Beruflich Dokumente

Kultur Dokumente

Melt Flow Index Tester MFI-100

Hochgeladen von

AamirMalikOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Melt Flow Index Tester MFI-100

Hochgeladen von

AamirMalikCopyright:

Verfügbare Formate

MELT FLOW INDEXER MFI-100

Basic Extrusion Plastometer for determining the melt flow index in thermoplastic materials (Gravimetric Method)

According to the standards: ASTM D1238 Method A - ISO 1133 ...

The determination of the MFI is essential for the characterization of thermoplastic materials and if required reliability on accuracy and

repeatability. Also, this tester is very effective in quality control and research and development

MFI-100 Standard model (need to weigh in the balance Precision extruded material back to calculate the melt flow index.

GRAVIMETRIC method

Low cost

Automatic Sample Cutting

Robust design with high rigidity

PID temperature controller (maintain +/- 0.1 ° C)

Time programmer and number of cutting cycles

Equipment ready to work with corrosive materials such as PVC

MFI-100 is designed specifically for use in the Quality Control Department as a quick and easy Melt Flow Indexer for thermoplastic

materials according to the “A” Method of the international standards of MFI - ASTM D 1238 and ISO 1133 A method.

TECHLAB SYSTEMS, S.L.

Head Office: Txatxamendi 10, Pol. 110 – 20100 Lezo – SPAIN

US Office: 1549 Ardmore Ave. –Itasca, Illinois 60143 USA

www.techlabsystems.com 1

MELT FLOW EXTRUSION PLASTOMETER MFI-100

To test Manual (Method A - Gravimetric)

q Standard equipment includes all the tools of labor-cleaning piston and standard Die.

q Standard Temperatures range up to + 325 ° C (*) with a resolution of 0.1 ° C

q Digital Timer: with a range of up to 9999 seconds

q Automatic sample Cutting

q 7 Weights and polished chromed included in the standard delivery:

1.2 kg - 2.16 kg - 3.8 kg - 5 kg - 5 kg - 6.6 and 10 Kg

* The weight of 21.6 kg is achieved by combining the weights of 5 kg, 6.6 kg and 10 kg

Recommended equipment required: Precision Balance with resolution of 0.001 g

The fluency of the polymer is a function of:

• Pressure used (weight of the piston)

• Diameter of Die

• Viscosity of the material

This index is of vital importance to those who make injection molding, extrusion, rotational molding or other manufacturing process

involving a thermoplastic part.

Beginning

The melt index measurement is performed by a meter Flow Index, which operates with a constant pressure exerted by a constant

force due to a known weight into a capillary tube whose area remains constant. ASTM-D1238 is commonly used to perform this

operation

The melt flow index (MFI) is a measure of the flowability of the resin under controlled conditions and can be easily measured with

equipment called plastometer, using very low strain rates, a temperature of 230 ° C and weighing 2.16 kg according to ASTM D 1238.

This variable is inversely related to the viscosity and molecular weight (MW), that is, with increasing the melt index of the resin, a

decrease is obtained in viscosity and molecular weight.

TECHLAB SYSTEMS, S.L.

Head Office: Txatxamendi 10, Pol. 110 – 20100 Lezo – SPAIN

US Office: 1549 Ardmore Ave. –Itasca, Illinois 60143 USA

www.techlabsystems.com 2

MELT FLOW EXTRUSION PLASTOMETER MFI-100

Accessories included in the standard delivery: Tungsten

Carbide die of 2,095 mm Ø, Piston, putty knife to take samples,

Spanner, bar to introduce samples into the heating barrel,

Material charger, funnel, cleaner of the heating barrel, scissors,

cleaner of the die.

q The standard supply includes 7 Weights, chrome and polished:

1,2 Kg - 2,16 Kg - 3,8 Kg - 5 Kg - 5 Kg - 6,6 y 10 Kg

* The 21,6 kg weight is the combination of the 5 kg, 6,6 kg y 10 kg weights

OPTIONAL: For weighing the extruded samples we recommend using a

Precision Scale:

