Beruflich Dokumente

Kultur Dokumente

United States Patent (19) : Peyman 45 Date of Patent: Aug. 15, 1989

Hochgeladen von

155Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

United States Patent (19) : Peyman 45 Date of Patent: Aug. 15, 1989

Hochgeladen von

155Copyright:

Verfügbare Formate

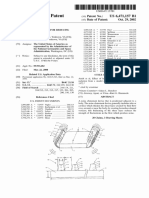

United States Patent (19) 11 Patent Number: 4,856,448

Peyman 45 Date of Patent: Aug. 15, 1989

(54). HARMONICA SAIL OTHER PUBLICATIONS

76 Inventor: R. Allan Peyman, P.O. Box 36, East Bob Ross, "Unfurling the Secret Sail', Sail Magazine,

Alton, Ill. 9/87, pp. 79,80, 82.

(21) Appl. No.: 179,742 Primary Examiner-Sherman D. Basinger

Attorney, Agent, or Firm-Senniger, Powers, Leavitt &

22 Filed: Apr. 11, 1988 Roedel

57 ABSTRACT

(51) Int. Cli. B63H 9/06 A sail for a boat comprising a first panel having a prede

52 U.S. C. .................................................... 114/103 termined draft therein, a second panel having a prede

58 Field of Search ..................... 114/39.1, 39.2, 102,

114/103 termined draft therein, and a plurality of baffles extend

ing between the first and second panels, the first and

56 References Cited second panels being open at the luff an leech edges to

U.S. PATENT DOCUMENTS allow wind to pass therebetween so that the first and

second panels can assume their respective predeter

2,569,318 9/1951 Kersten ............................... 114/103 mined draft shapes. The baffles preferably comprise a

3,053,219 9/1962 Coon ................................... 114/03 plurality of elevationally spaced, generally horizontal

3,298,346 l/1967 Cochran .............................. 114/03 webs extending substantially from the luff edges to the

3,403,653 0/1968 Bush .................................... 114/103 leech edges of the panels. These webs are preferably

4,006,701 2/1977 Corbellini. 14/102 cambered longitudinally in the luff to leach direction,

4,122,792 10/1978 Rhoades et al. . . 114/103

4,558,655 12/1985 Debarge ......... s... 14/39 with the leech end of each web elevationally higher

4,624,203 11/1986 Ferguson ... ... 14/39 than the luff end of the web.

4,677,928 7/1987 Hoyt ....... ... 114/39

4,685,410 8/1987 Fuller .................................. 114/02 17 Claims, 2 Drawing Sheets

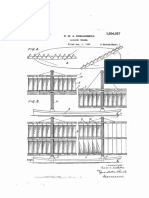

U.S. Patent Aug. 15, 1989 Sheet 1 of 2 4,856,448

U.S. Patent Aug. 15, 1989 Sheet 2 of 2 4,856,448

4,856,448 2

1.

mize sail distortion by optimizing the orientation of the

HARMON CASAL cloth in the sail. Finally there are various finishing pro

cesses that can reduce in-service distortion of the sail.

BACKGROUND OF THE INVENTION

5 SUMMARY OF THE INVENTION

This invention relates to sails, and in particular to a It is among the objects of the present invention to

double panel sail. provide a sail that gives increased sail area for a given

Conventional sails, like those still in use today, typi size. It is a further object of the present invention to

cally comprise a fabric panel which is constructed with provide such a sail that can be used on conventionally

a particular draft-or depth and curvature-so that 10

when properly trimmed it assumes a curved shape with rigged boats, with minimum of modification. It is also

a convex leeward side and a concave windward side. among the objects of the present invention to provide a

The velocity of the air on the convex leeward side of sail that is lightweight, flexible, and easy to handle, but

the sail is generally greater than the velocity of the air which resists distortion from its designed draft shape;

on the concave windward side of the sail. Since pres and to provide such a sail that is of simple and inexpen

sure generally decreases as the velocity increases, the 15 sive construction.

pressure is relatively lower on the leeward side of the Generally, the sail of the present invention comprises

sail than on the windward side of the sail. In addition, a first panel having a predetermined draft therein, a

the wind acts on the windward side of the sail to pro second panel having a predetermined draft therein, and

duce a force on the windward side of the sail. The re a plurality of baffles between the first and second pan

sulting strong relative negative pressure (or suction) on 20 els. The first and second panels are open at their respec

the leeward side of the sail and the moderate positive tive luff and leech edges so that wind can pass between

force on the windward side of the sail produces a thrust the first and second panels causing the panels to assume

on the mast that propels the sail boat. their designed draft configurations, with the spacers

The total driving force on the sail boat is a function of stabilizing each panel with respect to the other to mini

the total sail area. Thus sails are sized and shaped to 25 mize distortion from the predesigned draft. In the pre

maximize sail area, and the boat and rigging are de ferred embodiment the spacers are generally horizontal

signed to permit the use of various types of sails such as webs, extending substantially from luff to leach.

