Beruflich Dokumente

Kultur Dokumente

TDS PU Sealant Bamco BSSL - Eng - 2014 Rev.03

Hochgeladen von

JoeOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TDS PU Sealant Bamco BSSL - Eng - 2014 Rev.03

Hochgeladen von

JoeCopyright:

Verfügbare Formate

Dr.

Fixit PU Sealant

ONE-PART NON-SAG POLYURETHANE SEALANT

Description:

Dr. Fixit PU Sealant is a one-part Polyurethane Sealant composed of polyurethane

polymer, pigment, filler & additives. It is used for filling and sealing joints in buildings & structures.

Technical data sheet: PU Sealant

It is highly elastic & resilient; weather durable, none sagging, watertight with excellent adhesion to

almost all building construction materials.

Standard

ASTM C-920, Type S, Grade NS, Class 25, Use; NT, T, A, and M

DIN EN ISO 11600 – Type F – Classification 25 LM

Area of Application

Sealing of expansion and construction joints as well as joints between different construction

materials in high-rise buildings, basements, Floorings etc.

Sealing joints in between precast concrete panels.

Sealing Joints in between tiles, bricks, and marble etc.

Sealing joints of metal container finishing.

Repairing of non-moving concrete Cracks and control widths.

Perimeter pointing & curtain wall ceiling.

Features & Benefits

Single Component & Ready to use

Excellent Elasticity

Excellent adhesion to concrete & most of construction material

No sagging & staining

Excellent Weathering durability

Movement accommodation - Accommodates continuous and pronounced cyclic movements.

Can be over coated

Joint design

For various reasons, different types of joints are provided with width depth ratios in

different proportions. Depending on the horizontal or vertical movements, the cured sealant

should retain its original shape after the deformation of expansion/contraction. So width

depth ratio is important.

Width: Depth Ratio

Joint Width (mm.) Width : Depth Ratio

For 6 to 12 mm. joint width Depth shall be 1:1 (equal)

For 12 to 50 mm. joint width Depth shall be 2:1 (half)

S-PI-001 Rev.En03 1July 2015 P1/4

Dr. Fixit PU Sealant

ONE-PART NON-SAG POLYURETHANE SEALANT

Method of Application

Technical data sheet: PU Sealant

1. Joint Preparation:

Joint edges should be sound and free from grease or oil contaminations. if spelled, it should

be rectified properly by using polymer mortar or epoxy mortar.

Use a closed cell Dr.Fixit Backing Rod as a back up material. Back up material is used to

adjust width to depth ratio and falling of sealant while application. Ex: thermocol sheet can

be used as a back up material.

Fix a bond breaker tape over the backup material to prevent third surface adhesion.

Fix a masking tape on both sides of joint surface to get neat & clean appearance of joints

after application of sealant.

2. Application

Dr.Fixit PU Sealant is available in 600 ml sausages & 300 ml cartridge. Insert the sausage

in hand operated application gun. Apply nominal pressure over the trigger of the gun so that

sealant starts extruding out of the nozzle & fill the sealant in joints. Apply slightly in excess

for tooling & finishing purpose.

3. Finishing

Tool the sealant immediately with tooling knife by pressing against the joint to remove air

pockets & to ensure 100% contact and adhesion with the surface.

4. Cleaning

After sealing the joint the tools and equipments should be cleaned immediately with

kerosene or any other cleaning solvents.

Precautions & Limitations

Maximum width for application in a joint is 50 mm.

Minimum depth of seal is 6 mm.

Do not expose the sealant to high temperatures.

Avoid application on damp and moist substrates and at Temperature below 5°C.

Sealant will not adhere to substrates with contamination and traces of bitumen.

Adhesion of the sealant must only be on two opposite faces.

Do not carry out sealing operations during hot weather conditions.

Use of shalitex board as a back up material should be avoided.

Application to be started only after 30 minutes of priming the substrate.

White grade, May slightly yellow on exposure to UV light.

S-PI-001 Rev.En03 1July 2015 P2/4

Dr. Fixit PU Sealant

ONE-PART NON-SAG POLYURETHANE SEALANT

Technical data sheet: PU Sealant

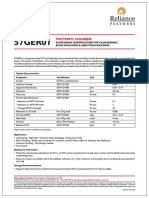

Technical Information

Properties Specification / Standard Results

Appearance - Pasty

Color - White/Grey

Density at 20 °C - 1.16 ± 0.05

Sagging (ISO 7390) None

Application temperature - 5 to 35 °C

Skin formation time at 23 °C and 50 - 5 to 10 h

%HR

Cure time at 23 °C and 50 % HR - > 2 mm/24 h

(Depending on climate

condition and joint size)

