AIRLOCK-4 SCD-22 600x600 150{ 125 4-WAY

FSD-28 CORRIDOR 700x300 1 SEE NOTES-1, 2, 3

027 1 LOCKER ROOM SCD-23 600x600 200{ 243 4-WAY

FSD-29 CORRIDOR 250x200 1 SEE NOTES-1, 2, 3

028 2 SITTING AREA/COMPUTER LAB. SCD-24 600x600 200{ 213 4-WAY FSD-30 CORRIDOR 300x300 1 SEE NOTES-1, 2, 3

BE

029 2 CORRIDOR-2 SCD-25 600x600 150{ 115 4-WAY FSD-31 CORRIDOR 200x200 1 SEE NOTES-1, 2, 3

PART,SHALL

030 1 CORRIDOR-3 SCD-26 600x600 150{ 128 4-WAY FSD-32 CORRIDOR 250x200 1 SEE NOTES-1, 2, 3 LEGEND

FSD-33 CORRIDOR 200x200 1 SEE NOTES-1, 2, 3

FSD-34 AIR LOCK-4 150x150 1 SEE NOTES-1, 2, 3 CFM - CUBIC FEET PER MINUTE

ECD - EXHAUST CEILING DIFFUSER

NOTE: FSD - FIRE SMOKE DAMPER

N

NO - NUMBER

I

1. COMBINATION FIRE & SMOKE DAMPER SHALL COMPLY WITH REQUIREMENTS OF UL 555 AND UL 555S.

EXHAUST/RETURN AIR DEVICES

QTY - QUANTITY

FULL,OR

AIR VOLUME 2. COMBINATION FIRE & SMOKE DAMPER SHALL BE UL LISTED AND BEAR IN THE LABEL OF AN APPROVED

FACE SIZE NECK SIZE

ROOM NO. QTY ROOM NAME REFERENCE REMARKS TESTING AGENCY INDICATING COMPLIANCE WITH 2009 IBC SECTION 716.3 AND NFPA 90A. RAG - RETURN AIR GRILLE

(MM) (MM) (CFM)

RCD - RETURN CEILING DIFFUSER

001 1 MAINTENANCE WORKSHOP RAG-1 - 550x350 2331 3. COMBINATION FIRE & SMOKE DAMPER SHALL HAVE 1.5 HRS FIRE RATING.

SAG - SUPPLY AIR GRILLE

002 1 ELECTRICAL ROOM RAG-2 - 300x200 382 4. POWER SUPPLY FOR ALL FSD'S SHALL BE FROM DDC PANEL.

N

I

SCD - SUPPLY CEILING DIFFUSER

003 1 COMMUNICATION ROOM RAG-3 - 300x250 333

ON

004 1 LIBRARY RCD-1 600x600 450x450 251

REPRODUCTI

005 1 CORRIDOR-1 RCD-2 600x600 450x450 140 REFERENCE DRAWINGS

DESCRIPTIONS DRAWING NO.

007 1 PLANNER & MATERIAL MAN RCD-3 600x600 450x450 166

DRAWING CONTROL FOR EWO-16S061A-001 BD-244992

008 2 SITTING & COMPUTER RM. RCD-4 600x600 450x450 119

CONSTRUCTION SCOPE OF WORK BE-244993

009 1 MAINTENANCE OFFICE RCD-5 600x600 450x450 172 HVAC FLOOR PLAN BA-005852-001

HVAC EQUIPMENT SCHEDULE BA-005853-001

010 1 HTC RCD-6 600x600 450x450 132

SAUDIARAMCO.NO

HVAC AIR FLOW DIAGRAM BA-005855-001

011 1 OPS STORE RCD-7 600x600 450x450 131

HVAC CONTROL DIAGRAM BA-005856-001

012 1 CLERK RCD-8 600x600 450x450 163 HVAC SEQUENCE OF OPERATION BA-005903-001

013 1 OPS FOREMAN RCD-9 600x600 450x450 172 HVAC SECTIONS BA-005904-001

HVAC DETAILS BA-005905-001

014 2 LOBBY/WAITING RCD-10 600x600 450x450 131

HVAC DETAILS BA-005906-001

016 1 DSO OFFICE RCD-11 600x600 450x450 166

017 1 SHIFT SUPERVISOR RCD-12 600x600 450x450 166

018 3 CONFERENCE ROOM RCD-13 600x600 450x450 199

OF

019 1 PRAYER ROOM RCD-14 600x600 450x450 394

PROPERTY

020 1 KITCHEN ECD-1 600x600 325x325 355

022 4 TOILET ECD-2 325x325 150x150 68

024 1 WORKSTATION-2 RCD-15 600x600 450x450 494

025 1 OFFICE RCD-16 600x600 450x450 250

SOLE

027 1 LOCKER ROOM ECD-3 600x600 325x325 243

028 2 SITTING AREA/COMPUTER LAB. RCD-17 600x600 450x450 197

029 1 CORRIDOR-2 RCD-18 600x600 450x450 318

THE

030 1 CORRIDOR-3 RCD-19 600x600 450x450 176

ARE N

HEREINED

SCALE:

CONTAI

REVISION VALIDATION

THIS REVISION NO. 00 IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

ON

16S061A-001

NFORMATI

DESIGN CERTIFICATION REVIEW FOR KEY DRAWINGS OTHER

(DESIGN AGENCY) x REQUIRED (SAUDI ARAMCO)

ENGG./DATE CERTIFIED BY/DATE CONST. AGENCY/DATE OPERATIONS/DATE BY/DATE

ATB ELS ABA

01/09/18 01/09/18 01/22/18

REV.NO. DATE REVISION DESCRIPTION

I

00 01/09/18 ISSUED FOR CONSTRUCTION

THE

JOB ORDER/EWO NO.

THIS REVISION IS NOT TO BE USED FOR

16S061A CONSTRUCTION UNTIL CERTIFIED AND DATED

SAUDI ARABIAN OIL COMPANY

AND

DRAWING TYPE

HVAC EQUIPMENT SCHEDULE SCH

NG

CENTRAL-OPERATION SUPPORT BUILDING

DRAWI

HARADH WATER INJECTION FACILITIES

HARADH SAUDI ARABIA

S

PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

THI

H14 K BA-005854 001 00

Saudi Aramco 2615 ENG. (05/05)

RESTRICTED VECTOR CADD-01

SAUDIARAMCO.

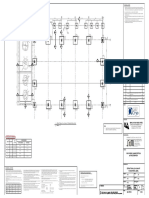

NOTES:

1. ALL I/O POINTS ARE CONNECTED TO THE DDC

UNLESS NOTED OTHERWISE.

2. ACTUAL CONTROL & WIRING ARE PREPARED BY

THE AUTHORIZED CONTROL SYSTEM CONTRACTOR.

3. HVAC INSTRUMENTS AND EQUIPMENT SHALL BE

OF

MONITORED AND CONTROLLED THROUGH A DEDICATED

DDC SYSTEM.

CONSENT

4. DDC PANEL SHALL HAVE 20% OF THE TOTAL I/O

POINTS AS SPARE.

TTEN

WRI

THE

TO FACP

THOUT

TO DDC TO DDC TO DDC TO DDC TO DDC TO DDC TO DDC

PANEL PANEL PANEL PANEL PANEL PANEL PANEL

DSD-2 TO DDC

PANEL

WI

5497 CFM FSD-2 FSD-10

RA

FSD-14

TO DDC

NG

DRAWI

TO DDC BELL

PANEL FSD-15 FSD-16 MOUTH

7333 CFM FSD-1 FSD-9 FSD-17

SA

FSD-13

TS-3

FSD-18

S

THI

STL-1 BELL VAV-1 VAV-3

DSD-1 TS-1 AF-1 MOUTH EDH-2

1836 CFM TO DDC

MD-1 AF-2

FROM

VAV-2

FRESH AIR INTAKE VD

TO DDC EDH-1 EDH-3

SAND TRAP LOUVER TO FACP

TO DDC TO DDC FSD-11

CFM

@ 1836 CFM

NED

FSD-5

FSD-7

FSD-8

TS-2

FSD-6

FSD-12

TO DDC

OBTAI

LEGEND

7333

293 251 95 345 333 394 382 104 140 184 166 192 172 238 264 148 132 181 163 184 166 192 172

TO DDC AF AIR FLOW SWITCH

CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM

C BDD BACK DRAFT DAMPER

BE

CFM CUBIC FEET PER MINUTE

PART,SHALL

DDC DIRECT DIGITAL CONTROLLER

DSD DUCT SMOKE DETECTOR

PACU-1

M TO DDC

EF EXHAUST FAN

COMM. PLANNER & MAINTENANCE SITTING & OPS

AIR CORRIDOR-1

LIBRARY ELECT. OFFICE DSO OFFICE FACP FIRE ALARM CONTROL PANEL

LOCK-1 ROOM MATERIAL MAN COMPUTER ROOM HTC CLERK FOREMAN

C 004 006 003 002 005 007 009 008 010 012 016 013

FSD FIRE SMOKE DAMPER

N

I

FINAL FILTER MD MOTORIZED VOLUME DAMPER

PRE-FILTER

FULL,OR

WASHABLE ALUMINUM PACU PACKAGE AIR CONDITIONING UNIT

PDS PDS

PDS PRESSURE DIFFERENTIAL SWITCH

RA RETURN AIR

SA SUPPLY AIR

TO DDC TO DDC TO DDC

TO DDC AF-7 TO DDC AF-6 AF-5

N

TS TEMPERATURE SENSOR

I

VD VOLUME DAMPER

ON

TO DDC TO DDC TO DDC TO DDC TO DDC

REPRODUCTI

PANEL PANEL PANEL PANEL PANEL

TO DDC TO DDC TO DDC TO DDC REFERENCE DRAWINGS

EF-3 EF-2 EF-1

PANEL PANEL PANEL PANEL

BDD BDD BDD DESCRIPTIONS DRAWING NO.

