Beruflich Dokumente

Kultur Dokumente

Large Axial Fans: Tce Consulting Engineers Limited Data Sheet A

Hochgeladen von

Nits KOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Large Axial Fans: Tce Consulting Engineers Limited Data Sheet A

Hochgeladen von

Nits KCopyright:

Verfügbare Formate

TCE.

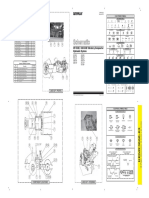

M4-106-05 TCE CONSULTING ENGINEERS LIMITED SECTION : D

ISSUE NO. R2

ENQ.SPEC.NO. DATA SHEET A

TCE. LARGE AXIAL FANS SHEET : 1 OF 3

1. DESIGNATION : 22.3 PERMISSIBLE PRESSURE DROP :

DESIGN DATA

(CONTINUED)

Kg/cm 2

2. NUMBER REQUIRED : ( W+ 22.4 QUALITY : AS PER

S)

3. TAG NUMBERS :

4. TYPE : TUBE AXIAL / VANE AXIAL

5. LOCATION : INDOOR / OUTDOOR 23. MOUNTING : ON CONCRETE

GENERAL

6. OPERATION : CONTINUOUS/ FOUNDATION

INTERMITTENT 24. MODE OF ADJUSTMENT OF GAS FLOW

Hrs/Day

7. LOCATION IN HAZARDOUS AREA : CONTROL: INLET GUIDE VANE /

YES / NO INLET VANE AND HYDRAULIC SPEED

8. HAZARDOUS AREA CLASSIFICATION: VARIABLE / DAMPER /VARIABLE

AS PER IS 5572 ZONE 0 / 1 / 2 PITCH CONTROL

9. ARRANGEMENT: AMCA STANDARD 25. TYPES OF BLADES:

ARRANGEMENT NO. (NOTE-1)

10. CAPACITY (FAD) : M³/ 26. CASING: AXIAL/RADIALLY SPLIT

Hr

10.1 NORMAL :

CONSTRUCTION FEATURES

10.2 MAXIMUM: 27. VOLUTE : DIFFUSER/

11. GAS HANDLED: MANUFACTURER’S STANDARD

12. TEMPERATURE OF GAS :

°C

13. DENSITY OF GAS: 28. SHAFT : COUPLED / VERTICAL /

Kg/M3

14. SUCTION HUMIDITY : MAXIMUM MANUFACTURER’S STANDARD

(RH%) :

MINIMUM

DESIGN DATA

15. STATIC PRESSURE : 29. COUPLING: FLEXIBLE

mmWC

16. VELOCITY PRESSURE : 30. MAIN BEARING : ROLLER BEARING

mmWC

17. TOTAL PRESSURE : FOR RADIAL AND THRUST BEARING

mmWC

18. DESIGN AMBIENT TEMPERATURE :

31. SEAL: BETWEEN NON ROTATING

°C

19. LUBRICATION : FORCED/BATH REGULATING LINKAGE AND

20. DESIGN MARGIN ON HYDRAULIC CYLINDER

20.1 CAPACITY: 32. BLADE THRUST BEARING:

%

20.2 TOTAL PRESSURE :

%

21. MAXIMUM SPEED : 33. BLADE ANGLE VARIATION:

RPM

21.1 FOR DUST LADEN GAS HYDRAULIC SYSTEM

900

21.2 FOR CLEAN AIR

1200

22. BEARING COOLING WATER 34. BLADES WITH RENEWABLE WEAR

22.1 INLET PRESSURE : Kg/cm 2(g) RING NOSES:

22.2 TEMPERATURE: IN/OUT / 35.

0

C

REV.NO. PPD. BY : JOB NO. CLIENT:

DATE CHD. BY : TCE.

REV. BY DATE : PROJCET :

FILE NAME: DA10605R2.DOC TCE FORM NO. 330 R1

TCE.M4-106-05 TCE CONSULTING ENGINEERS LIMITED SECTION : D

ISSUE NO. R2

ENQ.SPEC.NO. DATA SHEET A

TCE. LARGE AXIAL FANS SHEET : 2 OF 3

36. BAFFLE OR SPLITTER PLATE: 59. COUPLING GUARD : YES

FEATURES(CONTD.)

