Beruflich Dokumente

Kultur Dokumente

Kurma Rao Saini - Qualification Certificate044

Hochgeladen von

Anonymous AdofXEYAgE0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

21 Ansichten10 Seitenfsdfsdfdsf

Originaltitel

Kurma Rao Saini_qualification Certificate044

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenfsdfsdfdsf

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

21 Ansichten10 SeitenKurma Rao Saini - Qualification Certificate044

Hochgeladen von

Anonymous AdofXEYAgEfsdfsdfdsf

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 10

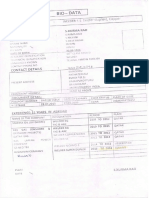

[ Madina Group WLLL. | |

WELDER QUALIFICATION RECORD.

CERTIMICATE Na |291/085m001 REV. 0

WELDERS Nant unm Ra Sins

| | stant ne swe |

DATE OF TEST iramay.2007

WELDING PROCESS(ES) USED GTAW = sMAW

ve MANUAL *

| | wevnmcaniqn oF wes FOLLOWED BY MADINA

|WPS USED DURING WELDING OF TEST COUPON ss,

BASE METAL MATERIALS) WELDED ASME SA 106 Gr ue

SIZE (THICKNESS SerscH eocisa6 iy 7."

MANUAL OR SEME-AUTOMATIC VARIABLE OF EACH PROCESS (ow.350 EYAL

BACKINa (METAL. WELD METAL. WHL_DED FROM BOTH SIDES, FLUXETC) (QW 402)

otaw wirvout _wrenor wour

saw wer om

ASNEP Na cowaon Rw re

. Par Tanh

<> FLAT « > Pe ENTER DIAMETER TFPI ES Fienmeon

BLLER METAL SFEEN(SPA S83 GoassincaripN‘gwao) —_ERNOSHWETN, nueva

FILLER METAL ENO. + Sd Wie Ou ora i ne

+i aking sMaw fe ita

JCONSUMANLE BERT FOR TAW OR PAW waon— won —

WIELD DEPOSE THICRNESS FOR EACH WELDING PROCESS omaw des ‘nn

sMAW 1426 ma Unlint

weetpmG POSMON (QW405) «a

PROGRESSION (UPRIL DOWNIE er

BACKING GAS FOR GTAW.PAWOR GMAN:FLEL GAS FOR OFW (QW-40) widen _ Wier wate

OMAW TRANSFER MODE (QW.409), NA WA

GTAW/SMAW WELDING CURRENT TYPE POLARITY (VE) DeNoc _ pana

VISUALEXAMINATION RESULTS (QWI86) : ACcHPTARLE

RADIOGHAPHICTEST RESULTS (QW:04 AND QW.305) + ccna

vornimalamqiunetmorarcorrwassrrncectanm «+ —=—‘REPORTRORTAI:OVANRGTASMESLOR

(CUED BEND TESTS TYVE < > QW-162.2 (SDE) RESULTS « > QW #4231) (TRANS RAH TYTE « > QW462.5 (9) (LONO RAR) REALLY

Na wa Na NA

Pun_.Er WELD -FRACTURETEST: wa LENGTH AND PERCENT OF DEFECTS: NA

MACKOTESTFUSON: = MA MLETIEGS@E lay i. CONCAVITYCONEXITY, A in

MADINA GROUP WL. (MECHANICAL DIVISION)

wa LABORATORY TIT NO:

Madina Group W.L.L.

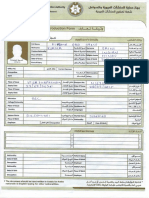

WELDER TION RECORD |

129170739001 REV

[ curtmicarese

WELDERS WAM: KUMARA RAO Samnt |

STAMPS waveis9i |

}) parcor mest eo.pee-s007

WELDING ERO TSMFS) USED oraw

on Manual

IDENTIFICATION OF WPS FOLLOWED BY MADINA ;

