Beruflich Dokumente

Kultur Dokumente

Wastewater Treatment Plant Develop An O&M Manual

Hochgeladen von

hashemiteOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Wastewater Treatment Plant Develop An O&M Manual

Hochgeladen von

hashemiteCopyright:

Verfügbare Formate

Wastewater Treatment Plant: Develop An O&M Manual

This article is intended to cover wastewater treatment plant - Develop an O&M Manual. Read on...

By Daniel L. Theobald

T

his is another in a series of educational articles on water/wastewater. This

document is intended to cover Wastewater Treatment Plant - Develop an O&M

Manual. This generic presentation utilizes my extended number of years of

experience working with Wastewater Treatment Plant - Develop an O&M Manual:

Presentation Details:

• Overview

• Applications and Uses

• Conclusion

Overview

An O&M manual should be targeted for operating the plant, especially in situations where

time may be decisive. It should be complete and thorough, but comfortable to apply. It

should not contain narrative copied from the Facilities Plan or Predesign Reports.

To represent information in the most accessible way, include less narrative and more

This is another in a drawings, schematics, tables, schedules, and checklists. An operator looking for a specific

bit of information should not have to read an essay to obtain it. Avoid boilerplate language

series of educational in favor of information that is specific to the treatment works.

articles on water/ The manual should identify the writer of the manual and any updates. The manual should

also admit the date prepared, settled, and dates of any updates.

wastewater!

Format

This document

Paper O&M manuals should be bound in 3-ring binders to accommodate future revisions.

is intended to All manufacturers’ literature should be bound individually. Sections should have appropriate

cover Wastewater tabs and labels.

Treatment Plant - Electronic manuals (e-manuals) use a menu-driven or intuitive “drill down” navigation

scheme that allows for fast recovery of data. The user should be able to rapidly and

Develop an O&M intuitively find the desired data without having to navigate an excessive act of sub-menus

Manual. or links. One time at the desired information, the drill-down pathway should be easily

identifiable.

84 Water Today - The Magazine l January 2017

For installations that are devoted to the electronic O&M manual b) Overall Process Description: Briefly describe the type

format, a printed version is unnecessarily redundant and not of treatment process employed and the various units or

needed. Notwithstanding, all e-manuals must include: processes incorporated into the installation.

• Backup capabilities in case of computer failure; and c) Plant Layout: Include plan-view diagrams of the plant and

outfall, along with the incoming wastewater.

• A printable user-guide on how to navigate and update the

manual is required. The user-guide must describe log-in d) Design Data Table: Include design population and flows,

protection features. design efficiency and effluent quality goals (BOD, TSS,

ammonia, nutrients, and others), and design capacity for each

• Manufacturers’ literature in a print-friendly format (for

process unit.

example, pdf

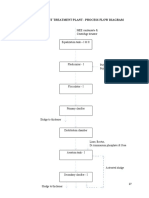

e) Flow diagrams: Include simple schematics.

E-manuals should also:

f) Hydraulic Profile

• Include an ever-present navigation menu with logically

labeled tabs, buttons, or menu headings and drop downs. g) Utilities: Include or reference a program that indicates how

The user should be able to easily identify and return to the the plant is supplied with water, gas, electricity, telephone,

homepage with a single click. and others as appropriate.

• Identify unit processes either graphically or via the menu h) Identify Preventative Maintenance & Asset Management

system. Systems.

• Be formatted and protected to easily allow necessary i) Operator and Management Responsibilities: Include operator

modifications and updates, but only by appropriate personnel. certification requirements, plant staffing requirements, and a

The e-manual should reflect when it was last updated. breakdown of work hours estimated to operate and sustain

the facility.

Applications and Uses:

j) Budget: Provide estimated budget costs.

The pursuit is a recommended O&M manual outline.

