Beruflich Dokumente

Kultur Dokumente

Niosh 7908-Ácidos No Volátiles

Hochgeladen von

DiegoRossoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Niosh 7908-Ácidos No Volátiles

Hochgeladen von

DiegoRossoCopyright:

Verfügbare Formate

NON-VOLATILE ACIDS (Sulfuric Acid and Phosphoric Acid) 7908

Formulae: H2SO4 MW: 98.08 CAS: 7664-93-9 RTECS: WS5600000

H3PO4 MW: 98.0 CAS: 7664-38-2 RTECS: TB6300000

METHOD: 7908, Issue 1 EVALUATION: FULL Issue 1: 10 May 2014

U.S. OELs PROPERTIES:

OSHA : 1 mg/m3 (H2SO4 & H3PO4) H2SO4: Liquid, mp = 3.0 °C (98%); 10 °C (100%); bp = 338

NIOSH: 1 mg/m3 (H2SO4 & H3PO4); STEL: 3 mg/m3 (H3PO4) °C (98%); 330 °C (100%); VP = < 0.0001 kPa @

Other 20 °C

OELs: [1,2] H3PO4: Solid (often used in an aqueous solution), mp = 42.4

°C; bp = 158 °C; vp = 0.0038 kPa @ 20 °C

SYNONYMS: H2SO4: hydrogen sulfate, oil of vitriol; H3PO4: ortho-phosphoric acid

SAMPLING MEASUREMENT

SAMPLER: FILTER, 37-mm diameter quartz fiber; or TECHNIQUE: ION CHROMATOGRAPHY (IC) with

polytetrafluoroethylene (PTFE), 0.45 µm pore conductivity detection

size

ANALYTES: Sulfate (SO42-) ion, phosphate (PO43-) ion

FLOW RATE: 1 to 5 L/min

EXTRACTION: Aqueous solution of sodium carbonate /

VOL-MIN: 15 L sodium hydrogen carbonate

-MAX: 2000 L

INJECTION

SHIPMENT: 4 °C

VOLUME: 50 µL

SAMPLE

ELUENT: 2.7 mM Na2CO3/0.3 mM NaHCO3, flow rate

STABILITY: Stable for 1 week at about 20 °C and at 4 °C

1.5 mL/min

thereafter to 28 days [3]

BLANKS: 3 field blanks minimum per set COLUMNS: Pre-column, anion-exchange column and

suppressor column

ACCURACY*

CALIBRATION

RANGE STUDIED: 0.005 to 2.0 mg/sample RANGE: H2SO4; 0.2 mg/L to 8 mg/L;

H3PO4; 0.8 mg/L to 8 mg/L [6]

BIAS*: Negligible [3]

ESTIMATED LOD: H2SO4 = 0.002 mg/m3;

OVERALL H3PO4 = 0.003 mg/m3 (1 m3 air volume)[6]

PRECISION ( ŜrT )*: H2SO4 = 0.086; H3PO4 = 0.106

PRECISION ( S ): H2SO4 = 0.043;

r

EXPANDED H3PO4 = 0.032 [3,7]

UNCERTAINTY*: less than 23% for both H2SO4 and

H3PO4 [6]

* Accuracy calculations were determined using references

5 and 6 rather than the traditional NIOSH accuracy criteria.

APPLICABILITY: The working range for H2SO4 is (at least) 0.002 to 1.0 mg/sample, for H3PO4 is 0.004 to 1.0 mg/sample for

a 420 Liter air sample [3,6].

INTERFERENCES: Particulate salts of sulfate or phosphate will give a positive interference.

OTHER METHODS: This procedure, which is consistent with ISO 21438-1 [6], replaces NIOSH 7903 [8] for the determina-

tion of sulfuric and phosphoric acid in workplace air samples by IC. The main advantage of NIOSH method 7908 is that it can

allow for the collection of the inhalable fraction of sulfuric and phosphoric acid aerosols by means of the pre-filter (housed

within an optional inhalable sampler.)