Capacity 210 g - Resolution 1 mg

Auto Cutting System

Included in standard supply

POWER SUPPLY: DELIVERY CONTENT:

Electrical: 230 V, 50/60 Hz > Melt Flow Indexer MFI-100

> Working and Cleaning Tools

> Piston

> Standard Die of 2,095 mm Ø of Tungsten Carbide

WEIGHT AND DIMENSIONS: > Set of 7 Weights (1,2 - 2,16 - 3,8 - 5 - 5 – 6 & 10 Kg)

Dimensions:

Equipment: 560 x 560 x 600 mm (W x D x H)

Transport Box 1: 750 x 750 x 700 mm (W x D x H)

Transport Box 2: 480 x 460 x 380 mm (W x D x H) (weights & accessories)

Net/Gross: 70 Kg / 125 Kg

* TECHLAB SYSTEMS, S.L. reserve the chance of modify the technical information without previous Doc.: MFI100-1-CAT-I-R3

notification

TECHLAB SYSTEMS, S.L.

Head Office: Txatxamendi 10, Pol. 110 – 20100 Lezo – SPAIN

US Office: 1549 Ardmore Ave. –Itasca, Illinois 60143 USA

www.techlabsystems.com 3

Das könnte Ihnen auch gefallen

- Benchtop particle counter 3905 3910 3920 catalogDokument2 SeitenBenchtop particle counter 3905 3910 3920 catalogJunaid JavedNoch keine Bewertungen

- Stb-03 Standard PenetrometerDokument1 SeiteStb-03 Standard PenetrometerSUPERB TECHNoch keine Bewertungen

- The Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsVon EverandThe Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsSylvain ClercNoch keine Bewertungen

- 4640-BDokument2 Seiten4640-Bmaikelga1977Noch keine Bewertungen

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisVon EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisBewertung: 4 von 5 Sternen4/5 (2)

- Quotation No 376 BURSTING STRENGTH TESTER Ozone Overseas PVT LTDDokument8 SeitenQuotation No 376 BURSTING STRENGTH TESTER Ozone Overseas PVT LTDSanjay KumarNoch keine Bewertungen

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesVon EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesBewertung: 5 von 5 Sternen5/5 (1)

- Aczel Balance CY BRDokument6 SeitenAczel Balance CY BRNook SudkhetNoch keine Bewertungen

- OC Sensor Pledia Specifications DocumentDokument2 SeitenOC Sensor Pledia Specifications DocumentLucasNoch keine Bewertungen

- POM Celcon M270Dokument3 SeitenPOM Celcon M270Er Shashi SinghNoch keine Bewertungen

- DMA-80 Testing ProcedureDokument3 SeitenDMA-80 Testing ProcedureOmar Alvarado Cadena0% (1)

- Cot. 400 Triaxial Ciclico 10 KP Geocomp V&V Contratistas Generales Tacna 2015Dokument2 SeitenCot. 400 Triaxial Ciclico 10 KP Geocomp V&V Contratistas Generales Tacna 2015Kevin Calizaya ValdezNoch keine Bewertungen

- Retention MeasurementDokument2 SeitenRetention MeasurementPedro CastroNoch keine Bewertungen

- PP GF50 - Celstran Ticona PP-GF50-0453P10-10Dokument4 SeitenPP GF50 - Celstran Ticona PP-GF50-0453P10-10armandoNoch keine Bewertungen

- AKE-BTU Meter-EMF GSDokument10 SeitenAKE-BTU Meter-EMF GSTrần Lê Trung LanhNoch keine Bewertungen

- List of The Equipments (R)Dokument12 SeitenList of The Equipments (R)Rubel RanaNoch keine Bewertungen

- Multi-Cycle Shut-In Tool: Reservoir MonitoringDokument2 SeitenMulti-Cycle Shut-In Tool: Reservoir MonitoringTheNourEldenNoch keine Bewertungen

- Lampiran SurveyDokument4 SeitenLampiran SurveyRijal PermanaNoch keine Bewertungen

- Microsoft Word - 10002013 - EN MeltindexDokument1 SeiteMicrosoft Word - 10002013 - EN Meltindexchavesierra20081 SierraNoch keine Bewertungen

