Beruflich Dokumente

Kultur Dokumente

DC Motors Explained White Paper

Hochgeladen von

Isaac TellezCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DC Motors Explained White Paper

Hochgeladen von

Isaac TellezCopyright:

Verfügbare Formate

DC Motors Explained: White Paper, Title Page

WHITE PAPER

DC Motors Explained

By Joe Kimbrell,

Product Manager, Drives, Motors & Motion, AutomationDirect

The #1 Value in Automation.™

DC Motors Explained: White Paper, pg. 2

How many types of DC motors are there?

There are several types of DC motors, including

shunt, series, compound wound or stabilized shunt,

permanent magnet, and brushless DC. The main

differences between these types of motors revolve

WHITE PAPER

around how the electromagnetic fields are

generated. For example, in a permanent magnet

motor, the magnetic field in the stator is supplied by

permanent magnets positioned just inside the frame

of the motor. The magnetic field in the rotor is

produced by the applied voltage. Permanent Magnet

motors are simple to operate: there are only two

wires to hook up. (Figure 1)

Figure 1: Permanent Magnet Motor

What are the key differences between AC and

DC motors?

As with the different types of DC motors, the main difference between AC and DC

motors centers around how the magnetic fields are generated. The rotor of a typical

AC induction motor has no electrical connection. The rotor is influenced by the field

generated by the stator, which is fed an AC voltage. A typical DC motor has a rotor

with electrical connections through a brush and commutator arrangement. The brush/

commutator acts as a switch which applies voltage to the different segments of the

rotor. The field can also have either an electrical connection or can be composed of

permanent magnets.

Why choose AC over DC?

AC motors and control have taken over many applications formerly driven by DC

motors. One of the main reasons many people prefer AC to DC is that AC motors

require less maintenance. While most motors require minimal maintenance, DC motors

require an extra step of monitoring and replacing the internal brushes. While this step

may be simple to perform on small motors, care must be taken on higher horsepower

DC motors to correctly install motor brushes. On smaller (2HP or less) Permanent

Magnet motors, the brush change-out can be accomplished in a matter of minutes.

Save up to 50% on DC Motors:

www.AutomationDirect.com/DC-Motors The #1 Value in Automation.™

DC Motors Explained: White Paper, pg. 3

Why choose DC over AC?

There are several reasons to choose DC motors over AC motors. High performance

(especially at low speeds), high power density, simplicity of control, and a large installed

base help determine applications for DC motors. DC motors develop full-load torque at

low speeds (Figure 2). This, combined with low inertias, result in excellent performance

WHITE PAPER

from DC motors. AC motors and controls have closed the performance gap, but general

purpose DC motors still outperform general purpose AC motors. To obtain comparable

low-speed performance from an AC motor, much more expensive AC drives and

motors must be used.

Figure 2: DC Motor Torque Characteristics

DC motors generally have much higher power density than AC motors. This allows a

customer to use a physically smaller DC motor than the equivalent-HP AC motor. The

control system for a DC motor is much simpler and less expensive than an equivalent

AC drive.

An AC drive must rectify incoming AC power into a DC bus and then create its own AC

voltage to send out to the motor. A DC drive rectifies the incoming AC waveform and

passes that rectified power out to the DC motor.

While AC motors and controls have made large inroads, DC motors have been around

for 100 years and have been used extensively in almost all industrial applications. There

is a large installed base of DC motors in the automation industry. Usually, replacing an

existing DC motor with a new DC motor is much quicker, easier and economical than

redesigning a control system to incorporate an AC motor and drive.

How do you power DC motors?

DC motors can be fed from a variety of DC power sources, even batteries. Typically,

though, industrial DC motors are driven from DC drives. The quality of output power

from different types of DC drives varies dramatically. This quality can be measured by

how much ripple current is produced by the drive. The ripple current is designated

Save up to 50% on DC Motors:

www.AutomationDirect.com/DC-Motors The #1 Value in Automation.™

DC Motors Explained: White Paper, pg. 4

by a drive’s Form Factor, which is the relationship of the ripple current to the main DC

current. High ripple current results in increased motor heating and possibly premature

brush failure.

A battery is considered the ideal current source, which has a current Form Factor of 1.0.

With a battery, there is a constant voltage (and current) to power the motor. A Pulse

Width Modulated (PWM) DC drive emulates pure DC so well, that it generally produces

WHITE PAPER

a Form Factor of 1.05 (only 5% ripple) (Figure 3).

Form Factor Table

Form factor DC voltage source

1.0 Battery (pure DC)

1.05 Pulse width modulation (PWM)

1.35 Full wave rectification (single phase)*

1.9 Half wave rectification (single phase)**

* Single phase full wave rectification is the most common form of DC drive in .33 to 2 hp range.

** Not Recommended

Figure 3: Form Factor Table

One of the more common drives for small horsepower DC motors is the Single-Phase

Full-Wave Rectified DC Drive. This drive takes an AC voltage and passes the positive half

of the wave and rectifies the negative part of the wave to produce a waveform with a

Form Factor of 1.4 (40% current ripple). These drives are commonly referred to as SCR

(Silicon Controlled Rectifier) drives. Many motors are “SCR-rated”, meaning their full

load torque and power are produced when using an SCR drive.

