Beruflich Dokumente

Kultur Dokumente

Data Sheet Aeration Control Unit TAT IntelliClean

Hochgeladen von

Atty AttyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Data Sheet Aeration Control Unit TAT IntelliClean

Hochgeladen von

Atty AttyCopyright:

Verfügbare Formate

ENVICON Aeration Control Page 1 of 4

TAT IntelliClean® Revision: 2

The ENVICON TAT-IntelliClean® Aeration Control is a self-parameterizing, intelligent

fuzzy control for wastewater treatment plants with intermittent aeration. Experience

has shown that use of the TAT-IntelliClean® fuzzy control leads to optimization of the

treatment process in the treatment plant concerned and, as a result of a high degree

of evening-out of the effluent values to a lower level, to energy savings of up to 30%.

Ntot [mg/l]

12

10 Start of TAT-IntelliClean®

8

6

4

2

0

15. 21. 29. 06. 13. 20. 10. 15. 17. 22. 31. 06. 07. 12. 14. 20. 21. 25. 28. 10.

06. 06. 06. 07. 07. 07. 08. 08. 08. 08. 08. 09. 09. 09. 09. 09. 09. 09. 09. 10.

00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

The economic advantages of the TAT-IntelliClean® Aeration Control result from the

ability to automatically adjust the aeration intensity to the actual load conditions in the

treatment plant ensuing from the inflow conditions and status of biocoenosis in the

aeration tank, with a minimum of measurement and control equipment.

Conventional controls - clocked controls, redox controls, and also controls based on

the parameters NH4, NO3, P, etc. - function according to threshold values, which are

merely empirically determined on the basis of operational experience. In terms of the

process, they do not function optimally, since the process conditions in the aeration

tank change constantly, i.e., they are dynamic. However, the control criteria for

aeration are rigid and static.

The TAT-IntelliClean® fuzzy control uses the actual time curve of process-defining

variables to control. According to a patented process, based on the analysis of the

signal time sequences according to fuzzy pattern classification, characteristic

patterns are generated as switching criteria. The switching criteria are no longer

absolute values, but signal curves. In order to adjust our control to the respective

Prepared Checked Released Document No.

on: 21.01.06 on: 21.01.06 on: 21.01.06 Data Sheet TAT Rev. 2

by: Field by: Wittka by: Charatjan

ENVICON Aeration Control Page 2 of 4

TAT IntelliClean® Revision: 2

treatment plant, the specific characteristics of the signal time curves (e.g., increase in

the oxygen concentration, operating frequencies,…) must be taken into account. For

this reason, a trial operation for 2-3 months is necessary, which is not a formal

replacement of the existing control, but corresponds to the cost, in terms of

engineering, of a process analysis and optimization.

The fuzzy control comprises a fuzzy control computer as a compact module,

complete with screen and keyboard, which is pre-installed in a wall cupboard in

accordance with DIN VDE 0110, 0113, 0660. A digital and analog interface system is

integrated in the computer, as well as a telecontrol option via a telephone connection.

Thus, permanent process analysis by means of visualization and recording and filing

the process data during the trial operation and also for later maintenance, is possible.

The prerequisite for the use of the fuzzy control is the existence of an oxygen, a

redox and a pH measuring sensor at each aeration tank and a telephone connection.

The TAT control computer provides the switching signals for the blowers of the SPC.

Optionally, direct control of the blowers via the O2 control is also possible.

Prepared Checked Released Document No.

on: 21.01.06 on: 21.01.06 on: 21.01.06 Data Sheet TAT Rev. 2

by: Field by: Wittka by: Charatjan

ENVICON Aeration Control Page 3 of 4

TAT IntelliClean® Revision: 2

Based on our experience in treatment plants of comparable size and mode of

operation, the following economic advantages can be expected as a result of the use

of our TAT-IntelliClean® Aeration Control:

improved preconditions for explaining the lowering of the wastewater levy as a

result of a high degree of evening-out of the effluent values to a lower level

savings in aeration energy > 10 – 30 %

increasing N elimination by up to 60 %

lowering of the precipitant requirement for P elimination as a result of improving

biological P removal

increasing the capacity of the treatment plant by up to 15 %

increasing technical and process safety as a result of improving the degree of

monitoring of the process parameters and the entire technical complex of the

aeration stage

increasing the stability of plant operation

Comparison: total annual costs according to LAWA for TAT-IntelliClean® Aeration

Control / conventional controls, taking as an example treatment plants for 40.000 PE /