stay sails, jibs, and other filler sails. The height of the When the boat is headed windward, sufficient wind

sails must be limited to prevent excessive heeling of the 30 can pass outside and between the first and second panels

boat and to keep the mast size within practical limits. to cause the panels to assume substantially their prede

Similarly the breadth of the sails must be limited to keep termined draft shaps. Thus the sail of the present inven

the boom and the rigging within practical limits. The tion provides two sail panels in the same space with the

use of stay sails is also limited, particularly in smaller same rigging for a single panel, and without the han

boats, due to the limitations of the rigging and the abil dling problems of separate stay sails. Furthermore the

ity of the crew to handle the additional sails. Space is 35 baffles stabilize each panel with respect to the other,

another limitation on the use of stay sails since it is helping to prevent localized distortions of either panel,

common practice to have several suits of sails for the helping to maintain the designed shape of the panels and

various wind conditions that may be encountered. The thereby maximizing the performance of the panels.

number of these stay sails is compounded by this prac These and other advantages will be in part apparent

tice, presenting a storage and handling problem, partic

ularly on a small boat. and in part pointed out herein after.

The draft of a sail is the source of sail power going BRIEF DESCRIPTION OF THE DRAWINGS

windward. The draft is designed taking into account the FIG. 1 is a side elevation view of a mainsail con

stability of the hull, the intended use of the boat, and the structed according to the principles of this invention;

anticipated wind and sea conditions. The design of the 45 FIG. 2 is a rear or leech elevation view of the sail;

draft also takes into account maximizing boat speed

while minimizing the pointing angle (the angle of the FIG. 3 is a top or head plan view of the sail;

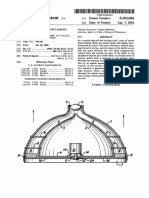

boat with respect to the apparent wind which deter FIG. 4 is a cross sectional view of the sail taken along

mines how efficiently the boat can "beat' or sail into the the plane of line 4-4 in FIG. 1, showing the sail under

wind). The shape of the curvature, including the posi 50 wind loading;

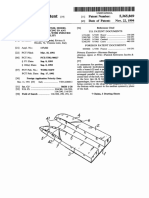

tion of the point of maximum curvature, and the depth FIG. 5 is a partial perspective view of a jib sail con

of curvature (the camber ratio), are designed for the structed according to the principles of this invention,

particular boat. Maintaining this designed draft for the showing one method of securing the clew; and

sail is important to efficient sailing. FIG. 6 is a partial perspective view of a jib sail con

It is difficult to construct the designed sail shape 55 structed according to the principles of this invention,

because the sail materials are lightweight and flexible, showing an alternate method of securing the clew.

and as a consequence tend to stretch. Stiffer, more FIG. 7 is an enlarged view of a sail portion adjacent

stretch-resistant materials tend to have less tear resis the mast.

tance and are also more difficult to handle. A great deal Corresponding references numerals indicate corre

of attention has been devoted to the mechanics of sail sponding parts throughout the several views of the

construction to minimize sail distortion. Careful selec drawings.

tion of the material and the use of composites and multi DETAILED DESCRIPTION OF THE

ply materials is one way of combating stretch. It is also PREFERRED EMBODIMENT

known that cloth stretches differently in different direc

tions, and thus selection of the weave and careful orien 65 A mainsail constructed according to the principles of

tation of the material is another way of controlling sail this invention, indicated generally as 20, is shown in

stretch. Miter cut, radial cut, spider web cut, and star FIG. 1 in an unloaded condition as it might be mounted

cut sail constructions are examples of attempts to mini on the mast 22 and boom 24 of a boat (not shown).

4,856,448 4.

3

Although FIGS. 1-4 show a mainsail, and FIGS. 5 and different weights or grades of the same material, or

6 show a jib sail, the sail construction of the present from segments of material with different orientations.

invention is not so limited, and could be applied to The transverse stretchability of the webs 30 is prefera

virtually any type of sail as would be apparent to a bly greatest between the points of maximum draft cur

person of ordinary skill of the art. 5 vature of the panels and the transverse stretchability

The mainsail 20 comprises a first panel 26 having a diminishes toward the luff and leech edges of the panels.

predetermined draft constructed therein, and a second In this preferred embodiment webs 30 comprise por

panel 28 also having a predetermined draft constructed tions 32, 34, and 36, 38, and 40 located at the luff, luff

therein. The drafts of the first and second panels 26 and sent, center, center leech, and leech regions of the pan

28 are not necessarily identical, although in the pre O els, respectively. For example, the luff and leech por

ferred embodiment the drafts are identical. The first and tions 32 and 40 might be made from a 3 ounce Dacron

second panels 26 and 28 are arranged substantially par (tm) for minimal stretching, while the luff-center and

allel with each other. However, the first and second the center leech portions 34 and 38 might be made of

panels 26 and 28 are not necessarily the same size, and 2ounce Dacron (tm) for somewhat greater stretchabil

thus may not be co-extensive. A plurality of baffles 15 ity, and the center portion might be made from 1 ounce

extend between the panels 26 and 28. In the preferred Dacron (tm) for the greatest stretchability to accommo

embodiment, these baffles are a plurality of generally date the greatest distances between the panels.

