Beruflich Dokumente

Kultur Dokumente

JOB Safety Analysis

Hochgeladen von

anon_2668375760 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

155 Ansichten2 SeitenCUTTING AND WELDING JSA

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCUTTING AND WELDING JSA

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

155 Ansichten2 SeitenJOB Safety Analysis

Hochgeladen von

anon_266837576CUTTING AND WELDING JSA

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

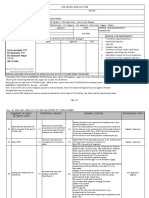

Megha Engineering & Infrastructure Ltd.

,

Doc No.: MEIL/SHE/JSA/01

Rev No.: 02 Safety Environment & Health

JOB Safety Analysis

JSA FOR ……………CUTTING AND WELDING………………..

Name of the Site : …GPRL 3143………

Plant & Machinery Involved : …PUMP HOUSE 3 & FABRICATION YARD………………

PPE/Safety Equipment Required : Welding helmet, Hand shield, Safety shoes, safety goggles,

insulated hand gloves, Heat resistant jacket ,Ear muffs, Barriers ,………………

Authorization Required : SITE ENGINEER, PROJECT IN CHARGE…….

PREPAIRED BY MR. JAYDEV SWAINE JR Engineer Safety.

Potential Hazard and

SL.NO Activity Control Measures Action By

Associated Risk

Sparks Contain your sparks as

far as possible.

Direct your sparks away

from other.

Remove all combustible

material.

Fire extinguisher must

be have.

Barricade area below

Hot Slag

when welding overhead.

Have fire extinguisher SITE

Cutting, Welding at hand. ENGINEER

01

and Grinding Remove / protect all /SITE

combustibles in the SUPERVISOR

vicinity.

Remove / protect all

Open flame combustibles in the

vicinity.

Always have fire

extinguisher at hand

Electricity Inspect all cables , plugs and

cords for damage before use.

Gas Do soap test on gas

Hot surface equipment before

use.

Inspect hoses for

damage.

Close all valve after

use.

Put all hot off cuts

from cutting work out

of harm’s way.

Do not paint near

open flames.

Store paint in

flammable liquid store.

No smoking while

painting.

2 Painting Hazardous No smoking / no open

substances(flammable) flame sign in paint work

area.

Dispose empty paint

tins as per safe working

procedures.

Ensure proper wind up

and housekeeping at

Scattered material work site.

The accessories (torch,

Windup & House

3 hoses, cylinder) not

keeping

being used must be

disconnected and store

separately.

Das könnte Ihnen auch gefallen

- HVAC Maintenance Job HazardsDokument2 SeitenHVAC Maintenance Job HazardsSreekumar0% (1)

- Percy Jackson - All Grown Up - Bruce T. ForbesDokument53 SeitenPercy Jackson - All Grown Up - Bruce T. ForbesNick LuaneNoch keine Bewertungen

- Job Hazard Analysis for Deep Well Drilling with HotworksDokument2 SeitenJob Hazard Analysis for Deep Well Drilling with Hotworksjay RNoch keine Bewertungen

- Excavation Procedure & Permitting GuideDokument4 SeitenExcavation Procedure & Permitting GuideTengku & Wan ResourcesNoch keine Bewertungen

- JSA DOWNLOADING RELAY CONFIGURATIONDokument4 SeitenJSA DOWNLOADING RELAY CONFIGURATIONfrancis_e_tan100% (1)

- JHA 02 Lifting and SlingingDokument4 SeitenJHA 02 Lifting and Slingingadil khanNoch keine Bewertungen

- Jsa Installation of HV ApparatusDokument6 SeitenJsa Installation of HV ApparatusLuqman OsmanNoch keine Bewertungen

- Power Distribution Works: Job Safety AnalysisDokument30 SeitenPower Distribution Works: Job Safety AnalysisRekha LinusNoch keine Bewertungen

- HAZARDS AND RISKS EXPLAINEDDokument20 SeitenHAZARDS AND RISKS EXPLAINEDJhunrey ObnialaNoch keine Bewertungen