- PP906-C Product Data SheetDokument2 SeitenPP906-C Product Data SheetAnh MinhNoch keine Bewertungen

- CVC 1103HDokument2 SeitenCVC 1103HAvinash KaleNoch keine Bewertungen

- 9912-2431 A TcehDokument3 Seiten9912-2431 A Tcehalfayha sciNoch keine Bewertungen

- Automatic Potentiometric Titrators: Soft-CapDokument4 SeitenAutomatic Potentiometric Titrators: Soft-CapSur VaniNoch keine Bewertungen

- F0031 Foam Porosity TesterDokument2 SeitenF0031 Foam Porosity TesterMAHESHBHAI PATANVADIANoch keine Bewertungen

- Seta Crude CatalogDokument8 SeitenSeta Crude CatalogAbdul RaheemNoch keine Bewertungen

- Tosilon TUR 200DDokument24 SeitenTosilon TUR 200DDave NakpodiaNoch keine Bewertungen

- 2014 Product Catalog-Rev5Dokument9 Seiten2014 Product Catalog-Rev5Rashed KaiserNoch keine Bewertungen

- Alsonic FXDokument4 SeitenAlsonic FXsyaziqNoch keine Bewertungen

- Dti 600Dokument2 SeitenDti 600UMESH CHAUHANNoch keine Bewertungen

- Sonagage IVDokument2 SeitenSonagage IVRushikesh JoshiNoch keine Bewertungen

- Flyer Segmented Cement BondDokument2 SeitenFlyer Segmented Cement BondarmandoplcNoch keine Bewertungen

- ION-LABXT-DS_063023Dokument2 SeitenION-LABXT-DS_063023nha vũNoch keine Bewertungen

- Technical Data 6000TOCiDokument4 SeitenTechnical Data 6000TOCimaintenanceNoch keine Bewertungen

- KAM Oid™ Optical Interface Detector: User ManualDokument21 SeitenKAM Oid™ Optical Interface Detector: User ManualLITO BABUNoch keine Bewertungen

- AFT800 Series ElectrolytesTCO2 Analyzer User ManualDokument95 SeitenAFT800 Series ElectrolytesTCO2 Analyzer User ManualSIELAB C.A.Noch keine Bewertungen

- PELJ0082 Particle AnalyzerDokument2 SeitenPELJ0082 Particle AnalyzerDAnielNoch keine Bewertungen

- Stackup - CN TDS 1911 03 S1000H S1000HBDokument2 SeitenStackup - CN TDS 1911 03 S1000H S1000HBMuhamad Sayid Akil MhsAkilNoch keine Bewertungen

- Leading water analysis instruments manufacturerDokument1 SeiteLeading water analysis instruments manufacturerEvita RahmawatiNoch keine Bewertungen

- Freezing Point Automatic Tester With Integrated Cooling (Stand-Alone Unit) ASTM D 2386 - IP 16 - ISO 3013 - DIN 51421Dokument1 SeiteFreezing Point Automatic Tester With Integrated Cooling (Stand-Alone Unit) ASTM D 2386 - IP 16 - ISO 3013 - DIN 51421Phu HaoNoch keine Bewertungen

- DH 21Dokument2 SeitenDH 21احمد حمديNoch keine Bewertungen

- IGNITION QUALITY TESTER (LQT™)Dokument2 SeitenIGNITION QUALITY TESTER (LQT™)Nestor MaldonadoNoch keine Bewertungen

- Sonowall 60 Datasheet Ufm 2017Dokument2 SeitenSonowall 60 Datasheet Ufm 2017Diego GamarraNoch keine Bewertungen

- A2006 126 Type 68 Datasheet Issue A Draft 2Dokument3 SeitenA2006 126 Type 68 Datasheet Issue A Draft 2Micah KipropNoch keine Bewertungen

- Bagging System: Chrono-Weigh E 25-G/E 55-G Reliable Net WeighersDokument4 SeitenBagging System: Chrono-Weigh E 25-G/E 55-G Reliable Net WeighersAlderine KuswardhaniNoch keine Bewertungen

