Beruflich Dokumente

Kultur Dokumente

Recommended Actions: Transmission or Engine Accessories (If Applicable)

Hochgeladen von

sjsshipOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Recommended Actions: Transmission or Engine Accessories (If Applicable)

Hochgeladen von

sjsshipCopyright:

Verfügbare Formate

RENR5622 51

Troubleshooting Section

Transmission or Engine Accessories (if • Oil level

applicable)

• Engine oil cooler

1. If the engine’s application has a transmission

neutral switch, test the operation of the • Turbocharger

transmission neutral switch. Ensure that the

machine is in neutral gear before attempting to • Valve guides

start the engine.

• Piston rings

2. Ensure free movement of the driveline.

• Incorrect installation of the compression ring and/or

3. Ensure that the timing pin was not left in the the intermediate ring

flywheel housing.

Recommended Actions

4. Remove any engine accessories that may lock up

the engine and inspect any engine accessories

Oil Leaks

that may lock up the engine.

Locate all oil leaks. Repair the oil leaks. Check for

The following list illustrates examples of engine

dirty crankcase breathers.

accessories that may lock up the engine:

• Hydraulic pump that is driven from the rear gear Oil Level

group

Inspect the engine oil level. Remove any extra oil

• Air compressor from the engine. Recheck all fluid levels.

• Engine oil pump Engine Oil Cooler

• Other components that are driven by the engine Check for leaks in the engine oil cooler. Check for oil

in the engine coolant. If necessary, repair the engine

Hydraulic Cylinder Lock oil cooler.

Check for fluid in the cylinders (hydraulic cylinder Turbocharger

lock) by removing the individual unit injectors.

Check the air inlet manifold for oil. Check for oil

Note: Drain the fuel from the cylinder head. Fuel will leakage past the seal rings in the impeller end of

flow from the cylinder head into the cylinders when the turbocharger shaft. If necessary, repair the

the unit injector is removed. turbocharger.

Internal Engine Problem Valve Guides

Disassemble the engine. Refer to the Disassembly If the valve guides are worn, reconditioning of the

and Assembly manual. Inspect the internal cylinder head is required.

components for the following conditions:

Piston Rings

• Seizure

Inspect the internal engine components. Replace any

• Broken components worn components.

• Bent components

i02304643

i02304642 Excessive Black Smoke

Excessive Engine Oil SMCS Code: 1000-038; 1901-038

Consumption

Probable Causes

SMCS Code: 1300-038; 1901-038

• Air shutoff (if applicable)

Probable Causes

• Air inlet and exhaust system

• Oil leaks

52 RENR5622

Troubleshooting Section

• Fuel injector Atmospheric Pressure Sensor

• Turbocharger 1. Check the atmospheric pressure sensor for dirt

and/or for debris. Remove the dirt and/or the

• Atmospheric pressure sensor debris. The atmospheric pressure should be

between 50 kPa (7.2 psi) and 100 kPa (14.5 psi).

• “Fuel Position” and/or “FRC Fuel Limit” The atmospheric pressure will vary depending

on your altitude. If there is an active diagnostic

• Flash file code, perform the diagnostic functional test

Troubleshooting, “Engine Sensor Open/Short

• Fuel quality Test”.

• Valve adjustment 2. Verify that the crankshaft and the camshaft drive

gears are set with the proper orientation. Refer to

the Disassembly and Assembly manual.

Recommended Actions

Air Shutoff (if applicable) Turbocharger Compressor Outlet

Pressure Sensor, “Fuel Position”, and/or

Check that both the air shutoffs are open. “FRC Fuel Limit”

Air Inlet and Exhaust System 1. Monitor the status of “Fuel Position” and “Rated

Fuel Limit” while the engine is operating under full

1. Check the air inlet system for restrictions and/or load. If “Fuel Position” equals “Rated Fuel Limit”

for leaks. and “Fuel Position” is less than “FRC Fuel Limit”,

the electronics are operating correctly. Otherwise,

a. Check for an air filter restriction. proceed to the next Step.

b. Check for derates and for alarms. 2. Verify that there are no active diagnostic codes

for the turbocharger compressor outlet pressure

c. Perform a visual inspection of the system for sensor.

restrictions and/or for leaks.