NIOSH Manual of Analytical Methods (NMAM), Fifth Edition

NON-VOLATILE ACIDS (Sulfuric Acid and Phosphoric Acid): METHOD 7908, Issue 1, dated 20 May 2014 - Page 2 of 5

REAGENTS: EQUIPMENT:

1. Water, deionized (DI), ≥18 MΩ-cm resistivity 1. Sampler: filter, 37-mm diameter quartz fiber; or

2. Sodium carbonate (Na2CO3), anhydrous, polytetrafluoroethylene (PTFE), 0.45 µm pore

American Chemical Society (ACS) analytical size, in cassette filter holder manufactured

grade from acid-resistant (chemically inert) material

3. Sodium hydrogen carbonate (NaHCO3), ACS NOTE: Quartz fiber filters should be binderless

analytical grade and heat-treated.

4. Extraction & eluent stock solution: 0.27 M 2. Personal sampling pump, 1 to 5 L/min, with

Na2CO3 / 0.03 M NaHCO3; dissolve 2.86 g flexible connecting tubing

Na2CO3 and 0.25 g NaHCO3 in 25 mL of 3. Ion chromatograph, with pre-column (50 mm

deionized water and swirl to mix. Then bring to by 4.0 mm), anion-exchange column (200 mm

100 mL in a volumetric flask, stopper and mix by 4.0 mm), suppressor column (4 mm) and

thoroughly. conductivity detector; and connected to data

5. Extraction & eluent solution: 0.0027 M Na2CO3 / processing unit

0.0003 M NaHCO3; transfer 10 mL of 0.27 M 4. Ultrasonic bath

Na2CO3 / 0.03 M NaHCO3 stock solution to a 5. Vessels, 10-mL, plastic (e.g., polypropylene),

1 L volumetric flask, dilute to the mark with with screw caps

deionized water, stopper and mix thoroughly. 6. Volumetric flasks, 25- to 1000 mL

6. Sulfate (SO42-) ion and phosphate (PO43-) ion 7. Pipets, 50 to 10000 µL

standard solutions, each 1000 mg/L 8. Beakers, 25 to 100 mL

7. Calibration stock solution, 100 mg/L (as the 9. Water purification system, to prepare greater

anion): Place 10 mL aliquots of sulfate and than or equal to18 MΩ-cm resistivity deionized

phosphate standard solution into a 100 mL water

volumetric flask, dilute to the mark and mix 10. Bottles, polyethylene, 100 mL

thoroughly. 11. Syringes, plastic, 5 mL

12. Syringe filter cartridges, with 0.8-µm pore size

*See Special Precautions polytetrafluoroethylene (PTFE) membrane

filters

13. Micro-syringes, 50 µL, with 60 mm x 0.6 mm

needles

14. Tweezers, PTFE-coated

15. Auto-sampler vials, 2 mL capacity

16. Analytical balance, with capability of weighing

to nearest 0.01 mg

SPECIAL PRECAUTIONS: Wear gloves, lab coat, and safety glasses while handling acids. All work

should be performed with adequate ventilation for personnel and equipment. It is imperative that acid

be added to water in order to avoid a violent exothermic reaction. There is risk of fire and explosion

when phosphoric acid has contact with bases, combustible substances, oxidizing agents, reducing

agents or water. Avoid physical contact since both sulfuric and phosphoric acid are both corrosive and

irritants to eyes, skin, and the respiratory system. These are caustic materials and can react with metals

to form flammable hydrogen gas. Do NOT mix with solutions containing bleach or ammonia [9,10].

SAMPLING, SAMPLE TRANSPORT AND STORAGE:

1. Calibrate each personal sampling pump with a representative sampler in-line.

2. Sample at an accurately known flow rate between 1 and 5 L/min for a total sample size of 15 to 1000

Liters. Avoid sampler overloading.

3. Immediately after sampling, remove the filter from the cassette with PTFE-coated

tweezers and place it in a 10-mL screw-cap plastic vessel. With about 2 mL extraction

NIOSH Manual of Analytical Methods (NMAM), Fifth Edition

NON-VOLATILE ACIDS (Sulfuric Acid and Phosphoric Acid): METHOD 7908, Issue 1, dated 20 May 2014 - Page 3 of 5

solution (0.27 M Na2CO3 0.03 M NaHCO3), rinse material from the inside surfaces of the cassette into

the vessel. Add additional extraction solution into the vessel until a final volume of 5 mL is reached.

4. Submit at least three field blanks for each set of samples collected per day. Handle these in the same

way as the field samples; i.e., place each filter into a vessel, add 5 mL of eluent solution and ship it to

the lab along with the remaining samples.

5. Refrigerate all samples that are to be stored overnight (or longer) prior to shipment to the

laboratory. Ship all samples to the laboratory in accordance with established chain-of-custody

procedures [11].