Operation and Control of Unit Processes

Table of Contents/Homepage

Each unit process should be under a separate tab. The

The table of contents should correspond to the tabs. For recommended unit process categories include: Influent Pump

e-manuals, the electronic menu system should act as a Table of Station, Headworks, Primary, Secondary, Tertiary, Disinfection,

Contents with tabs on the home page. Recycled Water, Solids Treatment/Storage, and Miscellaneous

Equipment.

Emergency Operations

This part should be separately and readily usable in case of Each unit process should contain the following information:

emergencies. Emergency phone numbers listed should include

a) Description of Unit Processes:

the regional Emergency Response System, local, utility, emergency

contacts (gas, electric, and water), and the local regulatory Office. i) Describe each unit mechanically, including each unit

This part should include copies of, and/or link to, the emergency component and its purpose.

and response programs. Describe or reference procedures for b) Control of Unit Processes:

chlorine leaks, fires, gas leaks, power outages, and so on.

i) Describe thoroughly and in detail how each unit process is to

General be operated and how to manage the unit process.

a) Historical Background: Provide a narrative on the setting ii) Include forms for recording startup and shutdown

and history of the facility. conditions.

Water Today - The Magazine l January 2017 85

c) Common Operating and Control Problems: Operation and Control of Other Mechanical Systems

i) Include handling common operating problems. Such arrangements may include alarms, telemetry, emergency

d) Alternate Operational Modes power and fuel transport systems, landscaping, irrigation,

chemical feeders, HVAC, seal water, level controls, current

i) Specify, if applicable, alternative operational modes.

meters, samplers, and thus alone. Offer data on how these

e) Emergency Operations and Failsafe Modes systems operate, and their operation and upkeep requirements.

i) Insure all applicable failsafe features or features incorporated Supplement with appropriate diagrams as necessary. Whatever

into the plan. these may be sufficiently complex to warrant a separate section

in the manual.

f) Start Up and Shutdown Procedures

Conclusion:

i) Include preparation for start-up and shutdown for each

particular unit in respect to mechanical operation and unit An O&M manual should be targeted for operating the plant,

operation. especially in situations where time may be decisive. It should be

g) Equipment Maintenance Summary complete and thorough, but comfortable to apply. It should not

contain narrative copied from the Facilities Plan or Predesign

i) Include a completed spreadsheet of the electronic

Reports. And then hopefully you are ready to examine now, your

maintenance scheduling system to be employed. To pull

developed Wastewater Treatment Plant; O&M Manual. However,

these details from the manufacturer’s O&M information

beforehand or in the process, feel free to reach out to me with

provided with each item of equipment. Review any draft of

your Wastewater Treatment Plant; O&M Manual or any other

this part before it is settled. This should list all equipment

Wastewater questions.

suppliers and service reps telephone numbers and contact

information.

About The Author

ii) Include a list of critical replacement components that may

Daniel L. Theobald is “Wastewater Dan,” proprietor of

or may not cause longer delivery times associated with them. Environmental Services. He is a professional wastewater

Usually the equipment manufacturers can make helpful and safety consultant/trainer with more than 24 years

recommendations. Show where the spares are to be laid in. of hands-on industry experience operating many variants of

wastewater treatment processing units and is eager to share with

h) Safety others his knowledge about water conservation. Wastewater Dan

i) Keep Safety Data Shee, (SDS) available and up to date. can be reached at TheWastewaterWiz01@gmail.com or www.