‘HPSTSEDOURNG WELDINGOFTESTOUTON —. on ol

ASE METAL MATERIALS) WADED ASMESA 1960.05 Y

sarc ozsmsenesemndllg

X nance

MANUAL OR SFSILAUTOMATIC VAMIABLE OF BACILTROCESS/OW-399) fie” gutta,

[ACKING (METAL. WELD METAL, WELDED FROM OTH SUES. FLU ETC) (OW) alt ae

oraw wrswout __win win ow

SMAW NA wae

ASMER.NO cowie) Ps Ramen |

<2 PLATE < > PIPT(ENTER DIAMETER IF Pipe) Ns iropp a ove

TLLERMETALSRECN (SPAY Sk . CLASSIFICATION (OW-0H) ER TEE Rat ena ™

FILLER METAL wo * Soe Wi ony ovaw i ALL

: saw we wa

ONSUMARLE INSERT FOR GTAW OK PAW Winn Wiha

\WE.D DEFOSIT THICKNESS FOR EACH! WELDING PROCESS om s5im0 iota saz

saw wa wa |

WEDINa PosITON (QWs) ra A

PROGRESSION (UPHILL : OWNER) emit Upon

BACKING GAS FOR GTAW, PAWOR GMAW: FULGAS FoR OFW (QW-40R Wiaow “Wie Wino

GMAW TRANSFER MODE {QV} WA wa |

GTAW WELDING CURRENT TY1E/FOLARITY (4) fat oem |

VISUAL EXAMINATION RESULTS 09190 ACCEITABLE |

railcars modern a |

(FORALTERNATIVE QUALINCATION OF GROOVE WELDS BV RADIOGRAPHY)

: REFONE N

‘OUDEDEND Test RESULTS |

UD REND TESTS TPE <> QW-H622 (IDE) RESULTS” ~ QW 2.44) TRAN RAI) TYPE <> W623 (ILENGRAP RESULT

wm Ta wa wa a wa

aera Fo LENOTHAND MIRCENT OFDEREETR wa

MACRO TESTFLSION PUETLEUSE ins in CONCAVIIVECONVINITY, Wa in

WELDING TIST CONDUCTED BY, MADINA GROUP W.LI (MECHANICAL DIVISION)

MECHANICAL TESTS CONDUCTED BY: wa LABORATORY TESTNO: Nia

WE CERTIFY THAT THE STATEMENTS IN THIS RECORD ARE CORRECT AND THAT THE TEST COUFONS WERE |

PREPARED WELDERESRUATBSTED IN ACCORDANCE WITH THE REQUIREMENTS OF SE ar THe |

pate:

Fara Ne TRPMIR Ror 0 Bir

aN

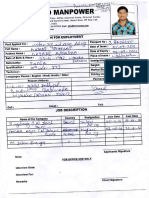

WELDER PERFORMANCE QUALIFICATION RECORD (POR)

(QW301, SECTION IX. ASME DOILER AND PRESSUT: VEsGT CODE

Wale aa _RURNIA RAD SAINT ratesioa No _MW= TT

Lucetctom of WHS foloved 06S Ren B Yo Conn DI Prac wot

hei al ipa o INS nae fee mat san Tr

rer MCN Ne Saar

“Teng Condon ta Gascon Linas :

‘Weiding Varanies (OW:380) Actua aloes

Weng pees ie) (GTAW Rout Pilend Cover a

: SS SSS oe

yp 6 mana em eu whe Taal Ties

| ssskes inva wed metal dover cvAw sities! baa sitar wt bacng —]

roe BD Preteneremsite toma. pn oF bey Sea Sa

sero Pr Sumber hr Nur Ties FEF PAT PD,

Fue moat or decode pesto SFAD foals) onw——a Scere

Fae ew deco enneatet foe) Craw _ Tete 7

tr mit Nant craw Fat Re]

coment GTAW or PAW ee

Fair syne ootadmenl or Nu coradipe der (GTA W or AW) GTAW Solid / etal see

sont mac foreach rece —_ re aes

SS ———

Troxes: GTAW Stoyss rina Ye IN ime Tit i

Proce 2 Siyes aim Cher Ne

Poston gain e < Troan ar

Se a Sees

| vores woreion rp a

| Type chet pr iOW) Wet Apptiate Tot peat

In 8 vce (GTAW. PAW. GMAW) craw: ‘aren Wi

refer ne (OMAW/FCAW) =e ee ——]

cure! Type (GTA) DCN De

rc RESULTS

roa Fsaranaon of Complew Weid(QW:2024) sata

(Cirenvere rove ben tetfQW 4623 3k. Congo oon tend eal QWAES Tor Cd tone es GWE

[Bie ond sesmen coarse’ oeray(QW=I62SKe15 Pe bed pci, coronaria overlay [QW4625

[Ci necro for toon 37625 Cac ies fr enon W723 (et

ie tea esa 7 Tas

ee ape eae a GT) — aa pen oT | ES ea

Tks wid (QW 180) Facre we (QW-182) Nog Appeal eng ad pees ees Mo

Fue Weise Pow OWGPTOT] CT — Ate Wewsin ine }QWws62e) CT

[Macro cares WTA) NL Apoteble isin (mens —_Nk_X RUA _ Coneviitonvsiy (aR wx

ones Tine

Fete rece SRE ey Company Nadia Group WL, Da

than ati ye Noi pplcabie labora Te Name Na

Lvetinesunewuedty “Haina

‘Werf teats TT THAT HST CDN TS TT TOT Tw TRS

Section SME Ce

Vest Comgucted! by (Madina) Fest Winessed &Ce by ETP Cet) Authorised Inspector (A) 1

