Beruflich Dokumente

Kultur Dokumente

Theory and Application of The Corrosometer

Hochgeladen von

Anonymous S9qBDVkyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Theory and Application of The Corrosometer

Hochgeladen von

Anonymous S9qBDVkyCopyright:

Verfügbare Formate

Engineering Encyclopedia

Saudi Aramco DeskTop Standards

THEORY AND APPLICATION

OF THE CORROSOMETER

Note: The source of the technical material in this volume is the Professional

Engineering Development Program (PEDP) of Engineering Services.

Warning: The material contained in this document was developed for Saudi

Aramco and is intended for the exclusive use of Saudi Aramco’s employees.

Any material contained in this document which is not already in the public

domain may not be copied, reproduced, sold, given, or disclosed to third

parties, or otherwise used in whole, or in part, without the written permission

of the Vice President, Engineering Services, Saudi Aramco.

Chapter : Corrosion For additional information on this subject, contact

File Reference: COE-102.03 PEDD Coordinator on 874-6556

Engineering Encyclopedia Corrosion Monitoring

Theory and Application of the Corrosometer

Content Page

PRINCIPLES OF CORROSOMETER OPERATION ..................................................... 2

History of Electrical Resistance Measurement Technique.................................. 2

Theory of Electrical Resistance Measurement ................................................... 2

Temperature Compensation ............................................................................... 4

Electrical Circuits ................................................................................................ 4

Types of Corrosometer Probes........................................................................... 6

Advantages of Probe Types ............................................................................... 7

Measuring Elements ........................................................................................... 7

Probe Selection .................................................................................................. 8

FIELD USE OF THE CORROSOMETER.................................................................... 11

Common Problems in Field Use ....................................................................... 11

Safety Precautions............................................................................................ 12

Interpretation of Corrosometer Data ................................................................. 13

Applications of the Corrosometer -- Advantages and Limitations ..................... 14

REFERENCE .............................................................................................................. 17

GLOSSARY................................................................................................................. 18

List of Figures

FIGURE 1. Typical Corrosometer Data ........................................................................ 3

FIGURE 2. Schematic of a Null Balance Circuit Used

in the Electrical Resistance Method for Corrosion Measurement.............. 5

FIGURE 3. Probe Selection for General Corrosion ...................................................... 9

FIGURE 4. Probe Selection for Process Upset Conditions ........................................ 10

FIGURE 5. Corrosion Rate Graph.............................................................................. 16

Saudi Aramco DeskTop Standards i

Engineering Encyclopedia Corrosion Monitoring

Theory and Application of the Corrosometer

PRINCIPLES OF CORROSOMETER OPERATION

History of Electrical Resistance Measurement Technique

The measurement of corrosion by electrical resistance

technique, such as with a corrosometer, uses the principle that

resistance of a metal specimen increases as its cross-section

decreases. For years the technique was limited to occasional

laboratory use. In 1954, a paper by Dravnicks and Cataldi

stirred interest in developing a practical field tool using the

electrical resistance technique. However, unstable temperature

control made field measurements of electrical resistance

unreliable. Eventually, temperature compensation methods

were developed so that temperature variations in test

specimens were no longer as critical. Subsequent refinements

in both instruments and probes have made the electrical

resistance measurement technique an excellent tool for rapid

corrosion measurement.

Theory of Electrical Resistance Measurement

The electrical resistance of a specimen of metal can be

expressed mathematically by equation 1.

L

R = ρA (1)

where R = resistance (ohm)

ρ = resistivity (ohm-cm)

L = length (cm)

A = cross-section area (cm2)

Examples: Cross-sectional area of a strip = width x thickness

Cross-sectional area of a wire = π x diameter2

Cross-sectional area of a tube = π x (outside

diameter2 - inside diameter2)

Saudi Aramco DeskTop Standards 2

Engineering Encyclopedia Corrosion Monitoring

Theory and Application of the Corrosometer

The electrical resistance of a fixed-length specimen depends on

its cross-sectional area. As the specimen corrodes, its cross-

sectional area decreases and its electrical resistance increases.

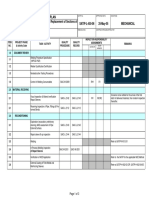

The resistance increase per unit time can be plotted on a graph.

The slope of the curve at any point in time represents the

corrosion rate. Figure 1 shows typical data recorded with a

corrosometer.

∆ Reading

Rate (MPY) = ∞ 0.365 ∞ Span

∆ Time (Days)

If probe = W40

Then span = 10 mils (0.010 in.)