Reference their location. Conserve-On-Water.com

86 Water Today - The Magazine l January 2017

Sustainable Water Management In Mining:

A Case Study From NLC

By Pradip Kumar Mishra

I ndia (537.6 million tons) is the fourth largest producer

of coal in the world after China (3,874 Mt), USA (906.9

Mt) and the Australia (644 Mt). India’s industrial journey was

is on the ground water regime of the region. The extracted/

seepage water during drilling and blasting used to collect in the

mine sump where partly used in the mining activities and the

excess amount is discharged into the surface drainage system.

built upon indigenous coal.Around 55% of energy production The water used for spraying on haul roads, conveyors, at loading

generated from coal compared to around 3% from nuclear energy and unloading points, bunkers etc. and the rest amount lost by

(CIL report, 2015). With a population of 1.25 billion,driven by evaporation. The minimal quantity of water used for the green

the rising population and expanding economy and a quest for belts and surrounding plantation areas. Many areas of the country

improved quality of life, the per capita energy consumption are faced with the problem of over exploitation of ground water

was 624 kgoe/year (data extracted from World Bank, 2012). resources resulting in alarming lowering of water table. Therefore

Considering the limited reserve potentiality of petroleum & a lot of care has to be taken in estimating the water need and the

natural gas, eco-conservation restriction on hydroelectric project mines of future are likely to be subjected to a lot of constraints

and geo-political perception of nuclear power, coal will continue on water use and discharge (Singh, 2005)

as up front choice to meet India’s energy scenario.

Breakthrough Initiative

Current Water Management Scenarios in the

Indian Mining Industry The Neyveli Lignite Township in Tamil Nadu’s Cuddalore district

is a golden example of sustainable development in the fields of

Coal mining and its associated activities not only extracts water

water management and land reclamation.

but also affects the hydrological regime of the region and often

affects the water quality. Large and deep opencast mines usually

Prior to 2005, the company employees residing in the township

have great impact on the hydrologic regime of the region. The

had to depend on water supply from a community borewell for

major hydrological impact of a large and deep opencast mine

A view of Neyveli Township surrounded by a dense forest Credit: NLC CSR report

88 Water Today - The Magazine l January 2017

Das könnte Ihnen auch gefallen

- Electrical Scope of WorkDokument5 SeitenElectrical Scope of WorkBoy SwitoNoch keine Bewertungen

- Wastestabilization PondsDokument29 SeitenWastestabilization PondsKamukwema johnNoch keine Bewertungen

- Operating A Water Treatment Plant Is Complex and Requires Knowledge of MachineryDokument12 SeitenOperating A Water Treatment Plant Is Complex and Requires Knowledge of MachineryJoshua OmolewaNoch keine Bewertungen

- Review Paper On Water Leakage Detection in Pipes Using SensorsDokument4 SeitenReview Paper On Water Leakage Detection in Pipes Using SensorsAmeen Ahmed0% (1)

- Semester 1, 2019 Examination: School of Engineering & Applied TechnologyDokument8 SeitenSemester 1, 2019 Examination: School of Engineering & Applied Technologyრაქსშ საჰაNoch keine Bewertungen

- Design Elements For Sedimentation Tank Construction With CalculationsDokument2 SeitenDesign Elements For Sedimentation Tank Construction With CalculationsAravindanNoch keine Bewertungen

- Smart MeterDokument32 SeitenSmart MeterSatheeshSomasekharanNoch keine Bewertungen

- Commissioning Plan Preparation Guide 0Dokument16 SeitenCommissioning Plan Preparation Guide 0Chokri ChakiirNoch keine Bewertungen

- Evaluation & Redesign of University of Guyana Sanitary Sewer SystemDokument32 SeitenEvaluation & Redesign of University of Guyana Sanitary Sewer SystemPeter NobregaNoch keine Bewertungen

- Power Point Presentation On Topic: Framework: Submitted By: Himani KathalDokument11 SeitenPower Point Presentation On Topic: Framework: Submitted By: Himani KathalHimani dmNoch keine Bewertungen

- EFFECT OF SILICA ON CELLULOSE ACETATE/PEG MEMBRANES FOR REVERSE OSMOSISDokument15 SeitenEFFECT OF SILICA ON CELLULOSE ACETATE/PEG MEMBRANES FOR REVERSE OSMOSISPendi Adi MertaNoch keine Bewertungen