3. Monitor the status of “Turbocharger compressor

2. Check the exhaust system for restrictions. outlet pressure” and “Atmospheric Pressure” for

normal operation on the Caterpillar Electronic

3. Repair any leaks that were found. Remove Technician (ET). When the engine is not running,

any restrictions that were found. Replace any “Turbocharger compressor outlet pressure” should

damaged components that were found. be 0 kPa (0 psi).

Note: A problem with the FRC will only cause black

Fuel Injector

smoke during acceleration. A problem with the FRC

Check that the injector trim codes have been entered. will not cause black smoke during steady state

operation.

Perform the “Cylinder Cutout Test”. Use similar

conditions for the test that were experienced during

operation. Refer to the diagnostic functional test Flash File

Troubleshooting, “Injector Solenoids”.

Verify that the correct flash file is installed. Refer

Turbocharger to Troubleshooting, “Flash Programming” for more

information.

Verify that the turbocharger has not failed. Periodic

inspection and cleaning is recommended for the Fuel Quality

turbocharger compressor housing (inlet side).

Cold weather adversely affects the characteristics of

the fuel. Refer to Operation and Maintenance Manual

for information on improving the characteristics of the

fuel during cold weather operation.

RENR5622 53

Troubleshooting Section

Valve Adjustment 2. Compare the coolant temperature from Cat ET to

the coolant temperature that is obtained from the

Check the valve adjustment. Refer to the Systems 6V-9130 Temperature Adapter (MULTIMETER).

Operation/Testing and Adjusting manual for more

information. Water Temperature Regulators

i02421039

Check the water temperature regulators for correct

operation. Verify that the engine reaches full

Excessive White Smoke operating temperature. If the engine does not reach

full operating temperature, a water temperature

SMCS Code: 1000-038; 1901-038 regulator may be stuck open. Remove the water

temperature regulator and inspect the water

Note: Some white smoke may be present during temperature regulator. If necessary, repair the

cold start-up conditions when the engine is operating water temperature regulator and/or replace the

normally. If the white smoke persists, there may be coolant temperature regulator. Refer to the Systems

a problem. Operation/Testing and Adjusting manual for the

proper procedure.

Probable Causes

Engine Speed/Timing

• Starting aids (if applicable)

Check the calibration of the engine speed/timing

• Coolant temperature sensor sensor. Refer to Troubleshooting, “Engine

Speed/Timing Sensor - Calibrate”.

• Water temperature regulators

Unit Injectors

• Engine speed/timing sensor

Perform the “Cylinder Cutout Test” on Cat ET in order

• Unit injectors to try to isolate any injectors that might be misfiring.

Refer to Troubleshooting, “Injector Solenoids”.

• Flash file

Flash File

• Fuel supply

Verify that the correct flash file is installed.

• Component wear

Fuel Supply

• Cooling system

1. Inspect the fuel system components.

Recommended Actions

2. Check the fuel pressure during engine cranking.

Starting Aids (if applicable) Check the filtered fuel pressure. Refer to the

Systems Operation/Testing and Adjusting manual

1. If equipped, check for proper operation of installed for the correct pressure values. If the fuel pressure

starting aids. is low, replace the fuel filters. If the fuel pressure

is still low, check the following items: fuel transfer

a. Ensure that the ether canister is not empty pump, fuel transfer pump coupling, and fuel

and/or low. Replace the ether canister if the pressure regulating valve.

ether canister is empty and/or low.

3. Check the fuel quality. Low cetane fuel can create

b. Actuate the system manually after start-up white smoke. If necessary, replace the fuel with a

and observe results. The ether system will higher cetane fuel.

not operate if the coolant temperature is too

high. Refer to the diagnostic functional test 4. Cold weather adversely affects the characteristics

Troubleshooting, “Ether Injection System”. of the fuel. Refer to the Operation and

Maintenance Manual for information on improving

the characteristics of the fuel during cold weather

Coolant Temperature Sensor

operation.