6. Refrigerate the samples (4 °C) immediately upon receipt at the lab until ready for analysis.

7. Analyze samples within 4 weeks of receipt.

SAMPLE PREPARATION:

8. Remove sample vessels from storage and bring them to room temperature.

9. Sonicate the samples in an ultrasonic bath for at least 15 minutes and allow to cool for at least 30

minutes.

10. Using 5-mL syringes, filter each sample extract solution through a PTFE filter into clean plastic

vessels or into autosampler vials (if autosampler used).

CALIBRATION AND QUALITY CONTROL:

11. Through dilution of the calibration stock solution in eluent solution, prepare calibration working

standard solutions covering the range of approximately 0.2 to 8 mg/L of sulfate and phosphate.

Store working standards in tightly sealed polyethylene bottles. Prepare fresh working standards

weekly.

12. Calibrate the ion chromatograph with at least six working standards covering the range of 0.2 to 8

mg/L of sulfate and phosphate ion per sample by preparing a calibration graph of anion peak height

(mm or µS [micro siemens]) vs. concentration (mg/L).

13. Analyze working standards together with samples, reagent blanks and field blanks at a frequency of

at least 1 per 20 samples (3 minimum of each).

MEASUREMENT:

14. Set the ion chromatograph to desired eluent flow rate, e.g.,1.5 mL/min, and column pressure, e.g.,

1.1 x 105 kPa, and other conditions as specified by the instrument manufacturer.

15. Inject a sample aliquot, e.g., 50-µL, into the chromatograph, and measure the peak heights of the

phosphate and sulfate peaks (at retention times of about 9 min and 11.6 min, respectively). If

the peak height exceeds the linear calibration range, dilute with eluent, reanalyze and apply the

appropriate dilution factor in calculations.

CALCULATIONS:

16. Calculate the mass concentration of each anion, C (mg/m3), in the air volume sampled, V (L):

(C 1*V 1 * Fd ) − (C 0*V 0 )

C ={ } * Fc

V

where:

C = mean concentration, in mg/L, of anion in the field blank test solutions;

0

C = concentration, in mg/L, of anion in the sample test solution;

1

V = volume, in liters, of the air sample;

V = volume, in mL, of the field blank test solutions;

0

NIOSH Manual of Analytical Methods (NMAM), Fifth Edition

NON-VOLATILE ACIDS (Sulfuric Acid and Phosphoric Acid): METHOD 7908, Issue 1, dated 20 May 2014 - Page 4 of 5

V = volume, in mL, of the sample test solutions

1

Fd = dilution factor for each sample test solution

Fc = conversion factor to convert from anion to acid concentration:

Fc = 1.021 for sulfate; Fc = 1.031 for phosphate

EVALUATION OF METHOD:

Laboratory testing with generated atmospheres of sulfuric acid mist yielded a collection efficiency of

greater than 95% over the range 0.5 to 10 mg/m3 of H2SO4 on 0.45 µm pore size PTFE filters [4]. Greater

than 95% recovery of sulfuric acid and phosphoric acid was found four weeks after sample collection.

On quartz fiber filters, 97 to 100% recovery of sulfuric acid was found four weeks after sample collection,

and no breakthrough was observed at sample loadings of up to 1 mg [3]. Mean analytical recovery

determined from the analysis of spiked quartz fiber filters has been found to be in the range of 97 to

100% for both acids [3,4]. The component of the coefficient of variation of the method that arises from

analytical variability, determined from the analysis of spiked quartz fiber filters, was 0.7% to 3.2% for

phosphoric acid and 0.5% to 2.6% for sulfuric acid [3]. An interlaboratory study with 26 participants

found negligible biases and interlaboratory relative standard deviations of 12 to 15% for sulfuric acid

and phosphoric acid concentrations between 0.05 and 1 mg/m3 [12]. The method has also been field

tested for sulfuric acid measurements at sample volumes of up to nearly 2,000 Liters [13]. The analytical

figures of merit for the method satisfy performance criteria specified in an applicable consensus

standard [14]. The back-up data and user check reports are references 4 and 12 respectively.

REFERENCES:

[1] ACGIH [2013]. TLVs and BEIs based on the documentation of the Threshold Limit Values for

chemical substances and physical agents and Biological Exposure Indices. Cincinnati, Ohio:

American Conference of Governmental Industrial Hygienists. [www.acgih.org]. [Data accessed April

2014.]