- 186 Soldering Flux Data SheetDokument2 Seiten186 Soldering Flux Data SheetBéla BődiNoch keine Bewertungen

- 31. ATKIHC-2020 SETNAGDokument2 Seiten31. ATKIHC-2020 SETNAGcyrano1091Noch keine Bewertungen

- Assignment On Uster Tester 6Dokument4 SeitenAssignment On Uster Tester 6ZAyed100% (1)

- Robotic Tool Changer, QC-110AMDokument6 SeitenRobotic Tool Changer, QC-110AMAmith PrasannaNoch keine Bewertungen

- DT600 User Manua 2014Dokument16 SeitenDT600 User Manua 2014AgisMaulidiNoch keine Bewertungen

- MeasurIT Quadbeam S20 Suspended Solids Sensor 0803Dokument2 SeitenMeasurIT Quadbeam S20 Suspended Solids Sensor 0803cwiejkowskaNoch keine Bewertungen

- M E HYDRAULICS PRIVATE LIMITED-06-feb-23 PDFDokument8 SeitenM E HYDRAULICS PRIVATE LIMITED-06-feb-23 PDFRasheshNoch keine Bewertungen

- BC-AIS Flyer-0217 (1) AustraliaDokument2 SeitenBC-AIS Flyer-0217 (1) AustraliaJose HuescaNoch keine Bewertungen

- GT-KC04B Upper and Vamp Material Cold Flexing TesterDokument2 SeitenGT-KC04B Upper and Vamp Material Cold Flexing Testernishad saifiNoch keine Bewertungen

- DS KF200 V41en 1504 PDFDokument14 SeitenDS KF200 V41en 1504 PDFTruong Tuan AnNoch keine Bewertungen

- II. 8 .2 Alat Laboratorium 2Dokument290 SeitenII. 8 .2 Alat Laboratorium 2085270710307Noch keine Bewertungen

- Carmel1400M-Brochure 09.2261Dokument2 SeitenCarmel1400M-Brochure 09.2261Ragil AjiNoch keine Bewertungen

- Spirapak 4033 HFM 183 VPP Uf DatasheetDokument2 SeitenSpirapak 4033 HFM 183 VPP Uf DatasheetJohnNoch keine Bewertungen

- Brosur WordDokument20 SeitenBrosur Wordu'LuppHa CLluNoch keine Bewertungen

- Batteries Costing 1008Dokument10 SeitenBatteries Costing 1008AamirMalikNoch keine Bewertungen

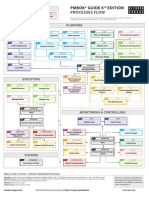

- Pmbok 5 PMDokument2 SeitenPmbok 5 PMtofy79Noch keine Bewertungen

- PMP Memory SheetsDokument6 SeitenPMP Memory SheetsAamirMalik100% (1)

- PMP Formulae & Tips Cheat SheetDokument5 SeitenPMP Formulae & Tips Cheat Sheetbhaveshkumar78100% (8)

- Ricardo Vargas Simplified Pmbok Flow 6ed Color En-A3Dokument1 SeiteRicardo Vargas Simplified Pmbok Flow 6ed Color En-A3Hero Sa Mac100% (1)

- Pmbok 5 PMDokument2 SeitenPmbok 5 PMtofy79Noch keine Bewertungen

- Batteries Costing 1008Dokument10 SeitenBatteries Costing 1008AamirMalikNoch keine Bewertungen

- Project Life Cycle Iterative and Adaptive - Ultimate GuideDokument14 SeitenProject Life Cycle Iterative and Adaptive - Ultimate GuideAamirMalikNoch keine Bewertungen

- Ricardo Vargas Pmbok Flow 6ed Color En-A0Dokument1 SeiteRicardo Vargas Pmbok Flow 6ed Color En-A0murdi.santoso83% (6)

- Power Generation From CoalDokument114 SeitenPower Generation From CoalOral KarahanNoch keine Bewertungen