60. COMMON BASE FRAME : YES

CONSTRUCTION

37. THERMO COUPLES AND BEARING 61. FOUNDATION BOLTS: YES/NO

TEMPERATURE MEASUREMENT: 62. FORCED LUBRICATION UNIT WITH

38. SPARK RESISTANT CONSTRUCTION PUMPS, COOLERS, FILTERS, OIL

ACCESSORIES

TYPE AS PER AMCA : A/ B/ LEVEL INDICATOR, CONNECTED

C

39. CASING: PIPING ETC: YES /

NO

63. LOCAL INSTRUMENTS: YES / NO

40. IMPELLER BLADE : 64. START-UP AND ESSENTIAL SPARES

FOR 2YEARS NORMAL OPERATION:

41. INLET CONE: YES / NO

42. OUTLET DIFFUSER: 65. HYDRAULIC CONTROL UNIT

WTH PUMPS, FILTERS, COOLERS,

MATERIALS OF CONSTRUCTION

43. IMPELLER HUB: ASTM A445 CONNECTED PIPING ETC.: YES / NO

66. REFER TCE.M4-907

44. SHAFT: 67. ESSENTIAL SPARES

45. MAIN BEARINGS: 67.1

SPARES AND MAINTENANCE

67.2

TOOLS AND TACKLES

46. BEARING HOUSING: 67.3

67.4

47. BLADE THRUST BEARING : 67.5

48. SHAFT SLEEVE: 67.7

49. COUPLING: 67.8

50. BLADE SHAFT PENETRATION SEAL: 67.9

67.10

51. FOUNDATION BOLTS: 68. AS PER TCE.M4-904 OR TCE.M4-185-01

52. AND TCE.M4-185-10, 39 OR

TESTS AND INSPECTION

53. TCE.M4-186-08(NOTE-2)

54. MOTOR : BY VENDOR / PURCHASER 69. PERFORMANCE TEST AT SITE

AS PER TCE. M4-203-01/02 REQUIRED :

ELECTRICAL

YES/NO

55. STARTER : BY VENDOR /PURCHASER 70.

56. 71.

57. 72.

58. 73.

REV.NO. PPD. BY : JOB NO. CLIENT:

DATE CHD. BY : TCE.

REV. BY DATE : PROJECT:

ISSUE NO. R2

FILE NAME: DA10605R2.DOC TCE FORM NO. 330 R1

TCE.M4-106-05 TCE CONSULTING ENGINEERS LIMITED SECTION : D

ENQ.SPEC.NO. DATA SHEET A

TCE. LARGE AXIAL FANS SHEET : 3 OF 3

74. PRIMER : EPOXY / RED OXIDE 79. CAPACITY (FAD) :

PERFORMANCE GUARANTEES

74.1 NUMBER OF COATS : (+) (-)

M3/Hr

74.2 DRY FILM THICKNESS PER COAT: 80. TOTAL PRESSURE :

(+) (-)

PAINTING

mmWC

75. FINISH PAINT : EPOXY / SYNTHETIC 81. POWER CONSUMPTION :

ENAMEL (+) (-) KW

75.1 NUMBER OF COATS : 82.

75.2 DRY FILM THICKNESS PER COAT: 83.

84.

76. FOR DESIGN, TESTING AND 85. POWER CONSUMPTION

INSPECTION : IS 3588 / BS 848 / Rs.

COST LOADING

AND PENALTY

STANDARDS

/KW

CODES AND

AMCA 203 / AMCA 210 / AMCA 303 / 86.

AMCA 311 / AMCA 410 87.

77. 88.

78. 89.

NOTES

1. REFER AMCA STANDARD 99-2404-78 IN AMCA STANDARDS HANDBOOK.

2. FOLLOWING ADDITIONAL TESTS INDICATED AS ‘B’ IN TCE.M4-186-08 SHALL ALSO BE

CARRIED OUT, WHEN TCE.M4-186-08 IS APPLICABLE.

REV.NO. PPD. BY : JOB NO. CLIENT:

DATE CHD. BY : TCE.

REV. BY DATE : PROJECT:

FILE NAME: DA10605R2.DOC TCE FORM NO. 330 R1

Das könnte Ihnen auch gefallen

- 6127-01-000-M-HD-201 0 Cent. PumpsDokument6 Seiten6127-01-000-M-HD-201 0 Cent. PumpsRodrigo CondorettyNoch keine Bewertungen

- Native File For Pump (Example)Dokument2 SeitenNative File For Pump (Example)Venturindo SiteNoch keine Bewertungen

- DMI-DS-70-005-A4 DS Fire Hydrant Rev.2 Approved - 16.4.19 PDFDokument9 SeitenDMI-DS-70-005-A4 DS Fire Hydrant Rev.2 Approved - 16.4.19 PDFaerfansNoch keine Bewertungen

- NSPR Ipp Ac 001Dokument1 SeiteNSPR Ipp Ac 001rutujaNoch keine Bewertungen

- Data Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Dokument7 SeitenData Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Panisa BanimaNoch keine Bewertungen