- AWDM 10 CH04 Water ConsumptionDokument49 SeitenAWDM 10 CH04 Water ConsumptionJalijashNoch keine Bewertungen

- Effluent Treatment Plant - Process Flow DiagramDokument45 SeitenEffluent Treatment Plant - Process Flow DiagramAmarnath PNoch keine Bewertungen

- Draft Scoping Report Pages 1-742Dokument74 SeitenDraft Scoping Report Pages 1-742iaessackjeeNoch keine Bewertungen

- Stabilization Pond: Types of Stabilization PondsDokument9 SeitenStabilization Pond: Types of Stabilization PondsPaolo Fetalco CruzNoch keine Bewertungen

- Design Calculations for Astana City Sewage Treatment Plant CapacityDokument31 SeitenDesign Calculations for Astana City Sewage Treatment Plant CapacityNataliaKNoch keine Bewertungen

- Trinity Point Scoping Report FinalDokument44 SeitenTrinity Point Scoping Report FinalIan KirkwoodNoch keine Bewertungen

- Smart Water SupplyDokument4 SeitenSmart Water Supplyhimanshucool21Noch keine Bewertungen

- MEMBRANE PROCESSES: FILTRATION, APPLICATIONS AND CLASSIFICATIONDokument35 SeitenMEMBRANE PROCESSES: FILTRATION, APPLICATIONS AND CLASSIFICATIONArie Ikhwan SaputraNoch keine Bewertungen

- Water Treatment Plant Design Specifications Checklist: A. Provincial/City/Municipality ProfileDokument2 SeitenWater Treatment Plant Design Specifications Checklist: A. Provincial/City/Municipality ProfileNiwled UyNoch keine Bewertungen

- Terms of Reference For 2023 CED 3rd YearDokument10 SeitenTerms of Reference For 2023 CED 3rd YearEugene DamoahNoch keine Bewertungen

- Biological Treatment of Waste Water & Design Calculation of Sequencing Batch Reactor ProcessDokument27 SeitenBiological Treatment of Waste Water & Design Calculation of Sequencing Batch Reactor Processفؤاد مهندسNoch keine Bewertungen

- WWTP Im - 2003Dokument118 SeitenWWTP Im - 2003zakariaasmNoch keine Bewertungen

- Report PaperDokument14 SeitenReport PaperAlreen-Nadzrif L. SakandalNoch keine Bewertungen

- 1 s2.0 S2468519421001774 MainDokument21 Seiten1 s2.0 S2468519421001774 Mainwinsyt35Noch keine Bewertungen

- WWTP ReportDokument10 SeitenWWTP ReportDeep SinojiyaNoch keine Bewertungen

- Commercializing AdUF MembraneDokument16 SeitenCommercializing AdUF MembraneFadhilatul AdhaNoch keine Bewertungen

- Construction of Digital Water Level Indi PDFDokument6 SeitenConstruction of Digital Water Level Indi PDFnadia elenaNoch keine Bewertungen

- Preparing Electrical Load SchedulesDokument7 SeitenPreparing Electrical Load SchedulesMila GamidoNoch keine Bewertungen

- Operate and Report On A Water Treatment PlantDokument3 SeitenOperate and Report On A Water Treatment PlantMziyanda Boet-Bhayi ShumîNoch keine Bewertungen

- Activated Sludge Process OverviewDokument5 SeitenActivated Sludge Process OverviewStamPortNoch keine Bewertungen

- O N M Assessment Guide WWTP PDFDokument20 SeitenO N M Assessment Guide WWTP PDFNima AhvaziNoch keine Bewertungen

- Water Manual Vol III v120130Dokument192 SeitenWater Manual Vol III v120130Rich'kid AListadoNoch keine Bewertungen

- Principles and Practices of Reverse OsmosisDokument9 SeitenPrinciples and Practices of Reverse OsmosisMohamadNoch keine Bewertungen