Rate A = 7.3 MPY

Rate B = 0 MPY

Rate C = 44 MPY

FIGURE 1. Typical Corrosometer Data

Saudi Aramco DeskTop Standards 3

Engineering Encyclopedia Corrosion Monitoring

Theory and Application of the Corrosometer

Temperature Compensation

The effect of temperature can be expressed as follows:

RT = R0(1 + α[T - T0]) (2)

where RT = resistance at temperature T

R0 = resistance at temperature T0

∝ = coefficient of resistivity

T = temperature T

T0 = temperature T0

As corrosion takes place, extremely small changes in resistance

occur. Temperature, as defined in equation 2, can cause

changes in resistance that will obscure the changes resulting

from corrosion. Compensation for change of resistivity with

temperature is achieved with a reference element protected

from the corrosion process. As the resistance of the specimen

increases with temperature, so does the resistance of the

reference element. Since the resistance ratio of the specimen

and the reference element remains unchanged, automatic

compensation for temperature changes is provided.

Electrical Circuits

The circuitry of the corrosometer determines the resistance ratio

of the specimen to the reference element. Figure 2 is a

schematic of the circuitry. The design of the circuits makes the

corrosion readings directly proportional to the amount of metal

removed from the specimen. Each corrosion reading, therefore,

is a direct indication of the average reduction in thickness of the

specimen. To determine the rate of corrosion, the loss of metal

occurring between any two readings is divided by the time

interval between the two readings.

Saudi Aramco DeskTop Standards 4

Engineering Encyclopedia Corrosion Monitoring

Theory and Application of the Corrosometer

FIGURE 2. Schematic of a Null Balance Circuit Used in the Electrical Resistance

Method for Corrosion Measurement

Saudi Aramco DeskTop Standards 5

Engineering Encyclopedia Corrosion Monitoring

Theory and Application of the Corrosometer

CORROSOMETER PROBES

Types of Corrosometer Probes

The probe is the heart of the corrosometer system. It functions

as a local sensor accumulating the corrosion history of the

environment and displaying or recording the corrosion data.

The probe is sometimes called an “electrical coupon”.

A variety of corrosometer probes are available to match various

applications. The following is a description of the major types of

corrosometer probes.

• Internal process monitoring probes

• Removable under system pressure

• Retractable system (for pressures up to

1,500 psi). Retractable process probes are

introduced into the system through a stuffing

box mounting external to a valve. A

retracting device is used to insert or remove

probes at pressures too high for safe

operation by hand.

• Retrievable system (for pressures up to

6,000 psi). Retrievable process probes are

sealed into the system in an access fitting.

A separate service valve and retriever is

used for insertion and removal of the probes

under system pressures.

• Non-removable under system pressure (fixed type)

Fixed-type probes are available as flange

mounting, fixed thread mounting, or adjustable

thread mounting.

• Laboratory probes

Laboratory probes have glass epoxy bodies that can be

used in low pressure systems. They are either clamped

over an open vessel or inserted through a rubber

stopper.

Saudi Aramco DeskTop Standards 6

Engineering Encyclopedia Corrosion Monitoring

Theory and Application of the Corrosometer

• Atmospheric corrosion probes

Atmospheric corrosion probes monitor the corrosivity of

the air or atmosphere in plant control rooms, near

exhaust stacks, or critical locations in a refinery or plant.

Advantages of Probe Types

• Probes that are removable under system pressure permit

inspection or change out of probes without shutting down

or isolating the system.

• Probes that are not removable under system pressure

are used for reasons of economy, safety, or special

process limitations.

Measuring Elements

There are four forms of corrosion measurement elements.

• Strip, tube, and wire loop elements

The strip, tube, and wire loop elements are more

economical and available in a wider range of alloys than

for other element forms. Two forms of element seals

protect the reference element within the probe body.

Glass-to-metal seals provide the highest seal integrity.

They are suitable for process fluid ranging between 0

and 9 pH and temperatures up to 500 °F. They are not

suitable for fluids containing fluoride ions, which attack

glass, ceramics, and epoxies.

Teflon coating and ceramic fill provide the alternative

seal of the reference element in loop elements.

Saudi Aramco DeskTop Standards 7

Engineering Encyclopedia Corrosion Monitoring

Theory and Application of the Corrosometer

• Cylindrical elements

Cylindrical elements are directly welded to the probe

body, providing the highest integrity seal for aggressive

environments. They provide a large surface area for

measurement and have the fastest dynamic response to

temperature transients. Cylindrical elements are the

least susceptible to the effects of conductive deposits

such as iron sulfide. Probes with cylindrical elements are

suitable in environments with pH 0 to 14 and

temperatures up to 500 °F. For high temperature

applications (above 500 °F), probes with specially

designed elements are available.

• Flush elements

Flush element probes monitor localized wall effects and

situations where protrusion into the line would damage

the probe, for example, during scraping operations.

• High sensitivity elements

High sensitivity element probes are used in minimally

corrosive environments where quick detection of

increased corrosion is important.