1. Use the Caterpillar Electronic Technician (ET) to

verify that the engine has exited cold mode.

Das könnte Ihnen auch gefallen

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsVon Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsBewertung: 1 von 5 Sternen1/5 (1)

- General InformationDokument111 SeitenGeneral Informationkhaledserag23Noch keine Bewertungen

- Sec 15C (4HL1)Dokument9 SeitenSec 15C (4HL1)Susilo purwanggiNoch keine Bewertungen

- Engine Repair 2Dokument104 SeitenEngine Repair 2mohamed A.abdeltwabNoch keine Bewertungen

- Maintenance Program For HFO Diesel EngineDokument11 SeitenMaintenance Program For HFO Diesel EngineUmit CengNoch keine Bewertungen

- Acceleration Is Poor or Throttle Response Is PoorDokument5 SeitenAcceleration Is Poor or Throttle Response Is PoorNay SoeNoch keine Bewertungen

- TMP XAPRtLDokument17 SeitenTMP XAPRtLengmohsen.ramadanhotmail.comNoch keine Bewertungen

- Engine Compartment: Section 2Dokument8 SeitenEngine Compartment: Section 2Juan Alfonso Romero HaroNoch keine Bewertungen

- Gasoline Engine Owners Maunal For H2I2Dokument16 SeitenGasoline Engine Owners Maunal For H2I2antNoch keine Bewertungen

- Wartsila - 18V34SG Maintenance ScheduleDokument8 SeitenWartsila - 18V34SG Maintenance ScheduleironiteNoch keine Bewertungen

- Aveo Sivi Ve Ariza Fabri̇ka Bi̇lgi̇leri̇Dokument8 SeitenAveo Sivi Ve Ariza Fabri̇ka Bi̇lgi̇leri̇Çağrı SivrikayaNoch keine Bewertungen

- Turbocharger Troubleshooting: 1 Compressor SurgingDokument3 SeitenTurbocharger Troubleshooting: 1 Compressor SurgingJatin JainNoch keine Bewertungen

- 31 Series Trouble ShootingDokument4 Seiten31 Series Trouble ShootingrburtonshawNoch keine Bewertungen

- Low Power/Poor or No Response To Throttle Probable Causes: Shutdown SIS Previous ScreenDokument5 SeitenLow Power/Poor or No Response To Throttle Probable Causes: Shutdown SIS Previous ScreenAmir Bambang YudhoyonoNoch keine Bewertungen

- OBDII Overview Drive CycleDokument23 SeitenOBDII Overview Drive CycleTrung Kiên Nguyễn ĐìnhNoch keine Bewertungen

- Chevrolet Captiva Service Manual 00Dokument19 SeitenChevrolet Captiva Service Manual 00krisdiarto@gmail.com100% (2)

- Description: Engine Lubrication System Description - Hydraulic CircuitDokument11 SeitenDescription: Engine Lubrication System Description - Hydraulic CircuitkavindaNoch keine Bewertungen

- 15C (4JA1) enDokument5 Seiten15C (4JA1) enARIF RACHMANNoch keine Bewertungen

- Hyundai Exel 89 1.5l.mantenimientoDokument18 SeitenHyundai Exel 89 1.5l.mantenimientoAlexander cesar neyra sotoNoch keine Bewertungen

- 2.introduction of Accent EngineDokument22 Seiten2.introduction of Accent EngineMusa TandiarrangNoch keine Bewertungen

- TurbochargerDokument111 SeitenTurbochargerMatthew BennieNoch keine Bewertungen

- Mooney M20 100hour PDFDokument2 SeitenMooney M20 100hour PDFsplyn100% (1)

- Maintenance Instruction V03Dokument18 SeitenMaintenance Instruction V03Farooq AhmadNoch keine Bewertungen

- Preventive Maintenance Check ListDokument23 SeitenPreventive Maintenance Check Listindrabhansingh22443Noch keine Bewertungen

- Eue-Lab Final See2Dokument29 SeitenEue-Lab Final See2Harsha SamagaraNoch keine Bewertungen