- Página: 1 De: 5Dokument6 SeitenPágina: 1 De: 5Rathawit SingpanjanateeNoch keine Bewertungen

- Data Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Dokument7 SeitenData Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Panisa BanimaNoch keine Bewertungen

- Tank DatasheetDokument5 SeitenTank DatasheetGandhi AlamsyahNoch keine Bewertungen

- ADO Filter Specs Sheet Query PDFDokument1 SeiteADO Filter Specs Sheet Query PDFmusaveerNoch keine Bewertungen

- Api 610 Datasheet PDF FreeDokument7 SeitenApi 610 Datasheet PDF FreeRisyda PutriNoch keine Bewertungen

- 1-MVCP00116-885PSVr2 20210524100343 852 XDokument4 Seiten1-MVCP00116-885PSVr2 20210524100343 852 XŁukasz BolewskiNoch keine Bewertungen

- Mechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraDokument5 SeitenMechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraAhmad RifaiNoch keine Bewertungen

- 1 MergedDokument18 Seiten1 MergedparveshNoch keine Bewertungen

- Process Data Sheet For Fired HeaterDokument8 SeitenProcess Data Sheet For Fired HeaterBangkiyak LanangNoch keine Bewertungen

- R-Pump Cal Sheet1Dokument12 SeitenR-Pump Cal Sheet1santosh kumarNoch keine Bewertungen

- 16673651-Pbo17-Ed1615 R0Dokument82 Seiten16673651-Pbo17-Ed1615 R0Jose Rafael CastroNoch keine Bewertungen

- Operating Conditions Liquid: Client: ServiceDokument1 SeiteOperating Conditions Liquid: Client: ServiceAde IskandarNoch keine Bewertungen

- 26622HE0253 Rev 0Dokument8 Seiten26622HE0253 Rev 0Fernando Ramírez CéspedesNoch keine Bewertungen

- 02 190 0012 MK 062Dokument9 Seiten02 190 0012 MK 062phuchau nguyenNoch keine Bewertungen

- Methanol Storage Facility Project: No. Dok.: - Revision No.Dokument1 SeiteMethanol Storage Facility Project: No. Dok.: - Revision No.Adhya RazanNoch keine Bewertungen

- DASDokument39 SeitenDASchakrapani vagish chandra pandeyNoch keine Bewertungen

- Packaged, Integrally Geared Centrifugal Air Compressors (Api 672 - 4Th Ed) Data Sheet SI UNITS (Bar)Dokument25 SeitenPackaged, Integrally Geared Centrifugal Air Compressors (Api 672 - 4Th Ed) Data Sheet SI UNITS (Bar)Manel DjafriNoch keine Bewertungen

- Index: Sheet 1 of 29 REV 01Dokument26 SeitenIndex: Sheet 1 of 29 REV 01Ayush ChoudharyNoch keine Bewertungen

- Waste Feedstock Bridge Cranes. Technical Data SheetDokument4 SeitenWaste Feedstock Bridge Cranes. Technical Data SheetCarmen FloresNoch keine Bewertungen

- Rotary Pump - Customary UnitsDokument2 SeitenRotary Pump - Customary UnitsVicky ANoch keine Bewertungen

- FEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0Dokument14 SeitenFEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0ddaalayamoct313024Noch keine Bewertungen

- 504 C 002 - UpdatedDokument10 Seiten504 C 002 - UpdatedAnupriya1913Noch keine Bewertungen

- API 675 Pump DatasheetDokument2 SeitenAPI 675 Pump DatasheetArun CPNoch keine Bewertungen

- Api 674Dokument6 SeitenApi 674meisamNoch keine Bewertungen

- Mechanical Design CalculationsDokument16 SeitenMechanical Design CalculationsparveshNoch keine Bewertungen

- 2598 8410 DS P2232 33 1 - A2Dokument7 Seiten2598 8410 DS P2232 33 1 - A2Ronald VillalongaNoch keine Bewertungen

- Mechanical Datasheet CompressorDokument4 SeitenMechanical Datasheet CompressorTaufiq AbdullahNoch keine Bewertungen

- Air and Flue Gas Ducts and Dampers Data Sheet - ADokument1 SeiteAir and Flue Gas Ducts and Dampers Data Sheet - Ajkhan_724384Noch keine Bewertungen

- 1 MergedDokument18 Seiten1 MergedparveshNoch keine Bewertungen

- Data Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)Dokument3 SeitenData Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)André HeunisNoch keine Bewertungen