Probe Selection

Probe selection is very important for the collection of reliable

corrosion data. Probe selection depends on many factors:

metallurgy, pressure, temperature, corrosion level. Generally, a

probe should have an element thickness to allow for about 0.5

percent of the element's useful life to be consumed per day at

the average corrosion rate expected. For critical applications,

more sensitive probes should be chosen.

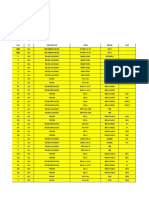

When corrosion probes are used to monitor general corrosion

rates and speed of response is less critical, Figure 3 should be

used as a selection guide. When corrosion probes are used in

process applications where speed of response to upset

conditions is of primary importance, probes should be selected

according to the response time in Figure 4.

Saudi Aramco DeskTop Standards 8

Engineering Encyclopedia Corrosion Monitoring

Theory and Application of the Corrosometer

With a corrosometer probe, 1 percent of the probe life (10

divisions of 1000 divisions) is a practical detection level. Probe

life, however, is not necessarily 100 times the response time,

because the upset corrosion rates are normally rather brief.

FIGURE 3. Probe Selection for General Corrosion

Saudi Aramco DeskTop Standards 9

Engineering Encyclopedia Corrosion Monitoring

Theory and Application of the Corrosometer

FIGURE 4. Probe Selection for Process Upset Conditions

Saudi Aramco DeskTop Standards 10

Engineering Encyclopedia Corrosion Monitoring

Theory and Application of the Corrosometer

FIELD USE OF THE CORROSOMETER

Common Problems in Field Use

• Poor location of corrosometer probes

In principle, corrosometer probes will give readings

anywhere. An electrically conductive environment is not

required. However, probes should be located where

corrosive conditions exists. For example, probes located

in the gas-filled upper portion of a line will gather no

information about the corrosion damage occurring in the

water-covered bottom section of the line. Probes should

be located at sites where corrosive conditions are

dynamic. Dead legs are not good sites.

• Inadequate monitoring points

Most applications require multiple corrosometer probes

to monitor various points in the system. Probes should

be located at critical points (velocity, turbulence,

temperature, and mixing), at points where upset may

occur, at points where abrupt changes occur, and “worst

case” points as determined by prior operating

experience.

• Fluctuating temperature

Although the effect of varying temperature has been

canceled by probe design, fluctuating temperature may

still affect measurements. Since the probe's reference

element is either coated or embedded, it responds more

slowly to temperature changes than the exposed test

element. Readings may go backward or jump

unrealistically. Under such conditions, plotting the

readings over a period of time will determine the best

curve to fit the data points.

• Build up of corrosion products on probe elements

Conductive corrosion products such as iron sulfide can

affect corrosometer measurements. Sometimes these

products have a conductivity approaching that of the

metal lost. Such conditions may cause measured

Saudi Aramco DeskTop Standards 11

Engineering Encyclopedia Corrosion Monitoring

Theory and Application of the Corrosometer

electrical resistance to indicate no loss of metal even

though the metal has been replaced by another material.

• Fatigue failure of the probe element

In a fast flowing stream, probe elements can fail from

fatigue. In such environments, a stronger, heavier

element or a shielded element is recommended.

• Corrosion of the probe housing

Corrosion of the probe housing occurs when the probe

selected is not the right one for the conditions. Examples

of this problem include the use of an austenitic stainless

probe in conditions that cause rapid stress corrosion

cracking or use of seals and other materials that would

not withstand the process temperature.

• Probe sensitivity

A high sensitivity probe in an aggressive environment will

not last long and will require frequent replacement. If the

probe is a fixed type, the system will have to be

depressurized or shut down to replace the probe.

A probe with sensitivity insufficient for the environment

being monitored will not provide useful data. To

determine which probe is appropriate, several probes

with varying sensitivity are sometimes installed in a new

environment.

Safety Precautions

• Only use probes that are compatible to the system being

monitored.

An improperly selected probe can be a serious safety

hazard. Probes should have the correct metallurgy and

appropriate pressure and temperature ratings for the

system to be monitored.

Saudi Aramco DeskTop Standards 12

Engineering Encyclopedia Corrosion Monitoring

Theory and Application of the Corrosometer

• Use common sense and established procedures for

installing and retrieving probes.

Improper installation can mechanically damage a probe

and its hardware. Improper alignment of the probe

during service could allow excessive erosion or

corrosion. A mechanically damaged probe may be

unsafe to retrieve while the system is pressurized.

Before a damaged probe is removed, the system should

be shut down or depressurized to a low level.

• Use applicable safety devices.