- Work at Height Safety EssentialsDokument58 SeitenWork at Height Safety EssentialsArdita S IrwanNoch keine Bewertungen

- Emergency Rescue Plan For Electric Shock (29!10!19)Dokument4 SeitenEmergency Rescue Plan For Electric Shock (29!10!19)Ashok sNoch keine Bewertungen

- JHA Stacks EDG Substation r0 14 August 2017 EdittedDokument5 SeitenJHA Stacks EDG Substation r0 14 August 2017 EdittedJeniffer Ong100% (1)

- Measuring health and safety performanceDokument31 SeitenMeasuring health and safety performancesohaibNoch keine Bewertungen

- Job Safety Analysis Sheet: Manual ExcavationDokument1 SeiteJob Safety Analysis Sheet: Manual Excavationwahyu nugroho100% (1)

- JSA FORM SAFETY ANALYSISDokument13 SeitenJSA FORM SAFETY ANALYSISPaulSwinbank100% (4)

- DOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerDokument4 SeitenDOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerProfessional TrustNoch keine Bewertungen

- Safety Analysis for Working at HeightsDokument4 SeitenSafety Analysis for Working at Heightsjithin shankar100% (1)

- Standard Operating Procedure Covid-19 Mitigation SkvinDokument7 SeitenStandard Operating Procedure Covid-19 Mitigation SkvinAdib Ikhwan100% (1)

- Toolbox Talks Hand and Portable Power Tools EnglishDokument1 SeiteToolbox Talks Hand and Portable Power Tools EnglishsuhasNoch keine Bewertungen

- Kta Alliance Spray /touch Up Painting of Project Materials: Job Safety Analysis (JSA)Dokument3 SeitenKta Alliance Spray /touch Up Painting of Project Materials: Job Safety Analysis (JSA)Ogunwa EmmanuelNoch keine Bewertungen

- Lock Out Tag Out Procedure For - : TitleDokument12 SeitenLock Out Tag Out Procedure For - : TitleerwinNoch keine Bewertungen

- Job Safety & Environment Analysis: Revision NoDokument3 SeitenJob Safety & Environment Analysis: Revision NonishanthNoch keine Bewertungen

- Observation Sheet AnasDokument6 SeitenObservation Sheet AnasNowfal HabeebNoch keine Bewertungen

- Toolbox Safety EssentialsDokument8 SeitenToolbox Safety Essentialsbeng acostaNoch keine Bewertungen

- JSA ScaffoldingDokument2 SeitenJSA Scaffoldingmyco samNoch keine Bewertungen

- Half Marathon Advanced Training Plan - KilometersDokument6 SeitenHalf Marathon Advanced Training Plan - KilometersBrooksRunning100% (3)

- Safe Work ProcedureDokument2 SeitenSafe Work ProcedureSuco IdeunkNoch keine Bewertungen

- Site Safety Procedure-RV1Dokument21 SeitenSite Safety Procedure-RV1raeiszNoch keine Bewertungen

- Confined Spaces Toolbox TalkDokument3 SeitenConfined Spaces Toolbox TalkWaSim AKramNoch keine Bewertungen

- JHA Blowing PressDokument5 SeitenJHA Blowing PressLuqman OsmanNoch keine Bewertungen

- Lock Out Tag OutDokument2 SeitenLock Out Tag OutPablo Arreola RomeroNoch keine Bewertungen

- 28.1.1 Mobile Equipment Inspection ChecklistDokument1 Seite28.1.1 Mobile Equipment Inspection Checklistmohamed abdelmoniemNoch keine Bewertungen

- NIOSH Work Permit System NewDokument92 SeitenNIOSH Work Permit System Newsanpkaru100% (1)

- Action Plan On Haze Management (Tiong Seng)Dokument8 SeitenAction Plan On Haze Management (Tiong Seng)Muhammad AliffNoch keine Bewertungen

- JSA Concereting and PaintingDokument4 SeitenJSA Concereting and PaintingHow Chin Engineering Sdn BhdNoch keine Bewertungen