Final Shore A hardness (ISO 868 – 3 ISO 868 – 3 Ca 25

seconds)

*Modulus at 100 % ASTM D412 0.3 Mpa

*Elongation at break ASTM D412 > 600 %

*Tensile Strength ASTM D412 2.6 Mpa

Temperature resistance - -30 to +80 °C

Resistance to dilute acids and bases - Average

UV resistance - Good

Water and salt spray resistance - Excellent

Compatibility with paints - Water based : yes

Solvent based : carry

out tests beforehand

S-PI-001 Rev.En03 1July 2015 P3/4

Dr. Fixit PU Sealant

ONE-PART NON-SAG POLYURETHANE SEALANT

Technical data sheet: PU Sealant

Packing

Dr.Fixit PU Sealant

600 ml sausage

300 ml catridge

Color ; White / Grey

Coverage

Total Number of liters required* = Joint width (mm.) x Joint depth (mm.)x Joint length (m.)

1000

* Wastage is not considered

Shelf Life & Storage

Shelf life is 12 months from the date of manufacturing.

Stored in cool and dry place

Health & Safety Precaution

Some people are sensitive to solvents, resins and hardeners and so it is advisable to use

hand gloves and goggles.

Avoid application on damp and moist substrates and at Temperature below 5°C.

S-PI-001 Rev.En03 1July 2015 P4/4

Das könnte Ihnen auch gefallen

- Issue #9 Printing and Graphics Science Group NewsletterVon EverandIssue #9 Printing and Graphics Science Group NewsletterNoch keine Bewertungen

- Low Modulus 1 Part Polyurethane SealantDokument2 SeitenLow Modulus 1 Part Polyurethane SealantVietpapayaNoch keine Bewertungen

- Joint Sealant - Colpor 200PFDokument3 SeitenJoint Sealant - Colpor 200PFAnonymous jhNiwHqpX0% (1)

- ABC Polyurethane SealantDokument1 SeiteABC Polyurethane SealantJohn Errol Saldevar MarcosNoch keine Bewertungen

- 02.3standard Rubber Test MethodsDokument46 Seiten02.3standard Rubber Test Methodsluis martinezNoch keine Bewertungen

- Elastomer Brochure 2010Dokument52 SeitenElastomer Brochure 2010mlombardiTONoch keine Bewertungen

- Solvent-Based Separation and Recycling of Waste Plastics A ReviewDokument14 SeitenSolvent-Based Separation and Recycling of Waste Plastics A ReviewChristhy Vanessa Ruiz MadroñeroNoch keine Bewertungen

- Elastopave 6551-102Dokument3 SeitenElastopave 6551-102Barbaros ReisNoch keine Bewertungen

- PVC 57ger01Dokument1 SeitePVC 57ger01rajesh patelNoch keine Bewertungen

- Adhesive Test MethodsDokument17 SeitenAdhesive Test MethodsTensile TestingNoch keine Bewertungen

- Silicone Hard Coating PDFDokument3 SeitenSilicone Hard Coating PDFgalati12345Noch keine Bewertungen

- Aquacer 497 en PDFDokument2 SeitenAquacer 497 en PDFmaheshNoch keine Bewertungen

- Polymer AdditivesDokument7 SeitenPolymer AdditivesS S S REDDY100% (1)

- Managing Adhesive Ooze PDFDokument3 SeitenManaging Adhesive Ooze PDFkapasariNoch keine Bewertungen

- Dow Latex PowderDokument2 SeitenDow Latex PowderLựuLiềuLìNoch keine Bewertungen

- TDS Siamvic 258RBDokument1 SeiteTDS Siamvic 258RBPinyaporn VeerapraditNoch keine Bewertungen

- Polyurea Vs Polyurethane & Polyurethane Polyurea What's The DifferenceDokument20 SeitenPolyurea Vs Polyurethane & Polyurethane Polyurea What's The Differencemiguel100% (1)

- Dabco Catalyst Package Vink EvoniksDokument36 SeitenDabco Catalyst Package Vink EvoniksKanagarajan Vijayakumar100% (2)

- Synthetic Resins and Their Raw Materials - United States Tariff CommissionDokument220 SeitenSynthetic Resins and Their Raw Materials - United States Tariff CommissionKevin Lora VillarrealNoch keine Bewertungen

- Tosoh Silica Precipitated Silica BrochureDokument16 SeitenTosoh Silica Precipitated Silica BrochureDewiNoch keine Bewertungen

