Beruflich Dokumente

Kultur Dokumente

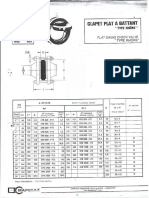

Small Flange Ball Valve With Weight

Hochgeladen von

nnaemeka omekeCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Small Flange Ball Valve With Weight

Hochgeladen von

nnaemeka omekeCopyright:

Verfügbare Formate

PE O M

D P

C

97 LIA

/2 N

3/ T

EC

UNIVERSAL

SOCKET

WELD

The Universal Socket Weld check valve is machined from bar stock and is designed for a minimum pressure drop. It

carries rugged, dependable Check-All trim and there are a wide variety of seat materials and cracking pressures to choose

from. The socket parts are machined to ANSI B16.11 dimensions.

NOTE: Please take precautionary measures when welding to prevent heat build-up and possible damage to the valve seat.

See page 48 for additional installation information.

Nom.

Size Orifice

Pipe

Code A B1 C2 D2 Diameter

Size

3/8 C 2.16 1-1/8 0.695 0.385 0.348

1/2 D 2.71 1-5/16 0.860 0.385 0.464

3/4 F 2.95 1-5/8 1.070 0.505 0.593

1 H 3.64 2-1/4 1.335 0.505 0.890

1-1/4 I 3.91 2-3/4 1.680 0.505 1.135

1-1/2 J 4.36 3-1/4 1.920 0.505 1.385

2 K 5.85 3-1/2 2.411 0.625 1.555

2-1/2 L 5.00 3-3/4 2.919 0.625 1.555

3 M 5.44 4-1/2 3.545 0.625 2.025

4 N 6.80 5-1/2 4.550 0.755 2.560

1May be larger and/or hex.

2Sockets per ASME/ANSI B16.11.

Body Material 3 Availability Non-Shock Pressure Rating

316 Stainless Steel (SS)

Standard

Carbon Steel (CS)

Alloy 20 (A2)

Hastelloy® C (HC) Semi-standard 3/8 - 2-1/2 3 4

Monel® (MO) 5000 PSIG @ 100°F 3000 PSIG @ 100°F 1500 PSIG @ 100°F

Hastelloy® B (HB) (1500 PSIG for o-ring seats) (1500 PSIG for o-ring seats)

Contact the factory for

Inconel® 600 (I6) availability of these or other

materials

Titanium (TI)

3See page 51 for material grade information.

CHECK-ALL VALVE MFG. CO. Phone: 515-224-2301 Fax: 515-224-2326 2006

Universal Socket Weld

For Water at 72°F

100

STYLE UN-SW (US)

Cv VALUES & VALVE WEIGHTS

.

.

2" .

/2"

/4"

/2"

"

"

"

Cv

3/8

1/2

2-1

3/4

SIZE SS & CS

1"

4"

3"

1-1

1-1

PRESSURE DROP - PSI

1.9 3/8 5.1 oz.

4.3 1/2 11.5 oz.

10 7.2 3/4 1.2 lb.

11.0 1 3.1 lb.

19.0 1-1/4 4.9 lb.

31.9 1-1/2 7.4 lb.

42.0 2 9.8 lb.

50.0 2-1/2 8.8 lb.

89.0 3 13.0 lb.

1 140 4 22.3 lb.

1 10 100 1000 See page 46 for Flow Formulae

WATER FLOWRATE - GPM

HOW TO ORDER

CHECK-ALL STYLE UN-SW (US)

BODY MATERIAL SPRING CRACKING PRESSURES

ALLOY® 20 = A2 CRACKING PRESSURE1 DECIMAL

CARBON STEEL = CS (PSI) FORMAT

HASTELLOY® B = HB 0.000 TO 0.999 = .XXX

1.00 TO 9.99 = X.XX

HASTELLOY® C = HC

10.0 TO 99.9 = XX.X

Inconel® 600 = I6

NO SPRING = NOSPRG SPECIAL OPTIONS

MONEL® = MO

316SS = SS T = FEP ENCAPSULATED SPRING

STANDARD CRACKING PRESSURES2

Titanium = TI Temperature rating

.125 .500 1.50 3.50

Temperature rating (Sizes C-I Only) Contact the factory for more options

US

VALVE STYLE

SIZE SEAT MATERIAL3 SPRING MATERIAL

3/8 = C AFLAS® = AS 316 SS = SS

1/2 = D BUNA-N = BN HASTELLOY® C = HC

3/4 = F EPDM = EP INCONEL® X-750 = IX

1 = H KALREZ® = KZ MONEL® = MO

1-1/4 = I METAL-TO-METAL = MT 17-7PH SS = PH

1-1/2 = J NEOPRENE = NE TITANIUM = TI

2 = K PTFE = TF Temperature ratings

2-1/2 = L VITON® = VT

3 = M Temperature ratings

4 = N

Listed above are the most common material selections. Please contact the factory for additional options.