DRAWING CONTROL FOR EWO-16S061A-001 BD-244992

FSD-26 FSD-27 CONSTRUCTION SCOPE OF WORK BE-244993

CFM

FSD-19

HVAC FLOOR PLAN BA-005852-001

BELL FSD-22 HVAC EQUIPMENT SCHEDULE BA-005853-001

308

MOUTH

SAUDIARAMCO.NO

FSD-23 BELL HVAC EQUIPMENT SCHEDULE BA-005854-001

MOUTH

FSD-31 FSD-32 FSD-33 HVAC CONTROL DIAGRAM BA-005856-001

FSD-28

HVAC SEQUENCE OF OPERATION BA-005903-001

FSD-21

VAV-4 HVAC SECTIONS BA-005904-001

VAV-5

HVAC DETAILS BA-005905-001

FSD-24 FSD-29 FSD-34 HVAC DETAILS BA-005906-001

FSD-20 EDH-6

EDH-4 EDH-5

FSD-30

FSD-25 VAV-6

OF

PROPERTY

288 262 147 131 260 184 166 426 394 394 459 597 717 318 295 243 243 125 269 250 528 494 128 176 39 269 269 355 355 129

CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM CFM

SOLE

T D/G

39

CFM

OPS AIR SHIFT SITTING AREA/ PRAYER CONFERENCE LOCKER WORKSTATION AIR

AIR

THE

LOBBY/WAITING SUPERVISOR COMPUTER LAB CORRIDOR-2 2

STORE LOCK-2 ROOM ROOM ROOM LOCK-4 OFFICE CORRIDOR-3 JANITOR TOILET KITCHEN LOCK-3

014 011 015 017 028 019 018 029 027 026 025 024 030 023 022 020 021

ARE N

HEREINED

SCALE: NTS

CONTAI

REVISION VALIDATION

THIS REVISION NO. 00 IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

ON

16S061A-001

NFORMATI

DESIGN CERTIFICATION REVIEW FOR KEY DRAWINGS OTHER

(DESIGN AGENCY) REQUIRED (SAUDI ARAMCO)

ENGG./DATE CERTIFIED BY/DATE CONST. AGENCY/DATE OPERATIONS/DATE BY/DATE

ATB ELS ABA

01/09/18 01/09/18 01/22/18

REV.NO. DATE REVISION DESCRIPTION

I

00 01/09/18 ISSUED FOR CONSTRUCTION

THE

JOB ORDER/EWO NO.

THIS REVISION IS NOT TO BE USED FOR

16S061A CONSTRUCTION UNTIL CERTIFIED AND DATED

SAUDI ARABIAN OIL COMPANY

AND

DRAWING TYPE

HVAC AIR FLOW DIAGRAM HVA

NG

CENTRAL-OPERATION SUPPORT BUILDING

DRAWI

HARADH WATER INJECTION FACILITIES

HARADH SAUDI ARABIA

S

PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

THI

H14 K BA-005855 001 00

Saudi Aramco 2615 ENG. (05/05)

RESTRICTED VECTOR CADD-01

SAUDIARAMCO.

NOTES:

1. ALL I/O POINTS ARE CONNECTED TO THE DDC

UNLESS NOTED OTHERWISE.

2. ACTUAL CONTROL & WIRING ARE PREPARED BY

THE AUTHORIZED CONTROL SYSTEM CONTRACTOR.

3. HVAC INSTRUMENTS AND EQUIPMENT SHALL BE

MONITORED AND CONTROLLED THROUGH A DEDICATED

OF

POWER SUPPLY (230VAC) DDC SYSTEM.

DDC PANEL

CONSENT

POWER SUPPLY #2 FROM 230VDC PANEL (BACK UP) 4. DDC PANEL SHALL HAVE 20% OF THE TOTAL I/O

POINTS AS SPARE

DO

FROM FIRE ALARM CONTROL PANEL (FACP) 5. POWER SUPPLY FOR FSD, VAV ACTIVATORS SHALL

DI BE PROVIDED THROUGH DDC PANEL.

OPERATOR PANEL

PRE-FILTER STATUS PACU-1

DI

TTEN

FINAL FILTER STATUS PACU-1

DI

WRI

PRE-FILTER STATUS PACU-2

DI

THE

FINAL FILTER STATUS PACU-2

DI PACU-1

THOUT

SUPPLY FAN MOTOR ON/OFF & STATUS PACU-1 FF PF FUSE

DO

SUPPLY FAN MOTOR ON/OFF & STATUS PACU-2 RUN FAIL MUTE

WI

DO

DI

EXHAUST FAN ON/OFF STATUS (EF-1) LIGHT

NG

DO PACU-2

DRAWI

DI

EXHAUST FAN ON/OFF STATUS (EF-2) FF PF

DO

DI

EXHAUST FAN ON/OFF STATUS (EF-3) RUN FAIL

DO BUZZER

S

THI

TELECOM ROOM TEMPERATURE

AI

LEGEND

DI

TELECOM ROOM HUMIDITY CONTROLLER EF-1 EF-2

FROM

DO

TELECOM ROOM HIGH TEMPERATURE ALARM AF AIR FLOW SWITCH

TO DDC DO EF-3

TO DDC AI ANALOG INPUT

NED

PACU-1 COMPRESSORS RUN/FAIL STATUS

DO CFM CUBIC FEET PER MINUTE

OBTAI

EDH-1 EDH-2 DDC DIRECT DIGITAL CONTROLLER

SUPPLY AIR TEMPERATURE PACU-1

DI

DI DIGITAL INPUT

TS-4 AF-3 PACU-2 COMPRESSORS RUN/FAIL STATUS DO DIGITAL OUTPUT

DO EDH-3 EDH-4

BE

DSD DUCT SMOKE DETECTOR

SUPPLY AIR TEMPERATURE PACU-2

2512 CFM DI

SA 2512 EDH ELECTRICAL DUCT HEATER

EDH-5 EDH-6

PART,SHALL

CFM PACU-1 FRESH AIR TEMPERATURE

VD FSD-3 AI EF EXHAUST FAN

FACP FIRE ALARM CONTROL PANEL

DSD-3 TO DDC RETURN AIR TEMPERATURE PACU-1

TO DDC TO DDC DI

PANEL FF FINAL FILTER

SYSTEM

PACU-2 FRESH AIR TEMPERATURE

AI FSD FIRE SMOKE DAMPER

START

RETURN AIR TEMPERATURE PACU-2 MD MOTORIZED VOLUME DAMPER

TO FACP

N

DI

I

STOP PDS PRESSURE DIFFERENTIAL SWITCH

TO DDC

STL-2 TS-6 AF-4

FULL,OR

PANEL AIR FLOW SWITCH (AF) EF-1 PF PRE FILTER

DI

RESET

PSU PRECISION SPLIT TYPE UNIT

181 CFM 2331 CFM FSD-4

AIR FLOW SWITCH (AF) EF-2

2331 DI SA SUPPLY AIR

CFM

CFM

MD-2 AIR FLOW SWITCH (AF) EF-3 TS TEMPERATURE SENSOR

DI

N

PSU-1 VAV VARIABLE AIR VOLUME

I

2512

FRESH AIR INTAKE DSD-4 AIR FLOW PACU-1 SUPPLY

SAND TRAP LOUVER TO DDC DI

RUN FAIL VD VOLUME DAMPER

ON

@ 181 CFM

REPRODUCTI

AIR FLOW PACU-1 RETURN

DI REFERENCE DRAWINGS

TO DDC TS-5

AIR FLOW PACU-2 SUPPLY ACCU-1 DESCRIPTIONS DRAWING NO.