Another type of drive has a much worse Form Factor: Single-Phase Half-Wave Rectified

DC drives. These drives only pass the positive half of the AC sine wave. These drives

have a form factor of 1.9 and are not recommended for use with many DC motors.

What is the maintenance for a DC motor?

DC motor maintenance follows basic AC motor maintenance standards (keep the motor

and fan clean, grease the bearings if non-sealed, etc). DC motors have one extra step:

brush maintenance. A general rule of thumb is to replace the brushes once they reach

1/3 of their original length. A good rule of thumb is to replace the brushes every 2,500

hours of use. This will ensure that the brushes are always within spec.

Save up to 50% on DC Motors:

www.AutomationDirect.com/DC-Motors The #1 Value in Automation.™

DC Motors Explained: White Paper, pg. 5

About AutomationDirect

In business since 1994, AutomationDirect is a distributor offering thousands of

industrial automation products for electrical control systems, including PLCs, operator

WHITE PAPER

interfaces, AC drives, motors, stepper systems, sensors, motor control, enclosures and

more. Their prices are typically well below the list price of more traditional automation

companies because of their model and focus on efficiency and the majority of their

products are stocked for same-day shipping. Plus, get free two-day delivery on orders

over $49; some limitations apply. For more information, contact them at 800-633-0405

or visit www.AutomationDirect.com/DC-Motors

Article first published in 2010.

Save up to 50% on DC Motors:

The #1 Value in Automation.™

www.AutomationDirect.com/DC-Motors © 2015 AutomationDirect.com, Inc. All rights reserved.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Fuel Injectors PDFDokument11 SeitenFuel Injectors PDFanshelNoch keine Bewertungen

- Aerospace Engineering Services JSCDokument76 SeitenAerospace Engineering Services JSCThanh QuangNoch keine Bewertungen

- The Transformation of Neuronal Activity Into Conscious Experience: The Syntergic Theory Jacobo GrinbergDokument10 SeitenThe Transformation of Neuronal Activity Into Conscious Experience: The Syntergic Theory Jacobo GrinbergsebastianNoch keine Bewertungen

- 10MW Solar Plant DesignDokument3 Seiten10MW Solar Plant DesignKishore0% (1)

- SIMATIC - Programming Guide S7-1200 and 1500 (3 - 2017)Dokument120 SeitenSIMATIC - Programming Guide S7-1200 and 1500 (3 - 2017)Jorge_Andril_5370100% (3)

- Belt Scale Application GuidelinesDokument25 SeitenBelt Scale Application Guidelinesบิ๊ก บิ๊กNoch keine Bewertungen

- Mechanical Vibration NotesDokument56 SeitenMechanical Vibration NotesYadanaNoch keine Bewertungen

- Working Clearance For Outdoor Installation Ref IEC 61936 Fig 3 Safety Clearance Sectional Clearance Safety ClearanceDokument1 SeiteWorking Clearance For Outdoor Installation Ref IEC 61936 Fig 3 Safety Clearance Sectional Clearance Safety ClearanceMeghavahinaNoch keine Bewertungen

- Air Leaves A Compressor in A Pipe With A Stagna - Tion Temperature and Pressure of 150 C, 300 KpaDokument242 SeitenAir Leaves A Compressor in A Pipe With A Stagna - Tion Temperature and Pressure of 150 C, 300 KpalfgmarcantoniNoch keine Bewertungen

- PIPE Final CoachingDokument53 SeitenPIPE Final CoachingCharles NunezNoch keine Bewertungen

- Gas TurbinesDokument74 SeitenGas TurbinesBhushan PatilNoch keine Bewertungen

- Trouble Codes C32Dokument10 SeitenTrouble Codes C32AliHabes100% (2)

- Electric Arc and Ladle Furnaces PDFDokument27 SeitenElectric Arc and Ladle Furnaces PDFrodolfo_tome8275Noch keine Bewertungen

- Beltscale Handbook 03 12 TL Calibracion de BalanzasDokument20 SeitenBeltscale Handbook 03 12 TL Calibracion de BalanzasTunoNegro1Noch keine Bewertungen

- Spray Cooling Continus CastingDokument15 SeitenSpray Cooling Continus CastingIsaac TellezNoch keine Bewertungen

- ABB DatasheetDokument9 SeitenABB DatasheetIsaac TellezNoch keine Bewertungen

- Load Cell Application Test Guideline April 2010Dokument29 SeitenLoad Cell Application Test Guideline April 2010PIY777Noch keine Bewertungen

- 1SBL176001R2110 Af16z 30 10 21 24 60v50 60hz 20 60vdc ContactorDokument5 Seiten1SBL176001R2110 Af16z 30 10 21 24 60v50 60hz 20 60vdc ContactorIsaac TellezNoch keine Bewertungen