The probe retractor is a device used to install and

remove probes in pressurized systems. Safety clamps

should also be used to secure retractable probes and to

prevent accidental ejection of the probe after installation,

especially when pressures exceed 100 psi.

In electrically hazardous locations, safety barriers should

be used to provide electrical isolation between line-

powered instruments and probes. The barriers isolate

the probes from power surges and electrical fault

conditions.

Protective shields should be used to prevent damage to

the exposed measuring element of the probe. High

velocity shields should be used with probes with loop

elements exposed to flow rates above 10 feet per second

or when there is significant particulate matter or viscosity

in the product stream.

Interpretation of Corrosometer Data

Interpretation of data from corrosometers is subject to the same

general limitations as data from coupons. Deposits on the

probe surface can shield the element from the corrosive

environment. In some cases, iron sulfide scale on the probe is

electrically conductive, causing an apparent increase in the

cross-section of the exposed element. These deposits result in

a lower corrosion rate measurement, zero apparent corrosion,

or a negative reading.

Saudi Aramco DeskTop Standards 13

Engineering Encyclopedia Corrosion Monitoring

Theory and Application of the Corrosometer

Pitting corrosion requires special consideration. Most element

readings are proportional to minimum, not average, element

thickness. Pitting, on the other hand, is a random occurrence

on probes. If nucleation occurs on one element but not on

another, a comparison of indicated corrosion will lead to false

conclusions. Therefore, probe elements should always be

examined when removed from service. Wire, tube, or strip

elements that experience pitting will indicate a corrosion rate

many times higher than elements without pitting. Although this

effect is not as serious in the wider flush-mounted and

cylindrical elements, they should still be carefully examined.

Applications of the Corrosometer -- Advantages and Limitations

The corrosometer has many applications. In the laboratory, the

corrosometer is invaluable for studying the mechanism of

corrosion and evaluating inhibitor tests. In refineries,

corrosometers primarily monitor and evaluate inhibitor

effectiveness in distillation units, geothermal systems, and

cooling towers. Other corrosometer applications include

marine, automotive, and oil field installations.

More recently, corrosometers have been used as monitoring

and alarm systems for rapid detection of extremely corrosive

conditions in chemical process streams. In certain chemicals,

the presence of moisture makes the difference between an

extremely corrosive environment and a noncorrosive

environment. Typical applications include hydrofluoric acid and

sulfuric acid alkylation units and chlorinated solvents where

hydrolysis with moisture can generate hydrochloric acid.

Corrosometers have the following advantages.

• Measurements of metal loss can be made frequently

without having to see or remove the specimen. Because

the sensor stays in place, gathering corrosion data for a

history is easy.

• Corrosion measurements can be made in just a few

minutes or monitored continuously. Continuous

monitoring can reveal changes in corrosion as they

occur. In some cases, it is then possible to modify the

process and decrease the corrosion rate.

Saudi Aramco DeskTop Standards 14

Engineering Encyclopedia Corrosion Monitoring

Theory and Application of the Corrosometer

• The corrodent can be either conductive or

nonconductive (gas, liquid, or solid).

• Sensitive corrosometer probes can detect corrosive

conditions that might have gone undetected for a long

time using weight-loss coupons.

Corrosometers have the following limitations.

• Pitting characteristics will not necessarily be evident

from corrosometer measurements. Pitting of the probe

element may cause no detectable change during the

early life of the probe. However, as the probe element

approaches the end of its useful life, very rapid changes

may occur. If high rates of corrosion are measured near

the end of the probe's anticipated life, the probe should

be visually inspected for uniformity of corrosion and for

pitting or velocity effects.

• Conductive corrosion products can adversely affect

corrosometer measurements.

• Fluctuating temperatures can affect the accuracy of

measurements. Wire and strip elements are more likely

to have this problem since their reference elements are

embedded in the body of the probe. Embedded

reference elements respond more slowly to temperature

changes than exposed test elements.

Saudi Aramco DeskTop Standards 15

Engineering Encyclopedia Corrosion Monitoring

Theory and Application of the Corrosometer

FIGURE 5. Corrosion Rate Graph

Saudi Aramco DeskTop Standards 16

Engineering Encyclopedia Corrosion Monitoring

Theory and Application of the Corrosometer

REFERENCE

• Modern Electrical Methods for Determining Corrosion

Rates (NACE Publication 3D170)

Saudi Aramco DeskTop Standards 17

Engineering Encyclopedia Corrosion Monitoring

Theory and Application of the Corrosometer

GLOSSARY

access fitting A small pipe and valve used to connect a retractable probe

assembly into a line, tank, or process equipment.

corrodent A substance that causes a metal to corrode.

corrosion The process by which metal is lost to the solution it

contains. This process can be one or a combination of

chemical and electrochemical action.