TO FACP DI

DRAWING CONTROL FOR EWO-16S061A-001 BD-244992

RUN FAIL

AIR FLOW PACU-2 RETURN CONSTRUCTION SCOPE OF WORK BE-244993

DI

HVAC FLOOR PLAN BA-005852-001

TO DDC DO HVAC EQUIPMENT SCHEDULE BA-005853-001

FIRE SMOKE DAMPER OPEN/CLOSE FSD-1 TO FSD-34 (34 NOS)

SAUDIARAMCO.NO

C DI HVAC EQUIPMENT SCHEDULE BA-005854-001

VAV-1 VAV-2

MAINTENANCE DO HVAC AIR FLOW DIAGRAM BA-005855-001

MOTORIZED DAMPER OPEN/CLOSE MD-1 TO MD-4 (4 NOS)

WORKSHOP DI HVAC SEQUENCE OF OPERATION BA-005903-001

VAV-3 VAV-4 HVAC SECTIONS BA-005904-001

001 DO

TELECOM ROOM PSU-1 ON/OFF

DI HVAC DETAILS BA-005905-001

PACU-2 DO HVAC DETAILS BA-005906-001

TO DDC TELECOM ROOM ACCU-1 ON/OFF VAV-5 VAV-6

M

DI

PACU-1 SPACE TEMPERATURE (T1)

AI

OF

PACU-2 SPACE TEMPERATURE (T2)

C AI

DO

PROPERTY

EDH-1 ON/OFF STATUS

FINAL FILTER DI

PRE-FILTER DO

EDH-2 ON/OFF STATUS

WASHABLE ALUMINUM DI

PDS PDS DO

EDH-3 ON/OFF STATUS

DI

DO

EDH-4 ON/OFF STATUS

SOLE

DI

DO

EDH-5 ON/OFF STATUS

TO DDC TO DDC DI

THE

DO

EDH-6 ON/OFF STATUS

DI

DO

VAV-1 ON/OFF STATUS

ARE

DI

DO

VAV-2 ON/OFF STATUS

DI

N

HEREI

DO

VAV-3 ON/OFF STATUS

DI

DO

VAV-4 ON/OFF STATUS

DI

NED

DO

VAV-5 ON/OFF STATUS SCALE:

DI

CONTAI

DO

VAV-6 ON/OFF STATUS

DI REVISION VALIDATION

SPARE

THIS REVISION NO. 00 IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

ON

SPARE 16S061A-001

NFORMATI

DESIGN CERTIFICATION REVIEW FOR KEY DRAWINGS OTHER

SPARE (DESIGN AGENCY) REQUIRED (SAUDI ARAMCO)

ENGG./DATE CERTIFIED BY/DATE CONST. AGENCY/DATE OPERATIONS/DATE BY/DATE

ATB ELS ABA

SPARE 01/09/18 01/09/18 01/22/18

REV.NO. DATE REVISION DESCRIPTION

I

SPARE 00 01/09/18 ISSUED FOR CONSTRUCTION

THE

JOB ORDER/EWO NO.

THIS REVISION IS NOT TO BE USED FOR

16S061A CONSTRUCTION UNTIL CERTIFIED AND DATED

SAUDI ARABIAN OIL COMPANY

AND

DRAWING TYPE

HVAC CONTROL DIAGRAM HVA

NG

CENTRAL-OPERATION SUPPORT BUILDING

DRAWI

HARADH WATER INJECTION FACILITIES

HARADH SAUDI ARABIA

S

PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

THI

H14 K BA-005856 001 00

Saudi Aramco 2615 ENG. (05/05)

RESTRICTED VECTOR CADD-01

SAUDIARAMCO.

NOTES:

1. ALL I/O POINTS ARE CONNECTED TO THE DDC

SEQUENCE OF OPERATION (DDC PANEL): UNLESS NOTED OTHERWISE.

PACKAGED AIR CONDITIONING UNIT (PACU-1 & PACU-2): 2. ACTUAL CONTROL & WIRING ARE PREPARED BY

THE AUTHORIZED CONTROL SYSTEM CONTRACTOR.

SYSTEM START AND STOP:

3. HVAC INSTRUMENTS AND EQUIPMENT SHALL BE

OF

MONITORED AND CONTROLLED THROUGH A DEDICATED

1. OFFICE AREA SHALL BE SERVED BY ONE PACKAGED AIR

DDC SYSTEM.

CONDITIONING UNIT PACU-1.

CONSENT

4. DDC PANEL SHALL HAVE 20% OF THE TOTAL I/O

2. WORKSHOP SHALL BE SERVED BY ONE PACKAGED POINTS AS SPARE

AIR CONDITIONING UNIT PACU-2.

3. POWER SUPPLY TO HVAC UNITS SHALL BE ENABLED MANUALLY.

TTEN

4. SYSTEM START AND STOP SHALL BE COMMANDED BY THE DDC

PANEL. BLOWER MOTOR OF PACU SHALL START WHEN VOLUME

WRI

DAMPERS ARE FULLY OPEN.

5. WHEN THE SYSTEM IS COMMANDED TO STOP THRU DDC PANEL,

THE

PACU AND THEIR ASSOCIATED MOTORIZED DAMPER SHALL CLOSE.

THOUT

DIRTY FILTER:

1. WHEN THE PRE-FILTER OR FINAL FILTER OF PACU IS DIRTY, THE

WI

PRESSURE DIFFERENTIAL SWITCH (PDS) ACROSS EACH FILTER

SHALL INITIATE AN ALARM ON THE DDC PANEL. THE ALARM

NG

SHALL BE RESET AFTER FILTERS ARE CLEANED OR REPLACED.

DRAWI

2. PRE-FILTER DIRTY CONDITION SHALL BE SET AT 125 PA

(0.5 IN OF WG) PRESSURE DIFFERENTIAL SWITCH (PDS) ACROSS

EACH FILTER.

S

THI

3. FINAL FILTER DIRTY CONDITION SHALL BE SET AT 250 PA

(1.0 IN OF WG) PRESSURE DIFFERENTIAL SWITCH (PDS) ACROSS

EACH FILTER.

FROM

POWER INPUT/OUTPUT:

345

1. POWER SUPPLY TO DDC PANEL SHALL BE 230V, 1PH, 60HZ.

NED

CFM

2. ON-OFF STATUS OF ALL PACU AND EXHAUST FANS

OBTAI

SHALL BE DISPLAYED AT DDC PANEL.

PSU-1

3. POWER SUPPLY FOR ALL FSD'S, VAV'S SHALL BE PROVIDED THROUGH

(STAND BY)

DDC PANEL. VAV POWER SUPPLY SHALL BE CO-ORDINATED WITH DDC

345

VENDOR.

BE

CFM

PART,SHALL

TELECOM ROOM:

LEGEND

1. PACU SHALL BE INTER LOCKED WITH PSU-1. WHEN PACU-1

STOPS THEN DDC PANEL SHALL ENERGIZE PSU-1 TO ACCU AIR COOLED CONDENSING UNIT

MAINTAIN TELECOM ROOM TEMPERATURE. T TO DDC

DCS DISTRIBUTED CONTROL SYSTEM

PANEL

2.TELECOM ROOM IS SERVED BY ONE WALL MOUNTED DDC DIRECT DIGITAL CONTROLLER

PRECISION TYPE UNIT AS STAND BY (PSU-1) INSIDE

N

FACP FIRE ALARM CONTROL PANEL

I

THE CEILING, CORRESPONDING UNIT (ACCU-1) IS

TO DDC PANEL

LOCATED OUTSIDE OF THE BUILDING.

FULL,OR

MD MOTORIZED VOLUME DAMPER

3. TELECOM ROOM SHALL HAVE HIGH TEMPERATURE SENSOR PACU PACKAGE AIR CONDITIONING UNIT

(SET POINT 80°F). COMM.

PDS PRESSURE DIFFERENTIAL SWITCH

ROOM

PSU PRECISION SPILT TYPE UNIT

003

SA SUPPLY AIR

N

TEMPERATURE CONTROL:

I

TS TEMPERATURE SENSOR

ON

1. THE TEMPERATURE SENSOR (TS) ON THE SUPPLY AIR DUCT

REPRODUCTI

OF PACU COMMUNICATES WITH THE DDC PANEL AND SUPPLY

REFERENCE DRAWINGS

AIR TEMPERATURE IS MAINTAINED AT AROUND 55°C.

DESCRIPTIONS DRAWING NO.