- Belt Scale Reference Guide: PN 180546 July 19, 2018Dokument16 SeitenBelt Scale Reference Guide: PN 180546 July 19, 2018Isaac TellezNoch keine Bewertungen

- 0.10 To 32 A - With Thermal and Electromagnetic Protection: MS116 Manual Motor StartersDokument11 Seiten0.10 To 32 A - With Thermal and Electromagnetic Protection: MS116 Manual Motor StartersIsaac TellezNoch keine Bewertungen

- RS232Connection PDFDokument2 SeitenRS232Connection PDFIsaac TellezNoch keine Bewertungen

- RS232Connection PDFDokument2 SeitenRS232Connection PDFIsaac TellezNoch keine Bewertungen

- RS232Connection PDFDokument2 SeitenRS232Connection PDFIsaac TellezNoch keine Bewertungen

- Legal MetrologyDokument12 SeitenLegal MetrologyIsaac TellezNoch keine Bewertungen

- 1 Channel DAC Using A PWM ZilogDokument14 Seiten1 Channel DAC Using A PWM ZilogIsaac TellezNoch keine Bewertungen

- 2 Loadcell CablingDokument8 Seiten2 Loadcell CablingTong Van NgocNoch keine Bewertungen

- Webinar Slides Belt Scales101 2015 12lDokument28 SeitenWebinar Slides Belt Scales101 2015 12lIsaac TellezNoch keine Bewertungen

- 3TK2826 20071012 enDokument70 Seiten3TK2826 20071012 enkadir kayaNoch keine Bewertungen

- Build Your Own z80Dokument306 SeitenBuild Your Own z80Blake HorensteinNoch keine Bewertungen

- 2 Loadcell CablingDokument8 Seiten2 Loadcell CablingTong Van NgocNoch keine Bewertungen

- KabelNet E PDFDokument3 SeitenKabelNet E PDFFahrul Songgolangit MangkubumiNoch keine Bewertungen

- LPG Instrumentation SafetyDokument2 SeitenLPG Instrumentation SafetySATISHNoch keine Bewertungen

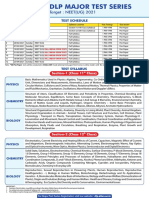

- DLP Major Test Series: Target: NEET (UG) 2021Dokument1 SeiteDLP Major Test Series: Target: NEET (UG) 2021Ankit singh TomarNoch keine Bewertungen

- Presentation OnDokument28 SeitenPresentation OnAnonymous umnT4ZZcuNoch keine Bewertungen

- IECEx TOTAL Standards AngolaDokument31 SeitenIECEx TOTAL Standards AngolaIso macnamareNoch keine Bewertungen

- Work, Energy, Power, and MachinesDokument46 SeitenWork, Energy, Power, and MachinesDee Doroin50% (2)

- TURCK - IM1 22ex RDokument2 SeitenTURCK - IM1 22ex RRamón F. Zapata SánchezNoch keine Bewertungen

- Chint Pricelist 2023Dokument108 SeitenChint Pricelist 2023SK EnterprisesNoch keine Bewertungen

- 3-Introduction To HVDC Transmission Comparison Between HVDC and HVAC Systems-01-08-2023Dokument29 Seiten3-Introduction To HVDC Transmission Comparison Between HVDC and HVAC Systems-01-08-2023saran killerNoch keine Bewertungen

- Comparative Study of Various Energy Recovery Devices Used inDokument44 SeitenComparative Study of Various Energy Recovery Devices Used inmichael_mendozaNoch keine Bewertungen

- Fan Coil Room Thermostat RDF510, RDF530 : en ZHDokument2 SeitenFan Coil Room Thermostat RDF510, RDF530 : en ZHمحمد عليNoch keine Bewertungen

- Battery BasicsDokument7 SeitenBattery BasicsAnil kumarNoch keine Bewertungen

- Powersafe Batterie - VF - BrochureDokument20 SeitenPowersafe Batterie - VF - BrochureMarco MatteucciNoch keine Bewertungen

- Megneto TherapyDokument15 SeitenMegneto TherapyedcanalNoch keine Bewertungen

- Emergency Lighting: Slim LightDokument2 SeitenEmergency Lighting: Slim LightbmxmmxNoch keine Bewertungen

- Axial Flow Gas Turbine HandoutDokument10 SeitenAxial Flow Gas Turbine HandoutOwais IdrisNoch keine Bewertungen

- Kesan Fotoelektrik 1Dokument2 SeitenKesan Fotoelektrik 1Aleva KongNoch keine Bewertungen

- 10 - Techno-Economic Analysis of Direct Air Carbon Capture With CO2Dokument10 Seiten10 - Techno-Economic Analysis of Direct Air Carbon Capture With CO2Emetovweke OchukoNoch keine Bewertungen

- ZMP 60578 FM 11W 730 PDFDokument4 SeitenZMP 60578 FM 11W 730 PDFtahseenahsanNoch keine Bewertungen

- Combined Over-Voltage & Under-Voltage Protection System Submitted byDokument9 SeitenCombined Over-Voltage & Under-Voltage Protection System Submitted byAdarsh ChavdaNoch keine Bewertungen