75.000 PE €/year

47.500

45.000

42.250

40.000

37.250

35.000

32.250

30.000

TAT Redox NO3 NH4

Prof. Dr. Frank Schäfer

Chair of Business Economics Amberg-Weiden College of Advanced Technology april 2001

The TAT-IntelliClean® fuzzy aeration control allows the treatment plant to be

operated according to the specific requirements of the operator of the plant in the

form of a compromise between the level of the effluent values and savings in

aeration energy.

The greater the load fluctuations at a plant, and the more the treatment plant finds

itself at the limit of its capacity, the greater the efficiency and saving potential of the

control.

Prepared Checked Released Document No.

on: 21.01.06 on: 21.01.06 on: 21.01.06 Data Sheet TAT Rev. 2

by: Field by: Wittka by: Charatjan

ENVICON Aeration Control Page 4 of 4

TAT IntelliClean® Revision: 2

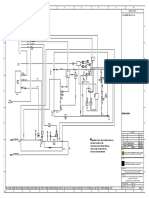

Other advantages of the fuzzy control are the simple, rugged and cost-effective

system for measuring the oxygen concentration, redox potential and pH value. Even

with changing load statuses, manual adjustment of the operating parameters is no

longer necessary. The control is relatively insensitive to zero drifts, sensor soiling and

ageing of the measuring sensors, since no absolute values, but merely curves from

signlas, are used as the basis for switching operations.

The fuzzy control can be used irrespective of the size of the treatment plant. Existing

plants can be retrofitted with simple means. The measured data is visualized and

filed. The control system can also be checked after start-up per remote control

(maintenance control possible). The TAT-IntelliClean® Aeration Control does not

interfere with existing control algorithms of the control system (SPC) and provides the

switching signals for the blowers completely independently:

blowers

control operating / monitoring

switchgear digital I/O

cabinet analog I / O

controller TAT-IntelliClean®

SPC fuzzy telephone connection

control

module

existing controller

1 module O2- / redox- / pH sensor

(measuring sensor)

1 module control system / controller

1 module relay connection for SPC (transmits

switching signals from PC to SPC)

external screen / optional additional screen

O2 / redox sensors with fuzzy surface

prerequisites: - redox / O2 sensors control

- separate telephone connection room

Prepared Checked Released Document No.

on: 21.01.06 on: 21.01.06 on: 21.01.06 Data Sheet TAT Rev. 2

by: Field by: Wittka by: Charatjan

Das könnte Ihnen auch gefallen

- Shell Manhole DetailsDokument1 SeiteShell Manhole DetailsAtty AttyNoch keine Bewertungen

- Engineering document revisions historyDokument1 SeiteEngineering document revisions historyAtty AttyNoch keine Bewertungen

- Concrete Mix DesignDokument2 SeitenConcrete Mix DesignAtty AttyNoch keine Bewertungen

- Ibikunomaa CV SurveyingDokument2 SeitenIbikunomaa CV SurveyingAtty AttyNoch keine Bewertungen

- NPD TKD Evf 07 Mod 0002Dokument1 SeiteNPD TKD Evf 07 Mod 0002Atty AttyNoch keine Bewertungen

- Engineering document revisions historyDokument1 SeiteEngineering document revisions historyAtty AttyNoch keine Bewertungen

- Engineering document revisions historyDokument1 SeiteEngineering document revisions historyAtty AttyNoch keine Bewertungen

- Engineering document revisions historyDokument1 SeiteEngineering document revisions historyAtty AttyNoch keine Bewertungen

- Engineering document revisions historyDokument1 SeiteEngineering document revisions historyAtty AttyNoch keine Bewertungen