- Lighting PlanDokument5 SeitenLighting PlanAnandababuNoch keine Bewertungen

- Chemical and MSDS RegisterDokument5 SeitenChemical and MSDS RegisterRhen HalfferzrheinsNoch keine Bewertungen

- C - 3 Job Skills & Craft Competency Training ProgramDokument5 SeitenC - 3 Job Skills & Craft Competency Training ProgramJamal Mohamed RahamathullahNoch keine Bewertungen

- Electrical Safety Hazards and PreventionDokument38 SeitenElectrical Safety Hazards and PreventionYvonne TohNoch keine Bewertungen

- Training Needs AssessmentDokument5 SeitenTraining Needs AssessmentahmadNoch keine Bewertungen

- JOB SAFETY PLAN Replacement of CylinderDokument2 SeitenJOB SAFETY PLAN Replacement of CylinderMaxi ProNoch keine Bewertungen

- Permit To Work ProceduceDokument4 SeitenPermit To Work ProceduceQuý Hoàng ChuNoch keine Bewertungen

- 694+ Illustrated Parts Catalog Revision 3.1 FROM SERIAL TRX01694CDGL11965Dokument549 Seiten694+ Illustrated Parts Catalog Revision 3.1 FROM SERIAL TRX01694CDGL11965Martín Lescano ParedesNoch keine Bewertungen

- Evacuation Drill Details 7-2018Dokument5 SeitenEvacuation Drill Details 7-2018Mustafa Adel100% (3)

- Permit To WorkDokument11 SeitenPermit To WorkKhuda BukshNoch keine Bewertungen

- Basic Safety Instructions For All Employees Visiting or Working in The Construction of The HgpepDokument42 SeitenBasic Safety Instructions For All Employees Visiting or Working in The Construction of The Hgpepmalik jahanNoch keine Bewertungen

- JHA # 009 - Hot WorkDokument7 SeitenJHA # 009 - Hot WorkkumarNoch keine Bewertungen

- 2 Risk AssessmentDokument9 Seiten2 Risk AssessmentRAHMAT SAFRIN H. MALIK -Noch keine Bewertungen

- Index: Cv. Dira Utama SejahteraDokument12 SeitenIndex: Cv. Dira Utama SejahteraFreshop SurabayaNoch keine Bewertungen

- HIRARC Part2Dokument54 SeitenHIRARC Part2Danial Akram Bakri100% (2)

- HSSE Management Procedure OverviewDokument65 SeitenHSSE Management Procedure OverviewnadaNoch keine Bewertungen

- Work at Height Safety AnalysisDokument2 SeitenWork at Height Safety AnalysiszebmechNoch keine Bewertungen

- JSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedDokument13 SeitenJSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedJoseph PerezNoch keine Bewertungen

- SandblastingDokument2 SeitenSandblastingAL SALEH ELECTRONoch keine Bewertungen

- The Environmental Monitoring Plan For The Albertine Graben 2012-2017Dokument100 SeitenThe Environmental Monitoring Plan For The Albertine Graben 2012-2017African Centre for Media Excellence100% (1)

- Method Statement For Worker WelfereDokument4 SeitenMethod Statement For Worker WelfereMohamad Hidayat Zainul MasriNoch keine Bewertungen

- Cable Pulling, Glanding and TerminationsDokument6 SeitenCable Pulling, Glanding and TerminationsnsadnanNoch keine Bewertungen

- JsaDokument10 SeitenJsaTanzeel LiaqatNoch keine Bewertungen

- Job Safety Analysis (JSA) : DefinitionDokument5 SeitenJob Safety Analysis (JSA) : DefinitionMesut MahmutogluNoch keine Bewertungen

- Critical housekeeping risksDokument5 SeitenCritical housekeeping risksZegera MgendiNoch keine Bewertungen

- For Information For Review For Approval For Construction As-BuiltDokument9 SeitenFor Information For Review For Approval For Construction As-BuiltUtku Can KılıçNoch keine Bewertungen