1Shown for part numbering format only: Contact factory for non-standard cracking pressure availability.

2.500 PSI is the only standard cracking pressure for spring materials other than Stainless Steel. Cracking

pressure tolerance is +/- 15%. 1/8 PSI springs are not recommended for installations with flow vertical down.

3Seat materials other than metal-to-metal have a maximum pressure rating of 1500 PSI. PTFE seats are not

resilient. See page 47 for allowable leakage rates.

www.checkall.com sales@checkall.com ISO 9001-2000 CERTIFIED 2006

Das könnte Ihnen auch gefallen

- Small Size Ball ValveDokument17 SeitenSmall Size Ball Valvennaemeka omekeNoch keine Bewertungen

- Ball Valve - FlowtekDokument6 SeitenBall Valve - Flowteknnaemeka omekeNoch keine Bewertungen

- Class 800 Steel Check ValvesDokument2 SeitenClass 800 Steel Check Valvesnnaemeka omekeNoch keine Bewertungen

- s07 PressurexmtrsDokument20 Seitens07 Pressurexmtrsnnaemeka omekeNoch keine Bewertungen

- CA44 and CA44S Carbon Steel Air and Gas Traps Flanged DN15 To DN25Dokument5 SeitenCA44 and CA44S Carbon Steel Air and Gas Traps Flanged DN15 To DN25nnaemeka omekeNoch keine Bewertungen

- RBS TwoInch System Retriever KitDokument3 SeitenRBS TwoInch System Retriever Kitnnaemeka omekeNoch keine Bewertungen

- Oliver Double Block and Bleed Valve CatalogDokument7 SeitenOliver Double Block and Bleed Valve Catalognnaemeka omekeNoch keine Bewertungen

- FM Mag Gauge Tg-L381e PDFDokument20 SeitenFM Mag Gauge Tg-L381e PDFnnaemeka omekeNoch keine Bewertungen

- Gate ValveDokument4 SeitenGate Valvennaemeka omekeNoch keine Bewertungen

- Needle Valves: Forged Integral BonnetDokument12 SeitenNeedle Valves: Forged Integral Bonnetnnaemeka omekeNoch keine Bewertungen

- Flat Swing Check Valve PDFDokument5 SeitenFlat Swing Check Valve PDFnnaemeka omekeNoch keine Bewertungen

- Class 800 Steel Swing Check ValvesDokument2 SeitenClass 800 Steel Swing Check Valvesnnaemeka omekeNoch keine Bewertungen

- Acris Isoria Mammouth: Butterfly Valves For High Corrosion, Ultra High Purity and General Industrial ApplicationsDokument12 SeitenAcris Isoria Mammouth: Butterfly Valves For High Corrosion, Ultra High Purity and General Industrial Applicationsnnaemeka omekeNoch keine Bewertungen

- Site Visit ReportDokument2 SeitenSite Visit Reportnnaemeka omekeNoch keine Bewertungen

- S/N Material QTY: 2 Bulkhead Penetration 8 PcsDokument9 SeitenS/N Material QTY: 2 Bulkhead Penetration 8 Pcsnnaemeka omekeNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Successful School LeadershipDokument132 SeitenSuccessful School LeadershipDabney90100% (2)

- Bhagwan Mahavir College of Architecture: Topic: Lacing, Batteneing, BracingDokument14 SeitenBhagwan Mahavir College of Architecture: Topic: Lacing, Batteneing, BracingJai MenDparaNoch keine Bewertungen

- 1207 - RTC-8065 II InglesDokument224 Seiten1207 - RTC-8065 II InglesGUILHERME SANTOSNoch keine Bewertungen

- BIO122 - CHAPTER 7 Part 1Dokument53 SeitenBIO122 - CHAPTER 7 Part 1lili100% (1)

- Pitch AnythingDokument8 SeitenPitch AnythingDoland drumb100% (1)