- Side Stream FiltrationDokument8 SeitenSide Stream FiltrationAhmed WagihNoch keine Bewertungen

- IWA - IAM - Water LossesDokument8 SeitenIWA - IAM - Water Lossessasa.vukojeNoch keine Bewertungen

- Sewage Sludge Management in Egypt - Ghazy 2009Dokument9 SeitenSewage Sludge Management in Egypt - Ghazy 2009Mohamed WahbyNoch keine Bewertungen

- DesaltinghandbookDokument310 SeitenDesaltinghandbookIigoNoch keine Bewertungen

- SBR DesignDokument10 SeitenSBR DesignQuốc TuyênNoch keine Bewertungen

- Forward Osmosis DesalinationDokument8 SeitenForward Osmosis DesalinationWahyu TriwahyudiNoch keine Bewertungen

- Waste Water Treatment Plant Energy Baseline StudyDokument43 SeitenWaste Water Treatment Plant Energy Baseline StudyNatarajan RamakrishnanNoch keine Bewertungen

- Motor Data CalculatorDokument6 SeitenMotor Data CalculatorSebastian R.Noch keine Bewertungen

- Purification of Brackish Water Using Hybrid CDI-EDI TechnologyDokument30 SeitenPurification of Brackish Water Using Hybrid CDI-EDI TechnologyamtNoch keine Bewertungen

- Clean Water Works - Volume 4Dokument32 SeitenClean Water Works - Volume 4Northeast Ohio Regional Sewer DistrictNoch keine Bewertungen

- Fluid Mechanics - Pump-Pipeline System Analysis & Design Solved Problem No.3Dokument6 SeitenFluid Mechanics - Pump-Pipeline System Analysis & Design Solved Problem No.3Mohamed Salah YassinNoch keine Bewertungen

- GPSX - Techref 01Dokument372 SeitenGPSX - Techref 01felixNoch keine Bewertungen

- Cycle Chemistry PH MeasurementDokument10 SeitenCycle Chemistry PH MeasurementVel MuruganNoch keine Bewertungen

- ECE4453 Physical Chemical Treatment I Week 4Dokument113 SeitenECE4453 Physical Chemical Treatment I Week 4Mohsen Mohammad0% (1)

- Operation and maintenance of water systemsDokument53 SeitenOperation and maintenance of water systemsvinayasm0% (1)

- Annexure-A. Job Scope Remote CalibrationDokument12 SeitenAnnexure-A. Job Scope Remote CalibrationVision100% (1)

- Process Control WWTP2Dokument5 SeitenProcess Control WWTP2Arima KouseiNoch keine Bewertungen

- Uncertainty Variables On Cost EstimationDokument8 SeitenUncertainty Variables On Cost EstimationHema Chandra IndlaNoch keine Bewertungen

- CSG Water Management PlanDokument83 SeitenCSG Water Management PlanABC News OnlineNoch keine Bewertungen

- Waste Stabilisation PondsDokument8 SeitenWaste Stabilisation PondsIndrie AgustinaNoch keine Bewertungen

- Lift Station - Design ProjectDokument30 SeitenLift Station - Design ProjectChristian DoriaNoch keine Bewertungen

- Topic Quiz QA Wastewater Treatment Dec 04.2021Dokument4 SeitenTopic Quiz QA Wastewater Treatment Dec 04.2021Julie Anne Cristales100% (1)

- Pulsator sludge blanket clarifier optimized performanceDokument2 SeitenPulsator sludge blanket clarifier optimized performancepjrapanutNoch keine Bewertungen

- WWTPDokument47 SeitenWWTPHar Ley QuinnNoch keine Bewertungen

- Sanitary Survey Guidance Manual For Ground Water Systems: October 2008 EPA 815-R-08-015Dokument154 SeitenSanitary Survey Guidance Manual For Ground Water Systems: October 2008 EPA 815-R-08-015fa forbNoch keine Bewertungen