DRAWING CONTROL FOR EWO-16S061A-001 BD-244992

AIR FLOW SWITCH:

CONSTRUCTION SCOPE OF WORK BE-244993

ACCU-1

HVAC FLOOR PLAN BA-005852-001

1. UPON DETECTION OF NO FLOW BY THE AIR FLOW SWITCH (STAND BY)

INSTALLED IN MAIN DUCT OF PACU-2 AN AUDIO VISUAL HVAC EQUIPMENT SCHEDULE BA-005853-001

CONTROL DIAGRAM FOR

SAUDIARAMCO.NO

ALARM SHALL BE INITIATED AT DDC PANEL. HVAC EQUIPMENT SCHEDULE BA-005854-001

STAND BY UNIT

HVAC AIR FLOW DIAGRAM BA-005855-001

DETAIL-1

SMOKE/FIRE DETECTION: HVAC CONTROL DIAGRAM BA-005856-001

HVAC SECTIONS BA-005904-001

1. WHEN SMOKE OR FIRE IS DETECTED WITHIN THE SPACES OR HVAC DETAILS BA-005905-001

INSIDE THE AIR STREAM BY THE DUCT SMOKE DETECTOR,

HVAC DETAILS BA-005906-001

SIGNAL SHALL BE SENT FROM FIRE ALARM CONTROL PANEL

(FACP) THRU DDC PANEL TO DE-ENERGIZE ALL OPERATING

PACU AND EXHAUST FANS.

OF

EQUIPMENT FAILURE:

PROPERTY

1. IN CASE OF EQUIPMENT FAILURE OR ANY ALARM SIGNALS, AN

AUDIBLE ALARM SHALL BE INITIATED AND VISUAL INDICATION

SHALL BE DISPLAYED AT DDC PANEL. AUDIBLE ALARM SHALL

HAVE THE PROVISION TO BE MUTE SILENCED. HOWEVER, VISUAL

ALARM SHALL LAST UNTIL THE FAULT IS ATTENDED AND RESET.

SOLE

THE

ARE N

HEREINED

SCALE: NTS

CONTAI

REVISION VALIDATION

THIS REVISION NO. 00 IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

ON

16S061A-001

NFORMATI

DESIGN CERTIFICATION REVIEW FOR KEY DRAWINGS OTHER

(DESIGN AGENCY) REQUIRED (SAUDI ARAMCO)

ENGG./DATE CERTIFIED BY/DATE CONST. AGENCY/DATE OPERATIONS/DATE BY/DATE

ATB ELS ABA

01/09/18 01/09/18 01/22/18

REV.NO. DATE REVISION DESCRIPTION

I

00 01/09/18 ISSUED FOR CONSTRUCTION

THE

JOB ORDER/EWO NO.

THIS REVISION IS NOT TO BE USED FOR

16S061A CONSTRUCTION UNTIL CERTIFIED AND DATED

SAUDI ARABIAN OIL COMPANY

AND

DRAWING TYPE

HVAC SEQUENCE OF OPERATION HVA

NG

CENTRAL-OPERATION SUPPORT BUILDING

DRAWI

HARADH WATER INJECTION FACILITIES

HARADH SAUDI ARABIA

S

PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

THI

H14 K BA-005903 001 00

Saudi Aramco 2615 ENG. (05/05)

RESTRICTED VECTOR CADD-01

SAUDIARAMCO.

NOTES:

1. ALL DIMENSIONS ARE IN MILLIMETERS AND

ELEVATIONS ARE IN METERS UNLESS OTHERWISE

NOTED.

OF

CONSENT

TTEN

WRI

J H G F E D C B A

THE

36500

THOUT

7000 4500 4500 4500 4500 4500 2500 4500

WI NG

DRAWI

T.O.P. +5.50

1000

SA 550x900 SA 450x900

250x300 SA 450x800 SA 400x700 SA 300x700 T.O.S. +4.50

RA 600x850 RA 600x700 FSD-14

150x350 200x250 200x200 FSD-13 RA 500x700 SA 450x700 RA 400x700 RA 300x700

S

THI

1100

DSD-1 FSD-1

STL-1 SAND TRAP FSD-29 FSD-34

FSD-2

LOUVER 600x1000

FROM

1000

@ 2.4M HIGH FROM 600x900

5500

FGL 250x500

250x400 200x350 250x300 200x200 250x250

4500

250x400 250x300

600x900

FSD-10 BELL MOUTH 150x150

RCD-2 BELL MOUTH 150x200 SCD-25 RCD-18 SCD-25 SCD-22

3697

BELL

3597

3497

3397

SCD-1 FSD-9

NED

3250

RCD-1 MOUTH

3120

PACU-1

DSD-2

2400

2281

2400

OBTAI

AIR LOCK

CORRIDOR-2 -4

LIBRARY

029 026

004 F.F.L. +0.00

FGL -0.15

BE

LEGEND / ABBREVIATIONS

MD-1

350x500

PART,SHALL

FFL FINISH FLOOR LEVEL

2200 2150

FGL FINISH GRADE LINE

FSD FIRE SMOKE DAMPER

MD MOTORIZED DAMPER

PACU PACKAGED AIR CONDITIONING UNIT

RAG RETURN AIR GRILLE

N

I

RCD RETURN CEILING DIFFUSER

A SECTION

FULL,OR

BA-005852

SCD SUPPLY CEILING DIFFUSER

SCALE 1:75 M

SH 001 SJD SUPPLY JET DIFFUSER

STL SAND TRAP LOUVER

VOLUME DAMPER

MOTORIZED DAMPER

N

I

FIRE SMOKE DAMPER

ON

REPRODUCTI

REFERENCE DRAWINGS

DESCRIPTIONS DRAWING NO.

DRAWING CONTROL FOR EWO-16S061A-001 BD-244992

CONSTRUCTION SCOPE OF WORK BE-244993

HVAC FLOOR PLAN BA-005852-001

HVAC EQUIPMENT SCHEDULE BA-005853-001

SAUDIARAMCO.NO

HVAC EQUIPMENT SCHEDULE BA-005854-001

HVAC AIR FLOW DIAGRAM BA-005855-001

HVAC CONTROL DIAGRAM BA-005856-001

HVAC SEQUENCE OF OPERATION BA-005903-001

HVAC DETAILS BA-005905-001

HVAC DETAILS BA-005906-001

G H J

OF

PROPERTY

11500

4500 7000

T.O.P. +8.80

1000

SOLE

T.O.S. +7.80

SUPPLY PLENUM

THE

DSD-3 600x700x1000

350x400 400x550

ARE

250x300 RAG-1

SJD-1 (TYP-2)

FSD-4

7800

(TYP-2)

N

FSD-3 DSD-4

HEREI

8800

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0

400x550

550x400

6350

METERS

NED

5750

6350

SCALE: 1 :75M

CONTAI

200x200 REVISION VALIDATION

THIS REVISION NO. 00 IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

2400

MAINTENANCE REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

MD-2

1327

WORKSHOP

ON

16S061A-001

F.F.L.

NFORMATI

001 PACU-2 +0.00

DESIGN CERTIFICATION REVIEW FOR KEY DRAWINGS OTHER

(DESIGN AGENCY) REQUIRED (SAUDI ARAMCO)

ENGG./DATE CERTIFIED BY/DATE CONST. AGENCY/DATE OPERATIONS/DATE BY/DATE

STL-2 SAND TRAP ATB ELS ABA

LOUVER 250x350 2000 3390 FGL -0.15 01/09/18 01/09/18 01/22/18

@ 2.4M HIGH FROM REV.NO. DATE REVISION DESCRIPTION

I

FGL 00 01/09/18 ISSUED FOR CONSTRUCTION

RETURN PLENUM

THE

JOB ORDER/EWO NO.

700x400x1500 THIS REVISION IS NOT TO BE USED FOR

16S061A CONSTRUCTION UNTIL CERTIFIED AND DATED

SAUDI ARABIAN OIL COMPANY

AND

DRAWING TYPE

HVAC SECTIONS HVA

B SECTION

NG

BA-005852 CENTRAL-OPERATION SUPPORT BUILDING

DRAWI

SCALE 1:75 M

SH 001

HARADH WATER INJECTION FACILITIES

HARADH SAUDI ARABIA

S

PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

THI

H14 K BA-005904 001 00

Saudi Aramco 2615 ENG. (05/05)

CONFIDENTIAL VECTOR CADD-01

SAUDIARAMCO.

FLEXIBLE DUCT

NOTES:

CONNECTION ( MIN LENGTH 1. INSULATION INSTALLED EXPOSED OUTDOORS SHALL

3 IN. MAX LENGTH 10 IN.) BE METAL CLADDED OR PROTECTED BY AN APPROVED

NOTE: AIR DUCT

AND ACCEPTABLE METHOD FROM MOISTURE AND

NON- HARDENING CUT A 12"x12" ACCESS HOLE IN THE DUCT ADJACENT SUNLIGHT DEGRADATION.

MASTIC SEALER TO THE HOUSING TO PERMIT CHECKING AND CLEANING

2.CONDENSATE DRAIN PIPE SIZE SHALL BE AS PER

SELF TAPPING SCREW. ALL AROUND (TYP.) OF THE SAMPLING TUBES. THE ACCESS HOLE MUST BE MAX. WIDTH

STEEL ANGLE SIZE VENDOR RECOMMENDATIONS.