electrical resistance That property of an electrically conductive material that

causes a portion of the energy of an electric current in a

circuit to be converted into heat.

erosion The process that removes solids by the flow of gas,

liquids, solids, or any combination of the three.

flange mounting A type of mounting that uses pipe coupling made in two

halves. Each half is screwed or welded to a length of pipe

and the two halves are then bolted together, joining the

two lengths of pipe.

nucleation Initiation of localized corrosion or pitting.

pitting Highly localized corrosion resulting in deep penetration.

probe A device placed in a system to monitor corrosion activity

probe element The sensing part of the probe; test specimen that is

available in a number of configurations (wire, tube, strip,

etc.) and alloys.

reference element A non-corroding portion of the probe element or test

specimen used to compensate for temperature changes.

retractable probe A type of probe that can be removed under system

pressure using a specially designed retracting device.

This probe has a lower pressure rating than a retrievable

probe.

Saudi Aramco DeskTop Standards 18

Das könnte Ihnen auch gefallen

- Engineering Encyclopedia: Miscellaneous Mechanical ComponentsDokument36 SeitenEngineering Encyclopedia: Miscellaneous Mechanical ComponentsLogeswaran AppaduraiNoch keine Bewertungen

- Engineering Encyclopedia: Pumps and CompressorsDokument191 SeitenEngineering Encyclopedia: Pumps and CompressorsReda100% (1)

- 34 Samss 122Dokument13 Seiten34 Samss 122naruto256Noch keine Bewertungen

- Saudi Aramco Typical Inspection PlanDokument3 SeitenSaudi Aramco Typical Inspection PlanAnonymous S9qBDVkyNoch keine Bewertungen

- 00 Saip 75 PDFDokument64 Seiten00 Saip 75 PDFluke luckyNoch keine Bewertungen

- Engineering Encyclopedia: Electric MotorsDokument53 SeitenEngineering Encyclopedia: Electric MotorsLogeswaran AppaduraiNoch keine Bewertungen

- Mex 10403Dokument83 SeitenMex 10403Yousef Adel HassanenNoch keine Bewertungen

- Sae 44Dokument26 SeitenSae 44Anonymous 4IpmN7OnNoch keine Bewertungen

- Instrumentation and Control ReviewDokument84 SeitenInstrumentation and Control ReviewDanish Afroz100% (1)

- Engineering Encyclopedia: Fabrication, Inspection, and Testing of Heat ExchangersDokument31 SeitenEngineering Encyclopedia: Fabrication, Inspection, and Testing of Heat ExchangersAfzaalUmair100% (1)

- DistilationDokument105 SeitenDistilationbahaaabdelnaserNoch keine Bewertungen

- Mex 30210Dokument43 SeitenMex 30210Yousef Adel HassanenNoch keine Bewertungen

- Session IX HydraulicsDokument72 SeitenSession IX Hydraulicsjoe_b_32607Noch keine Bewertungen

- SAES-J-604 - Protective Rotating PDFDokument12 SeitenSAES-J-604 - Protective Rotating PDFinfo_shakib100% (1)

- SAIC-L-2014 Flange Joint Insp PDFDokument7 SeitenSAIC-L-2014 Flange Joint Insp PDFAnonymous S9qBDVkyNoch keine Bewertungen

- Evaluating The Material Requirements of Compressor Mechanical ComponentsDokument133 SeitenEvaluating The Material Requirements of Compressor Mechanical ComponentsTasawwur TahirNoch keine Bewertungen

- Presentation On Modern Trends in PackagingDokument24 SeitenPresentation On Modern Trends in PackagingBhupendra Singh100% (1)

- Coe10508 PDFDokument25 SeitenCoe10508 PDFcvg ertdNoch keine Bewertungen

- 17 Samss 006Dokument13 Seiten17 Samss 006Ahamedulla KhanNoch keine Bewertungen

- 34-Samss-010 2018Dokument9 Seiten34-Samss-010 2018asimazami69Noch keine Bewertungen

- Casein in Milk - WordDokument16 SeitenCasein in Milk - Wordgovind rajpurohit75% (4)

- Saes y 301Dokument10 SeitenSaes y 301kartik_harwani4387Noch keine Bewertungen

- Engineering Encyclopedia: Distillation ProcessDokument70 SeitenEngineering Encyclopedia: Distillation ProcessLogeswaran AppaduraiNoch keine Bewertungen

- 34 Samss 617Dokument9 Seiten34 Samss 617Rodolfo Garcia HernandezNoch keine Bewertungen

- PCI20107, Overview of Boiler Commissioning and Startup PDFDokument17 SeitenPCI20107, Overview of Boiler Commissioning and Startup PDFMarc AnmellaNoch keine Bewertungen