- Chemical Spill Procedure: 1. PurposeDokument2 SeitenChemical Spill Procedure: 1. PurposeWalter A. Mustafa Takeo100% (1)

- Grila All ChannelsDokument24 SeitenGrila All ChannelsCiprianCristeaNoch keine Bewertungen

- Big Weekend Ahead: ... More Than Just A GAMEDokument5 SeitenBig Weekend Ahead: ... More Than Just A GAMEfelix kagotaNoch keine Bewertungen

- My Computer DetailsDokument2 SeitenMy Computer DetailsSoinik PanditNoch keine Bewertungen

- Bullets-history&typology-1-1Dokument77 SeitenBullets-history&typology-1-1Ryl-annNoch keine Bewertungen

- Knee PainDokument2 SeitenKnee PainKKNoch keine Bewertungen

- Statement of ClaimDokument17 SeitenStatement of ClaimUbysseyNewsNoch keine Bewertungen

- Sierra 7mm08 Reloading DataDokument9 SeitenSierra 7mm08 Reloading DataBIBI1978Noch keine Bewertungen

- Afl Fact SheetDokument1 SeiteAfl Fact Sheetapi-257609033Noch keine Bewertungen

- System ToolsDokument16 SeitenSystem ToolsJohn SuarezNoch keine Bewertungen

- 2009 #49 - Wagons Ho! Corral 14 - A Living HeritageDokument52 Seiten2009 #49 - Wagons Ho! Corral 14 - A Living HeritageDV49erNoch keine Bewertungen

- STADIUMSDokument10 SeitenSTADIUMSAyan BhattacharjeeNoch keine Bewertungen

- Cambridge English Young Learners' Picture BankDokument47 SeitenCambridge English Young Learners' Picture BankSara Hidalgo100% (1)

- DFA Classic BattleTech House Rules v1.1Dokument10 SeitenDFA Classic BattleTech House Rules v1.1IainTiberiusSwordNoch keine Bewertungen

- Ankle Fractures (Broken Ankle) : AnatomyDokument9 SeitenAnkle Fractures (Broken Ankle) : AnatomyWisnu Syahputra SuryanullahNoch keine Bewertungen

- Lifeboat CheatsheetDokument2 SeitenLifeboat Cheatsheetx213451seNoch keine Bewertungen

- SM6-UT-U4 UnitTest With AnswersDokument3 SeitenSM6-UT-U4 UnitTest With AnswersRaquel Prous TrigoNoch keine Bewertungen

- Technical Self-Assesment SheetDokument2 SeitenTechnical Self-Assesment SheetAzeddine LANoch keine Bewertungen

- Game CrashDokument50 SeitenGame CrashLeia BruzingaNoch keine Bewertungen

- Moonwalker Coloring BookDokument33 SeitenMoonwalker Coloring BookMarcie80% (5)

- Leviathan Mission Pack-1-2Dokument2 SeitenLeviathan Mission Pack-1-2Felslipes BNoch keine Bewertungen

- 5a8fbc22d0ce57481 PDFDokument80 Seiten5a8fbc22d0ce57481 PDFMahendra SofyanNoch keine Bewertungen

- When I Close My EyesDokument2 SeitenWhen I Close My Eyesindah toatubunNoch keine Bewertungen

- MausoleumDokument2 SeitenMausoleumapi-3801057100% (2)

- AlyssaDokument1 SeiteAlyssaicetrolaNoch keine Bewertungen

- English Course Exam BASIC UNIT 4, 5Dokument2 SeitenEnglish Course Exam BASIC UNIT 4, 5Carlos Augusto Rincon PinzonNoch keine Bewertungen

- Personal Best B1+ Unit 8 Vocab TestDokument1 SeitePersonal Best B1+ Unit 8 Vocab Testhongochaphuong080205Noch keine Bewertungen

- 1 Manual Perforadore Spiradrill-LHD-SeriesDokument12 Seiten1 Manual Perforadore Spiradrill-LHD-SeriesRogelio VenturaNoch keine Bewertungen