- Engineering document revisions historyDokument1 SeiteEngineering document revisions historyAtty AttyNoch keine Bewertungen

- Engineering document revisions historyDokument1 SeiteEngineering document revisions historyAtty AttyNoch keine Bewertungen

- Engineering document revisions historyDokument1 SeiteEngineering document revisions historyAtty AttyNoch keine Bewertungen

- Engineering document revisions historyDokument1 SeiteEngineering document revisions historyAtty AttyNoch keine Bewertungen

- NPD TKD Olf 07 Mod 0002Dokument1 SeiteNPD TKD Olf 07 Mod 0002Atty AttyNoch keine Bewertungen

- NPD TKD Orf 07 Asb 0001Dokument1 SeiteNPD TKD Orf 07 Asb 0001Atty AttyNoch keine Bewertungen

- NPD TKD Olf 07 Mod 0002Dokument1 SeiteNPD TKD Olf 07 Mod 0002Atty AttyNoch keine Bewertungen

- BRASS WALKWAY DIAGRAM Layout 5Dokument1 SeiteBRASS WALKWAY DIAGRAM Layout 5Atty AttyNoch keine Bewertungen

- Engineering document revisions historyDokument1 SeiteEngineering document revisions historyAtty AttyNoch keine Bewertungen

- BRASS WALKWAY DIAGRAM Layout 3Dokument1 SeiteBRASS WALKWAY DIAGRAM Layout 3Atty AttyNoch keine Bewertungen

- BRASS WALKWAY DIAGRAM Layout 4Dokument1 SeiteBRASS WALKWAY DIAGRAM Layout 4Atty AttyNoch keine Bewertungen

- Engineering document revisions historyDokument1 SeiteEngineering document revisions historyAtty AttyNoch keine Bewertungen

- Engineering document revisions historyDokument1 SeiteEngineering document revisions historyAtty AttyNoch keine Bewertungen

- Engineering Request From NAOC PDFDokument1 SeiteEngineering Request From NAOC PDFAtty AttyNoch keine Bewertungen

- BRASS WALKWAY DIAGRAM Layout 2Dokument1 SeiteBRASS WALKWAY DIAGRAM Layout 2Atty AttyNoch keine Bewertungen

- KATADokument2 SeitenKATAAtty AttyNoch keine Bewertungen

- BRASS WALKWAY DIAGRAM Layout 1Dokument1 SeiteBRASS WALKWAY DIAGRAM Layout 1Atty AttyNoch keine Bewertungen

- CNC-KTL-PR-GEN-PFD-001 - Rev 3.0 PDFDokument1 SeiteCNC-KTL-PR-GEN-PFD-001 - Rev 3.0 PDFAtty AttyNoch keine Bewertungen

- Cqs Epr Ts Gen Dts 001 Rev 3.0Dokument10 SeitenCqs Epr Ts Gen Dts 001 Rev 3.0Atty AttyNoch keine Bewertungen

- CNC-KTL-PR-GEN-PID-001 - Rev 3.0 PDFDokument1 SeiteCNC-KTL-PR-GEN-PID-001 - Rev 3.0 PDFAtty AttyNoch keine Bewertungen

- Cqs Epr Ts Gen PHL 001 Rev 3.0Dokument25 SeitenCqs Epr Ts Gen PHL 001 Rev 3.0Atty AttyNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Ioannou Web Ch7Dokument63 SeitenIoannou Web Ch7Yasemin BarutcuNoch keine Bewertungen

- 70-411 R2 Test Bank Lesson 16Dokument11 Seiten70-411 R2 Test Bank Lesson 16Mazaher MohamedaliNoch keine Bewertungen

- Playboy Philippines Mocha Girls PDF 154Dokument4 SeitenPlayboy Philippines Mocha Girls PDF 154Glen S. Reyes0% (2)

- 250 - U MarelDokument16 Seiten250 - U MareldicaveNoch keine Bewertungen

- CandidateHallTicket PDFDokument2 SeitenCandidateHallTicket PDFHimanshu GuptaNoch keine Bewertungen