[Eee [mains Group Watt Dane Cig —_| fore |

sew a fee ee :

fe arte ae = |

a Whew ea

Das könnte Ihnen auch gefallen

- Kurma Rao Saini - CVDokument1 SeiteKurma Rao Saini - CVAnonymous AdofXEYAgENoch keine Bewertungen

- Intro FormDokument2 SeitenIntro FormAnonymous AdofXEYAgENoch keine Bewertungen

- Kurma Rao Saini - Introduction Form040Dokument2 SeitenKurma Rao Saini - Introduction Form040Anonymous AdofXEYAgENoch keine Bewertungen

- Kurma Rao Saini - CVDokument1 SeiteKurma Rao Saini - CVAnonymous AdofXEYAgENoch keine Bewertungen

- Vantakula Rambabu-Experience CertificatesDokument10 SeitenVantakula Rambabu-Experience CertificatesAnonymous AdofXEYAgENoch keine Bewertungen

- Receipt Report IE-2485530Dokument1 SeiteReceipt Report IE-2485530Anonymous AdofXEYAgENoch keine Bewertungen

- JD FormDokument1 SeiteJD FormAnonymous AdofXEYAgENoch keine Bewertungen

- JD FormDokument1 SeiteJD FormAnonymous AdofXEYAgENoch keine Bewertungen

- JD FormDokument1 SeiteJD FormAnonymous AdofXEYAgENoch keine Bewertungen

- 7.interview PersonalDokument1 Seite7.interview PersonalAnonymous AdofXEYAgENoch keine Bewertungen

- Vantakula Rambabu-Resume PDFDokument1 SeiteVantakula Rambabu-Resume PDFAnonymous AdofXEYAgENoch keine Bewertungen

- Mohammad Mukhtar Ali-CvDokument15 SeitenMohammad Mukhtar Ali-CvAnonymous AdofXEYAgENoch keine Bewertungen

- Pradhan Bhagirathi CVDokument1 SeitePradhan Bhagirathi CVAnonymous AdofXEYAgENoch keine Bewertungen

- Behra Dombo l9997839 CVDokument28 SeitenBehra Dombo l9997839 CVAnonymous AdofXEYAgENoch keine Bewertungen

- Kommuji Eswar A Rao - Intro FormDokument2 SeitenKommuji Eswar A Rao - Intro FormAnonymous AdofXEYAgENoch keine Bewertungen

- Pradhan Bhagirathi - JD Manpower FormDokument1 SeitePradhan Bhagirathi - JD Manpower FormAnonymous AdofXEYAgENoch keine Bewertungen

- Pandi Devaraju Reddy p6303778 CVDokument36 SeitenPandi Devaraju Reddy p6303778 CVAnonymous AdofXEYAgENoch keine Bewertungen

- Bus Service 103Dokument2 SeitenBus Service 103Anonymous AdofXEYAgENoch keine Bewertungen

- Pyarechand Kumar - Qualification Certificate064Dokument1 SeitePyarechand Kumar - Qualification Certificate064Anonymous AdofXEYAgENoch keine Bewertungen

- Rabindra Nayak - Qualification Certificate025Dokument6 SeitenRabindra Nayak - Qualification Certificate025Anonymous AdofXEYAgENoch keine Bewertungen

- Department of Clinical Biochemistry Liver Function TestDokument1 SeiteDepartment of Clinical Biochemistry Liver Function TestAnonymous AdofXEYAgENoch keine Bewertungen

- 1144 TWI Diploma in Welding Engineering July 2012 PDFDokument1 Seite1144 TWI Diploma in Welding Engineering July 2012 PDFdaimaheshNoch keine Bewertungen

- Transcript of Marks: Name: Date of BirthDokument2 SeitenTranscript of Marks: Name: Date of BirthAnonymous AdofXEYAgENoch keine Bewertungen

- Agent Profile SheetDokument1 SeiteAgent Profile SheetAnonymous AdofXEYAgENoch keine Bewertungen

- Agent Application FormDokument1 SeiteAgent Application FormAnonymous AdofXEYAgENoch keine Bewertungen

- Curriculum Vitae HariprasadDokument2 SeitenCurriculum Vitae HariprasadAnonymous AdofXEYAgENoch keine Bewertungen

- String Weave and Heat InputDokument4 SeitenString Weave and Heat InputAnonymous AdofXEYAgENoch keine Bewertungen

- Transcript of Mark List: Harish RDokument2 SeitenTranscript of Mark List: Harish RAnonymous AdofXEYAgENoch keine Bewertungen

- BPVC-IX-Interp Stnd-63 2015 Jan PDFDokument6 SeitenBPVC-IX-Interp Stnd-63 2015 Jan PDFAnonymous AdofXEYAgENoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)