- Fluid Pump Maintenance ProcedureDokument8 SeitenFluid Pump Maintenance ProcedureTrue StoryNoch keine Bewertungen

- Maint Sched W32Dokument9 SeitenMaint Sched W32enzobvNoch keine Bewertungen

- Ariel Atom Reference Material - 2017Dokument9 SeitenAriel Atom Reference Material - 2017andre.anibal.neiraNoch keine Bewertungen

- Troble Shoting ComainrilDokument68 SeitenTroble Shoting ComainrilJajle Rooster FramNoch keine Bewertungen

- Unit Iv Classification of Jet Engine ComponentsDokument81 SeitenUnit Iv Classification of Jet Engine Componentsraj6062Noch keine Bewertungen

- 04 W34DF 20210809 enDokument14 Seiten04 W34DF 20210809 enSalman KapoorNoch keine Bewertungen

- Wärtsilä 32 Engine Instruction Manual 04. Maintenance ScheduleDokument12 SeitenWärtsilä 32 Engine Instruction Manual 04. Maintenance ScheduleSalman Kapoor100% (1)

- Important Question For AEMRDokument4 SeitenImportant Question For AEMRNambi RajanNoch keine Bewertungen

- Engine Misfires, Runs Rough or Is Unstable: TroubleshootingDokument4 SeitenEngine Misfires, Runs Rough or Is Unstable: Troubleshootingnay hlaing SoeNoch keine Bewertungen

- Generator PM SOWsbsDokument1 SeiteGenerator PM SOWsbsVinay ThakurNoch keine Bewertungen

- 2500 HD 2014 5.7LDokument287 Seiten2500 HD 2014 5.7LJuan PerezNoch keine Bewertungen

- Grand Cherokee 2008 5.7LDokument254 SeitenGrand Cherokee 2008 5.7LlefontNoch keine Bewertungen

- AIB XRHS 836 CD ENDokument27 SeitenAIB XRHS 836 CD ENcristianrblr100% (1)

- TA2 950G Wheel Loader AYLDokument21 SeitenTA2 950G Wheel Loader AYLMekanik Alat Berat100% (2)

- Engine Cranks But Not StartDokument4 SeitenEngine Cranks But Not StartAntonio MejicanosNoch keine Bewertungen

- 303-00 Diagnosis and TestingDokument10 Seiten303-00 Diagnosis and TestingFerhan SerdarogluNoch keine Bewertungen

- V40232 Clark C270 Torque ConverterDokument44 SeitenV40232 Clark C270 Torque ConverterRemHenry100% (4)

- Monthly PM - EDGDokument3 SeitenMonthly PM - EDGMuhammad RosihanNoch keine Bewertungen

- Nissan - H20 II Operation - ManualDokument48 SeitenNissan - H20 II Operation - ManualStephen Rivett86% (7)

- 2016 Grand Cherokee - 3.0L TURBO DIESEL PDFDokument665 Seiten2016 Grand Cherokee - 3.0L TURBO DIESEL PDFprueba2Noch keine Bewertungen

- Engine Systems SpecificationDokument10 SeitenEngine Systems SpecificationAroonBhagwandinNoch keine Bewertungen

- Milton Cat Preventive Maintenance PM 1 and PM 2 Marketing PieceDokument2 SeitenMilton Cat Preventive Maintenance PM 1 and PM 2 Marketing PieceEdwin AlexNoch keine Bewertungen

- Owner's Manual: Gasoline EngineDokument41 SeitenOwner's Manual: Gasoline EngineKidus GetachewNoch keine Bewertungen

- Can Not Reach Top Engine RPM: Diagnostic CodesDokument4 SeitenCan Not Reach Top Engine RPM: Diagnostic CodesAmir Bambang YudhoyonoNoch keine Bewertungen

- Kubota BX 2200 Operators ManualDokument64 SeitenKubota BX 2200 Operators ManualMark Dubravec63% (16)

- Chapter 4 Part C:: Fuel and Exhaust Systems - K-Jetronic Fuel Injection - 16 Valve EnginesDokument6 SeitenChapter 4 Part C:: Fuel and Exhaust Systems - K-Jetronic Fuel Injection - 16 Valve EnginesmohhizbarNoch keine Bewertungen