horizontal webs 30 extending substantially from the luff The webs 30 are sufficiently flexible to allow the

edges to the leech edges of the panels. relative shifting of the panels when the leeward panel

The inventor has discovered that under at least cer 20 becomes the windward panel and vice versa as the sail

tain conditions it is desirable that the webs 30 have a moves from one side of the boat to the other. Portions

slight camber in the longitudinal or luff-to-leech direc of the webs 30 may be stiffened, for example with bat

tion. It is also desirable that the leech ends of the baffles tells.

be slightly elevationally higher than the luff ends. The The first and second panels 26 and 28 are open at their

inventor has discovered that the cambering of the webs 25 luff and leech edges to allow wind to pass through sail

and the elevating of the leech end of the webs relative to 20, between the panels 26 and 28, so that the panels 26

the luff ends makes it easier to achieve airflow between and 28 can fill with air. As noted above, even if the

the panels and fill the sail as more fully described below. designed drafts of the first and second panels are identi

The term "generally horizontal” as used to describe the cal, the actual shapes of the panels will not be identical

webs 30 herein should therefore be understood to in 30

clude such slight variations from horizontal. because of differences in loading. As described above,

The webs 30 each have first and second side edges the webs 30 preferably stretch to accommodate this

secured to the first and second panels 26 and 28, respec difference in the shapes of the panels, while they stabi

tively. The first edge of each web is preferably con lize each panel with respect to the other. The webs 30

toured to the shape of the first panel 26 along the line of 35 thereby and help to support each panel relative to the

their attachment. Similarly, the second edge of each other so that the panels maintain substantially their

web is preferably coutoured to the shape of the second predetermined draft shapes, and thus sail 20 maintains

panel 28 along the line of their attachment. In the pre its overall designed draft shape. It will be noted from

FIG. 4 that the cross section of sail 20 is more like that

ferred embodiment, when the webs are shaped the of a rigid air foil or wing than a simple sail, and it is

drafts of the two panels are considered to extend oppo believed that this configuration improves performance

sitely, so that the webs have a generally barrel shape, in addition to stabilizing the draft shape of the sail.

with convex side edges. In sailing in one direction the first panel 26 may be the

As will be readily understood by a person of ordinary

skill in the art, even if the panels are formed with identi leeward panel and the second panel 28 may be the wind

cal drafts, in use the shapes of the first and second panels 45 ward panel. As the boat comes about, the panels change

26 and 28 will be different because of the difference in their relative positions so that the second panel 28 be

wind loading between the panels. Generally the wind comes the leeward panel and the first panel 26 becomes

ward panel will have a flatter configuration than the the windward panel. The webs 30 are sufficiently flexi

leeward panel. Thus, as best shown in FIG. 4, the spac ble to allow this change. Furthermore the webs are

ing between the panels, and thus the transverse dimen 50 sufficiently stretchable to allow the difference in shape

sion of each of the webs 30 is not constant from luff to of the panels in the new orientation.

leech. Generally, the distance between the panels will Because the first and second panels 26 and 28 alter

be the greatest in the area of maximum draft or maxi nate between being leeward and windward as the boat

mum curvature of the panels, and the distance will be sails, the drafts of the two panels are preferably identi

the smallest adjacent the luff and leech edges of the 55 cal, so that boat performance can remain about the same

panels. This variable spacing can be accommodated by in either mode of sailing. The design of the draft prefer

making the webs 30 wider in the area of maximum draft ably takes into account that each panel serves alter

and narrower between the luff and leech edges of the nately as the leeward and windward panel during use.

panels, and thus have the general barrel shape described The stretchability of the webs accommodates the

above. change in shapes of the panels while supporting each

The webs 30 are preferably made from a flexible panel relative to the other.

material and thus have some degree of inherent stretch It is desirable to rig the sail 20 so that the luff edge of

ability. In the preferred embodiment the webs are con the panel can move rearwardly relative to luff edge of

structed to be transversely stretchable, and preferably the windward panel. There are a number of ways of

to have varying transverse stretchability. This varying 65 rigging sail 20 as is apparent to a person of ordinary skill

transverse stretchability may be accomplished in a num in the art. For example, the luff edges of the panels may

ber of ways, including constructing the webs 30 from be provided with bolt ropes 42 and 44. Lashings 46 and

segments of different materials, or from segments of 48 extending from the bolt ropes 42 and 44, respec

4,856,448

5 6

tively, may be looped through slides 50 which engage a a plurality of baffles extending between the first and

track 52 on the mast. second panels, the baffles comprising a plurality of

FIGS. 5 and 6 illustrate two alternate ways of rigging elevationally spaced, generally horizontal webs of

a sail constructed according to the present invention. In stretchable material extending substantially from