- Saep 22 PDFDokument15 SeitenSaep 22 PDFnadeem shaikhNoch keine Bewertungen

- Age 10802Dokument162 SeitenAge 10802vinoratheeshNoch keine Bewertungen

- Engineering Encyclopedia: Maintenance and Repair of Heat ExchangersDokument69 SeitenEngineering Encyclopedia: Maintenance and Repair of Heat ExchangersAfzaalUmairNoch keine Bewertungen

- Engineering Encyclopedia: Positive Displacement PumpsDokument23 SeitenEngineering Encyclopedia: Positive Displacement PumpsLogeswaran AppaduraiNoch keine Bewertungen

- Engineering Encyclopedia: Reciprocating CompressorsDokument30 SeitenEngineering Encyclopedia: Reciprocating CompressorsLogeswaran Appadurai100% (1)

- SSG Manual: Dow Performance SiliconesDokument59 SeitenSSG Manual: Dow Performance SiliconesAditya KNoch keine Bewertungen

- Sterilization and DisinfectionDokument48 SeitenSterilization and DisinfectionBharanija100% (2)

- ChE 206.01 Introduction To Hydrate Inhibition and DehydrationDokument95 SeitenChE 206.01 Introduction To Hydrate Inhibition and DehydrationMo'tasem SerdanehNoch keine Bewertungen

- Metal Joining ProcessesDokument68 SeitenMetal Joining Processessibi_s_rajNoch keine Bewertungen

- Instrument Installation: NIOEC-SP-70-02Dokument23 SeitenInstrument Installation: NIOEC-SP-70-02Mohammad AminiNoch keine Bewertungen

- Engineering Encyclopedia: Severe Service Control Valve Specification IssuesDokument19 SeitenEngineering Encyclopedia: Severe Service Control Valve Specification Issuescvg ertdNoch keine Bewertungen

- Control Valves FekerDokument180 SeitenControl Valves FekerTayebASherifNoch keine Bewertungen

- PFDDokument19 SeitenPFDCyril JohnsonNoch keine Bewertungen

- 6743 6 52 0053Dokument72 Seiten6743 6 52 0053svijay1969100% (1)

- SAIC-L-2084 Material Storage and Preservation (EE) PDFDokument3 SeitenSAIC-L-2084 Material Storage and Preservation (EE) PDFAnonymous S9qBDVkyNoch keine Bewertungen

- Design Specifications - Validation - ARAMCODokument5 SeitenDesign Specifications - Validation - ARAMCOMohanNoch keine Bewertungen

- Conventional Type Pressure Relief Valve NumbersDokument18 SeitenConventional Type Pressure Relief Valve NumbersswatkoolNoch keine Bewertungen

- Engineering Encyclopedia: Centrifugal CompressorsDokument47 SeitenEngineering Encyclopedia: Centrifugal CompressorsLogeswaran AppaduraiNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Review of Welding Procedure Specification SAIC-W-2001 25-May-05 WeldDokument13 SeitenSaudi Aramco Inspection Checklist: Review of Welding Procedure Specification SAIC-W-2001 25-May-05 WeldAnonymous S9qBDVky100% (1)

- National Oil Corporation: Rev Date Description Checked ApprovedDokument40 SeitenNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Installation of Fired Heaters and Its Components SAIC-F-2006 25-May-05 MechDokument10 SeitenSaudi Aramco Inspection Checklist: Installation of Fired Heaters and Its Components SAIC-F-2006 25-May-05 MechAnonymous S9qBDVkyNoch keine Bewertungen

- Flowmeter SelectionDokument86 SeitenFlowmeter SelectionCenk Yağız Özçelik100% (1)

- Saudi Aramco Inspection Checklist: Review of Refractory Installation Procedure SAIC-N-2018 25-May-05 MechDokument4 SeitenSaudi Aramco Inspection Checklist: Review of Refractory Installation Procedure SAIC-N-2018 25-May-05 MechAnonymous S9qBDVky100% (1)

- Hartford Evaluation Pipeline Design FactorsDokument94 SeitenHartford Evaluation Pipeline Design FactorspiolinwallsNoch keine Bewertungen

- Material For HEDokument36 SeitenMaterial For HEMohd Idris MohiuddinNoch keine Bewertungen

- 7Dokument81 Seiten7Alberto Fonseca UribeNoch keine Bewertungen

- ChE 206.01 Introduction To Hydrate Inhibition and DehydrationDokument79 SeitenChE 206.01 Introduction To Hydrate Inhibition and DehydrationMo'tasem Serdaneh100% (1)

- Proper Steam Turbine OperationDokument32 SeitenProper Steam Turbine OperationBalasubramanian C100% (1)

- Engineering Encyclopedia: Heat Exchanger Concepts, BasicDokument22 SeitenEngineering Encyclopedia: Heat Exchanger Concepts, Basicdineshnandhu007Noch keine Bewertungen