NO. 14 x 1" LG COVERED AND SEALED WHEN NOT IN USE. OF DUCT OR

(MM & INCH)

OF

FAN IN MM

INSULATED L38x38x6 ALL AROUND

CONSENT

0 TO 1060 L-25x25x3 (1"x1"x„")

AIR DUCT FASTENED ON SLEEVE

UNIT 1061 TO 2420 L-40x40x4 (1•"x1•"x‰")

A/ HOUSING

C

AI DU OVER 2420 L-50x50x6 (2"x2"x‚")

R C

OU T

AC SU TL

TTEN

CE PP ET

SS INL LY SA

HO ET OR MP

DU LE

WRI

C SA R LI

NG NO. 8x16 mm METAL 16mm 2

DE T M RU MP ET

TE O BB LI UR TU SCREW @ 305mm O.C. INSULATED COPPER

CT N U N N BE

ER G CONNECTING (GROUNDING)

ƒ OR TE AI

THE

"

{ D PL TUB R SHEET METAL WIRE. (TYPICAL)

& F SM UG E

CO LE OK "U" STRIP (TYP.)

50 50 GU N X E

NE I BL STEEL ANGLE

THOUT

A C E

WI C C TO CO

TH ON R

ƒ ND

RS " DU LI QU UI AIR DUCT

{ I

T T

C ID

HU B

WI

( T

3/ B OX

4" ES I GH

{ T

)C

NG

ON

ALUM. DUCT TAPE CONCRETE GROUT NE

DRAWI

CT

OR

UNIT

HOUSING

Ga.20 GALV. SHEET

COMPRESSED

S

THI

SLEEVE ALL AROUND

FIBER GLASS

INSULATION

10mm. MACH. BOLT

FROM

3mm CANVASS FLEXIBLE

W/NUT & WASHER

DUCT CONNECTION

DUCT THRU WALL DUCT SMOKE DETECTOR DETAILS (MIN LENGTH 3 IN,

MAX LENGTH 10 IN)

FLEXIBLE CONNECTION DETAIL

NED

BETWEEN DUCT AND HVAC UNIT

OBTAI

BE

PART,SHALL

PACU

1" DIA. UNION

ANTI-VIBRATION

PAD

PIPE SUPPORT

LEGEND

L 1" NIPPLE

WHERE L=1/3 W (MIN.)

PIPE 200MM ABOVE

IN. - INCH

N

I

GRADE LEVEL

PACU - PACKAGE AIR CONDITIONING UNIT

FULL,OR

W

1" PIPE

MIN - MINIMUM

30° MAX PLUG (SCREWED)

CLEAR)

45 DEGREE ENTRY 0 = 45° MAX - MAXIMUM

CONCRETE PAD

CLOSE OPENING 1" ELBOW

SEE CIVIL DWG DIA - DIAMETER

AT CORNERS

50

N

(

I

50

ON

GRADE LEVEL

REPRODUCTI

REFERENCE DRAWINGS

BRANCH CONNECTION DETAIL ECCENTRIC TRANSITION FLOOR DESCRIPTIONS DRAWING NO.

DRAIN DRAWING CONTROL FOR EWO-16S061A-001 BD-244992

1" TEE CONSTRUCTION SCOPE OF WORK BE-244993

HVAC FLOOR PLAN BA-005852-001

HVAC EQUIPMENT SCHEDULE BA-005853-001

CONDENSATE DRAIN

SAUDIARAMCO.NO

HVAC EQUIPMENT SCHEDULE BA-005854-001

HVAC AIR FLOW DIAGRAM BA-005855-001

HVAC CONTROL DIAGRAM BA-005856-001

HVAC SEQUENCE OF OPERATION BA-005903-001

HVAC SECTIONS BA-005904-001

‚"{ MASONRY ANCHOR HVAC DETAILS BA-005906-001

DUCT INSULATION

15mm WIDE GALVANIZED

W/ FACTORY APPLIED

STEEL STRAP BAND

NO. 14 SELF TAPPING ALUMINUM FOIL

W @ 300 mm O.C.

SCREW ( FOR METAL WALL)

DE

VAPOR BARRIER

NSI

ALUMINUM FOIL

OF

W-10

PINS WELDED TO DUCT LAP JOINT

I

@ 450 mm O.C.

PROPERTY

UNIT NO. W H

DUCT

PACU-1 1000 600 ND DS D 25x25x100mm.

BA AN DE

DE

M B ED UL GALV. SHEET

NU 3- AC MO ION

OUTSI

PACU-2 350 250 I GALV. METAL

M DE SP OF CORNER BEADING

SOLE

SELF-EMPTYING SAND U I { AT

51

25 102 51 AL OV LY MM L SHEET DUCT

DRAIN HOLES PR AL 00 N) MM NSU NON-FLAMMABLE

( I

U 9

EQ R IO 50 E

VERT. BLADES E LAT PIP DUCT ADHESIVE

P U

THE

W+102

INS

INDOOR DUCT INSULATION DETAIL

ARE

OUTSIDE DUCT INSIDE

M

76 76 INT NU D

I

JO UM SE ON CA

L

N

25

HEREI

ION .AL PO ATI NI

A

AT K EX UL

CH

UL TH R NS ME

I

NO. 14 SELF TAPPING NS

I mm

O

F R N

I

40 ET HE G

SCREW (FOR METAL 0. CK AT I N

E N DUCT INSULATION

NED

WALL) JA W UN ALUMINUM CLADDING

PE

SCALE:

O R W/ FACTORY APPLIED

PI T D 0.04mm THICK

CONTAI

NT AN OM ALUMINUM FOIL

RA RO VAPOR BARRIER

GE REVISION VALIDATION

FRI ALUMINUM FOIL

RE S PINS WELDED TO DUCT LAP JOINT THIS REVISION NO. 00 IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

AS REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

H+102

GL NG @ 450 mm O.C.

H-10

SAND

ON

I

H

16S061A-001

TRAP VE IZE GG

SI S LA

NFORMATI

LOUVER HE E H DESIGN CERTIFICATION REVIEW FOR KEY DRAWINGS OTHER

AD PR OT (DESIGN AGENCY) x REQUIRED (SAUDI ARAMCO)

ING CL ENGG./DATE CERTIFIED BY/DATE CONST. AGENCY/DATE OPERATIONS/DATE BY/DATE

ND ATB ELS ABA

BO 01/09/18 01/09/18 01/22/18

GALV. METAL REV.NO. DATE REVISION DESCRIPTION

I

SHEET DUCT 00 01/09/18 ISSUED FOR CONSTRUCTION

NON-FLAMMABLE

THE

JOB ORDER/EWO NO.

THIS REVISION IS NOT TO BE USED FOR

25

DUCT ADHESIVE

VERT. BLADES 16S061A CONSTRUCTION UNTIL CERTIFIED AND DATED

SAUDI ARABIAN OIL COMPANY

AND

W+102 ‚"{ MASONRY REFRIGERANT PIPE INSULATION DETAIL DRAWING TYPE

ANCHOR

FINE MESH SELF-EMPTYING HVAC DETAILS HVA

NG

SCREEN SAND DRAIN

CENTRAL-OPERATION SUPPORT BUILDING

DRAWI

HOLES

HARADH WATER INJECTION FACILITIES

OUTDOOR/ EXPOSED DUCT INSULATION DETAIL

SAND TRAP LOUVERS HARADH SAUDI ARABIA

S

PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

THI

H14 K BA-005905 001 00

Saudi Aramco 2615 ENG. (05/05)

RESTRICTED VECTOR CADD-01

SAUDIARAMCO.

NOTES:

1. PRE-INSULATED DOUBLE WALL FLEXIBLE DUCTS

SHALL BE USED AT THE CONNECTION OF AIR

DIFFUSING DEVICES, IN ACCORDANCE WITH THE

REQUIREMENTS OF NFPA 90A. FLEXIBLE DUCTS

LOW VELOCITY CONCRETE WALL SHALL NOT EXCEED 1. FOOT (0.3 METER) IN

SUPPLY DUCT OVERALL LENGTH AND SHALL NOT HAVE MORE

OF

THAN 1 BEND NO GREATER THAN 45°.

VOLUME …" MASONRY ANCHOR

DAMPER

CONSENT

NG

OPENI

TTEN

WALL

FRAME

GALV. STEEL CINCH CLAMP

WRI

CAM LOCK

ROUND NECK SUPPLY

CONTINUOUS HINGE

CEILING DIFFUSER

THE

152 127 152

EXHAUST AIR GRILLE DOOR FRAME

FIXED BLADE TYPE NO. 14x•" LG.

THOUT

TAPPING SCREW

DOOR PLATE TYP. SECTION

CEILING

BACK-DRAFT DAMPER

EXHAUST FAN

WI

OPPOSED BLADE ( INTEGRAL WITH UNIT) AIR DUCT FIELD JOINT

UNIT

VOLUME DAMPER S-SLIP (TYP.)