- This Is Our Selection of The Best Free Practice Questions On The WebDokument1 SeiteThis Is Our Selection of The Best Free Practice Questions On The WebAamirMalikNoch keine Bewertungen

- Operation Aspects & Boiler EmergenciesDokument54 SeitenOperation Aspects & Boiler EmergenciesPravivVivpraNoch keine Bewertungen

- Frank T. Anbari - Q & A's For The PMBOK Guide Third Edition - Project Management Institute (2005)Dokument205 SeitenFrank T. Anbari - Q & A's For The PMBOK Guide Third Edition - Project Management Institute (2005)AamirMalikNoch keine Bewertungen

- Battery Sizing Calculation For Ups Application: Need Constant Power Discharge Characteristics UndersizedDokument2 SeitenBattery Sizing Calculation For Ups Application: Need Constant Power Discharge Characteristics UndersizedAamirMalik100% (3)

- Cleanroom Design in 10 Easy StepsDokument8 SeitenCleanroom Design in 10 Easy StepsAamirMalikNoch keine Bewertungen

- Merv Rating ChartDokument1 SeiteMerv Rating ChartAamirMalikNoch keine Bewertungen

- Cavitation Resistant Materials For Impellers c022-1 - MC Nally InstituteDokument2 SeitenCavitation Resistant Materials For Impellers c022-1 - MC Nally InstituteAamirMalikNoch keine Bewertungen

- 175 PMP Sample QuestionsDokument107 Seiten175 PMP Sample QuestionsAmanda DickersonNoch keine Bewertungen

- Corn-Cob Vs Local CoalDokument1 SeiteCorn-Cob Vs Local CoalAamirMalikNoch keine Bewertungen

- Calculation ProgressDokument1 SeiteCalculation ProgressAamirMalikNoch keine Bewertungen

- Electric Inspector Form-BDokument11 SeitenElectric Inspector Form-BAamirMalikNoch keine Bewertungen

- Biannual Maintenance of CFB BoilerDokument3 SeitenBiannual Maintenance of CFB BoilerAamirMalikNoch keine Bewertungen

- Flow Diagram of Fly Ash Brick PlantDokument1 SeiteFlow Diagram of Fly Ash Brick PlantAamirMalikNoch keine Bewertungen

- Relay Coordination GuidelinesDokument16 SeitenRelay Coordination GuidelinesNitesh Ostwal91% (11)

- Layout DrawingDokument1 SeiteLayout DrawingAamirMalikNoch keine Bewertungen

- On Line Flue Gas Monitoring SystemDokument2 SeitenOn Line Flue Gas Monitoring SystemAamirMalikNoch keine Bewertungen

- FLY ASH The ReportDokument14 SeitenFLY ASH The ReportPKS_20085% (13)

- Peter Brotherhood turbine inventory partsDokument4 SeitenPeter Brotherhood turbine inventory partsAamirMalikNoch keine Bewertungen

- Biannual Maintenance of CFB BoilerDokument3 SeitenBiannual Maintenance of CFB BoilerAamirMalikNoch keine Bewertungen

- Sap ThufingteDokument10 SeitenSap ThufingtehangsinfNoch keine Bewertungen

- Oecumenius’ Exegetical Method in His Commentary on the RevelationDokument10 SeitenOecumenius’ Exegetical Method in His Commentary on the RevelationMichał WojciechowskiNoch keine Bewertungen

- 1.2 - Sewing Machine and Special AttachmentsDokument3 Seiten1.2 - Sewing Machine and Special Attachmentsmaya_muth0% (1)

- Embankment PDFDokument5 SeitenEmbankment PDFTin Win HtutNoch keine Bewertungen

- Analysis and Calculations of The Ground Plane Inductance Associated With A Printed Circuit BoardDokument46 SeitenAnalysis and Calculations of The Ground Plane Inductance Associated With A Printed Circuit BoardAbdel-Rahman SaifedinNoch keine Bewertungen

- Interactive Architecture Adaptive WorldDokument177 SeitenInteractive Architecture Adaptive Worldhoma massihaNoch keine Bewertungen

- Project On Stones & TilesDokument41 SeitenProject On Stones & TilesMegha GolaNoch keine Bewertungen