- TDS Ydf 170Dokument2 SeitenTDS Ydf 170LONG LASTNoch keine Bewertungen

- 21 CFR 177Dokument6 Seiten21 CFR 177i_flyNoch keine Bewertungen

- MP DiolDokument6 SeitenMP DiolJijo T GeorgeNoch keine Bewertungen

- Mowrer Polysiloxane Ctgs InnovDokument16 SeitenMowrer Polysiloxane Ctgs InnovUsama AwadNoch keine Bewertungen

- Characterization of Polymer FoamsDokument35 SeitenCharacterization of Polymer Foamsssm_majeed100% (1)

- Types of Sealants Used For Joints in Buildings - Properties, Uses, WorkingDokument6 SeitenTypes of Sealants Used For Joints in Buildings - Properties, Uses, WorkingJustin MusopoleNoch keine Bewertungen

- Slip AdhesivosDokument24 SeitenSlip AdhesivosMiguelAngelPerezEsparza100% (1)

- Latapoxy SP 100 TDSDokument3 SeitenLatapoxy SP 100 TDSBithika DattaNoch keine Bewertungen

- Properties of EVM Compounds in Relation To The Vinyl Acetate Content of The PolymerDokument10 SeitenProperties of EVM Compounds in Relation To The Vinyl Acetate Content of The PolymerabiliovieiraNoch keine Bewertungen

- ISO 14000 AuditDokument3 SeitenISO 14000 Auditjohnthep20090% (1)

- ASTM D1763 00 Epoxy Resins PDFDokument4 SeitenASTM D1763 00 Epoxy Resins PDFHemant YesajiNoch keine Bewertungen

- Product Information Sheet CE-1618, Methyl Palmitate/ OleateDokument2 SeitenProduct Information Sheet CE-1618, Methyl Palmitate/ OleateYassine LemsyehNoch keine Bewertungen

- OH Determination For Polyether PolyolDokument4 SeitenOH Determination For Polyether PolyolHoang Cong ThanhNoch keine Bewertungen

- De AssignmentDokument9 SeitenDe AssignmentManish MohapatraNoch keine Bewertungen

- Harwick AcceleratorsDokument5 SeitenHarwick AcceleratorsAkash KumarNoch keine Bewertungen

- Adhesive SelectionDokument17 SeitenAdhesive SelectionPubg fansNoch keine Bewertungen

- Mastertop 1205: Three Component Solvent Free High Build Epoxy Floor CoatingDokument3 SeitenMastertop 1205: Three Component Solvent Free High Build Epoxy Floor CoatingEngTamerNoch keine Bewertungen

- Composite Bopp FilmDokument1 SeiteComposite Bopp FilmTahir MahmoodNoch keine Bewertungen

- Arkema M52Dokument33 SeitenArkema M52yigitilgazNoch keine Bewertungen

- D4209Dokument2 SeitenD4209uocmogiandi_aNoch keine Bewertungen

- Additives PE Swapan DharaDokument79 SeitenAdditives PE Swapan DharatrydeepNoch keine Bewertungen

- Impact Modifiers Processing Aids Lubricants Microorganism InhibitorsDokument19 SeitenImpact Modifiers Processing Aids Lubricants Microorganism InhibitorsSheena GagarinNoch keine Bewertungen

- IS 3400 (Part 9) 2020 - Vulcanized RubberDokument14 SeitenIS 3400 (Part 9) 2020 - Vulcanized RubberSuvro ChakrabortyNoch keine Bewertungen

- Environmental Biodegradation of Synthetic Polymers I. Test Methodologies and ProceduresDokument16 SeitenEnvironmental Biodegradation of Synthetic Polymers I. Test Methodologies and ProceduressonchemenNoch keine Bewertungen

- PolyureaDokument47 SeitenPolyureaNabored SiakoNoch keine Bewertungen

- TDS Irganox B 215Dokument2 SeitenTDS Irganox B 215Jorge David Rojas CardenasNoch keine Bewertungen

- Alkyd Resins synthesis-PET PDFDokument5 SeitenAlkyd Resins synthesis-PET PDFDonald_12Noch keine Bewertungen

- Adhesion and Adhesive ApplicationDokument2 SeitenAdhesion and Adhesive ApplicationTarani TharanNoch keine Bewertungen

- New Stabilizer Solutions For Polyolefin Film GradesDokument52 SeitenNew Stabilizer Solutions For Polyolefin Film GradesZirve Polimer100% (1)

- Dimethyl TerephthalateDokument9 SeitenDimethyl Terephthalatehung_metalNoch keine Bewertungen

- Carboxyl End Group Content of Polyethylene Terephthalate (PET) YarnsDokument3 SeitenCarboxyl End Group Content of Polyethylene Terephthalate (PET) YarnsLupita RamirezNoch keine Bewertungen

