Beruflich Dokumente

Kultur Dokumente

Decompipes III

Hochgeladen von

Murillo SirtoliOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Decompipes III

Hochgeladen von

Murillo SirtoliCopyright:

Verfügbare Formate

Decommissioning of Offshore Oil and Gas Installations

IBC Conference, London, 20-21 January 2000

Decommissioning of Pipelines

Per Damsleth

Chief Engineer

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 1

Contents

➤ Introduction

➤ What are the Options?

➤ Environmental Aspects

➤ Decommissioning Operations

➤ Re-certification of Pipelines

➤ Risks Associated with Pipeline Removal

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 2

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 3

Introduction

➤ Design lifetime of offshore pipelines ranges 7 - 20 - 50 years

➤ North Sea fields built since 1974 are becoming depleted

➤ Decisions have to be made when and how to decommission pipelines

➤ No specific regulations exist for decommissioning pipelines

➤ Responsibility of operators for protecting the environment and not

hindering third party activity

➤ Flexibility for operators to find economic and acceptable solutions

➤ Norwegian Governmental Study

➤ Buried pipelines best left alone after flushing out hydrocarbons

➤ Exposed pipelines have to be covered, eventually

➤ Trenching better and less expensive than rock dumping

➤ Removal and re-use gives lower emissions than new pipe

➤ Land disposal causes greater burden on the environment than leaving

in-situ

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 4

What are the options?

➤ Preservation of pipelines “in-situ”

➤ Most common solution (Ekofisk, Frigg, Forties)

➤ Flush with seawater to remove hydrocarbons

➤ Cover ends to prevent trawling net damage

➤ Monitor exposed pipelines for spans or damage until buried

➤ Removal

➤ Re-use (Q8 project, numerous studies)

➤ Recycling

➤ Disposal (Staffa flowline)

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 5

Ekofisk II Field Layout

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 6

Environmental Aspects

➤ Fishing Activity

➤ Newly decommissioned pipeline does not hinder fishing more than

operating pipeline

➤ Fishing nets can be damaged by partially decayed pipeline

➤ Rock berms covering pipelines can also damage nets

➤ Atmospheric Emissions

➤ Removal releases 1/2 as much CO2 as manufacturing new pipe

➤ Trenching releases 1/3 as much CO2 as removal

➤ Marine Pollution

➤ Most pipeline materials do not damage environment

➤ Local leaching of heavy metals from some older anodes

➤ Removal disturbs seabed sediments and spreads toxic materials

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 7

Pipeline Interaction with Fishing

Pipeline in a freespan Pipeline in contact with seabed

60

Fp

50

Pullover Force (kN)

40

Vertical Force, Fz

30

Horizontal Force, Fp

20

10

Lateral and vertical force 0

0.6 sec

0.2

0.8

Tp

0.4

0.6

1.2

0

1

component Time (sec)

Force-time history

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 8

Decommissioning Operations

➤ Preparation

➤ Flushing with seawater to 40ppm hydrocarbons

➤ Internal inspection for re-use

➤ Disconnection from structures

➤ Covering ends to avoid catching anchor lines and fishing nets

➤ Marine operations

➤ No specially adapted equipment available

➤ Reverse laying process

➤ Cut and lift in congested areas

➤ Tow short infield lines

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 9

Reeling Method

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 10

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 11

S-Lay Method

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 12

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 13

S-Lay Barge Layout

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 14

Cut and Lift Method

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 15

Tow Method

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 16

Decommissioning Operations, Cont’d

➤ Cost comparision

➤ Removal for disposal

➤ Recovery and installation

➤ Trench and backfill for preservation in-situ

ACTIVITY COST COMMENT

(GBP)

S-lay: removal for disposal 7,500,000 Offload pipe to pipe carrier vessel

Reeling: removal for disposal 9,000,000 3 trips required to empty reel

S-lay: recovery & installation 12,500,000 Onboard storage + pipe carrier

Reeling: recovery & installation 12,000,000 3 trips to new site required

Trench/backfill: for preservation 3,000,000

Table 1: Marine operations cost of pipeline removal, recovery/installation and

burial

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 17

Decommissioning Operations, Cont’d

➤ Weighing the options

! Few pipelines are the same, seldom interchangeable

! Recovery for re-use = twice the marine operations

! New pipe quality vs used pipe

! Contractually responsible suppliers, guarantees

! Experience? (Q8 project)

! Onshore operations

! No established re-cycling or disposal industry

! Pipe coating yards best equipped to handle large quantities of pipe

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 18

Re-certification of Pipelines

➤ Design Code Checks

! Available inspection and operating records are reviewed

! Corrosion most common cause of damage occurring over time

! Examples of pipelines in good or unacceptable condition

! Strength Criteria for Operation

! Finite Element analysis of global behavior and local strength

! Limit State approach

! Reliability methods

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 19

Magnetic Flux Inspection Pig

Type 2 sensor array

Type 1 sensor array

Permanent Magnetic Brushes

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 20

Internal Inspection

Girth Weld

6” diameter branch

pipe attachment

9

Light corrosion with

depths up to 15% nwt.