- Systematic Methods of Water Quality Parameters Analysis: Analytical MethodsVon EverandSystematic Methods of Water Quality Parameters Analysis: Analytical MethodsNoch keine Bewertungen

- Nitrogen Removal Performance of Municipal Reverse Osmosis Concentrate With Low C - N Ratio by Membrane-Aerated Biofilm ReactorDokument11 SeitenNitrogen Removal Performance of Municipal Reverse Osmosis Concentrate With Low C - N Ratio by Membrane-Aerated Biofilm ReactorhashemiteNoch keine Bewertungen

- Enhanced Heterogeneous Fenton-Like Activity by Cu-Doped BiFeO3 Perovskite For Degradation of Organic PollutantsDokument10 SeitenEnhanced Heterogeneous Fenton-Like Activity by Cu-Doped BiFeO3 Perovskite For Degradation of Organic PollutantshashemiteNoch keine Bewertungen

- Electrochemical Removal of Nitrate in Industrial WastewaterDokument14 SeitenElectrochemical Removal of Nitrate in Industrial WastewaterhashemiteNoch keine Bewertungen

- Effect of Chemical Dose On Phosphorus Removal and Membrane Fouling Control in A UCT-MBRDokument11 SeitenEffect of Chemical Dose On Phosphorus Removal and Membrane Fouling Control in A UCT-MBRhashemiteNoch keine Bewertungen

- Efficient Photoelectrochemical Oxidation of Rhodamine B On Metal Electrodes Without Photocatalyst or Supporting ElectrolyteDokument6 SeitenEfficient Photoelectrochemical Oxidation of Rhodamine B On Metal Electrodes Without Photocatalyst or Supporting ElectrolytehashemiteNoch keine Bewertungen

- Sodium Hypochlorite Safety and Handling GuideDokument1 SeiteSodium Hypochlorite Safety and Handling GuidehashemiteNoch keine Bewertungen

- Warning: Poly Aluminium Chloride PowderDokument2 SeitenWarning: Poly Aluminium Chloride Powderhashemite0% (1)

- O N M Assessment Guide WWTP PDFDokument20 SeitenO N M Assessment Guide WWTP PDFNima AhvaziNoch keine Bewertungen

- Operation & Maintenance Manual - Sewage Treatment PlantDokument147 SeitenOperation & Maintenance Manual - Sewage Treatment PlanthashemiteNoch keine Bewertungen

- W Wom Manual 112712Dokument18 SeitenW Wom Manual 112712wahyuhendrosNoch keine Bewertungen

- O&M Manual and Preventive Maintenance Logs For Small Water & Wastewater SystemsDokument38 SeitenO&M Manual and Preventive Maintenance Logs For Small Water & Wastewater SystemshashemiteNoch keine Bewertungen

- Tahap Amalan Penggunaan Lestari Dalam Kalangan Guru Di Puchong, SelangorDokument8 SeitenTahap Amalan Penggunaan Lestari Dalam Kalangan Guru Di Puchong, SelangorMasliana SahadNoch keine Bewertungen

- Wind farm project NPV and LCOE analysisDokument5 SeitenWind farm project NPV and LCOE analysisPedro Galvani72% (32)

- UGC MarketingDokument16 SeitenUGC MarketingJK MarketingNoch keine Bewertungen

- How to ping NodeB and RNC using RTN transmission IPDokument14 SeitenHow to ping NodeB and RNC using RTN transmission IPPaulo DembiNoch keine Bewertungen

- Online Ticket Reservation SystemDokument100 SeitenOnline Ticket Reservation SystemPiya SharmaNoch keine Bewertungen

- Why Geomechanical Reservoir KpiDokument43 SeitenWhy Geomechanical Reservoir KpiKevin MusterNoch keine Bewertungen

- Utility Classes - Installation Guide: Dalestech LTDDokument6 SeitenUtility Classes - Installation Guide: Dalestech LTDbvitalNoch keine Bewertungen