[2] Institut fur Arbeitsschutz der Deutschen Gesetzlichen Unfallversicherung [2013]. GESTIS database

on international limit values for hazardous substances (German Social Accident Insurance). Sankt

Augustin, FRG: [http://www.dguv.de/ifa/Gefahrstoffdatenbanken/GESTIS-Stoffdatenbank/index-2.

jsp]. [Data accessed April 2014.]

[3] Breuer D [2002]. Inorganic acid mists (H2SO4, H3PO4). In: Kettrup A, Greim H, eds. Analyses of

hazardous substances in air (Deutsche Forschungsgemeinschaft). Vol. 6. Weinheim, FRG: Wiley-VCH.

pp. 67-78.

[4] Breuer D [1999]. Measurement of vapor-aerosol mixtures. J Environ Monit. 1:299-305.

[5] ISO (International Organization for Standardization) [1995]. ISO Guide 98: Guide to the expression

of uncertainty in measurement. Geneva, Switzerland: ISO.

[6] ISO [2007]. ISO 21438-1: Workplace atmospheres – Determination of inorganic ions by ion

chromatography – Part 1: Non-volatile acids (sulfuric acid and phosphoric acid). Geneva,

Switzerland: International Organization for Standardization (ISO).

[7] Breuer D [2013]. Anorganische säuren, partikulär: phosphorsäure, schwefelsäure (Inorganic acid

mists: phosphoric acid, sulfuric acid), in IFA Working Folder, Sheet No. 6173. Berlin, FRG: Erich-

Schmidt Verlag. ISBN 978-3-503-13084-9.

[8] NIOSH [1994]. Acids, inorganic: Method 7903. In: Eller PM, Cassinelli ME, eds. NIOSH Manual of

analytical methods, 4th ed., Cincinnati, OH: U.S. Department of Health and Human Services, Center

for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS

(NIOSH). Publication No. 94-113. [www.cdc.gov/niosh/nmam.]

[9] NIOSH [2005]. NIOSH Pocket guide to chemical hazards. Barsan ME, ed. Cincinnati, OH: US

Department of Health and Human Services, Centers for Disease Control and Prevention, National

Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 2005-149.

NIOSH Manual of Analytical Methods (NMAM), Fifth Edition

NON-VOLATILE ACIDS (Sulfuric Acid and Phosphoric Acid): METHOD 7908, Issue 1, dated 20 May 2014 - Page 5 of 5

[10] Furr AK, ed. [1995] CRC Handbook of laboratory safety, 4th ed. Boca Raton, FL: CRC Press.

[11] ASTM International [2010]. ASTM D4840: Standard guide for sampling chain of custody procedures.

West Conshohocken, PA: ASTM International.

[12] Breuer D, Howe A [2006]. Performance of methods for measurement of exposure to inorganic acids

in workplace air. J Environ Monit. 8:120-126.

[13] Breuer D, Heckmann P, Gusbeth K, Schwab G, Blaskowitz M, Moritz A [2012]. Sulfuric acid at

workplaces – applicability of the new indicative occupational exposure limit value (IOELV) to

thoracic particles. J Environ Monit. 14:440-445.

[14] Comité Européen de Normalisation (CEN) [2012]. EN 482, Workplace exposure — General

requirements for the performance of procedures for the measurement of chemical agents. Brussels,

Belgium: Comité Européen de Normalisation (CEN).

METHOD WRITTEN BY:

Dietmar Breuer, Dr. rer. nat., Institute for Occupational Safety and Health of the German Social Accident

Insurances, Sankt Augustin, Germany; and Kevin Ashley, Ph.D., NIOSH/DART

Disclaimer: Mention of any company or product does not constitute endorsement by the National

Institute for Occupational Safety and Health. In addition, citations to Web sites external to NIOSH do

not constitute NIOSH endorsement of the sponsoring organizations or their programs or products.

Furthermore, NIOSH is not responsible for the content of these Web sites. All Web addresses

referenced in this document were accessible at the time of publication.