Corrosion with

3

pitting depths up

6

to 65% nwt.

12

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 21

Finite Element Analysis

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 22

Risks Associated with Pipeline Removal

➤ Financial

➤ Inspection not 100% complete or accurate

➤ Pipe damage during recovery

➤ Outer coating deterioration

➤ Human

➤ Marine operations

➤ Failure of pipe butt weld during recovery

➤ Life Cycle Cost

➤ Include risk cost of recovering or damaged subsea pipeline

LCC(NPV) = CAPEX(NPV) + OPEX(NPV) + RISKEX(NPV)

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 23

Conclusions

➤ National regulations provide the framework and incentives for

operators to plan and carry out their decommissioning projects.

Guidelines have been prepared to help evaluate proposals,

case-by-case

➤ Preservation in-situ environmentally friendly and economical

compared to removal and disposal

➤ Re-use of pipelines has potential where synergies with other

projects exist (case by case). Collaboration is important to

success.

➤ Most environmentally friendly and economical is re-use in -situ by

extending operating life of pipelines to provide transportation

infrastructure.

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 24

Decommissioning of Offshore Oil and Gas Installations

IBC Conference, London, 20-21 January 2000

Decommissioning of Pipelines

Per Damsleth

Chief Engineer

ABB Offshore Systems

ABB Oil, Gas & Petrochemicals

03.01.00 Page no. 25

Das könnte Ihnen auch gefallen

- Electronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionVon EverandElectronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionBewertung: 5 von 5 Sternen5/5 (1)

- Training Manual - Instruments: Globe Control ValveDokument14 SeitenTraining Manual - Instruments: Globe Control ValveSanjay SoniNoch keine Bewertungen

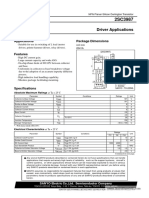

- 2SC2909Dokument4 Seiten2SC2909BIMO MODELADONoch keine Bewertungen

- EHYD6 Hydraulic Valves HY14-2502k001Dokument9 SeitenEHYD6 Hydraulic Valves HY14-2502k001Ahmet SaygılıNoch keine Bewertungen

- Color TV Horizontal Deflection Output ApplicationsDokument3 SeitenColor TV Horizontal Deflection Output Applicationsbakos_andrasNoch keine Bewertungen

- CaseStudy Turbo ExpanderCompressorActiveMagneticBearingTripsReduction PDFDokument23 SeitenCaseStudy Turbo ExpanderCompressorActiveMagneticBearingTripsReduction PDFWidya PermonoNoch keine Bewertungen

- Study CaseDokument23 SeitenStudy CaseWidya PermonoNoch keine Bewertungen

- 2SA1208/2SC2910: High-Voltage Switching Audio 80W Output Predriver ApplicationsDokument4 Seiten2SA1208/2SC2910: High-Voltage Switching Audio 80W Output Predriver ApplicationsEliberto MorenoNoch keine Bewertungen

- Color TV Horizontal Deflection Output ApplicationsDokument3 SeitenColor TV Horizontal Deflection Output ApplicationsYeik Frey Caro CNoch keine Bewertungen

- High GOR Environmentl - SPE Format - Rev1Dokument30 SeitenHigh GOR Environmentl - SPE Format - Rev1SrewaBenshebilNoch keine Bewertungen

- Flow AssignmentDokument5 SeitenFlow AssignmentUsman MuhammadNoch keine Bewertungen

- Adjustments, Weor: CleoroncesDokument4 SeitenAdjustments, Weor: CleoroncesAwliya TaqwaNoch keine Bewertungen

- Presentacion para Enviar VictaulicDokument30 SeitenPresentacion para Enviar Victaulicantonio reda0% (1)

- Sp20 DescripcionDokument2 SeitenSp20 DescripcionJuan Pablo Moreno Téllez Moreno TéllezNoch keine Bewertungen