FIG. 5, a jib sail constructed according to the principles the luff edges to the leech edges of the panels, each

of this is shown. The clews of each panel 26' and 28, are web comprising at least two portions having differ

joined together and secured with a single line 54. Alter ent transverse stretchability, the first and second

natively, as shown in FIG. 6, the clews of panels 26 and panels being open at the luff and leech edges to

28 could be secured with separate lines 56 and 58, if allow wind to pass therebetween so that the first

there is sufficient room and if local sailing rules permit. 10 and second panels can assume their respective pre

When the boat is not headed windward, for example determined draft shapes.

if the boat is on a dead run, no wind will pass between 5. The sail according to claim 4 wherein the portions

the panels. In this case the sail 20 will operate as a con of the webs between the panels at their maximum draft

ventional sail.

15

curvature have the maximum transverse stretchability.

OPERATION 6. The sail according to claim 4 wherein each web

comprises a plurality of portions of different transverse

The sail of this invention is raised on the rigging of stretchability, the portion between the points of maxi

the boat. When the sail is properly trimmed and the boat mum draft curvature of the panels having the greatest

pointed windward, wind blows over the sail 20 and 20 transverse stretchability, and the portions between the

through sail 20 between panels 26 and 28 causing panels panels at the luff and leech edges having lesser trans

26 and 28 to fill with air. The luff edge of the leeward verse stretchability.

sail advances relative to the luff edge of the windward 7. The sail according to claim 6 wherein each web is

sail. The webs 30 extending between the panels support cambered longitudinally in the luff to leach direction.

the panels and help to maintain the shape of the panels. 25 8. The sail according to claim 7 wherein the leech end

The webs 30 stretch to accommodate the shapes of the of each web is elevationally higher than the luff end of

panels 26 and 28. The central portions 34 of the webs the web.

stretching transversely more than portions 32 and 36 to 9. The sail according to claim 1 wherein the webs

accommodate the greater distance between the central include a plurality of stiffeners.

portion of the panels 32 and 36. This allows the panels 30 10. The sail according to claim 1 wherein the webs

to maintain substantially their designed shapes, thereby are sufficiently flexible to permit the relative advance

operating at maximum efficiency. The sail can be ment of the luff edge of the leeward panel with respect

moved from one side of the boat to the other. The webs to the luff edge of the windward panel.

30 flex sufficiently so that the panels can shift relative to 11. A sail for a boat comprising:

each other as the sail moves from one side of the boat to 35 a first panel having a predetermined draft therein;

the other. a second panel having a predetermined draft therein;

In view of the above, it will be seen that the several and

objects of the invention are achieved and other advanta a plurality of elevationally spaced generally horizon

geous results attained. tal webs connecting and spacing the panels, each

As various changes could be made in the above con web being cambered longitudinally in the luff to

structions without departing from the scope of the in leech direction, the panels being open at their luff

vention, it is intended that all matter contained in the and leech edges to allow air to pass between the

above description or shown in the accompanying draw panels so that the first and second panels can fill

ings shall be interpreted as illustrative and not in a limit with air, the webs being sized and shaped to space

ing sense. 45 the first and second panels to maintain their re

I claim: spective predetermined drafts.

1. A sail for a boat comprising: 12. The sail according to claim 11 wherein the leech

a first panel having a predetermined draft therein; end of each web is elevationally higher than the luffend

a second panel having a predetermined draft therein; of the web.

and 50 13. The sail according to claim 11 wherein the web

a plurality of baffles extending between the first and comprises at least two portions of differing transverse

second panels, the baffles comprising a plurality of stretchability.

elevationally spaced, generally horizontal webs 14. The sail according to claim 13 wherein the por

extending substantially from the luff edges to the tions of the webs between the panels at their maximum

leech edges of the panels, the first and second pan 55 draft curvature have the maximum transverse stretch

els being open at the luff and leech edges to allow ability.

wind to pass therebetween so that the first and 15. The sail according to claim 11 wherein each web

second panels can assume their respective predeter comprises a plurality of portions of different transverse

mined draft shapes. stretchability, the portion between the points of maxi

2. The sail according to claim 1 wherein each web is 60 mum draft curvature of the panels having the greatest

cambered longitudinally in the luff to leach direction. transverse stretchability, and the portions between the

3. The sail according to claim 2 wherein the leech end panels at the luff and leech edges having lesser trans

of each web is elevationally higher than the luff end of verse stretchability.

the web. 16. The said according to claim 15 wherein the leech

4. A sail for a boat comprising: 65 end of each web is elevationally higher than the luffend

a first panel having a predetermined draft therein; of the web.

a second panel having a predetermined draft therein; 17. A sail for a boat comprising:

and a first panel having a predetermined draft therein;

4,856,448

7 8

2 ind panel having a predetermined draft therein; webs being sized and shaped to space the first and

2

second panels to maintain their respective prede

o

a plurality of generally horizontal webs extending termined drafts when the luff edge of the W

substantially from the luff edges to the leech edges panel is advanced relative to the luff edge of the

of the panels, the webs connecting and spacing the 5

panels, the panels being open at their luff and leech windward panel.

edges to allow air to pass between the panels, the x x . . .