NG

DRAWI

FIRE/SMOKE

DUCT ACCESS PANEL

S

LINK ASSEMBLY

THI

DAMPER

ASSEMBLY

ACTUATOR

SUPPLY CEILING DIFFUSER INSTALLATION DETAIL WALL EXHAUST FAN DETAIL SHAFT

FROM

RIVETS @ 305mm

(MAX. O.C).

ON SLEEVE

NED

DUCT ACCESS

PANEL

OBTAI

FUSIBLE LINK

18 GA. SLEEVE

UL LISTED

BE

L-38x38x6 STEEL ANGLE

SEALANT ALL AROUND

PART,SHALL

ALL AROUND

EQUIPMENT FIRE RATED WALL STARTER TAB

HOUSING

DUCT

DUCT SUPPORT

EQUIPMENT BASE

STUD CONTINUOUS THREADED FIRE/SMOKE DAMPER

13{ NUT

N

ROUND BAR 12mm (1/2") DIA

I

MAIN DUCT & WASHER

CAST VINYL GASKET

FULL,OR

NEOPRENE VIBRATION

ANGLE BAR CARBON

MOUNTING PAD

STEEL (38x38x6.4mm)

VD 75mm MIN. THICKNESS FRAME (GALV. STEEL)

13{ ANCHOR

BOLT DOOR PLATE

(GALV. STEEL)

N

I

CONCRETE PAD

25mm FIBERGLASS CAM LOCK

ON

CEILING DIFFUSER INSULATION

REPRODUCTI

DOOR FRAME REFERENCE DRAWINGS

CEILING LINE (GALV. STEEL)

DESCRIPTIONS DRAWING NO.

DRAWING CONTROL FOR EWO-16S061A-001 BD-244992

DIFFUSER FACE PLATE CONSTRUCTION SCOPE OF WORK BE-244993

RESTING ON T-RUNNER DUCT ACCESS PANEL TYP. SECTION HVAC FLOOR PLAN BA-005852-001

HVAC EQUIPMENT SCHEDULE BA-005853-001

SAUDIARAMCO.NO

HVAC EQUIPMENT SCHEDULE BA-005854-001

HVAC AIR FLOW DIAGRAM BA-005855-001

HVAC CONTROL DIAGRAM BA-005856-001

TYPICAL DUCT INSTALLATION DETAIL

VIBRATION PAD MOUNTING DETAIL HVAC SEQUENCE OF OPERATION BA-005903-001

HVAC SECTIONS BA-005904-001

HVAC DETAILS BA-005905-001

OF

PROPERTY

HANGER

ANGLES HANGER RODS

STRAPS

SOLE

DUCT DUCT DUCT

10mm BOLT FIXTURE

CLIPS

(MINIMUM) H

THE

ANGLE H

PUSH NUTS

R

25mm 25mm

ARE

(ALT.-1) (ALT.-2) (ALT.-3)

F

ANGLE

H

W

N

W

HEREI

RECOMMENDED CONSTRUCTION FOR RECTANGULAR SHEET METAL DUCTS

W

TYPE RE 3

GI SHEET GAGE RECOMMENDED CONSTRUCTION

NED

DUCT DIMENSIONS RADIUS ELBOW

TRANSVERSE JOINTS, BRACING AND REINFORCING

TYPE RE 4 SCALE:

WITH VANES

CONTAI

(IN.) DUCT SLIP

TYPE RE 2

SQUARE THROAT ELBOW

UP TO 24 24 24 POCKET SLIP OR BAR S- SLIP, SPACED NOT MORE THAN EIGHT FEET APART. WITHOUT VANES SQUARE THROAT ELBOW REVISION VALIDATION

(1000 FPM MAXIMUM VELOCITY) WITH VANES THIS REVISION NO. 00 IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

24 TO 30 24 24 REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

ON

POCKET SLIP OR BAR S- SLIP, SPACED NOT MORE THAN FOUR FEET APART.

W2

16S061A-001

31 TO 60 22 22

NFORMATI

DESIGN CERTIFICATION REVIEW FOR KEY DRAWINGS OTHER

(DESIGN AGENCY) x REQUIRED (SAUDI ARAMCO)

REINFORCED POCKET SLIP OR REINFORCED BAR S- SLIP, SPACED NOT MORE THAN FOUR FEET APART

ENGG./DATE CERTIFIED BY/DATE CONST. AGENCY/DATE OPERATIONS/DATE BY/DATE

61 TO 72 20 20 1-1/2 X 1-1/2 X 1/8" DIAGONAL ANGLE REINFORCING OR 1-1/2 X 1-1/2 X 1/8" GIRTH ANGLE REINFORCING ATB ELS ABA

01/09/18 01/09/18 01/22/18

LOCATED MIDWAY BETWEEN JOINTS.

REV.NO. DATE REVISION DESCRIPTION

I

00 01/09/18 ISSUED FOR CONSTRUCTION

REINFORCED POCKET SLIP OR REINFORCED BAR S- SLIP, SPACED NOT MORE THAN FOUR FEET APART

THE

R2

JOB ORDER/EWO NO.

1-1/2 X 1-1/2 X 1/8" DIAGONAL ANGLE REINFORCING OR 1-1/2 X 1-1/2 X 1/8" GIRTH ANGLE REINFORCING H THIS REVISION IS NOT TO BE USED FOR

73 TO 90 20 20 16S061A

R1

CONSTRUCTION UNTIL CERTIFIED AND DATED

LOCATED MIDWAY BETWEEN JOINTS.

R

H H SAUDI ARABIAN OIL COMPANY

AND

1-1/4 X 1/8" BAND IRON STAY BRACING FOR DUCT WIDTH 73" TO 90".

W1 W DRAWING TYPE

F

REINFORCED POCKET SLIP OR REINFORCED BAR S- SLIP, SPACED NOT MORE THAN FOUR FEET APART

HVAC DETAILS HVA

W

NG

1-1/2 X 1-1/2 X 1/8" DIAGONAL ANGLE REINFORCING OR 1-1/2 X 1-1/2 X 1/8" GIRTH ANGLE REINFORCING TYPE RE 1 CENTRAL-OPERATION SUPPORT BUILDING

DRAWI

91 AND UP 18 20 LOCATED MIDWAY BETWEEN JOINTS. TYPE RE 5 MITERED ELBOW

RADIUS ELBOW HARADH WATER INJECTION FACILITIES

(CENTERLINE R =3W/2 = STD RADIUS) DUAL RADIUS ELBOW

1-1/4 X 1/8" BAND IRON STAY BRACING FOR DUCT WIDTH 91" TO 120". HARADH SAUDI ARABIA

S

1-1/4 X 1/8" BAND IRON STAY BRACING SPACED 48" APART FOR DUCT WIDTH 121" AND UP. PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

THI

RECTANGULAR ELBOWS DETAIL

H14 K BA-005906 001 00

Saudi Aramco 2615 ENG. (05/05)

RESTRICTED VECTOR CADD-01

Das könnte Ihnen auch gefallen

- Instant Assessments for Data Tracking, Grade 2: MathVon EverandInstant Assessments for Data Tracking, Grade 2: MathNoch keine Bewertungen

- Hvac North HRDHDokument9 SeitenHvac North HRDHkdpmansiNoch keine Bewertungen

- Ground Floor: B RA-620717 001 B 961 G203Dokument1 SeiteGround Floor: B RA-620717 001 B 961 G203muthuvelaaNoch keine Bewertungen

- J414221002PADokument1 SeiteJ414221002PASehna SerajNoch keine Bewertungen

- General notes for CO2 and N2 tank foundationDokument1 SeiteGeneral notes for CO2 and N2 tank foundationmhazarath murariNoch keine Bewertungen

- SaudiAramco's Massive Oil Facility DesignDokument1 SeiteSaudiAramco's Massive Oil Facility DesignMahaboob PashaNoch keine Bewertungen

- LTHE-ELPG-TCF-004_00-SH 01 OF 01Dokument1 SeiteLTHE-ELPG-TCF-004_00-SH 01 OF 01AHMED TAHERNoch keine Bewertungen

- RFQ PebDokument28 SeitenRFQ Pebxhzk7p97r8Noch keine Bewertungen

- Changes Per All Backcircled: NotesDokument1 SeiteChanges Per All Backcircled: Notesheri_prasetyadiNoch keine Bewertungen

- Road E: Line Sd-1Dokument1 SeiteRoad E: Line Sd-1karem YousefNoch keine Bewertungen

- Refer To Drawing No.: 620356 SH-002 Refer To Drawing No.: 620356 SH-003Dokument1 SeiteRefer To Drawing No.: 620356 SH-002 Refer To Drawing No.: 620356 SH-003muthuvelaaNoch keine Bewertungen