NIOSH Manual of Analytical Methods (NMAM), Fifth Edition

Das könnte Ihnen auch gefallen

- Experiment 2 Pre LabDokument4 SeitenExperiment 2 Pre LabM ReyNoch keine Bewertungen

- 1 MCQ Pharmaceutical TechnologyDokument23 Seiten1 MCQ Pharmaceutical TechnologySSB79% (14)

- TP R.elect Modulo 1 PatDokument13 SeitenTP R.elect Modulo 1 PatAlicia Petersen100% (1)

- EverExceed - Batería - MSDS - Solar Gel Range VRLA - 2008Dokument3 SeitenEverExceed - Batería - MSDS - Solar Gel Range VRLA - 2008chuckreyesNoch keine Bewertungen

- EIGA - Doc 30-13 Disposal of GasesDokument81 SeitenEIGA - Doc 30-13 Disposal of Gasesfrapa070Noch keine Bewertungen

- Water: Standard Terminology Relating ToDokument75 SeitenWater: Standard Terminology Relating ToPyone Ei ZinNoch keine Bewertungen

- Iso 1999 2013 en PDFDokument11 SeitenIso 1999 2013 en PDFluis orlando rodelo100% (1)

- Pigging Valve Brochure Argus ValvesDokument7 SeitenPigging Valve Brochure Argus ValvesIsares PodkohNoch keine Bewertungen

- Aceite TC200Dokument2 SeitenAceite TC200Jhonatan OyolaNoch keine Bewertungen

- Chemical Engineering Magazine Sept2005Dokument124 SeitenChemical Engineering Magazine Sept2005DiegoRosso100% (1)

- Chlorine Institute Manual 2000Dokument68 SeitenChlorine Institute Manual 2000Misael RamírezNoch keine Bewertungen

- 5S Visual Workplace HandbookDokument19 Seiten5S Visual Workplace HandbookDiegoRosso100% (1)

- E 246 - 10 (2015)Dokument9 SeitenE 246 - 10 (2015)ruben carcamoNoch keine Bewertungen

- G1-03 (Reapproved 2017) E1Dokument9 SeitenG1-03 (Reapproved 2017) E1Aries MarteNoch keine Bewertungen

- Niosh 6009 PDFDokument5 SeitenNiosh 6009 PDFCaleb ConnerNoch keine Bewertungen

- Iso 13137 2013 en PDFDokument11 SeitenIso 13137 2013 en PDFRodrigo MendesNoch keine Bewertungen

- PETRO TCS Ops Manual 700-30 35Dokument56 SeitenPETRO TCS Ops Manual 700-30 35paulm3565Noch keine Bewertungen

- Iso 14042 2000 en FR PDFDokument8 SeitenIso 14042 2000 en FR PDFMOHAMED MANSOURNoch keine Bewertungen

- Flammability: A Safety Guide For Users: Best Practice Guidelines N°Dokument48 SeitenFlammability: A Safety Guide For Users: Best Practice Guidelines N°Sameer Khadka100% (1)

- Ficha Tecnica de Espuma 3% Fluoroproteinica Buckeye UlDokument2 SeitenFicha Tecnica de Espuma 3% Fluoroproteinica Buckeye UlDanny AlejandroNoch keine Bewertungen

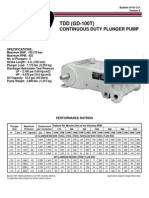

- 1038 TDD GD 100t Continuous Duty Pump Brochure Data SheetDokument2 Seiten1038 TDD GD 100t Continuous Duty Pump Brochure Data SheetYeins Edson OrdoñezNoch keine Bewertungen

- As ISO 14050-1999 Environmental Management - VocabularyDokument8 SeitenAs ISO 14050-1999 Environmental Management - VocabularySAI Global - APACNoch keine Bewertungen

- ASTM D5741-96 Characterizing Surface Wind Using A Wind Vane and Rotating AnemometerDokument5 SeitenASTM D5741-96 Characterizing Surface Wind Using A Wind Vane and Rotating AnemometerFredi Cari CarreraNoch keine Bewertungen

- Astm D 4804Dokument6 SeitenAstm D 4804Boris AguilarNoch keine Bewertungen

- Astm D3418 2012Dokument7 SeitenAstm D3418 2012Rodrigo TomazNoch keine Bewertungen

- Manual Detector de GasesDokument221 SeitenManual Detector de GasesjimenezjacoboNoch keine Bewertungen

- Structure Fires Caused by Hot Work: Marty AhrensDokument14 SeitenStructure Fires Caused by Hot Work: Marty AhrensBurgosg ValeryNoch keine Bewertungen