- SPE 158655 Design, Qualification, and Installation of Openhole Gravel Packs: Mari B Field, Offshore IsraelDokument17 SeitenSPE 158655 Design, Qualification, and Installation of Openhole Gravel Packs: Mari B Field, Offshore IsraelTheNourEldenNoch keine Bewertungen

- Hydraulic Model Inventory - Sotano RCI - WTGDokument2 SeitenHydraulic Model Inventory - Sotano RCI - WTGJohnNoch keine Bewertungen

- Ultrahigh-Definition CRT Display Horizontal Deflection Output ApplicationsDokument4 SeitenUltrahigh-Definition CRT Display Horizontal Deflection Output ApplicationsGabriel RacovskyNoch keine Bewertungen

- MPC 03 Pilot Operated Check ValveDokument3 SeitenMPC 03 Pilot Operated Check ValveJose Luis Quispe LuqueNoch keine Bewertungen

- Injection and Disposal Wells: - What Is Different - How To Convert Producers To InjectorsDokument49 SeitenInjection and Disposal Wells: - What Is Different - How To Convert Producers To Injectorsdriller22Noch keine Bewertungen

- Brochure o Water Sewage Small STC 13Dokument2 SeitenBrochure o Water Sewage Small STC 13jose coelhoNoch keine Bewertungen

- VMOT-H53-300-03-Electrical Load ChartDokument11 SeitenVMOT-H53-300-03-Electrical Load ChartVECTOR MARINE & OFFSHORE TECHNOLOGYNoch keine Bewertungen

- Ultrahigh-Speed Switching Use: Low ON-resistance. Ultrahigh-Speed Switching. 4V Drive. Meets Radial Taping. Unit: MMDokument4 SeitenUltrahigh-Speed Switching Use: Low ON-resistance. Ultrahigh-Speed Switching. 4V Drive. Meets Radial Taping. Unit: MMHectorOmarAraozNoch keine Bewertungen

- Switching Regulator ApplicationsDokument4 SeitenSwitching Regulator ApplicationsmiguelNoch keine Bewertungen

- C3987 SanyoSemiconDeviceDokument4 SeitenC3987 SanyoSemiconDeviceucb51525354Noch keine Bewertungen

- 4 SOP-Tank Farm Final Sent To ZonesDokument37 Seiten4 SOP-Tank Farm Final Sent To ZonesVijayNoch keine Bewertungen

- Project Inventory - MODELAMIENTO 2 DE MAYO - WTGDokument2 SeitenProject Inventory - MODELAMIENTO 2 DE MAYO - WTGRobert Lopez OsorioNoch keine Bewertungen

- Art's Liq Vapor SeparatorRev1Dokument12 SeitenArt's Liq Vapor SeparatorRev1iuiuiooiuNoch keine Bewertungen

- 1.0 Appendix 1 Basis of DesignDokument13 Seiten1.0 Appendix 1 Basis of DesignParthiban NagarethinamNoch keine Bewertungen

- Data SheetDokument3 SeitenData SheetRafael MonzónNoch keine Bewertungen

- 03 Formation DamageDokument23 Seiten03 Formation Damagecv sabiraNoch keine Bewertungen

- Coiled Tubing Emergency ProceduresDokument50 SeitenCoiled Tubing Emergency ProceduresMustafa NaithelNoch keine Bewertungen

- Project Inventory - MODELAMIENTO BARRIOS ALTOS +AMANGAY - WTGDokument2 SeitenProject Inventory - MODELAMIENTO BARRIOS ALTOS +AMANGAY - WTGJavier Andres Nùñez LimoNoch keine Bewertungen

- Check Valve, Poppet Type, In-Line: Model G1, M1, SDokument2 SeitenCheck Valve, Poppet Type, In-Line: Model G1, M1, SRicham HamzeNoch keine Bewertungen

- Flow AssuranceDokument22 SeitenFlow AssuranceAlberto100% (1)

- Technical Description For New Habour Village WWTP Editedjun 30 PDFDokument139 SeitenTechnical Description For New Habour Village WWTP Editedjun 30 PDFKhang TrầnNoch keine Bewertungen

- 8 3....... 2225 PDFDokument29 Seiten8 3....... 2225 PDFنيرمين احمدNoch keine Bewertungen

- Datasheet Transistor C5476Dokument4 SeitenDatasheet Transistor C5476fchavestaNoch keine Bewertungen

- 01 - Operating LimitationsDokument5 Seiten01 - Operating LimitationsRoberto PepióNoch keine Bewertungen