- 1kz-Te Turbocharger PDFDokument18 Seiten1kz-Te Turbocharger PDFwill meridithNoch keine Bewertungen

- Rexton Y200Dokument1.627 SeitenRexton Y200Xuân Hùng NguyễnNoch keine Bewertungen

- General Information: Section 0BDokument3.772 SeitenGeneral Information: Section 0BLeandro Lcar AutomotivoNoch keine Bewertungen

- Watchkeeping and TroubleshootingDokument16 SeitenWatchkeeping and TroubleshootingAditya JoglekarNoch keine Bewertungen

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0011Dokument4 SeitenA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0011PeterNoch keine Bewertungen

- Odes 800cc1000cc - WorkshopDokument131 SeitenOdes 800cc1000cc - WorkshopIvan RochfordNoch keine Bewertungen

- Gasoline Engine 160F-190F G120F-G420F - ManualDokument40 SeitenGasoline Engine 160F-190F G120F-G420F - ManualConstantinNoch keine Bewertungen

- MFM Consolidated Preventive Maintenance Ver 2 - 3132017Dokument201 SeitenMFM Consolidated Preventive Maintenance Ver 2 - 3132017Paul CansinoNoch keine Bewertungen

- 3541RL 3541RL: Service Manual Service ManualDokument18 Seiten3541RL 3541RL: Service Manual Service Manualyousef ALadwanNoch keine Bewertungen

- Boiler Low Level Control Electrical DrawingDokument1 SeiteBoiler Low Level Control Electrical DrawingsjsshipNoch keine Bewertungen

- Clue Map For Egg HiderDokument2 SeitenClue Map For Egg HidersjsshipNoch keine Bewertungen

- Norme Istallaz. Serie DLX 03-04Dokument1 SeiteNorme Istallaz. Serie DLX 03-04sjsshipNoch keine Bewertungen

- D48877F DEIF Control PanelDokument1 SeiteD48877F DEIF Control PanelsjsshipNoch keine Bewertungen

- Backhoe Range: For Tractors From 15HPDokument8 SeitenBackhoe Range: For Tractors From 15HPsjsshipNoch keine Bewertungen

- 1000 Ideas About Easter Riddles On Pinterest Scavenger HuntDokument1 Seite1000 Ideas About Easter Riddles On Pinterest Scavenger HuntsjsshipNoch keine Bewertungen

- UT-Vessel GH SpecificationDokument3 SeitenUT-Vessel GH SpecificationsjsshipNoch keine Bewertungen

- MOSS-Vessel GH SpecificationDokument3 SeitenMOSS-Vessel GH SpecificationsjsshipNoch keine Bewertungen

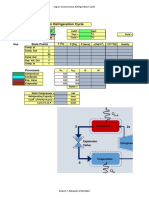

- Vapor Compression Refrigeration Cycle: State PointsDokument6 SeitenVapor Compression Refrigeration Cycle: State PointssjsshipNoch keine Bewertungen

- R134aaa PDFDokument5 SeitenR134aaa PDFsjsshipNoch keine Bewertungen

- Hiller Plant InstructableDokument5 SeitenHiller Plant InstructablesjsshipNoch keine Bewertungen

- Term Time For SkoolsDokument6 SeitenTerm Time For SkoolssjsshipNoch keine Bewertungen

- Frequently Asked Questions: " (Type Subject of Faqs) " Rulefinder User GuideDokument1 SeiteFrequently Asked Questions: " (Type Subject of Faqs) " Rulefinder User GuidesjsshipNoch keine Bewertungen

- Buddy Arc200: 200 Amp Stick / Live TIG WelderDokument2 SeitenBuddy Arc200: 200 Amp Stick / Live TIG WeldersjsshipNoch keine Bewertungen

- Recharge FeonDokument8 SeitenRecharge FeonsjsshipNoch keine Bewertungen

- Adverse Childhood Experiences (Aces) : Underpinning TheoryDokument4 SeitenAdverse Childhood Experiences (Aces) : Underpinning TheorysjsshipNoch keine Bewertungen