- Global Scenario On Toluene Diisocyanate (TDI) : Nandini Consultancy CenterDokument13 SeitenGlobal Scenario On Toluene Diisocyanate (TDI) : Nandini Consultancy Centeranuj242100% (1)

- Safety Data Sheet: 1. IdentificationDokument8 SeitenSafety Data Sheet: 1. IdentificationShinthya DewiNoch keine Bewertungen

- Additive MasterbatchesDokument4 SeitenAdditive MasterbatchesChinmoy DholeNoch keine Bewertungen

- 590-534 1K Black (CF590-534)Dokument3 Seiten590-534 1K Black (CF590-534)karla arzateNoch keine Bewertungen

- Desmocoll 540 5Dokument2 SeitenDesmocoll 540 5lobocernaNoch keine Bewertungen

- Chemlok 205 - 220 영문Dokument5 SeitenChemlok 205 - 220 영문Ardiansyah Andry100% (1)

- Cleaning and disinfection of food factories: a practical guideVon EverandCleaning and disinfection of food factories: a practical guideNoch keine Bewertungen

- S 10 Eurofins Leed Confirmation Eq 4 1 20101019 e 1Dokument2 SeitenS 10 Eurofins Leed Confirmation Eq 4 1 20101019 e 1JoeNoch keine Bewertungen

- Ottoseal® S69: The Acetate Silicone For Clean Rooms and Room Ventilation SystemsDokument3 SeitenOttoseal® S69: The Acetate Silicone For Clean Rooms and Room Ventilation SystemsJoeNoch keine Bewertungen

- S 70 Eurofins Leed Conformation Eq 4 1 20101015 e 1Dokument2 SeitenS 70 Eurofins Leed Conformation Eq 4 1 20101015 e 1JoeNoch keine Bewertungen

- Ottoseal® S70: The Premium Natural Stone SiliconeDokument5 SeitenOttoseal® S70: The Premium Natural Stone SiliconeJoeNoch keine Bewertungen

- Ottoseal® S94: Technical DatasheetDokument3 SeitenOttoseal® S94: Technical DatasheetJoeNoch keine Bewertungen

- Ottocoll® P83: The PU Adhesive/sealantDokument3 SeitenOttocoll® P83: The PU Adhesive/sealantJoeNoch keine Bewertungen

- Ottoseal® S 120: The Premium Alkoxy Window SiliconeDokument5 SeitenOttoseal® S 120: The Premium Alkoxy Window SiliconeJoeNoch keine Bewertungen

- Otto Cleanprimer 1101: The Adhesion ImproverDokument2 SeitenOtto Cleanprimer 1101: The Adhesion ImproverJoeNoch keine Bewertungen

- Ottocoll® M 590: The Hybrid-Adhesive For Full-Surface BondingDokument3 SeitenOttocoll® M 590: The Hybrid-Adhesive For Full-Surface BondingJoeNoch keine Bewertungen

- Ottocoll® M 500: The Water-Resistant Premium Hybrid Adhesive/sealantDokument4 SeitenOttocoll® M 500: The Water-Resistant Premium Hybrid Adhesive/sealantJoeNoch keine Bewertungen

- Tds OTTOCOLL M 500 42 - 28gb PDFDokument4 SeitenTds OTTOCOLL M 500 42 - 28gb PDFJoeNoch keine Bewertungen

- Ottocoll® Hitack: The Hybrid Adhesive With High Initial AdhesionDokument4 SeitenOttocoll® Hitack: The Hybrid Adhesive With High Initial AdhesionJoeNoch keine Bewertungen

- Otto Primer 1216: The Primer For Natural Stone and MetalDokument2 SeitenOtto Primer 1216: The Primer For Natural Stone and MetalJoeNoch keine Bewertungen

- The ASTM D4263 Concrete Moisture TestDokument4 SeitenThe ASTM D4263 Concrete Moisture TestJoe100% (1)

- Sikadur - 31 (IN) : 2-Part Thixotropic Epoxy AdhesiveDokument4 SeitenSikadur - 31 (IN) : 2-Part Thixotropic Epoxy AdhesiveJoeNoch keine Bewertungen

- Sikadur - 52: Low Viscosity Injection ResinDokument3 SeitenSikadur - 52: Low Viscosity Injection ResinJoeNoch keine Bewertungen

- Sika SBR 100: SBR Based Multipurpose Polymer For Waterproofing and RepairDokument3 SeitenSika SBR 100: SBR Based Multipurpose Polymer For Waterproofing and RepairJoeNoch keine Bewertungen