- 06.09.10 - Presentation 4 - Guillermo Kelly - Demostración de Tecnología Geoleach en Quebrada BlancaDokument31 Seiten06.09.10 - Presentation 4 - Guillermo Kelly - Demostración de Tecnología Geoleach en Quebrada Blancaworquera2507Noch keine Bewertungen

- Turbo Expander PDFDokument105 SeitenTurbo Expander PDFwqs_1960% (5)

- Coiled Tubing - Emergency ProceduresDokument50 SeitenCoiled Tubing - Emergency ProceduresSarasevina Anggraeni100% (2)

- RV RV RV RV: Product Data Sheet Product Data Sheet Product Data Sheet Product Data SheetDokument2 SeitenRV RV RV RV: Product Data Sheet Product Data Sheet Product Data Sheet Product Data SheetIndra PutraNoch keine Bewertungen

- 2SA1207/2SC2909: High-Voltage Switching AF 60W Predriver ApplicationsDokument4 Seiten2SA1207/2SC2909: High-Voltage Switching AF 60W Predriver Applicationsabdkrim31Noch keine Bewertungen

- Design of Precast Pier Cap - 1Dokument24 SeitenDesign of Precast Pier Cap - 1Ankush SharmaNoch keine Bewertungen

- D-1309 Sizing Calc Sht1Dokument1 SeiteD-1309 Sizing Calc Sht1NKNoch keine Bewertungen

- Color TV Horizontal Deflection Output ApplicationsDokument5 SeitenColor TV Horizontal Deflection Output Applicationscliffy64Noch keine Bewertungen

- JVCVReport1215 PDFDokument1 SeiteJVCVReport1215 PDFUlises BadilloNoch keine Bewertungen

- Kuwait 20" Pipeline: OilstoneDokument3 SeitenKuwait 20" Pipeline: OilstoneShravan ThangallapalliNoch keine Bewertungen

- Low-Frequency Power Amplifier Applications: 2SA1705/2SC4485Dokument4 SeitenLow-Frequency Power Amplifier Applications: 2SA1705/2SC4485billNoch keine Bewertungen

- CENT Pump - 7Dokument2 SeitenCENT Pump - 7diepriyeNoch keine Bewertungen

- 2SA2099 / 2SC5888: High-Current Switching ApplicationsDokument5 Seiten2SA2099 / 2SC5888: High-Current Switching ApplicationsnguyenhieuproNoch keine Bewertungen

- Ultrahigh-Definition CRT Display Horizontal Deflection Output ApplicationsDokument3 SeitenUltrahigh-Definition CRT Display Horizontal Deflection Output ApplicationsPhilip EgyNoch keine Bewertungen

- Semiconductor Technical Data: Schottky Barrier Rectifiers 20 Amperes 60-100 VOLTSDokument4 SeitenSemiconductor Technical Data: Schottky Barrier Rectifiers 20 Amperes 60-100 VOLTSHatake KakashiNoch keine Bewertungen

- Gas Turbine Simple Cycle SCRDokument20 SeitenGas Turbine Simple Cycle SCRJung Kyung WooNoch keine Bewertungen

- 2 SD 1883Dokument3 Seiten2 SD 1883MiguelZaragozaNoch keine Bewertungen

- Horizontal Multi-Stage Pumps: Component MaterialDokument2 SeitenHorizontal Multi-Stage Pumps: Component MaterialBrayan CJNoch keine Bewertungen

- D2627-Sanyo Semicon Device PDFDokument4 SeitenD2627-Sanyo Semicon Device PDFHerculano ArantesNoch keine Bewertungen

- Ultrahigh-Definition CRT Display Horizontal Deflection Output ApplicationsDokument4 SeitenUltrahigh-Definition CRT Display Horizontal Deflection Output Applicationsmancebo100% (1)

- Dual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDokument3 SeitenDual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelNoch keine Bewertungen

- Case Study LenovoDokument10 SeitenCase Study LenovoGOHAR GHAFFARNoch keine Bewertungen

- Aquamine 50.01Dokument17 SeitenAquamine 50.01Armando RelajoNoch keine Bewertungen

- HSN-Lube 2007 PDFDokument45 SeitenHSN-Lube 2007 PDFCecilio Valderrama100% (3)

- Transformers: Z Z Z S S Z S SDokument17 SeitenTransformers: Z Z Z S S Z S SSreenivasaraoDharmavarapu100% (1)