- Coliform BacteriaDokument4 SeitenColiform BacteriasjsshipNoch keine Bewertungen

- Anode Current SettingsDokument1 SeiteAnode Current SettingssjsshipNoch keine Bewertungen

- SeturiStantecuActionareManuala Greenlee-GERKONELECTRO PDFDokument18 SeitenSeturiStantecuActionareManuala Greenlee-GERKONELECTRO PDFFlorin FlorinNoch keine Bewertungen

- South Region Breakdown ReportDokument156 SeitenSouth Region Breakdown ReportTruck TrailerNoch keine Bewertungen

- CTE Z20E Ops ManualDokument69 SeitenCTE Z20E Ops ManualTanveer Sarang100% (1)

- EP 8 CPC (Q) D15 18T8 Parts Manual 201908 20190809 172515Dokument106 SeitenEP 8 CPC (Q) D15 18T8 Parts Manual 201908 20190809 172515Виталий ЧерновNoch keine Bewertungen

- Hydraulic Ratchet and Clutch ControlDokument4 SeitenHydraulic Ratchet and Clutch ControlPremragunathan D (Instrumentation)100% (1)

- Install Manual For PEP50 PDFDokument44 SeitenInstall Manual For PEP50 PDFRafael Sotelo BNoch keine Bewertungen

- Ervice AND Arts Anual: Elmhults Konstruktions AbDokument63 SeitenErvice AND Arts Anual: Elmhults Konstruktions AbMelanie GerdesNoch keine Bewertungen

- Tfe Module 3Dokument14 SeitenTfe Module 3Anandhu ANoch keine Bewertungen

- Transeals Identifying Hydraulic SealsDokument28 SeitenTranseals Identifying Hydraulic Sealsvikram_007Noch keine Bewertungen

- Zyc120bs GB1Dokument32 SeitenZyc120bs GB1Mel ErphandNoch keine Bewertungen

- Hydraulic Pipe Bending MachineDokument19 SeitenHydraulic Pipe Bending MachineViraj Phalke75% (8)

- Introduction and Customer Information: Left Side View of John Deere 250D and 300D Dump Truck (Manufactured 2002-)Dokument470 SeitenIntroduction and Customer Information: Left Side View of John Deere 250D and 300D Dump Truck (Manufactured 2002-)Juan Carlos Cruz Rodriguez100% (1)

- Remove BushingDokument17 SeitenRemove BushingarfanilyasNoch keine Bewertungen

- Regenerative Shock AbsorbersDokument34 SeitenRegenerative Shock AbsorbersAswin Varghese TharakanNoch keine Bewertungen

- 10 Series Air Operated Liquid Pumps: P U M P SDokument24 Seiten10 Series Air Operated Liquid Pumps: P U M P SDjeisonSeccoNoch keine Bewertungen

- 302 DMR HydraulicSealsCatalogue U CupsDokument28 Seiten302 DMR HydraulicSealsCatalogue U CupsGustavo OliveiraNoch keine Bewertungen

- Hydraulic Cylinder For Use WTH:-HVL, HPS, HLS, HSS, Has, HHS, HHR, Hda & HgsDokument8 SeitenHydraulic Cylinder For Use WTH:-HVL, HPS, HLS, HSS, Has, HHS, HHR, Hda & HgsKundan Kumar MishraNoch keine Bewertungen

- Hydraulic Rock Drill HL 700, HL 710, HL 700 S, HL 710 S Lifting InstructionsDokument75 SeitenHydraulic Rock Drill HL 700, HL 710, HL 700 S, HL 710 S Lifting Instructionsandrei_rh10100% (3)

- High Performance Swing Velocity Tracking Control of Hydraulic ExcavatorsDokument6 SeitenHigh Performance Swing Velocity Tracking Control of Hydraulic ExcavatorsJack SonNoch keine Bewertungen

- Fig. 2.1: Bending TerminologyDokument6 SeitenFig. 2.1: Bending TerminologyeshwariNoch keine Bewertungen