- Ce PFD 010Dokument1 SeiteCe PFD 010wivipa3560Noch keine Bewertungen

- SDGM Oil WellDokument1 SeiteSDGM Oil WellPrakash RajNoch keine Bewertungen

- ARAMCO SAUDI NOTESDokument1 SeiteARAMCO SAUDI NOTESmuthuvelaaNoch keine Bewertungen

- Batching Plant Architectural DrawingDokument1 SeiteBatching Plant Architectural DrawingTaposh Paul100% (1)

- Saudi Arabian Oil Company: NotesDokument1 SeiteSaudi Arabian Oil Company: Noteshany mohamedNoch keine Bewertungen

- QP10 Q 2426 - TypicalSteelTank10,000m TopInlet Rev0Dokument1 SeiteQP10 Q 2426 - TypicalSteelTank10,000m TopInlet Rev0Nassif Abi AbdallahNoch keine Bewertungen

- U44-D-2213 - Pipe SupportsDokument4 SeitenU44-D-2213 - Pipe SupportsJamil AhmadNoch keine Bewertungen

- Ik2-Bam - B2-SC-D-6503 - 02 PDFDokument1 SeiteIk2-Bam - B2-SC-D-6503 - 02 PDFkramlester1982Noch keine Bewertungen

- (0030) Salman Town Solar Project Solar SMDBDokument6 Seiten(0030) Salman Town Solar Project Solar SMDBSavio SunnyNoch keine Bewertungen

- Test Meter Unit 310-90-FM-0050: Saudi Arabian Oil CompanyDokument1 SeiteTest Meter Unit 310-90-FM-0050: Saudi Arabian Oil Companyamit sharmaNoch keine Bewertungen

- AjhDokument1 SeiteAjhbillNoch keine Bewertungen

- THD-0500-ARC-GF-PL-8404 Ground Floor Wet Area Waterproofing Works Layout Code B Approved As NotedDokument2 SeitenTHD-0500-ARC-GF-PL-8404 Ground Floor Wet Area Waterproofing Works Layout Code B Approved As NotedQAQC GCCNoch keine Bewertungen

- C538096001V00 - Utility Sections Underground Utility SectionsDokument1 SeiteC538096001V00 - Utility Sections Underground Utility SectionssyedkhaffoorNoch keine Bewertungen

- WA 229860.0001.002 Default 000Dokument1 SeiteWA 229860.0001.002 Default 000Maein AbreenNoch keine Bewertungen

- Saudi Aramco pipe support drawingDokument1 SeiteSaudi Aramco pipe support drawingFahadNoch keine Bewertungen

- Ha431892003v0f1 (Cable Routing Details)Dokument1 SeiteHa431892003v0f1 (Cable Routing Details)Malik MalikNoch keine Bewertungen

- DRAWING LIMIT N 9403.624: Saudi Arabian Oil CompanyDokument1 SeiteDRAWING LIMIT N 9403.624: Saudi Arabian Oil CompanybillNoch keine Bewertungen

- Issued For Construction: Detail Detail Section SectionDokument1 SeiteIssued For Construction: Detail Detail Section SectionFahadNoch keine Bewertungen

- General Notes:: SSL +72.910 MDokument1 SeiteGeneral Notes:: SSL +72.910 MAnonymous qEPNPwANoch keine Bewertungen

- ARAMCO Saudi consent notesDokument1 SeiteARAMCO Saudi consent notesmuthuvelaaNoch keine Bewertungen

- SaudiAramco ladder designDokument1 SeiteSaudiAramco ladder designDomie Neil Bucag SalasNoch keine Bewertungen

- C RA-620208 002 B 961 A310: Ground Floor Firefighting Part Plan 1Dokument1 SeiteC RA-620208 002 B 961 A310: Ground Floor Firefighting Part Plan 1muthuvelaaNoch keine Bewertungen

- 10 Bc-Core DetailsDokument1 Seite10 Bc-Core DetailsAshwin AdveNoch keine Bewertungen

- K H110984004V00Dokument1 SeiteK H110984004V00Anonymous X3PnFL6Noch keine Bewertungen

- 01 - Foundation LayoutDokument1 Seite01 - Foundation LayoutSolomon Ndugwa BalemeziNoch keine Bewertungen

- Northern Railway: Ircon International LTDDokument4 SeitenNorthern Railway: Ircon International LTDRayees AhmadNoch keine Bewertungen

- Da179165 001Dokument1 SeiteDa179165 001John BuntalesNoch keine Bewertungen

- Ba 204302 001Dokument1 SeiteBa 204302 001Muhammad ArshadNoch keine Bewertungen

- GC ST 01Dokument1 SeiteGC ST 01mhazarath murariNoch keine Bewertungen

- Materiales #2Dokument6 SeitenMateriales #2andresromerounirNoch keine Bewertungen

- Notes:: Hornsea 02 Reactive Compensation Station Reactor Sea Fastening, Details Structural Steel, TopsideDokument1 SeiteNotes:: Hornsea 02 Reactive Compensation Station Reactor Sea Fastening, Details Structural Steel, TopsideAjizul Rohim AkbarNoch keine Bewertungen

- Refer To Drawing No.: 620620 SH-002 Refer To Drawing No.: 620620 SH-003Dokument1 SeiteRefer To Drawing No.: 620620 SH-002 Refer To Drawing No.: 620620 SH-003muthuvelaaNoch keine Bewertungen

- Section-A Section-A: Saudi Arabian Oil CompanyDokument1 SeiteSection-A Section-A: Saudi Arabian Oil CompanyAbu Anas M.SalaheldinNoch keine Bewertungen

- A-703-Schedules of Opening - UpvcDokument1 SeiteA-703-Schedules of Opening - UpvcEmmanuel InfanteNoch keine Bewertungen

- HR Department It & SMC Department: Inochem Non-Process Buildings & Facilities For Soda Ash & Calcium Chloride PlantDokument1 SeiteHR Department It & SMC Department: Inochem Non-Process Buildings & Facilities For Soda Ash & Calcium Chloride PlantSADDAMNoch keine Bewertungen

- Ha4321650010f4 (Cable Routing Details)Dokument1 SeiteHa4321650010f4 (Cable Routing Details)Malik MalikNoch keine Bewertungen

- Foundation PlanDokument1 SeiteFoundation PlanHEET MEWADANoch keine Bewertungen

- A29 P LTG Va 240416 003 - 00 PDFDokument1 SeiteA29 P LTG Va 240416 003 - 00 PDFbillNoch keine Bewertungen

- Building layout and HVAC detailsDokument1 SeiteBuilding layout and HVAC detailsAnonymous X3PnFL6Noch keine Bewertungen

- 10-603159-4200000030-SAC-SRV-WIR-000109_01Dokument7 Seiten10-603159-4200000030-SAC-SRV-WIR-000109_01Domie Neil Bucag SalasNoch keine Bewertungen

- Reference Drawings: Saudi Arabian Oil CompanyDokument1 SeiteReference Drawings: Saudi Arabian Oil CompanyJohn Philip BuntalesNoch keine Bewertungen

- Saudi Arabian Oil Company: NotesDokument1 SeiteSaudi Arabian Oil Company: NotesJohn Philip BuntalesNoch keine Bewertungen

- Saudi Arabian Oil Company: NotesDokument1 SeiteSaudi Arabian Oil Company: NotesJohn Philip BuntalesNoch keine Bewertungen

- Cathodic protection installation notesDokument1 SeiteCathodic protection installation notesJohn Philip BuntalesNoch keine Bewertungen

- Paul Cafe@Marassi Galleria Bahrain SD Mep Single Line Diagram Layout R 00Dokument1 SeitePaul Cafe@Marassi Galleria Bahrain SD Mep Single Line Diagram Layout R 00arulselvan22Noch keine Bewertungen

- Sectional View of 220Kv Xmer Bay & Metering Bay: Cost Basis ReportDokument1 SeiteSectional View of 220Kv Xmer Bay & Metering Bay: Cost Basis Reportask.kulkarni KulkarniNoch keine Bewertungen

- Footing Plan DrawingDokument1 SeiteFooting Plan Drawingyash ayreNoch keine Bewertungen

- H041675001V00Dokument1 SeiteH041675001V00Mohammed IrfanNoch keine Bewertungen

- Single Line DiagramDokument2 SeitenSingle Line DiagramSaahil KhaanNoch keine Bewertungen

- Refrigeration and Air Conditioning Textbook Multiple Choice QuestionsDokument1 SeiteRefrigeration and Air Conditioning Textbook Multiple Choice QuestionskdpmansiNoch keine Bewertungen

- Multiple Evaporator and Compressor Systems::. Mass of Vapours Formed byDokument1 SeiteMultiple Evaporator and Compressor Systems::. Mass of Vapours Formed bykdpmansiNoch keine Bewertungen

- Compound Vapor System3Dokument1 SeiteCompound Vapor System3kdpmansiNoch keine Bewertungen