- Course Weekly Schedule Health Science TheoryDokument6 SeitenCourse Weekly Schedule Health Science Theoryapi-466810096Noch keine Bewertungen

- MINUZA Laptop Scheme Programs ThyDokument9 SeitenMINUZA Laptop Scheme Programs Thyanualithe kamalizaNoch keine Bewertungen

- NeoResin DTM Presentation 9-01Dokument22 SeitenNeoResin DTM Presentation 9-01idreesgisNoch keine Bewertungen

- Lesson Plan in Advanced Chemistry AlcohoDokument17 SeitenLesson Plan in Advanced Chemistry AlcohoGlaiza Mapute CaringalNoch keine Bewertungen

- 1Manuscript-BSN-3y2-1A-CEDILLO-222 11111Dokument32 Seiten1Manuscript-BSN-3y2-1A-CEDILLO-222 11111SHARMAINE ANNE POLICIOSNoch keine Bewertungen

- Bee Keeping-KVK MorenaDokument6 SeitenBee Keeping-KVK MorenaAsh1Scribd100% (1)

- Dual Laminate Piping HandbookDokument46 SeitenDual Laminate Piping HandbookA.Subin DasNoch keine Bewertungen

- 1979 The Cult Phenomenon in The United States - DR John Gordon ClarkDokument8 Seiten1979 The Cult Phenomenon in The United States - DR John Gordon ClarkFrederick BismarkNoch keine Bewertungen

- Preservative MaterialsDokument2 SeitenPreservative MaterialsmtcengineeringNoch keine Bewertungen

- Work of Asha Bhavan Centre - A Nonprofit Indian Organisation For Persons With DisabilityDokument10 SeitenWork of Asha Bhavan Centre - A Nonprofit Indian Organisation For Persons With DisabilityAsha Bhavan CentreNoch keine Bewertungen

- LYON Conditions of Secondment 3500EUR enDokument4 SeitenLYON Conditions of Secondment 3500EUR enabdu1lahNoch keine Bewertungen

- PBL 2 Case PresentationDokument12 SeitenPBL 2 Case PresentationRamish IrfanNoch keine Bewertungen

- On How To Design A Low Voltage SwitchboardDokument11 SeitenOn How To Design A Low Voltage SwitchboardsabeerNoch keine Bewertungen

- English BeginnersDokument34 SeitenEnglish BeginnersCristina ZamfirNoch keine Bewertungen

- Occlusal Appliance TherapyDokument14 SeitenOcclusal Appliance TherapyNam BuiNoch keine Bewertungen

- Class 7 Work Book Answers Acid Bases and SaltsDokument2 SeitenClass 7 Work Book Answers Acid Bases and SaltsGaurav SethiNoch keine Bewertungen

- Preparing Polymers For The Jar TestDokument5 SeitenPreparing Polymers For The Jar Testarvin4dNoch keine Bewertungen

- PYMS Is A Reliable Malnutrition Screening ToolsDokument8 SeitenPYMS Is A Reliable Malnutrition Screening ToolsRika LedyNoch keine Bewertungen

- Learning Activity Sheet MAPEH 10 (P.E.) : First Quarter/Week 1Dokument4 SeitenLearning Activity Sheet MAPEH 10 (P.E.) : First Quarter/Week 1Catherine DubalNoch keine Bewertungen

- Transmission Lines SMART EDGE VILLARUEL For April 2024 v1Dokument89 SeitenTransmission Lines SMART EDGE VILLARUEL For April 2024 v1mayandichoso24Noch keine Bewertungen

- Periodontology Question BankDokument44 SeitenPeriodontology Question BankVanshika Jain100% (6)

- 00516-CLIA-Newsletter Jan 06Dokument4 Seiten00516-CLIA-Newsletter Jan 06losangelesNoch keine Bewertungen

- ReferensiDokument4 SeitenReferensiyusri polimengoNoch keine Bewertungen

- Medical Nutrition Therapy For DiabetesDokument27 SeitenMedical Nutrition Therapy For Diabetesdr.Uci BaharNoch keine Bewertungen

- Impact of Job Design On Employee Engagement: A Theoretical and Literature ReviewDokument6 SeitenImpact of Job Design On Employee Engagement: A Theoretical and Literature ReviewAnonymous CwJeBCAXpNoch keine Bewertungen

- RDG UNIT 2 Skimming Class A 2021Dokument17 SeitenRDG UNIT 2 Skimming Class A 2021Yuly Rumondang Wulan SiallaganNoch keine Bewertungen