- Emergency ShutdownDokument77 SeitenEmergency ShutdownNazim MirzaNoch keine Bewertungen

- 32 Samss 100Dokument38 Seiten32 Samss 100EngTamerNoch keine Bewertungen

- Sabp J 510Dokument7 SeitenSabp J 510KrishnamoorthyNoch keine Bewertungen

- J 05Dokument20 SeitenJ 05Rochdi SahliNoch keine Bewertungen

- 32 Samss 008Dokument27 Seiten32 Samss 008Eagle SpiritNoch keine Bewertungen

- Sabp Z 018Dokument23 SeitenSabp Z 018Eagle SpiritNoch keine Bewertungen

- Comparison of Standards For Cooling Water Pipes (IS3589 vs. API5L)Dokument17 SeitenComparison of Standards For Cooling Water Pipes (IS3589 vs. API5L)Anonymous gr5Pr9AVNoch keine Bewertungen

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsVon EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahNoch keine Bewertungen

- Engineering Encyclopedia: Instrumented ScrapersDokument16 SeitenEngineering Encyclopedia: Instrumented ScrapersabyNoch keine Bewertungen

- MQ SP I 7003 PDFDokument92 SeitenMQ SP I 7003 PDFJaseelKanhirathinkalNoch keine Bewertungen

- Engineering Encyclopedia: Instrument TransformersDokument30 SeitenEngineering Encyclopedia: Instrument Transformerscvg ertd100% (1)

- Safety ValvesDokument3 SeitenSafety ValvesGiovanni LerasNoch keine Bewertungen

- Engineering Encyclopedia: Basic Properties of SectionsDokument62 SeitenEngineering Encyclopedia: Basic Properties of SectionsVijay KumarNoch keine Bewertungen

- Materials System SpecificationDokument9 SeitenMaterials System SpecificationHandri YantoNoch keine Bewertungen

- Materials System SpecificationDokument6 SeitenMaterials System SpecificationEagle SpiritNoch keine Bewertungen

- Flow Overview Brochure PDFDokument64 SeitenFlow Overview Brochure PDFRenzoNoch keine Bewertungen

- "State-Of-The-Art" Delayed Coking Structure For Frontier RefiningDokument13 Seiten"State-Of-The-Art" Delayed Coking Structure For Frontier Refiningandy175Noch keine Bewertungen

- Sabp P 002 PDFDokument15 SeitenSabp P 002 PDFAnonymous evKjt4OeENoch keine Bewertungen

- Icmerepi 357Dokument5 SeitenIcmerepi 357Renalyn TorioNoch keine Bewertungen

- SAIC N 2029 InspofRepairsofCastableRefractories EL RevDokument3 SeitenSAIC N 2029 InspofRepairsofCastableRefractories EL RevAnonymous S9qBDVkyNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 25-May-05 MechDokument2 SeitenSaudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 25-May-05 MechAnonymous S9qBDVkyNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeDokument7 SeitenSaudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeAnonymous S9qBDVkyNoch keine Bewertungen

- SAIC-W-2009 Revw-Control of Weld Consum - On PlotDokument1 SeiteSAIC-W-2009 Revw-Control of Weld Consum - On PlotAnonymous S9qBDVkyNoch keine Bewertungen

- SAIC W 2009 Revw Control of Weld Consum (EE) RLC FFDokument1 SeiteSAIC W 2009 Revw Control of Weld Consum (EE) RLC FFAnonymous S9qBDVkyNoch keine Bewertungen

- SAIC-W-2031 In-Process Welding Inspection of Hot TapDokument2 SeitenSAIC-W-2031 In-Process Welding Inspection of Hot TapAnonymous S9qBDVkyNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeDokument7 SeitenSaudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeAnonymous S9qBDVkyNoch keine Bewertungen

- SAIC N 2023 PreQualTestApplicator&AppProcCastRefract EL Rev2Dokument3 SeitenSAIC N 2023 PreQualTestApplicator&AppProcCastRefract EL Rev2Anonymous S9qBDVkyNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Inspection of Furnace Dryout SAIC-N-2030 25-May-05 MechDokument4 SeitenSaudi Aramco Inspection Checklist: Inspection of Furnace Dryout SAIC-N-2030 25-May-05 MechAnonymous S9qBDVky0% (1)

- SAIC N 2029 InspofRepairsofCastableRefractories EL RevDokument3 SeitenSAIC N 2029 InspofRepairsofCastableRefractories EL RevAnonymous S9qBDVkyNoch keine Bewertungen

- SAIC N 2025 in ProcessInspPneumaticallyAppliedRefract EL RevDokument3 SeitenSAIC N 2025 in ProcessInspPneumaticallyAppliedRefract EL RevAnonymous S9qBDVkyNoch keine Bewertungen