- Dashrath Nandan JAVA (Unit2) NotesDokument18 SeitenDashrath Nandan JAVA (Unit2) NotesAbhinandan Singh RanaNoch keine Bewertungen

- TAPPI T 810 Om-06 Bursting Strength of Corrugated and Solid FiberboardDokument5 SeitenTAPPI T 810 Om-06 Bursting Strength of Corrugated and Solid FiberboardNguyenSongHaoNoch keine Bewertungen

- Prof Ed 3 Module 1Dokument9 SeitenProf Ed 3 Module 1alexa dawatNoch keine Bewertungen

- SCHEMA - Amsung 214TDokument76 SeitenSCHEMA - Amsung 214TmihaiNoch keine Bewertungen

- LampiranDokument26 SeitenLampiranSekar BeningNoch keine Bewertungen

- Ebook Computer Forensics Principles and Practices 1St Edition Volonino Test Bank Full Chapter PDFDokument29 SeitenEbook Computer Forensics Principles and Practices 1St Edition Volonino Test Bank Full Chapter PDFmundifycoucheefnhgl100% (10)

- Perbandingan Implementasi Smart City Di Indonesia: Studi Kasus: Perbandingan Smart People Di Kota Surabaya Dan Kota MalangDokument11 SeitenPerbandingan Implementasi Smart City Di Indonesia: Studi Kasus: Perbandingan Smart People Di Kota Surabaya Dan Kota Malanglely ersilyaNoch keine Bewertungen

- Day 2 - Evident's Official ComplaintDokument18 SeitenDay 2 - Evident's Official ComplaintChronicle Herald100% (1)

- 3Dokument76 Seiten3Uday ShankarNoch keine Bewertungen

- Sample TRM All Series 2020v1 - ShortseDokument40 SeitenSample TRM All Series 2020v1 - ShortseSuhail AhmadNoch keine Bewertungen

- Calculus of Finite Differences: Andreas KlappeneckerDokument30 SeitenCalculus of Finite Differences: Andreas KlappeneckerSouvik RoyNoch keine Bewertungen

- Integra Facade BrochureDokument2 SeitenIntegra Facade BrochureHarshit PatadiyaNoch keine Bewertungen

- Chapter 2.2 Quantitative Analysis NewDokument44 SeitenChapter 2.2 Quantitative Analysis NewMinase TilayeNoch keine Bewertungen

- EHVACDokument16 SeitenEHVACsidharthchandak16Noch keine Bewertungen

- Acdc - DC Motor - Lecture Notes 5Dokument30 SeitenAcdc - DC Motor - Lecture Notes 5Cllyan ReyesNoch keine Bewertungen

- End Points SubrogadosDokument3 SeitenEnd Points SubrogadosAgustina AndradeNoch keine Bewertungen

- Muhammad Firdaus - A Review of Personal Data Protection Law in IndonesiaDokument7 SeitenMuhammad Firdaus - A Review of Personal Data Protection Law in IndonesiaJordan Amadeus SoetowidjojoNoch keine Bewertungen

- RESUME1Dokument2 SeitenRESUME1sagar09100% (5)

- CV TitchievDokument3 SeitenCV TitchievIna FarcosNoch keine Bewertungen

- Blackstone The Dash Model #1610 Owner's ManualDokument53 SeitenBlackstone The Dash Model #1610 Owner's ManualSydney Adam SteeleNoch keine Bewertungen

- KV4BBSR Notice ContractuaL Interview 2023-24Dokument9 SeitenKV4BBSR Notice ContractuaL Interview 2023-24SuchitaNoch keine Bewertungen

- Bus105 Pcoq 2 100%Dokument9 SeitenBus105 Pcoq 2 100%Gish KK.GNoch keine Bewertungen

- PERSONAL DEVELOPMENT (What Is Personal Development?)Dokument37 SeitenPERSONAL DEVELOPMENT (What Is Personal Development?)Ronafe Roncal GibaNoch keine Bewertungen

- 009 Attached-1 NAVFAC P-445 Construction Quality Management PDFDokument194 Seiten009 Attached-1 NAVFAC P-445 Construction Quality Management PDFSor sopanharithNoch keine Bewertungen

- Consequences of Self-Handicapping: Effects On Coping, Academic Performance, and AdjustmentDokument11 SeitenConsequences of Self-Handicapping: Effects On Coping, Academic Performance, and AdjustmentAlliah Kate SalvadorNoch keine Bewertungen