- Lec9-Rock Cutting ToolsDokument35 SeitenLec9-Rock Cutting ToolsAmraha NoorNoch keine Bewertungen

- Henry Stevens - Hitler's Flying Saucers - A Guide To German Flying Discs of The Second World War New Edition (2013, Adventures Unlimited Press) - Libgen - lc-116-120Dokument5 SeitenHenry Stevens - Hitler's Flying Saucers - A Guide To German Flying Discs of The Second World War New Edition (2013, Adventures Unlimited Press) - Libgen - lc-116-120sejoh34456Noch keine Bewertungen

- Lee Et Al - 2013Dokument9 SeitenLee Et Al - 2013Taka MuraNoch keine Bewertungen

- Tds G. Beslux Komplex Alfa II (25.10.19)Dokument3 SeitenTds G. Beslux Komplex Alfa II (25.10.19)Iulian BarbuNoch keine Bewertungen

- Effect of Some Algal Filtrates and Chemical Inducers On Root-Rot Incidence of Faba BeanDokument7 SeitenEffect of Some Algal Filtrates and Chemical Inducers On Root-Rot Incidence of Faba BeanJuniper PublishersNoch keine Bewertungen

- Air Arms S400 EXPDokument3 SeitenAir Arms S400 EXPapi-3695814Noch keine Bewertungen

- The Apu Trilogy - Robin Wood PDFDokument48 SeitenThe Apu Trilogy - Robin Wood PDFSamkush100% (1)

- Canon imageFORMULA DR-X10CDokument208 SeitenCanon imageFORMULA DR-X10CYury KobzarNoch keine Bewertungen

- 2 - Elements of Interior DesignDokument4 Seiten2 - Elements of Interior DesignYathaarth RastogiNoch keine Bewertungen

- Transport of OxygenDokument13 SeitenTransport of OxygenSiti Nurkhaulah JamaluddinNoch keine Bewertungen

- CIRC 314-AN 178 INP EN EDENPROD 195309 v1Dokument34 SeitenCIRC 314-AN 178 INP EN EDENPROD 195309 v1xloriki_100% (1)

- CAT Ground Engaging ToolsDokument35 SeitenCAT Ground Engaging ToolsJimmy Nuñez VarasNoch keine Bewertungen

- DENSO COMMON RAIL INJECTOR REPAIR GUIDEDokument22 SeitenDENSO COMMON RAIL INJECTOR REPAIR GUIDEMarcoNoch keine Bewertungen

- Daftar Spesifikasi Teknis Pembangunan Gedung Kantor BPN BojonegoroDokument6 SeitenDaftar Spesifikasi Teknis Pembangunan Gedung Kantor BPN BojonegoroIrwin DarmansyahNoch keine Bewertungen

- KINETIC THEORY OF GASES TUTORIALDokument6 SeitenKINETIC THEORY OF GASES TUTORIALMat SyafiqNoch keine Bewertungen

- JUPITER 9000K H1PreliminaryDokument1 SeiteJUPITER 9000K H1PreliminaryMarian FlorescuNoch keine Bewertungen

- Diia Specification: Dali Part 252 - Energy ReportingDokument15 SeitenDiia Specification: Dali Part 252 - Energy Reportingtufta tuftaNoch keine Bewertungen

- Validation Master PlanDokument27 SeitenValidation Master PlanPrashansa Shrestha85% (13)

- Retaining Wall-Masonry Design and Calculation SpreadsheetDokument6 SeitenRetaining Wall-Masonry Design and Calculation SpreadsheetfarrukhNoch keine Bewertungen

- Antonovsky (1979)Dokument280 SeitenAntonovsky (1979)M.Fakhrul Kurnia100% (1)

- Descripcion Unidad 9, Dos CiudadesDokument13 SeitenDescripcion Unidad 9, Dos CiudadesGabriela ValderramaNoch keine Bewertungen

- Naukri LalitaSharma (3y 4m)Dokument2 SeitenNaukri LalitaSharma (3y 4m)rashika asraniNoch keine Bewertungen