- File 5Dokument1 SeiteFile 5VENKATACHALAM SUBBARAJNoch keine Bewertungen

- Cam 200-390-110kwDokument4 SeitenCam 200-390-110kwbocahjeblogNoch keine Bewertungen

- Engro Daharki - Pakistan Small Capacity Ammonia Pump-Preliminary Data Sheet 0Dokument6 SeitenEngro Daharki - Pakistan Small Capacity Ammonia Pump-Preliminary Data Sheet 0Arslan NisarNoch keine Bewertungen

- API 673 3rd Ed Data SheetsDokument27 SeitenAPI 673 3rd Ed Data Sheetsjuan ninaNoch keine Bewertungen

- Brown & Root, Inc.: Centrifugal Pump (Api 610-8Th) Data Sheet Si UnitsDokument15 SeitenBrown & Root, Inc.: Centrifugal Pump (Api 610-8Th) Data Sheet Si UnitsLipika GayenNoch keine Bewertungen

- 22-DS-R-002 Rev 0 API 616 Turbine Data SheetDokument13 Seiten22-DS-R-002 Rev 0 API 616 Turbine Data SheetChike NwachukwuNoch keine Bewertungen

- API 560-2007 Datasheets - SIDokument56 SeitenAPI 560-2007 Datasheets - SIasdfdfNoch keine Bewertungen

- SP0793 3110 71 2602 0Dokument1 SeiteSP0793 3110 71 2602 0JULIO INQUILLAYNoch keine Bewertungen

- Generator Data Sheet PDFDokument13 SeitenGenerator Data Sheet PDFTerence WoodNoch keine Bewertungen

- Greater Nile Petroleum Company Limited OGP Technical Services SDN BHDDokument2 SeitenGreater Nile Petroleum Company Limited OGP Technical Services SDN BHDwado11Noch keine Bewertungen

- General: CRUDE OIL / Liquid 313.9 / 313.9Dokument1 SeiteGeneral: CRUDE OIL / Liquid 313.9 / 313.9amirNoch keine Bewertungen

- Mad1161a1hd-401 BDokument1 SeiteMad1161a1hd-401 BPablo VargasNoch keine Bewertungen

- Crane ds1Dokument2 SeitenCrane ds1Nurcahyo Djati WNoch keine Bewertungen

- Sp0793 - Pueblo Viejo PH 1: Pull Wire SwitchDokument1 SeiteSp0793 - Pueblo Viejo PH 1: Pull Wire SwitchJULIO INQUILLAYNoch keine Bewertungen

- Data Sheet No. Ds-P-5983 Rev. 1: Centrifugal Pump Data Sheet U.S. Customary UnitsDokument10 SeitenData Sheet No. Ds-P-5983 Rev. 1: Centrifugal Pump Data Sheet U.S. Customary Unitsrajindo1Noch keine Bewertungen

- Centrifugal Compressor Specification Sheet: Operating ConditionsDokument6 SeitenCentrifugal Compressor Specification Sheet: Operating ConditionsIsmail SayyedNoch keine Bewertungen

- Feuilles Des Données de Nouveau Groupe de Pompage Moteur DieselDokument7 SeitenFeuilles Des Données de Nouveau Groupe de Pompage Moteur DieselBilel MahjoubNoch keine Bewertungen

- Fan & Blower Specification Sheet: Karnaphuli Fertilizer Company LimitedDokument2 SeitenFan & Blower Specification Sheet: Karnaphuli Fertilizer Company LimitedfazlulfaisalNoch keine Bewertungen

- Brown & Root, Inc.: Centrifugal Compressor Data Sheet (Api 617-6Th) U.S. Customary UnitsDokument12 SeitenBrown & Root, Inc.: Centrifugal Compressor Data Sheet (Api 617-6Th) U.S. Customary UnitsPebriyantoNoch keine Bewertungen

- Chiller Data SheetDokument3 SeitenChiller Data SheetMoriyasuNguyenNoch keine Bewertungen

- Feuilles Des Données de Nouveau Groupe de Pompage Moteur ÉlectriqueDokument6 SeitenFeuilles Des Données de Nouveau Groupe de Pompage Moteur ÉlectriqueBilel MahjoubNoch keine Bewertungen

- Pressure Safety Valve-Preliminary Sizing: Input DataDokument5 SeitenPressure Safety Valve-Preliminary Sizing: Input DataTun Naing WinNoch keine Bewertungen

- PSV-Scrapper TrapDokument1 SeitePSV-Scrapper TrapUmer KhanNoch keine Bewertungen

- Case 1Dokument2 SeitenCase 1Chiks JpegNoch keine Bewertungen

- KEIYU NDT Ultrasonic TransducerDokument6 SeitenKEIYU NDT Ultrasonic TransducersrgokuNoch keine Bewertungen