- Table 2.3: Range of Capture Velocity and Face Velocity (ACGIH, 2009)Dokument1 SeiteTable 2.3: Range of Capture Velocity and Face Velocity (ACGIH, 2009)Leonidas IoannouNoch keine Bewertungen

- D2878Dokument5 SeitenD2878rimi7alNoch keine Bewertungen

- Multilab IV PDFDokument240 SeitenMultilab IV PDFJuanjoNoch keine Bewertungen

- Bauer Mariner Owners Service Manual PDFDokument90 SeitenBauer Mariner Owners Service Manual PDFMark WoodsNoch keine Bewertungen

- Niosh 7301 PDFDokument8 SeitenNiosh 7301 PDFAngelicaNoch keine Bewertungen

- Isoflex Topas L 32Dokument2 SeitenIsoflex Topas L 32c108Noch keine Bewertungen

- FMDS0788Dokument45 SeitenFMDS0788hhNoch keine Bewertungen

- Spiromatic S8 ScbaDokument36 SeitenSpiromatic S8 ScbaForum PompieriiNoch keine Bewertungen

- Data Hasil Pengukuran Gas Free: Area Tanki: Tanggal: No. Jam Hasil Pengukuran Kondisi KeteranganDokument1 SeiteData Hasil Pengukuran Gas Free: Area Tanki: Tanggal: No. Jam Hasil Pengukuran Kondisi KeterangansalsabilaNoch keine Bewertungen

- ICMM Good Practice Guidance On Occupational Health Risk AssessmentDokument68 SeitenICMM Good Practice Guidance On Occupational Health Risk AssessmentSalim Vohra100% (1)

- PDS Hempathane Topcoat 55210 en-GBDokument2 SeitenPDS Hempathane Topcoat 55210 en-GBJames PittsNoch keine Bewertungen

- FMDS07111FDokument8 SeitenFMDS07111Fyerrisiddappa KNoch keine Bewertungen

- Astm-g32-16-Standard Method of Vibratory Cavitation Erosion TestDokument16 SeitenAstm-g32-16-Standard Method of Vibratory Cavitation Erosion TestIMSNoch keine Bewertungen

- Dihydrogen Monoxide (DHMO) MSDS Safety Data SheetDokument5 SeitenDihydrogen Monoxide (DHMO) MSDS Safety Data Sheetskeja2411Noch keine Bewertungen

- Pulso Oximetro 1905 RiesterDokument2 SeitenPulso Oximetro 1905 RiestereduardoNoch keine Bewertungen

- 2530Dokument4 Seiten2530pollux23100% (1)

- En Iso 20471 - 2013Dokument4 SeitenEn Iso 20471 - 2013SiddharthBhasney100% (2)

- Jotun Thinner 10 SafetyDokument15 SeitenJotun Thinner 10 SafetyamaricanNoch keine Bewertungen

- ANSI Z308.1-2009 (First Aid Kits)Dokument15 SeitenANSI Z308.1-2009 (First Aid Kits)Jeff100% (1)

- Hoja de Seguridad Cintas PolykenDokument7 SeitenHoja de Seguridad Cintas PolykenCarlos TarquinoNoch keine Bewertungen

- Shengmei PDFDokument83 SeitenShengmei PDFWilly Villa SalsavilcaNoch keine Bewertungen

- Rc14001 Transition GuideDokument8 SeitenRc14001 Transition Guidemano1574Noch keine Bewertungen

- Post-Tensioning Institute: Tri-Service Infrastructure Systems ConferenceDokument52 SeitenPost-Tensioning Institute: Tri-Service Infrastructure Systems ConferenceTuroyNoch keine Bewertungen

- 10th Latin American Conference On Process Safety 1694623902Dokument9 Seiten10th Latin American Conference On Process Safety 1694623902Julian CeronNoch keine Bewertungen

- Safety Data Sheet Linx Fast-Drying Solvent 1512Dokument5 SeitenSafety Data Sheet Linx Fast-Drying Solvent 1512Anselmo SanchezNoch keine Bewertungen

- Vibration Meter 2513Dokument6 SeitenVibration Meter 2513info5280Noch keine Bewertungen

- Voters Id 2017 PDFDokument188 SeitenVoters Id 2017 PDFchadvillelaNoch keine Bewertungen

- File 1416992597Dokument9 SeitenFile 1416992597Roberto BrionesNoch keine Bewertungen