15

20

25

30

35

45

50

55

60

65

Das könnte Ihnen auch gefallen

- Dr. Mike Israetel Training Volume Landmarks Hypertrophy RoutineDokument26 SeitenDr. Mike Israetel Training Volume Landmarks Hypertrophy RoutineJose Fernando PereiraNoch keine Bewertungen

- Internment - Samira AhmedDokument254 SeitenInternment - Samira Ahmedboop50% (4)

- 12 Elements of Firearms TrainingDokument6 Seiten12 Elements of Firearms TraininglildigitNoch keine Bewertungen

- Scientific American Supplement, No. 787, January 31, 1891Von EverandScientific American Supplement, No. 787, January 31, 1891Noch keine Bewertungen

- United States Patent (19) : VicardDokument4 SeitenUnited States Patent (19) : Vicard155100% (1)

- United States Patent (19) : VicardDokument4 SeitenUnited States Patent (19) : Vicard155100% (1)

- Fluids Mechanics HomeworkDokument92 SeitenFluids Mechanics Homeworkm3994794% (31)

- Lisca - Lingerie Catalog II Autumn Winter 2013Dokument76 SeitenLisca - Lingerie Catalog II Autumn Winter 2013OvidiuNoch keine Bewertungen

- United States Patent (19) : (21) Appl. No.: 927,123Dokument7 SeitenUnited States Patent (19) : (21) Appl. No.: 927,123155Noch keine Bewertungen

- United States Patent (19) : Ammen Et AlDokument9 SeitenUnited States Patent (19) : Ammen Et Al55Noch keine Bewertungen

- US4624203Dokument11 SeitenUS4624203524Noch keine Bewertungen

- United States Patent (10) Patent No.: US 6,170,421 B1: Ross (45) Date of Patent: Jan. 9, 2001Dokument8 SeitenUnited States Patent (10) Patent No.: US 6,170,421 B1: Ross (45) Date of Patent: Jan. 9, 2001155Noch keine Bewertungen

- US4388888Dokument19 SeitenUS4388888524Noch keine Bewertungen

- United States Patent (19Dokument19 SeitenUnited States Patent (1912348Noch keine Bewertungen

- United States Patent (19) : PreticDokument5 SeitenUnited States Patent (19) : Pretic63Noch keine Bewertungen

- United States Patent (19) : Stevenson, IV 11 Patent Number: 5,014,637 (45) Date of Patent: May 14, 1991Dokument15 SeitenUnited States Patent (19) : Stevenson, IV 11 Patent Number: 5,014,637 (45) Date of Patent: May 14, 199163Noch keine Bewertungen

- United States PatentDokument13 SeitenUnited States Patent155Noch keine Bewertungen

- US4418632Dokument10 SeitenUS4418632524Noch keine Bewertungen

- United States PatentDokument6 SeitenUnited States Patent155Noch keine Bewertungen

- United States Patent: (54) SailboatDokument5 SeitenUnited States Patent: (54) Sailboat155Noch keine Bewertungen

- United States Patent (19) : Debarge Dec. 17, 1985Dokument9 SeitenUnited States Patent (19) : Debarge Dec. 17, 198563Noch keine Bewertungen

- United States Patent (19) : (54) Roll-Reefing JibsailDokument8 SeitenUnited States Patent (19) : (54) Roll-Reefing Jibsail63Noch keine Bewertungen

- Umted States Patent (191 (11) Patent Number: 5,718,184: Holland (45) Date of Patent: Feb. 17, 1998Dokument8 SeitenUmted States Patent (191 (11) Patent Number: 5,718,184: Holland (45) Date of Patent: Feb. 17, 1998احمد عبدالكريمNoch keine Bewertungen

- United States Patent (19) : Menegus (11) 4,047,493Dokument18 SeitenUnited States Patent (19) : Menegus (11) 4,047,493155Noch keine Bewertungen

- United States Patent (19) : 11) Patent Number: 5,181,477 45 Date of Patent: Jan. 26, 1993Dokument10 SeitenUnited States Patent (19) : 11) Patent Number: 5,181,477 45 Date of Patent: Jan. 26, 199312348Noch keine Bewertungen

- United States Patent (19) : A26%/A A2%2W2 Azaa2%2Dokument17 SeitenUnited States Patent (19) : A26%/A A2%2W2 Azaa2%2fitri auliyatinNoch keine Bewertungen

- United States Patent (19) 11) Patent Number: 4,669,407: Cobb 45) Date of Patent: Jun. 2, 1987Dokument8 SeitenUnited States Patent (19) 11) Patent Number: 4,669,407: Cobb 45) Date of Patent: Jun. 2, 198763Noch keine Bewertungen