- IGCA Home Visit ReportDokument7 SeitenIGCA Home Visit Reportspostula5207Noch keine Bewertungen

- 5 16 Engineered Installation InstructionsDokument14 Seiten5 16 Engineered Installation InstructionsNeil V. MonteleoneNoch keine Bewertungen

- Newton System 500 Brochure November2012Dokument5 SeitenNewton System 500 Brochure November2012Aneeta HariNoch keine Bewertungen

- AAC Floor Systems Install Guide - March 2019 PDFDokument17 SeitenAAC Floor Systems Install Guide - March 2019 PDFSergeyGalkinNoch keine Bewertungen

- BASF Company ProfileDokument4 SeitenBASF Company ProfileAhmed Mostafa AL-AboudyNoch keine Bewertungen

- Welding Vinyl FlooringDokument4 SeitenWelding Vinyl FlooringFloorkitNoch keine Bewertungen

- Warranty Quick-Step VinylDokument7 SeitenWarranty Quick-Step VinylRicardo BalauNoch keine Bewertungen

- Design Source and MaterialDokument193 SeitenDesign Source and MaterialAdarsh AgarwalNoch keine Bewertungen

- M/S Sanwariya Stone Trading Co.: Stone Cutting and Polishing UnitDokument3 SeitenM/S Sanwariya Stone Trading Co.: Stone Cutting and Polishing UnitPUNEET JAINNoch keine Bewertungen

- Chemproof ChemicalsDokument11 SeitenChemproof Chemicalsreddy garuNoch keine Bewertungen

- Dura FlexDokument16 SeitenDura FlexJohn ChivNoch keine Bewertungen

- PARAS Quartier-BrochureDokument16 SeitenPARAS Quartier-BrochureAjay YadavNoch keine Bewertungen

- Technical Information Product Technology No. 2.2Dokument12 SeitenTechnical Information Product Technology No. 2.2Muhannad AbdulRaoufNoch keine Bewertungen

- Floor Finishes M50/150/SHEET 005/11: Architectural Standards Product Data SheetDokument1 SeiteFloor Finishes M50/150/SHEET 005/11: Architectural Standards Product Data SheetNay Win MaungNoch keine Bewertungen

- Holistic Cost Break Down FinalDokument76 SeitenHolistic Cost Break Down FinalABELNoch keine Bewertungen

- Tiles Proposal From Al BalaghDokument3 SeitenTiles Proposal From Al BalaghHariKumar PNoch keine Bewertungen

- How To Install A PEX PipeDokument2 SeitenHow To Install A PEX PipePEX Tubing Store PEX Supply100% (1)

- Parchet Laminat - EnglezaDokument45 SeitenParchet Laminat - EnglezaBalint EdeNoch keine Bewertungen

- Chapter 43 Interior Finishing MaterialsDokument14 SeitenChapter 43 Interior Finishing MaterialsRicha ChamariaNoch keine Bewertungen

- Taber Test Reference by Method PDFDokument2 SeitenTaber Test Reference by Method PDFОлегNoch keine Bewertungen

- 170 - Help Points List PDFDokument6 Seiten170 - Help Points List PDFRaju PuttaswamyNoch keine Bewertungen

- DecorativePaint PDFDokument128 SeitenDecorativePaint PDFAndreea JoitaNoch keine Bewertungen

- Dream Bedroom ProjectDokument4 SeitenDream Bedroom ProjectAshley LaurenNoch keine Bewertungen

- Floor Plan BrochurebrigadeDokument13 SeitenFloor Plan BrochurebrigadepiyushNoch keine Bewertungen

- NG Teng Fong General Hospital (NTFGH) Jurong East, SingaporeDokument12 SeitenNG Teng Fong General Hospital (NTFGH) Jurong East, SingaporeShagufta AinNoch keine Bewertungen

- Civil Engineering Program: Submitted To: Dr. Furkan Uysal Team No.: 21 Submitted By: Mohamed Ayman AhmedDokument24 SeitenCivil Engineering Program: Submitted To: Dr. Furkan Uysal Team No.: 21 Submitted By: Mohamed Ayman AhmedJehad AlyafiNoch keine Bewertungen

- Floor Underlayment (Allied Custom Gypsum) PDFDokument12 SeitenFloor Underlayment (Allied Custom Gypsum) PDFDonald EssenNoch keine Bewertungen

- Fort St. John - RCMP Building Construction Letters of IntentDokument9 SeitenFort St. John - RCMP Building Construction Letters of IntentAlaskaHighwayNewsNoch keine Bewertungen

- Smart City Ecological Park BOQDokument21 SeitenSmart City Ecological Park BOQJalal TamboliNoch keine Bewertungen