- ILO - Ambient Factors in The Workplace - 2001Dokument80 SeitenILO - Ambient Factors in The Workplace - 2001nicholisNoch keine Bewertungen

- Thermal Work LimitDokument9 SeitenThermal Work LimitindaNoch keine Bewertungen

- FlygtDokument40 SeitenFlygtAbdo MawjoudNoch keine Bewertungen

- lv4403 PDFDokument1 Seitelv4403 PDFalvaro_arcvNoch keine Bewertungen

- NMKL Procedure No. 8, 4. Ed. (2008) : OntentsDokument33 SeitenNMKL Procedure No. 8, 4. Ed. (2008) : OntentsTrầnXuânSơnNoch keine Bewertungen

- LQ-F090 Niosh 7906Dokument6 SeitenLQ-F090 Niosh 7906Marilu Tello PaucarNoch keine Bewertungen

- NIOSH 7907 - Ácidos VolátilesDokument6 SeitenNIOSH 7907 - Ácidos VolátilesjosepthfrancisNoch keine Bewertungen

- NIOSH 7903 - Acidos InorganicosDokument6 SeitenNIOSH 7903 - Acidos InorganicosNoe Adrianzen MNoch keine Bewertungen

- Niosh 6013Dokument4 SeitenNiosh 6013Frank OspinaNoch keine Bewertungen

- Alkali Metal Cations Na, K, Li 7405: NIOSH Manual of Analytical Methods (NMAM), Fifth EditionDokument5 SeitenAlkali Metal Cations Na, K, Li 7405: NIOSH Manual of Analytical Methods (NMAM), Fifth EditionLINDA IVON PARRADO SÁNCHEZNoch keine Bewertungen

- NIOSH - (Naoh) - KOH LIOH7401 PDFDokument4 SeitenNIOSH - (Naoh) - KOH LIOH7401 PDFEnrique Alejandro OvandoNoch keine Bewertungen

- Cloruro de Zinc PDFDokument3 SeitenCloruro de Zinc PDFPaola RiveraNoch keine Bewertungen

- KilnDokument20 SeitenKilnzabira50% (2)

- Method 7Dokument12 SeitenMethod 7NadiedaNoch keine Bewertungen

- DOE Engineering Symbols-HandbookDokument96 SeitenDOE Engineering Symbols-Handbookapi-3717958Noch keine Bewertungen

- Engineering Drawing Handbook PDFDokument120 SeitenEngineering Drawing Handbook PDFRobert Nixon100% (1)

- M 6-D S D E F S S: 1.0 Scope and ApplicationDokument18 SeitenM 6-D S D E F S S: 1.0 Scope and ApplicationBenoitNoch keine Bewertungen

- SO2 + SO3 en chimenea-EPA PDFDokument9 SeitenSO2 + SO3 en chimenea-EPA PDFDiegoRossoNoch keine Bewertungen

- NAAQSManual Volume IDokument74 SeitenNAAQSManual Volume INataraj NagarajanNoch keine Bewertungen

- Muestreo en Chimenea-Partículas y GasesDokument43 SeitenMuestreo en Chimenea-Partículas y GasesDiegoRossoNoch keine Bewertungen

- 651 NonExistent1Dokument23 Seiten651 NonExistent1DiegoRossoNoch keine Bewertungen

- Compressed Earth BlocksDokument192 SeitenCompressed Earth BlocksAlfred BoyeNoch keine Bewertungen

- 5S Visual Workplace Handbook PDFDokument19 Seiten5S Visual Workplace Handbook PDFDiegoRossoNoch keine Bewertungen

- std01 078686Dokument15 Seitenstd01 078686Max SdNoch keine Bewertungen

- Quality Criteria For WaterDokument477 SeitenQuality Criteria For WaterDiegoRossoNoch keine Bewertungen

- General Procedure For The Sampling of SoilsDokument7 SeitenGeneral Procedure For The Sampling of SoilsDiegoRossoNoch keine Bewertungen

- Plugin Pulp and Paper Tool GuidanceDokument140 SeitenPlugin Pulp and Paper Tool GuidancevolteanuNoch keine Bewertungen

- Pilares de AlbañileríaDokument4 SeitenPilares de AlbañileríaDiegoRossoNoch keine Bewertungen