- RFCMDokument220 SeitenRFCMAkella Ramana KumarNoch keine Bewertungen

- Welding RobotDokument2 SeitenWelding RobotengrodeNoch keine Bewertungen

- Scope and Limitations of The StudyDokument6 SeitenScope and Limitations of The Studyjon rey lumayag100% (1)

- IGraph:MDokument238 SeitenIGraph:Mhecaicedo77Noch keine Bewertungen

- AMIE Lab Report Ravi KumarDokument26 SeitenAMIE Lab Report Ravi KumarDivakar Maurya60% (5)

- Bruno Mars Digital Marketing StrategyDokument3 SeitenBruno Mars Digital Marketing Strategyapi-234351882Noch keine Bewertungen

- PRPI-048 D20 D25 IBOX Automation ApplicationsDokument49 SeitenPRPI-048 D20 D25 IBOX Automation Applicationsrommel76Noch keine Bewertungen

- BIM in Bridge Design - 638318 - FULLTEXT01 PDFDokument83 SeitenBIM in Bridge Design - 638318 - FULLTEXT01 PDFPaulo De Araujo Regis100% (1)

- Chapter 3: User Interfaces: ObjectivesDokument24 SeitenChapter 3: User Interfaces: ObjectivesAbdullahSarfarazNoch keine Bewertungen

- Vice President Director Sales in Orlando FL Resume Beverly Rider PDFDokument3 SeitenVice President Director Sales in Orlando FL Resume Beverly Rider PDFIsmaelNoch keine Bewertungen

- 14-Channel Programmable Switchable I C TFT-LCD Reference Voltage Generator With Integrated 4-Channel Static Gamma Drivers FeaturesDokument10 Seiten14-Channel Programmable Switchable I C TFT-LCD Reference Voltage Generator With Integrated 4-Channel Static Gamma Drivers FeaturesRepararelcd LcdNoch keine Bewertungen

- Siemens SIMATIC Step 7 Programmer PDFDokument71 SeitenSiemens SIMATIC Step 7 Programmer PDFkamelNoch keine Bewertungen

- Cyber LawDokument16 SeitenCyber LawAmrit Raz100% (1)

- Simplex Optimization of Production Mix A Case of Custard Producing Industries in NigeriaDokument10 SeitenSimplex Optimization of Production Mix A Case of Custard Producing Industries in NigeriaAqueel Amir AliNoch keine Bewertungen

- 04 PandasSQL PDFDokument18 Seiten04 PandasSQL PDFmgrubisicNoch keine Bewertungen

- Jakarta Struts: Manually Validating InputDokument30 SeitenJakarta Struts: Manually Validating Inputluislaar33Noch keine Bewertungen

- 106106140Dokument2 Seiten106106140A vyasNoch keine Bewertungen

- WT01 2008 en Gesamt PDFDokument105 SeitenWT01 2008 en Gesamt PDFRandy LangleyNoch keine Bewertungen

- 02 6Dokument13 Seiten02 6chaitanyaNoch keine Bewertungen

- C# Multithreaded and Parallel Programming Sample ChapterDokument36 SeitenC# Multithreaded and Parallel Programming Sample ChapterPackt PublishingNoch keine Bewertungen

- What Was Alan TuringDokument11 SeitenWhat Was Alan TuringAdeel DurraniNoch keine Bewertungen

- Sap Scripts Tutorial PDFDokument89 SeitenSap Scripts Tutorial PDFdamljanovic100% (2)

- OSSEC Log Mangement With ElasticsearchDokument24 SeitenOSSEC Log Mangement With Elasticsearchkindaegi50% (2)

- Geodatabase Topology Rules and Topology Error FixeDokument29 SeitenGeodatabase Topology Rules and Topology Error FixeRahul DekaNoch keine Bewertungen

- For Microsoft: Lexis Office Tip Sheet-Check Cite FormatDokument2 SeitenFor Microsoft: Lexis Office Tip Sheet-Check Cite FormatMehboob UsmanNoch keine Bewertungen