- Design Guide On Hydraulic CylindersDokument20 SeitenDesign Guide On Hydraulic Cylindersvinod ybNoch keine Bewertungen

- ECT Symons 7s For SaleDokument2 SeitenECT Symons 7s For SaleOrlando MelipillanNoch keine Bewertungen

- Greenfield Jack Manual MA-114 01Dokument96 SeitenGreenfield Jack Manual MA-114 01fred simmonsNoch keine Bewertungen

- Unit-I Aircraft Systems (Hydraulic System)Dokument70 SeitenUnit-I Aircraft Systems (Hydraulic System)Ram Kumar100% (1)

- O4 - FCO200-00-H - REV 02Dokument23 SeitenO4 - FCO200-00-H - REV 02ROBERT ERNESTO RUPPRECHT LAREZNoch keine Bewertungen

- Report Minipro Ese644 Final DraftDokument19 SeitenReport Minipro Ese644 Final DraftROHIDAHNoch keine Bewertungen

- How Do Elevators Work and StuffDokument11 SeitenHow Do Elevators Work and StuffLópez JovannyNoch keine Bewertungen

- Spare Parts List E3325338891: Roll Clamp Roll ClampDokument13 SeitenSpare Parts List E3325338891: Roll Clamp Roll ClampDmitriy100% (1)

- 30103Dokument144 Seiten30103Leobardo Genaro Roque NájeraNoch keine Bewertungen

- Chapter 5 Present E PDFDokument33 SeitenChapter 5 Present E PDFHabtamu GeremewNoch keine Bewertungen

- Automotive Wiring and Electrical SystemsVon EverandAutomotive Wiring and Electrical SystemsBewertung: 4.5 von 5 Sternen4.5/5 (3)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerVon EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerBewertung: 4.5 von 5 Sternen4.5/5 (54)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterVon EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNoch keine Bewertungen

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestVon EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestBewertung: 4 von 5 Sternen4/5 (28)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialVon EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNoch keine Bewertungen

- ANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionVon EverandANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionNoch keine Bewertungen

- Electric Motor Control: DC, AC, and BLDC MotorsVon EverandElectric Motor Control: DC, AC, and BLDC MotorsBewertung: 4.5 von 5 Sternen4.5/5 (19)

- Powder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsVon EverandPowder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsBewertung: 4.5 von 5 Sternen4.5/5 (17)

- How to Fabricate Automotive Fiberglass & Carbon Fiber PartsVon EverandHow to Fabricate Automotive Fiberglass & Carbon Fiber PartsBewertung: 5 von 5 Sternen5/5 (4)

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsVon EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsNoch keine Bewertungen

- Shorting the Grid: The Hidden Fragility of Our Electric GridVon EverandShorting the Grid: The Hidden Fragility of Our Electric GridBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Electric Motors and Drives: Fundamentals, Types and ApplicationsVon EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsBewertung: 4.5 von 5 Sternen4.5/5 (12)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentVon EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentBewertung: 4.5 von 5 Sternen4.5/5 (21)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyVon EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyBewertung: 5 von 5 Sternen5/5 (1)

- CDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionVon EverandCDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionBewertung: 5 von 5 Sternen5/5 (2)

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingVon EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingBewertung: 4.5 von 5 Sternen4.5/5 (9)

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingVon EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingNoch keine Bewertungen

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionBewertung: 5 von 5 Sternen5/5 (1)

- Data Acquisition from HD Vehicles Using J1939 CAN BusVon EverandData Acquisition from HD Vehicles Using J1939 CAN BusNoch keine Bewertungen

- Automotive Electronic Diagnostics (Course 1)Von EverandAutomotive Electronic Diagnostics (Course 1)Bewertung: 5 von 5 Sternen5/5 (6)

- Why We Drive: Toward a Philosophy of the Open RoadVon EverandWhy We Drive: Toward a Philosophy of the Open RoadBewertung: 4.5 von 5 Sternen4.5/5 (21)

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceVon EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceNoch keine Bewertungen

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsVon EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNoch keine Bewertungen

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesVon EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesBewertung: 4.5 von 5 Sternen4.5/5 (21)