- Zero Energy Architecture-2Dokument45 SeitenZero Energy Architecture-2Avjeet SinghNoch keine Bewertungen

- Bitsler DicebotDokument4 SeitenBitsler DicebotShinsNoch keine Bewertungen

- Avinash Excat Full ProjectDokument87 SeitenAvinash Excat Full ProjectNaguSwamyNoch keine Bewertungen

- Social Skills LessonDokument5 SeitenSocial Skills LessonAshley DavidsonNoch keine Bewertungen

- Design of Coin Sorter Counter Based On MCU: Articles You May Be Interested inDokument5 SeitenDesign of Coin Sorter Counter Based On MCU: Articles You May Be Interested inArchana BenkarNoch keine Bewertungen

- Watershed & Four Water ConceptDokument31 SeitenWatershed & Four Water ConceptNarendra SinghNoch keine Bewertungen

- MASTERSEAL 755 SPF v1 PDFDokument2 SeitenMASTERSEAL 755 SPF v1 PDFJaga Nath100% (1)

- Asi X Packer 105243965Dokument3 SeitenAsi X Packer 105243965Esteban RochaNoch keine Bewertungen

- M&S Systems Model MC350A Master Unit Owner's GuideDokument10 SeitenM&S Systems Model MC350A Master Unit Owner's GuidemauricioNoch keine Bewertungen

- Motori Industriali Serie ASC Da 160 A 315mmDokument52 SeitenMotori Industriali Serie ASC Da 160 A 315mmdungga1Noch keine Bewertungen

- 13.2EN Funds-Flow-Analysis Final V1-1 PDFDokument2 Seiten13.2EN Funds-Flow-Analysis Final V1-1 PDFvishnupriyaNoch keine Bewertungen

- LRP I Approved ProjectsDokument1 SeiteLRP I Approved ProjectsTheReviewNoch keine Bewertungen

- Engine and vehicle parameter monitoringDokument170 SeitenEngine and vehicle parameter monitoringAlejandro Samuel100% (2)

- The 717Dokument2 SeitenThe 717An LeNoch keine Bewertungen

- Datasheet TachogeneratorDokument4 SeitenDatasheet TachogeneratorNurulHidayatNoch keine Bewertungen

- DELL XPS 11 VAZ90 LA-A161P Rev 1.0 (A00) 20130814Dokument49 SeitenDELL XPS 11 VAZ90 LA-A161P Rev 1.0 (A00) 20130814Sonel SmithNoch keine Bewertungen

- Honda General Pursone Engine Gx120k1Dokument215 SeitenHonda General Pursone Engine Gx120k1Ricky VilNoch keine Bewertungen

- PQA824 ManualDokument100 SeitenPQA824 ManualElkin AguasNoch keine Bewertungen

- 30x173 - TPDS-T - MK317 Mod0 - NAVSEA - 2011Dokument16 Seiten30x173 - TPDS-T - MK317 Mod0 - NAVSEA - 2011Anonymous jIzz7woS6Noch keine Bewertungen

- Perencanaan Produksi Dan Kebutuhan Material: Modul 4Dokument48 SeitenPerencanaan Produksi Dan Kebutuhan Material: Modul 4Ivanca Earltina Miranda SimanungkalitNoch keine Bewertungen

- Enprep - 110 EC Steel Cu BrassDokument3 SeitenEnprep - 110 EC Steel Cu BrassLựuLiềuLìNoch keine Bewertungen

- Download Descargar libro de geometria analitica de ricardo figueroa bookDokument3 SeitenDownload Descargar libro de geometria analitica de ricardo figueroa bookJuniorNoch keine Bewertungen

- Be 2K OEM's Manual: Bernini Design SRL - ItalyDokument48 SeitenBe 2K OEM's Manual: Bernini Design SRL - ItalySergio Ricardo IbañezNoch keine Bewertungen