- Electric Traction Elevators for Shubaily Grand Mall ComplianceDokument9 SeitenElectric Traction Elevators for Shubaily Grand Mall CompliancekdpmansiNoch keine Bewertungen

- Ac Exercise-2Dokument1 SeiteAc Exercise-2kdpmansiNoch keine Bewertungen

- Infiltration and Natural VentillationDokument1 SeiteInfiltration and Natural VentillationkdpmansiNoch keine Bewertungen

- Compound Vapor System5Dokument1 SeiteCompound Vapor System5kdpmansiNoch keine Bewertungen

- A Textbook of Refrigeration and Air Conditioning: H, IY/hDokument1 SeiteA Textbook of Refrigeration and Air Conditioning: H, IY/hkdpmansiNoch keine Bewertungen

- Textbook Refrigeration and Air Conditioning: C.O.P. The SystemDokument1 SeiteTextbook Refrigeration and Air Conditioning: C.O.P. The SystemkdpmansiNoch keine Bewertungen

- Compound Vapor System4Dokument1 SeiteCompound Vapor System4kdpmansiNoch keine Bewertungen

- Compound Vapour System-1Dokument1 SeiteCompound Vapour System-1kdpmansiNoch keine Bewertungen

- Compound Vapor System2Dokument1 SeiteCompound Vapor System2kdpmansi100% (1)

- Infiltration and Natural Ventilation: CommentsDokument1 SeiteInfiltration and Natural Ventilation: CommentskdpmansiNoch keine Bewertungen

- High Perfomance GlazingDokument1 SeiteHigh Perfomance GlazingkdpmansiNoch keine Bewertungen

- Vapour Compression4Dokument1 SeiteVapour Compression4kdpmansiNoch keine Bewertungen

- Heat Gains Through Windows: Exhaust Duct Inner Pane Stays WarmDokument1 SeiteHeat Gains Through Windows: Exhaust Duct Inner Pane Stays WarmkdpmansiNoch keine Bewertungen

- Vapour Compression3Dokument1 SeiteVapour Compression3kdpmansiNoch keine Bewertungen

- South Facing WindowDokument1 SeiteSouth Facing WindowkdpmansiNoch keine Bewertungen

- Simple Vapour Compress o Refr Ge: I N I Ration SystemsDokument1 SeiteSimple Vapour Compress o Refr Ge: I N I Ration SystemskdpmansiNoch keine Bewertungen

- Vapour Compression - 1Dokument1 SeiteVapour Compression - 1kdpmansiNoch keine Bewertungen

- Pump head calculation sheetDokument44 SeitenPump head calculation sheetkdpmansi50% (2)

- Air Refrigeration Systems ExplainedDokument3 SeitenAir Refrigeration Systems ExplainedkdpmansiNoch keine Bewertungen

- Change Order-05-09-2021Dokument3 SeitenChange Order-05-09-2021kdpmansiNoch keine Bewertungen

- Al Shadi: QuotationDokument2 SeitenAl Shadi: QuotationkdpmansiNoch keine Bewertungen

- Fire Fighting Work - Man HourDokument2 SeitenFire Fighting Work - Man HourkdpmansiNoch keine Bewertungen

- Pump head calculation sheetDokument44 SeitenPump head calculation sheetkdpmansi50% (2)

- International Plumbing Code: TotalDokument6 SeitenInternational Plumbing Code: TotalkdpmansiNoch keine Bewertungen

- Supply Fan Control For Constant Air Volume Air Handling UnitsDokument6 SeitenSupply Fan Control For Constant Air Volume Air Handling UnitskdpmansiNoch keine Bewertungen

- Basin Elevations: Finished Floor Level BasinDokument1 SeiteBasin Elevations: Finished Floor Level BasinkdpmansiNoch keine Bewertungen

- (Contract Agreement For Water Cooled Chillers) : The Contract Assures ThatDokument5 Seiten(Contract Agreement For Water Cooled Chillers) : The Contract Assures ThatkdpmansiNoch keine Bewertungen

- Direction: Analyze and Answer Carefully The Following Questions. Choose The BestDokument5 SeitenDirection: Analyze and Answer Carefully The Following Questions. Choose The BestGener ToledoNoch keine Bewertungen

- Shaberth Users ManualDokument255 SeitenShaberth Users Manualanhntran4850Noch keine Bewertungen

- Heartbeat Protocol: Computer Science Computer SystemDokument3 SeitenHeartbeat Protocol: Computer Science Computer SystemDomalina LouielynNoch keine Bewertungen

- What Are The PrefixesDokument17 SeitenWhat Are The PrefixesAmeer AzharNoch keine Bewertungen

- Hvac Prob 1 FINALDokument6 SeitenHvac Prob 1 FINALDatu JonathanNoch keine Bewertungen

- Bulletin 30RB-30RQ Option 12Dokument2 SeitenBulletin 30RB-30RQ Option 12vickersNoch keine Bewertungen

- TN48 - U-Values of Windows (7 PP)Dokument7 SeitenTN48 - U-Values of Windows (7 PP)Steve MarrNoch keine Bewertungen

- Comparison of Calculation Standards of NGL and LPG PDFDokument22 SeitenComparison of Calculation Standards of NGL and LPG PDFnitoxxx666Noch keine Bewertungen

- Notes: Internal Column Cladding (Laminate)Dokument1 SeiteNotes: Internal Column Cladding (Laminate)manjunath hrNoch keine Bewertungen

- Vaporizer Technology F LNGRG For LNG Re-Gas: Comparisons of Various MethodsDokument15 SeitenVaporizer Technology F LNGRG For LNG Re-Gas: Comparisons of Various Methodsdeion29Noch keine Bewertungen

- Decarboxylation of Tetrahydrocannabinolic Acid (THCA) To Active THCDokument3 SeitenDecarboxylation of Tetrahydrocannabinolic Acid (THCA) To Active THCMichal Tőzsér100% (2)

- Calculo de Carga Sala de Reuniones PDFDokument8 SeitenCalculo de Carga Sala de Reuniones PDFRubens KunNoch keine Bewertungen

- Topic 7 - Cooling Water System DesignDokument23 SeitenTopic 7 - Cooling Water System DesignMuhammad Nur Fahmi NaimemNoch keine Bewertungen

- Trane AHU SpecificationsDokument3 SeitenTrane AHU SpecificationsVitalremainsNoch keine Bewertungen

- Refrigeration Commissioning ProcedureDokument12 SeitenRefrigeration Commissioning ProcedureLmaoNoch keine Bewertungen

- Astm D2892Dokument32 SeitenAstm D2892Mahmoud Maklad100% (1)

- Chemkin IIIDokument162 SeitenChemkin IIINicanor MariottiNoch keine Bewertungen

- Thermodynamic Properties of Oxygen From 20-100KDokument2 SeitenThermodynamic Properties of Oxygen From 20-100Kwesileh981Noch keine Bewertungen

- 1 Katalog Hicop Heat Pump Type Aw New 2016Dokument3 Seiten1 Katalog Hicop Heat Pump Type Aw New 2016Joko SubagyoNoch keine Bewertungen

- Product Catalog: Ductless Mini-Splits, Light Commercial and Multi-Zone SystemsDokument72 SeitenProduct Catalog: Ductless Mini-Splits, Light Commercial and Multi-Zone SystemsFernando ChaddadNoch keine Bewertungen

- Detroit ManualDokument435 SeitenDetroit Manualvictorhernandezrega50% (2)

- HVAC Designing Course Presentation S-1,2 PDFDokument106 SeitenHVAC Designing Course Presentation S-1,2 PDFNaqqash SajidNoch keine Bewertungen

- Concepts in Condenser System (Vacuum Equipment)Dokument7 SeitenConcepts in Condenser System (Vacuum Equipment)Mustafa DemircioğluNoch keine Bewertungen

- CodeAster With Mazar ModelDokument16 SeitenCodeAster With Mazar ModelPabloNoch keine Bewertungen

- Mannai Corporation: Mannai Trading Co. WLLDokument18 SeitenMannai Corporation: Mannai Trading Co. WLLAyu Oktaviani100% (2)

- CatalogoStar CoolDokument85 SeitenCatalogoStar Coolbyu byuNoch keine Bewertungen

- SCHWING Fluidized Bed Process Technique enDokument6 SeitenSCHWING Fluidized Bed Process Technique enariefNoch keine Bewertungen

- Comparing Stability of Metal and Fused Silica SPRTsDokument8 SeitenComparing Stability of Metal and Fused Silica SPRTsAlexandraAndreeaNoch keine Bewertungen

- PHYSICS CRITICAL QUESTIONS BANK FOR JEE (ADVANCEDDokument71 SeitenPHYSICS CRITICAL QUESTIONS BANK FOR JEE (ADVANCEDhitheshNoch keine Bewertungen