- United States PatentDokument13 SeitenUnited States Patent63Noch keine Bewertungen

- United States Patent (19) : Hood Et Al.Dokument5 SeitenUnited States Patent (19) : Hood Et Al.8787Noch keine Bewertungen

- Diseño de Impulsores para Mezcla de SuspensionesDokument9 SeitenDiseño de Impulsores para Mezcla de SuspensionesrwtoorresdNoch keine Bewertungen

- United States Patent (19) : Anderson Et Al. 54 Yacht Mast 11) 4,072,121Dokument7 SeitenUnited States Patent (19) : Anderson Et Al. 54 Yacht Mast 11) 4,072,12112348Noch keine Bewertungen

- Stern FlapDokument35 SeitenStern FlapMuhamad Nazren Mohamed ZaidiNoch keine Bewertungen

- United States Patent (19) : Gazalel, 72 8Dokument7 SeitenUnited States Patent (19) : Gazalel, 72 8Mihai RobertNoch keine Bewertungen

- United States Patent: ABSTRACT: Boundary Layer Separation in Surface Ships IsDokument4 SeitenUnited States Patent: ABSTRACT: Boundary Layer Separation in Surface Ships IsArthur HugenNoch keine Bewertungen

- US Patent 7090236 Land SailingDokument8 SeitenUS Patent 7090236 Land SailingDimas MaulanaNoch keine Bewertungen

- United States Patent (19) : WalkerDokument8 SeitenUnited States Patent (19) : Walker155Noch keine Bewertungen

- Fan DetailsDokument6 SeitenFan DetailsShivom SharmaNoch keine Bewertungen

- United States Patent (19) 11 Patent Number: 5,474,257: Fisher Et Al. (45. Date of Patent: Dec. 12, 1995Dokument11 SeitenUnited States Patent (19) 11 Patent Number: 5,474,257: Fisher Et Al. (45. Date of Patent: Dec. 12, 1995155Noch keine Bewertungen

- Us 4812080Dokument10 SeitenUs 4812080JonNoch keine Bewertungen

- United States Patent (19) : GravelineDokument15 SeitenUnited States Patent (19) : Graveline155Noch keine Bewertungen

- Fied Feb. 5, 1967: 2. Sheets-Sheet LDokument5 SeitenFied Feb. 5, 1967: 2. Sheets-Sheet L155Noch keine Bewertungen

- Us 5054463Dokument17 SeitenUs 5054463RajenderNoch keine Bewertungen

- United States Patent 19 11 Patent Number: 5,697,468: Russell, Jr. Et Al. (45) Date of Patent: Dec. 16, 1997Dokument8 SeitenUnited States Patent 19 11 Patent Number: 5,697,468: Russell, Jr. Et Al. (45) Date of Patent: Dec. 16, 1997155Noch keine Bewertungen

- US20040016851A1Dokument10 SeitenUS20040016851A1B.EKICINoch keine Bewertungen

- United States Patent: Appl. No. 853,670Dokument9 SeitenUnited States Patent: Appl. No. 853,670gorgiNoch keine Bewertungen

- United States PatentDokument10 SeitenUnited States Patent63Noch keine Bewertungen

- United States Patent (191: BulgariniDokument6 SeitenUnited States Patent (191: Bulgariniاحمد عبدالكريمNoch keine Bewertungen

- Patent Application Publication (10) Pub. No.: US 2013/0014683 A1Dokument12 SeitenPatent Application Publication (10) Pub. No.: US 2013/0014683 A1sam a g mNoch keine Bewertungen

- United States Patent, (191: FindleyDokument6 SeitenUnited States Patent, (191: Findleywan nazrolNoch keine Bewertungen

- US4219241Dokument7 SeitenUS4219241aungkyawzoreNoch keine Bewertungen

- Patent Application Publication (10) Pub. No.: US 2006/0118021 A1Dokument13 SeitenPatent Application Publication (10) Pub. No.: US 2006/0118021 A1sam a g mNoch keine Bewertungen

- US5335644Dokument7 SeitenUS5335644Radek HoffmannNoch keine Bewertungen

- Arnason TF-JFPDokument7 SeitenArnason TF-JFPIvan SABONoch keine Bewertungen

- Synopsis of Midway PaperDokument6 SeitenSynopsis of Midway Paperknowme73Noch keine Bewertungen

- Reusser C. Modern Ship Engineering, Design and Operations, 2021Dokument87 SeitenReusser C. Modern Ship Engineering, Design and Operations, 2021Xue Feng DuNoch keine Bewertungen

- United States Patent: SimpsonDokument5 SeitenUnited States Patent: Simpsonاحمد عبدالكريمNoch keine Bewertungen

- Patente Del SuperadobeDokument7 SeitenPatente Del Superadoberafalejo9Noch keine Bewertungen

- Shell Structure: 5.1 Thickness of Shell PlatesDokument8 SeitenShell Structure: 5.1 Thickness of Shell PlatesJuan SilvaNoch keine Bewertungen