- Autoclave CatalogueDokument17 SeitenAutoclave CatalogueUMARALEKSANA, CVNoch keine Bewertungen

- Lin Guo - The First Line of Code - Android Programming With Kotlin-Springer (2022)Dokument714 SeitenLin Guo - The First Line of Code - Android Programming With Kotlin-Springer (2022)İsmail SaygınNoch keine Bewertungen

- Software Testing Lab Manual 3Dokument50 SeitenSoftware Testing Lab Manual 3Arya RajuNoch keine Bewertungen

- Game of SultansDokument268 SeitenGame of Sultansmnz gmz100% (1)

- Trihedron TNB Frame PDFDokument43 SeitenTrihedron TNB Frame PDFAneelaNoch keine Bewertungen

- Branches of Science and Sub SciencesDokument5 SeitenBranches of Science and Sub SciencesSha BtstaNoch keine Bewertungen

- Custom Content v3 - 0 PDFDokument208 SeitenCustom Content v3 - 0 PDFJan ReumateuszNoch keine Bewertungen

- Optimization Technique Group 1Dokument60 SeitenOptimization Technique Group 1jmlafortezaNoch keine Bewertungen

- Question 197: (Forces Moments) : (At The 50cm Mark)Dokument8 SeitenQuestion 197: (Forces Moments) : (At The 50cm Mark)ekjon1Noch keine Bewertungen

- Serto Up To Date 33Dokument7 SeitenSerto Up To Date 33Teesing BVNoch keine Bewertungen

- From External Alarm 17pli061 Asam - Asam - JorongDokument4 SeitenFrom External Alarm 17pli061 Asam - Asam - JorongAMSARAH BR MUNTHENoch keine Bewertungen

- Software Engineering 2Dokument9 SeitenSoftware Engineering 2ch muneeb0% (1)

- Economics 101: Interactive BrokersDokument11 SeitenEconomics 101: Interactive BrokersDennys FreireNoch keine Bewertungen

- AI CalculatorDokument41 SeitenAI CalculatorAneeza zafarNoch keine Bewertungen

- 0 - Actions On Structures Wind Loads - CIB ReportDokument100 Seiten0 - Actions On Structures Wind Loads - CIB ReportWilliam PolNoch keine Bewertungen

- PumpsDokument8 SeitenPumpskannagi198Noch keine Bewertungen

- Ict SS 1Dokument37 SeitenIct SS 1angus ogwucheNoch keine Bewertungen

- RBH AxiomV Catalog v2011Dokument16 SeitenRBH AxiomV Catalog v2011Sundar RamasamyNoch keine Bewertungen

- Fan Laws: Table 1 Fan Laws Parameters Variable ‘n' Speed Variable ‘ρ' Density Variable ‘d' Impeller Diameter p Q PpowDokument3 SeitenFan Laws: Table 1 Fan Laws Parameters Variable ‘n' Speed Variable ‘ρ' Density Variable ‘d' Impeller Diameter p Q Ppowgeetikag_23Noch keine Bewertungen

- Chapter 1-Thermodynamic-Merged-CompressedDokument60 SeitenChapter 1-Thermodynamic-Merged-CompressedAina SyafiqahNoch keine Bewertungen

- Wolkite University Department of Information TechnologyDokument27 SeitenWolkite University Department of Information Technologytamirat alemayewNoch keine Bewertungen

- The Chemistry of Copper: Number 83 WWW - Curriculum-Press - Co.ukDokument5 SeitenThe Chemistry of Copper: Number 83 WWW - Curriculum-Press - Co.uks7076728g100% (1)

- Lasal: Laser Cutting SolutionsDokument4 SeitenLasal: Laser Cutting SolutionsGeorge ZiovasNoch keine Bewertungen

- F2700 PDFDokument12 SeitenF2700 PDFAhmad Zubair RasulyNoch keine Bewertungen

- JT - Installation Manual For PV Modules B1Dokument18 SeitenJT - Installation Manual For PV Modules B1FreeLatinBird100% (1)

- CP-533E / CS-533E Vibratory Compactor Hydraulic System: Lines GP - PropelDokument2 SeitenCP-533E / CS-533E Vibratory Compactor Hydraulic System: Lines GP - PropelMayumi Lizarme BuezoNoch keine Bewertungen

- API TutorialDokument22 SeitenAPI TutorialKomarudinNoch keine Bewertungen

- Venturi and OrificemeterDokument10 SeitenVenturi and OrificemeterVikrant KumarNoch keine Bewertungen