- The Periodic Table An Eight Period Table For The 21st Centrury 5008Dokument9 SeitenThe Periodic Table An Eight Period Table For The 21st Centrury 5008DiegoRossoNoch keine Bewertungen

- MSDS Soda Ash DenseDokument14 SeitenMSDS Soda Ash DenseNamanNoch keine Bewertungen

- AATCC - 6 - 2001 - CF To Acid & AkalineDokument1 SeiteAATCC - 6 - 2001 - CF To Acid & AkalineNguyễn Công ThoạiNoch keine Bewertungen

- Hardness SoalDokument2 SeitenHardness SoalSarah Winda FauziahNoch keine Bewertungen

- NSS Chemistry Part 4 Acids and Bases - MCDokument35 SeitenNSS Chemistry Part 4 Acids and Bases - MCFelix YueNoch keine Bewertungen

- State of The Art of RO PosttratamientoDokument9 SeitenState of The Art of RO PosttratamientoFlavio AranedaNoch keine Bewertungen

- Dyeing of Polyester and Cotton BlendDokument50 SeitenDyeing of Polyester and Cotton BlendarafathosainNoch keine Bewertungen

- Rs KJ Fefjr Jax Jksxu) Èkqykbz Fcvqfeul) Dkyk) Vey) (KKJ) Ikuh VKSJ Dyksjhu Fojksèk Osq Fy, Fof'Kf"VDokument11 SeitenRs KJ Fefjr Jax Jksxu) Èkqykbz Fcvqfeul) Dkyk) Vey) (KKJ) Ikuh VKSJ Dyksjhu Fojksèk Osq Fy, Fof'Kf"VRoushan KumarNoch keine Bewertungen

- 5-2-10 - Sink or Swim Spaghetti - Discrepant EventDokument3 Seiten5-2-10 - Sink or Swim Spaghetti - Discrepant EventjoeldvNoch keine Bewertungen

- Experiment 4 5 6 PDFDokument14 SeitenExperiment 4 5 6 PDFreay jiNoch keine Bewertungen

- Chemical Spill Response GuidelineDokument19 SeitenChemical Spill Response GuidelineBandita DattaNoch keine Bewertungen

- Lime Soda Ash Softening Calculations PDFDokument34 SeitenLime Soda Ash Softening Calculations PDFDaniel Ortiz100% (1)

- Chemical Physical ChangesDokument6 SeitenChemical Physical ChangesIsaias dos Santos MatosNoch keine Bewertungen

- Reactive and Nylon DyestuffsDokument49 SeitenReactive and Nylon DyestuffsMianAbrarAnjumNoch keine Bewertungen

- Experiment 6'SDokument12 SeitenExperiment 6'SShennyKoh67% (3)

- Capstone-Chapter-1-Done NaaDokument24 SeitenCapstone-Chapter-1-Done NaaRacyl Joyce TobiasNoch keine Bewertungen

- Boiler Water Treatment: AlkalinityDokument21 SeitenBoiler Water Treatment: AlkalinitySalwan ShubhamNoch keine Bewertungen

- Reversible Reactions (Multiple Choice) QPDokument6 SeitenReversible Reactions (Multiple Choice) QPJennifer LohNoch keine Bewertungen

- Group 1 RevisedDokument3 SeitenGroup 1 RevisedkarrizzeNoch keine Bewertungen

- Arabian Journal For Science and Engineering, 2022, 47, 5587-5599Dokument13 SeitenArabian Journal For Science and Engineering, 2022, 47, 5587-5599DanCosminNoch keine Bewertungen

- Back Titration QUestios1Dokument2 SeitenBack Titration QUestios1RSLNoch keine Bewertungen

- Quality Control For The Athenium Baking Soda CompanyDokument21 SeitenQuality Control For The Athenium Baking Soda CompanyJack DupeeNoch keine Bewertungen

- List of Approve Standard For CertificationDokument16 SeitenList of Approve Standard For CertificationmrkhaireeNoch keine Bewertungen

- Soda AshDokument8 SeitenSoda AshRamanamurthy PalliNoch keine Bewertungen

- 06 Chapter 10Dokument34 Seiten06 Chapter 10M Zia DogarNoch keine Bewertungen

- Chemistry IDokument5 SeitenChemistry IDecemei CuaboNoch keine Bewertungen

- Experiment Baking SsodaDokument7 SeitenExperiment Baking Ssodaatynzaty0% (1)