- United States Patent (19) : 11) Patent Number: 5,200,256 (45) Date of Patent: Apr. 6, 1993Dokument8 SeitenUnited States Patent (19) : 11) Patent Number: 5,200,256 (45) Date of Patent: Apr. 6, 1993Tibebu MerideNoch keine Bewertungen

- May 25, 1943. R. V. Jennings. 2,319,999: Filed Dec. 13, 1939 - 2 Sheets-Sheet 1Dokument6 SeitenMay 25, 1943. R. V. Jennings. 2,319,999: Filed Dec. 13, 1939 - 2 Sheets-Sheet 163Noch keine Bewertungen

- United States PatentDokument15 SeitenUnited States PatentJjp ParmarNoch keine Bewertungen

- Ship Design For Efficiency and Economy-7-226-61-65Dokument5 SeitenShip Design For Efficiency and Economy-7-226-61-65galin8575Noch keine Bewertungen

- United States Patent (19) : TinkerDokument12 SeitenUnited States Patent (19) : TinkerJoel AndradeNoch keine Bewertungen

- United States PatentDokument7 SeitenUnited States PatentBrilliant DavidsonNoch keine Bewertungen

- United States Patent: (12) (10) Patent No.: US 7,165,759 B2Dokument8 SeitenUnited States Patent: (12) (10) Patent No.: US 7,165,759 B2Vijay KotiNoch keine Bewertungen

- Us 5312228Dokument6 SeitenUs 5312228Saeed JavdaniNoch keine Bewertungen

- Fied Feb. 5, 1967: 2. Sheets-Sheet LDokument5 SeitenFied Feb. 5, 1967: 2. Sheets-Sheet L155Noch keine Bewertungen

- United States Patent (19) : (76) Inventor: John Guthrie, Suite 1401-555-13th ST.Dokument10 SeitenUnited States Patent (19) : (76) Inventor: John Guthrie, Suite 1401-555-13th ST.155Noch keine Bewertungen

- United States Patent (19) : Menegus (11) 4,047,493Dokument18 SeitenUnited States Patent (19) : Menegus (11) 4,047,493155Noch keine Bewertungen

- C. W. A. Koelkebeck: 6 Sheets-Sheet LDokument10 SeitenC. W. A. Koelkebeck: 6 Sheets-Sheet L155Noch keine Bewertungen

- July 17, 1951 W. W. Wels-Coates 2,561,253: Filed Dec. 4, 1946 10 Sheets-Sheet LDokument16 SeitenJuly 17, 1951 W. W. Wels-Coates 2,561,253: Filed Dec. 4, 1946 10 Sheets-Sheet L155Noch keine Bewertungen

- United States Patent: (54) SailboatDokument5 SeitenUnited States Patent: (54) Sailboat155Noch keine Bewertungen

- United States Patent (19) 11 Patent Number: 5,474,257: Fisher Et Al. (45. Date of Patent: Dec. 12, 1995Dokument11 SeitenUnited States Patent (19) 11 Patent Number: 5,474,257: Fisher Et Al. (45. Date of Patent: Dec. 12, 1995155Noch keine Bewertungen

- United States Patent (19) : WalkerDokument8 SeitenUnited States Patent (19) : Walker155Noch keine Bewertungen

- United States PatentDokument13 SeitenUnited States Patent155Noch keine Bewertungen

- United States PatentDokument6 SeitenUnited States Patent155Noch keine Bewertungen

- United States Patent (10) Patent No.: US 6,471,157 B1: Streett Et Al. (45) Date of Patent: Oct. 29, 2002Dokument8 SeitenUnited States Patent (10) Patent No.: US 6,471,157 B1: Streett Et Al. (45) Date of Patent: Oct. 29, 2002155Noch keine Bewertungen

- United States Design Patent (10) Patent No .:: US D807, 823 SDokument9 SeitenUnited States Design Patent (10) Patent No .:: US D807, 823 S155Noch keine Bewertungen

- W. Castles, JR: Filed Jan. 11, 1957Dokument3 SeitenW. Castles, JR: Filed Jan. 11, 1957155Noch keine Bewertungen

- United States Design Patent (10) Patent No.:: USD639,239 SDokument9 SeitenUnited States Design Patent (10) Patent No.:: USD639,239 S155Noch keine Bewertungen

- United States Patent (19) 11 Patent Number: 5,992,793: Perry Et Al. (45) Date of Patent: Nov.30, 1999Dokument8 SeitenUnited States Patent (19) 11 Patent Number: 5,992,793: Perry Et Al. (45) Date of Patent: Nov.30, 1999155Noch keine Bewertungen

- United States Design Patent (10) Patent No.: US D478,598 SDokument5 SeitenUnited States Design Patent (10) Patent No.: US D478,598 S155Noch keine Bewertungen