- SAIC-N-2020 RecvInspRefractRawMatlsAnchSuppHexsteel-EL-Rev PDFDokument4 SeitenSAIC-N-2020 RecvInspRefractRawMatlsAnchSuppHexsteel-EL-Rev PDFAnonymous S9qBDVkyNoch keine Bewertungen

- SAIC N 2019 ReviewVerifyApplicatorPre QualRecord EL RevDokument2 SeitenSAIC N 2019 ReviewVerifyApplicatorPre QualRecord EL RevAnonymous S9qBDVkyNoch keine Bewertungen

- SAIC N 2034 InspofRepairstoExtErosResistRefractInst EL RevDokument3 SeitenSAIC N 2034 InspofRepairstoExtErosResistRefractInst EL RevAnonymous S9qBDVkyNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Inspection of Furnace Dryout SAIC-N-2030 25-May-05 MechDokument4 SeitenSaudi Aramco Inspection Checklist: Inspection of Furnace Dryout SAIC-N-2030 25-May-05 MechAnonymous S9qBDVky0% (1)

- Chapter 4 - Design For Single ReactionsDokument21 SeitenChapter 4 - Design For Single ReactionsPHƯƠNG ĐẶNG YẾNNoch keine Bewertungen

- ExportDokument686 SeitenExportRony JamesNoch keine Bewertungen

- Photobleaching of 5,10,15,20 Tetrakis (M Hydroxyphenyl) PorphyrinDokument8 SeitenPhotobleaching of 5,10,15,20 Tetrakis (M Hydroxyphenyl) PorphyrinEsteban ArayaNoch keine Bewertungen

- (VCE Biology) 2007 Chemology Unit 1 Exam and SolutionsDokument28 Seiten(VCE Biology) 2007 Chemology Unit 1 Exam and SolutionsJustine LyNoch keine Bewertungen

- VukcevicEtAl GhostFluidMethodInPolyhedralFV AnnotatedDokument19 SeitenVukcevicEtAl GhostFluidMethodInPolyhedralFV AnnotatedputhenkulamNoch keine Bewertungen

- Eh40 2005Dokument74 SeitenEh40 2005Adel SukerNoch keine Bewertungen

- Liste Des FiltresDokument6 SeitenListe Des FiltresYacine MokhtariNoch keine Bewertungen

- Lead Acid vs. Lithium-Ion Battery ComparisonDokument5 SeitenLead Acid vs. Lithium-Ion Battery ComparisonRasbihari SharmaNoch keine Bewertungen

- IntegralDokument4 SeitenIntegralprasenjitsayantanNoch keine Bewertungen

- Terra P Operating ManualDokument55 SeitenTerra P Operating ManualosecaloNoch keine Bewertungen

- Markel Paintstik MSDSDokument5 SeitenMarkel Paintstik MSDSAnt EnnaNoch keine Bewertungen

- Section 5.5 Free Body DiagramsDokument25 SeitenSection 5.5 Free Body Diagramstwy113100% (2)

- Packer Failure PDFDokument23 SeitenPacker Failure PDFAnonymous rey6aU3ZNoch keine Bewertungen

- Demulsification Kinetics of W/O Emulsion in An A.C. Electric FieldDokument7 SeitenDemulsification Kinetics of W/O Emulsion in An A.C. Electric FieldajostosNoch keine Bewertungen

- Abel PD PumpsDokument8 SeitenAbel PD PumpsvisitabhinavNoch keine Bewertungen

- Thesis PagesDokument68 SeitenThesis PagesarunNoch keine Bewertungen

- Structural Analysis Tutorial 7Dokument5 SeitenStructural Analysis Tutorial 7pratyush mishraNoch keine Bewertungen

- AP Practice - Chapter 8 & 9 - 10Dokument3 SeitenAP Practice - Chapter 8 & 9 - 10Harin ParikhNoch keine Bewertungen

- OCVProd Ref GuideDokument127 SeitenOCVProd Ref Guidejeff.triaxis100% (1)

- Latihan AmaliDokument14 SeitenLatihan Amaliazman94Noch keine Bewertungen

- Spesifikasi Erba, Automated Clinical Chemistry Analyzer, XL 600Dokument2 SeitenSpesifikasi Erba, Automated Clinical Chemistry Analyzer, XL 600matto89Noch keine Bewertungen

- ChE253M Liquid Flow - Lab+Report - Rev20120124Dokument7 SeitenChE253M Liquid Flow - Lab+Report - Rev20120124hongluc1991Noch keine Bewertungen

- Constructing Ashby MapDokument9 SeitenConstructing Ashby MapIr FankovicNoch keine Bewertungen