- United States Patent (10) Patent No.: US 6,578,798 B1: Ave., #129, Anaheim, CA (US) 92801 S A 2: RegDokument24 SeitenUnited States Patent (10) Patent No.: US 6,578,798 B1: Ave., #129, Anaheim, CA (US) 92801 S A 2: Reg155Noch keine Bewertungen

- United States Patent: (10) Patent No.: US 6,168,383 B1Dokument17 SeitenUnited States Patent: (10) Patent No.: US 6,168,383 B1155Noch keine Bewertungen

- United States Patent 19 11 Patent Number: 5,697,468: Russell, Jr. Et Al. (45) Date of Patent: Dec. 16, 1997Dokument8 SeitenUnited States Patent 19 11 Patent Number: 5,697,468: Russell, Jr. Et Al. (45) Date of Patent: Dec. 16, 1997155Noch keine Bewertungen

- United States PatentDokument18 SeitenUnited States Patent155Noch keine Bewertungen

- United States PatentDokument17 SeitenUnited States Patent155Noch keine Bewertungen

- United States Patent (10) Patent No.: US 6,910,434 B2: Lundgren (45) Date of Patent: Jun. 28, 2005Dokument17 SeitenUnited States Patent (10) Patent No.: US 6,910,434 B2: Lundgren (45) Date of Patent: Jun. 28, 2005155Noch keine Bewertungen

- United States Patent (19) : GravelineDokument15 SeitenUnited States Patent (19) : Graveline155Noch keine Bewertungen

- Hydrostatics-Assignment 3: MPI td9Dokument2 SeitenHydrostatics-Assignment 3: MPI td9whoeverNoch keine Bewertungen

- DVH-P4950 P4050Dokument111 SeitenDVH-P4950 P4050roto44100% (1)

- Theories of DissolutionDokument17 SeitenTheories of DissolutionsubhamNoch keine Bewertungen

- Object: Annex A, B, C DDokument74 SeitenObject: Annex A, B, C DfjsdNoch keine Bewertungen

- Related Literature BioplasticsDokument19 SeitenRelated Literature BioplasticsJames LimNoch keine Bewertungen

- Hemiplegia LectureDokument37 SeitenHemiplegia LectureRancesh FamoNoch keine Bewertungen

- Principles of ForecastingDokument41 SeitenPrinciples of Forecastingrajeevseth100% (1)

- MCQs Saudia Pharmacy Registration ExamDokument7 SeitenMCQs Saudia Pharmacy Registration ExamAli ButtNoch keine Bewertungen

- Single Nozzle Air-Jet LoomDokument7 SeitenSingle Nozzle Air-Jet LoomRakeahkumarDabkeyaNoch keine Bewertungen

- Curicullum Vitae Hendri Zand Franxiscus LahaguDokument3 SeitenCuricullum Vitae Hendri Zand Franxiscus LahaguSepta Yudistira Inggil PambudiNoch keine Bewertungen

- "Automatic Tyre Pressure Inflation System": Bachelor of TechnologyDokument41 Seiten"Automatic Tyre Pressure Inflation System": Bachelor of Technologymd washiqeNoch keine Bewertungen

- Salvado de Arroz Fermentado: Una Alternativa de Ingrediente para PanificaciónDokument10 SeitenSalvado de Arroz Fermentado: Una Alternativa de Ingrediente para PanificaciónAnelise RibeiroNoch keine Bewertungen

- MiniNova GuideDokument41 SeitenMiniNova GuideBob FredNoch keine Bewertungen

- Poster - Combur10 Test Parameters PDFDokument1 SeitePoster - Combur10 Test Parameters PDFAde FeriyatnaNoch keine Bewertungen

- Derivation of Gravity Loads PDFDokument4 SeitenDerivation of Gravity Loads PDFHenry TuganoNoch keine Bewertungen

- Comsol ProfileDokument4 SeitenComsol ProfilePrashant KumarNoch keine Bewertungen

- 2022 Specimen Paper 1 Mark Scheme 1Dokument4 Seiten2022 Specimen Paper 1 Mark Scheme 1Herman HermanNoch keine Bewertungen

- Fisher N551 ESVDokument2 SeitenFisher N551 ESVWynn ChoNoch keine Bewertungen

- Digital DividesDokument25 SeitenDigital DividesKumaraswamy ChannabasaiahNoch keine Bewertungen

- Minor Losses ExperimentDokument4 SeitenMinor Losses ExperimentRaj GuptaNoch keine Bewertungen

- SWOT Analysis Textile IndustryDokument23 SeitenSWOT Analysis Textile Industrydumitrescu viorelNoch keine Bewertungen

- 06-Soil Fert Nutr MGTDokument8 Seiten06-Soil Fert Nutr MGTAndres LuqueNoch keine Bewertungen

- Scripture Passages Suitable For Lectio Divina: 1 John 4:7-11Dokument2 SeitenScripture Passages Suitable For Lectio Divina: 1 John 4:7-11Victor AugustoNoch keine Bewertungen

- Practice Test 1 + 2Dokument19 SeitenPractice Test 1 + 2yếnNoch keine Bewertungen